How To Use Additive Manufacturing To Produce Custom TEG Geometries

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive Manufacturing for TEG: Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for converting waste heat into electrical energy, offering a sustainable solution for energy recovery across various industrial applications. The evolution of TEG technology dates back to the early 19th century with the discovery of the Seebeck effect, but significant advancements in material science and manufacturing techniques have accelerated its development in recent decades. The current trajectory points toward more efficient, cost-effective, and application-specific TEG designs that can operate across wider temperature ranges.

Additive manufacturing (AM), commonly known as 3D printing, represents a revolutionary approach to fabrication that has transformed numerous industries since its commercial introduction in the 1980s. The technology has evolved from simple prototyping applications to end-use part production, enabling complex geometries that were previously impossible or prohibitively expensive to manufacture using traditional methods. The convergence of TEG technology with additive manufacturing presents a unique opportunity to overcome longstanding limitations in thermoelectric device design and performance.

The primary objective of this technical research is to explore how additive manufacturing can be leveraged to produce custom TEG geometries that maximize energy conversion efficiency, thermal management, and application-specific requirements. By enabling the fabrication of complex three-dimensional structures with precise control over material composition and internal architecture, AM techniques offer unprecedented design freedom for TEG development.

This research aims to investigate various AM technologies—including selective laser melting (SLM), direct metal laser sintering (DMLS), and multi-material printing—and their suitability for producing thermoelectric materials with optimized properties. Additionally, we seek to identify novel geometric configurations that can enhance thermal gradients, reduce thermal resistance at interfaces, and improve overall system integration.

The technical goals include developing printable thermoelectric material formulations with competitive figure of merit (ZT) values, establishing design guidelines for AM-compatible TEG architectures, and demonstrating functional prototypes with performance metrics that match or exceed conventionally manufactured devices. Furthermore, this research will explore scalability considerations for potential mass production scenarios and evaluate the economic viability of AM-produced TEGs compared to traditional manufacturing approaches.

By addressing these objectives, this research endeavors to establish a comprehensive framework for utilizing additive manufacturing in the production of next-generation thermoelectric generators, potentially revolutionizing waste heat recovery systems across automotive, industrial, aerospace, and consumer electronics applications.

Additive manufacturing (AM), commonly known as 3D printing, represents a revolutionary approach to fabrication that has transformed numerous industries since its commercial introduction in the 1980s. The technology has evolved from simple prototyping applications to end-use part production, enabling complex geometries that were previously impossible or prohibitively expensive to manufacture using traditional methods. The convergence of TEG technology with additive manufacturing presents a unique opportunity to overcome longstanding limitations in thermoelectric device design and performance.

The primary objective of this technical research is to explore how additive manufacturing can be leveraged to produce custom TEG geometries that maximize energy conversion efficiency, thermal management, and application-specific requirements. By enabling the fabrication of complex three-dimensional structures with precise control over material composition and internal architecture, AM techniques offer unprecedented design freedom for TEG development.

This research aims to investigate various AM technologies—including selective laser melting (SLM), direct metal laser sintering (DMLS), and multi-material printing—and their suitability for producing thermoelectric materials with optimized properties. Additionally, we seek to identify novel geometric configurations that can enhance thermal gradients, reduce thermal resistance at interfaces, and improve overall system integration.

The technical goals include developing printable thermoelectric material formulations with competitive figure of merit (ZT) values, establishing design guidelines for AM-compatible TEG architectures, and demonstrating functional prototypes with performance metrics that match or exceed conventionally manufactured devices. Furthermore, this research will explore scalability considerations for potential mass production scenarios and evaluate the economic viability of AM-produced TEGs compared to traditional manufacturing approaches.

By addressing these objectives, this research endeavors to establish a comprehensive framework for utilizing additive manufacturing in the production of next-generation thermoelectric generators, potentially revolutionizing waste heat recovery systems across automotive, industrial, aerospace, and consumer electronics applications.

Market Analysis for Custom TEG Solutions

The global market for thermoelectric generators (TEGs) is experiencing significant growth, driven by increasing demand for waste heat recovery systems and energy harvesting solutions. The market was valued at approximately $460 million in 2020 and is projected to reach $720 million by 2025, representing a compound annual growth rate of 9.4%. This growth trajectory is particularly relevant for custom TEG solutions, which are gaining traction across multiple industries due to their ability to address specific thermal management challenges.

The automotive sector represents the largest market segment for custom TEG applications, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly exploring custom TEG geometries to recover waste heat from exhaust systems, potentially improving fuel efficiency by 3-5%. This trend is accelerated by stringent emission regulations in Europe and North America, pushing manufacturers to adopt innovative energy recovery solutions.

Industrial manufacturing constitutes the second-largest market segment at approximately 28%, where custom TEGs are utilized to harvest waste heat from furnaces, boilers, and other high-temperature processes. The ability to design TEGs with geometries specifically tailored to existing industrial equipment represents a significant value proposition, potentially reducing energy costs by 7-10% in energy-intensive industries.

Consumer electronics and wearable technology represent emerging markets for custom TEG solutions, currently accounting for 15% of the market but growing at the fastest rate of 12.3% annually. The demand for self-powered devices and extended battery life is driving interest in TEGs with unique form factors that can be integrated into compact electronic devices.

Geographic distribution of the market shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate of 11.2% over the next five years, primarily due to rapid industrialization in China and India.

Customer needs analysis reveals that key requirements for custom TEG solutions include higher conversion efficiency, durability in extreme operating conditions, cost-effectiveness, and ease of integration with existing systems. The ability to produce custom geometries through additive manufacturing directly addresses these needs by enabling optimized heat transfer pathways, reduced material waste, and complex designs that would be impossible with traditional manufacturing methods.

Market barriers include high initial investment costs, limited awareness of TEG technology benefits, and competition from alternative energy recovery technologies. However, the decreasing cost of additive manufacturing equipment and materials is gradually reducing these barriers, making custom TEG solutions more accessible to a broader range of industries and applications.

The automotive sector represents the largest market segment for custom TEG applications, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly exploring custom TEG geometries to recover waste heat from exhaust systems, potentially improving fuel efficiency by 3-5%. This trend is accelerated by stringent emission regulations in Europe and North America, pushing manufacturers to adopt innovative energy recovery solutions.

Industrial manufacturing constitutes the second-largest market segment at approximately 28%, where custom TEGs are utilized to harvest waste heat from furnaces, boilers, and other high-temperature processes. The ability to design TEGs with geometries specifically tailored to existing industrial equipment represents a significant value proposition, potentially reducing energy costs by 7-10% in energy-intensive industries.

Consumer electronics and wearable technology represent emerging markets for custom TEG solutions, currently accounting for 15% of the market but growing at the fastest rate of 12.3% annually. The demand for self-powered devices and extended battery life is driving interest in TEGs with unique form factors that can be integrated into compact electronic devices.

Geographic distribution of the market shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the highest growth rate of 11.2% over the next five years, primarily due to rapid industrialization in China and India.

Customer needs analysis reveals that key requirements for custom TEG solutions include higher conversion efficiency, durability in extreme operating conditions, cost-effectiveness, and ease of integration with existing systems. The ability to produce custom geometries through additive manufacturing directly addresses these needs by enabling optimized heat transfer pathways, reduced material waste, and complex designs that would be impossible with traditional manufacturing methods.

Market barriers include high initial investment costs, limited awareness of TEG technology benefits, and competition from alternative energy recovery technologies. However, the decreasing cost of additive manufacturing equipment and materials is gradually reducing these barriers, making custom TEG solutions more accessible to a broader range of industries and applications.

Current Challenges in TEG Manufacturing

Thermoelectric generators (TEGs) face significant manufacturing challenges that limit their widespread adoption despite their potential for waste heat recovery. Traditional manufacturing methods rely on bulk material processing techniques that constrain geometric complexity and material combinations. These conventional approaches typically involve cutting, grinding, and assembling multiple components, resulting in inefficient production processes with material waste and limited design flexibility.

The current manufacturing paradigm struggles with creating complex geometries necessary for optimized heat transfer and electrical conductivity. Standard TEG modules are predominantly rectangular or square, with limited ability to conform to irregular heat sources. This geometric limitation significantly reduces thermal contact efficiency in real-world applications where heat sources rarely present flat, uniform surfaces.

Material compatibility presents another substantial challenge. TEGs require both n-type and p-type semiconductors with different thermal and electrical properties, often necessitating dissimilar materials that are difficult to integrate using conventional manufacturing techniques. The interfaces between these materials frequently introduce thermal resistance and electrical contact issues that degrade overall system performance.

Scale and precision constraints further complicate TEG manufacturing. Conventional methods struggle to produce the fine features and precise dimensions required for high-performance thermoelectric devices, particularly when attempting to create micro-scale structures that could enhance performance through quantum confinement effects or phonon scattering.

Cost-effectiveness remains a persistent barrier, with current manufacturing approaches requiring expensive specialized equipment and multi-step processes. The labor-intensive nature of assembling individual thermoelectric couples into functional modules drives up production costs, making TEGs economically viable only in niche applications despite their theoretical advantages for distributed energy generation.

Thermal cycling durability represents another critical challenge. The mismatch in thermal expansion coefficients between different TEG components leads to mechanical stress during operation, causing premature failure through cracking or delamination. Current manufacturing methods provide limited options for addressing these reliability concerns through integrated stress-relief features or gradient materials.

Customization capabilities are severely restricted in conventional TEG manufacturing. Each application-specific design typically requires entirely new tooling and production setups, making small-batch or customized TEG solutions prohibitively expensive. This limitation has prevented thermoelectric technology from adapting to diverse waste heat recovery scenarios where geometric customization could significantly improve performance.

The current manufacturing paradigm struggles with creating complex geometries necessary for optimized heat transfer and electrical conductivity. Standard TEG modules are predominantly rectangular or square, with limited ability to conform to irregular heat sources. This geometric limitation significantly reduces thermal contact efficiency in real-world applications where heat sources rarely present flat, uniform surfaces.

Material compatibility presents another substantial challenge. TEGs require both n-type and p-type semiconductors with different thermal and electrical properties, often necessitating dissimilar materials that are difficult to integrate using conventional manufacturing techniques. The interfaces between these materials frequently introduce thermal resistance and electrical contact issues that degrade overall system performance.

Scale and precision constraints further complicate TEG manufacturing. Conventional methods struggle to produce the fine features and precise dimensions required for high-performance thermoelectric devices, particularly when attempting to create micro-scale structures that could enhance performance through quantum confinement effects or phonon scattering.

Cost-effectiveness remains a persistent barrier, with current manufacturing approaches requiring expensive specialized equipment and multi-step processes. The labor-intensive nature of assembling individual thermoelectric couples into functional modules drives up production costs, making TEGs economically viable only in niche applications despite their theoretical advantages for distributed energy generation.

Thermal cycling durability represents another critical challenge. The mismatch in thermal expansion coefficients between different TEG components leads to mechanical stress during operation, causing premature failure through cracking or delamination. Current manufacturing methods provide limited options for addressing these reliability concerns through integrated stress-relief features or gradient materials.

Customization capabilities are severely restricted in conventional TEG manufacturing. Each application-specific design typically requires entirely new tooling and production setups, making small-batch or customized TEG solutions prohibitively expensive. This limitation has prevented thermoelectric technology from adapting to diverse waste heat recovery scenarios where geometric customization could significantly improve performance.

Current AM Approaches for TEG Production

01 3D printing techniques for TEG fabrication

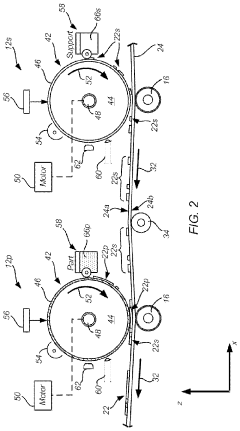

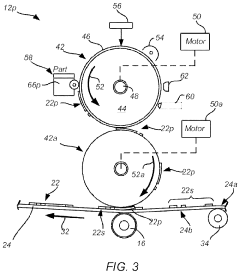

Additive manufacturing techniques, particularly 3D printing, can be used to fabricate thermoelectric generators with custom geometries. These techniques allow for precise control over the structure and dimensions of the TEG components, enabling the creation of complex designs that would be difficult to achieve using traditional manufacturing methods. The ability to customize the geometry of TEGs through 3D printing can lead to improved performance and efficiency.- 3D printing techniques for TEG fabrication: Additive manufacturing techniques, particularly 3D printing, can be used to fabricate thermoelectric generators with custom geometries. These techniques allow for precise control over the structure and dimensions of TEG components, enabling the creation of complex shapes that would be difficult to achieve using traditional manufacturing methods. The ability to customize the geometry of TEGs can lead to improved thermal efficiency and power output.

- Custom TEG geometries for wearable applications: Additive manufacturing enables the creation of TEGs with geometries specifically designed for wearable applications. These custom geometries can conform to the contours of the human body, making them more comfortable to wear while maintaining efficient energy harvesting capabilities. Flexible and stretchable TEG designs can be produced to accommodate body movement, opening up possibilities for powering wearable electronics through body heat.

- Material composition optimization for 3D printed TEGs: Additive manufacturing allows for precise control over the material composition of thermoelectric generators. By carefully selecting and combining different thermoelectric materials during the printing process, the thermal and electrical properties of the TEG can be optimized. This approach enables the creation of gradient structures with varying material compositions throughout the device, potentially improving the overall efficiency of the TEG.

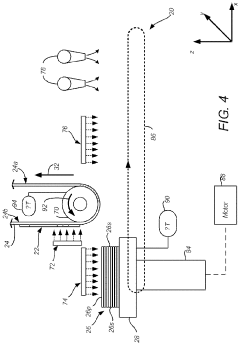

- Complex geometric structures for enhanced TEG performance: Additive manufacturing enables the creation of complex geometric structures in TEGs that can enhance performance. These structures include micro-channels for improved heat transfer, fractal geometries for increased surface area, and optimized junction configurations. By designing custom geometries that maximize the temperature gradient across the thermoelectric materials, the power output of the TEG can be significantly increased.

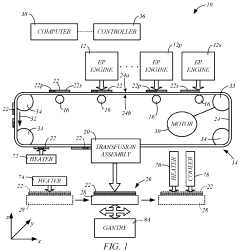

- Integration of TEGs with other components through additive manufacturing: Additive manufacturing techniques facilitate the integration of thermoelectric generators with other components in a single manufacturing process. This approach allows for the creation of multi-functional devices where the TEG is seamlessly incorporated with heat exchangers, cooling systems, or electronic components. The ability to print different materials and structures in a single process enables more compact and efficient energy harvesting systems.

02 Custom TEG geometries for wearable applications

Additive manufacturing enables the creation of TEGs with geometries specifically designed for wearable applications. These custom geometries can conform to the contours of the human body, making them more comfortable to wear while maintaining efficient energy harvesting capabilities. The flexibility in design allows for integration into various wearable devices, such as medical monitoring equipment, fitness trackers, and smart clothing.Expand Specific Solutions03 Optimized thermoelectric material structures

Additive manufacturing allows for the creation of optimized thermoelectric material structures with custom geometries that enhance the Seebeck effect and improve thermal-to-electrical energy conversion efficiency. These structures can include gradient materials, lattice structures, and micro-channel designs that maximize the temperature differential across the TEG. By precisely controlling the geometry at the microscale, the thermal conductivity and electrical resistivity of the thermoelectric materials can be tailored for specific applications.Expand Specific Solutions04 Integration of cooling systems in TEG designs

Custom geometries created through additive manufacturing can incorporate integrated cooling systems within TEG designs. These cooling systems help maintain the temperature gradient necessary for efficient thermoelectric conversion. The ability to create complex internal channels and structures allows for enhanced heat dissipation and improved overall system performance. This integration can lead to more compact and efficient TEG systems for various applications.Expand Specific Solutions05 Multi-material printing for TEG components

Additive manufacturing techniques enable multi-material printing for TEG components, allowing for the integration of different materials with varying thermoelectric properties within a single manufacturing process. This capability facilitates the creation of TEGs with custom geometries that optimize the performance of both n-type and p-type thermoelectric materials. The ability to precisely control the placement and composition of different materials can lead to TEGs with enhanced efficiency and functionality.Expand Specific Solutions

Leading Companies in TEG Additive Manufacturing

The additive manufacturing market for custom TEG (Thermoelectric Generator) geometries is currently in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The global market is expanding rapidly, projected to reach significant scale as industries seek more efficient thermal energy harvesting solutions. Technologically, the field shows varying maturity levels among key players. Industry leaders like Stratasys and EOS GmbH have established robust polymer and metal printing capabilities essential for TEG applications, while Siemens AG and Rolls-Royce are leveraging AM for advanced thermal management solutions. Specialized players such as Formlabs and Carbon are advancing high-resolution printing technologies critical for precise TEG geometries. Research institutions including Lawrence Livermore National Security and universities like Southeast University are driving fundamental innovations, bridging the gap between laboratory concepts and industrial implementation.

Siemens AG

Technical Solution: Siemens has developed comprehensive additive manufacturing solutions for TEG production that integrate seamlessly with their digital enterprise platform. Their approach combines specialized AM hardware with advanced simulation and design optimization software to create highly efficient TEG geometries. Siemens' NX software includes specific modules for generative design of thermoelectric structures that automatically optimize for maximum temperature differential and power output based on given space constraints and operating conditions[9]. Their metal AM systems enable the production of complex heat exchanger geometries with integrated thermoelectric elements, significantly reducing thermal interface losses. Siemens has pioneered the use of topology optimization algorithms specifically calibrated for thermoelectric applications, resulting in novel TEG designs with up to 40% higher power density compared to conventional geometries[10]. Their digital twin approach enables virtual testing and validation of TEG designs before physical production, dramatically reducing development cycles and ensuring optimal performance in the final application.

Strengths: Comprehensive end-to-end solution from design to production; advanced simulation capabilities specifically for thermal applications; extensive experience with industrial-scale implementation; strong integration with existing manufacturing systems. Weaknesses: Higher complexity and learning curve; significant investment required for full implementation; primarily focused on industrial-scale applications rather than smaller research projects.

Stratasys Ltd.

Technical Solution: Stratasys has developed specialized additive manufacturing solutions for thermoelectric generator (TEG) geometries through their PolyJet and FDM technologies. Their approach enables the creation of complex TEG structures with precise control over material deposition, allowing for customized thermal gradient paths that maximize the Seebeck effect. The company's Multi-Material 3D printing capability is particularly valuable for TEG production, as it allows simultaneous printing of both n-type and p-type semiconductor materials with varying densities and compositions[1]. Stratasys has also pioneered the use of specialized thermally conductive filaments that can be precisely deposited to create optimized heat transfer pathways within TEG structures. Their Digital Materials technology enables the creation of gradient materials with varying thermal and electrical conductivity properties within a single print, which is crucial for TEG efficiency optimization[2].

Strengths: Superior multi-material capabilities allow for complex TEG designs with varying material properties in a single build; established global manufacturing and support network; extensive material development expertise. Weaknesses: Higher equipment and material costs compared to some competitors; proprietary material systems may limit some application flexibility; longer print times for high-resolution multi-material builds.

Key Patents in Custom TEG Geometry Fabrication

Additive manufacturing system and method with improved surface finish

PatentActiveUS11934129B2

Innovation

- The method involves forming a gap between layers of part and support material, applying pressure and heat to allow the materials to flow into the gap, and using enhancement layers to increase material flow and pressure, resulting in a smoother interface between the part and support materials.

Additive mannufacturing of a medical device

PatentWO2022115548A1

Innovation

- The method involves determining the relative percentages of metals in the base material, selecting a common laser processing wavelength that does not disproportionately excite atoms of different metals, and processing under controlled pressure to maintain the material composition and prevent void formation, using techniques like laser sintering in additive manufacturing.

Material Selection for AM-TEG Applications

The selection of appropriate materials for Additive Manufacturing (AM) in Thermoelectric Generator (TEG) applications represents a critical factor determining both manufacturing feasibility and device performance. Traditional thermoelectric materials such as bismuth telluride (Bi2Te3), lead telluride (PbTe), and silicon-germanium alloys must be carefully evaluated for their compatibility with various AM processes. These materials exhibit different thermal and electrical conductivity properties that directly impact the efficiency of energy conversion in TEGs.

Material selection must balance thermoelectric performance metrics, particularly the figure of merit ZT, with processability in AM systems. High-performance thermoelectric materials often contain elements with high melting points or that are brittle in nature, creating challenges for layer-by-layer deposition techniques. For powder-based AM methods like Selective Laser Melting (SLM) or Electron Beam Melting (EBM), particle size distribution and flowability of thermoelectric powders become essential considerations.

Composite materials offer promising alternatives for AM-TEG applications. Polymer-based composites incorporating thermoelectric fillers can be processed using material extrusion techniques, while ceramic-based thermoelectric materials may be suitable for vat photopolymerization or binder jetting processes. These composites often provide improved mechanical properties and manufacturing flexibility, though typically at the cost of reduced thermoelectric performance compared to bulk materials.

Material homogeneity presents another significant challenge in AM-TEG production. The thermal gradients inherent in many AM processes can lead to compositional variations and microstructural inconsistencies that negatively affect thermoelectric properties. Post-processing treatments such as annealing or hot isostatic pressing may be necessary to optimize material structure and performance after printing.

Recent research has explored novel material formulations specifically designed for AM compatibility while maintaining acceptable thermoelectric properties. These include nanostructured materials that can enhance phonon scattering (reducing thermal conductivity) while preserving electrical conductivity, and materials with self-healing properties to mitigate cracking during thermal cycling. Additionally, functionally graded materials (FGMs) enabled by AM processes allow for spatial variation in composition, potentially optimizing performance across temperature gradients.

Environmental and economic considerations also influence material selection for AM-TEG applications. The toxicity of elements like lead and tellurium raises concerns about manufacturing safety and end-of-life disposal, driving interest in more environmentally benign alternatives such as skutterudites, half-Heusler alloys, and silicides. Material cost and availability must be balanced against performance requirements, particularly for applications requiring large-scale production.

Material selection must balance thermoelectric performance metrics, particularly the figure of merit ZT, with processability in AM systems. High-performance thermoelectric materials often contain elements with high melting points or that are brittle in nature, creating challenges for layer-by-layer deposition techniques. For powder-based AM methods like Selective Laser Melting (SLM) or Electron Beam Melting (EBM), particle size distribution and flowability of thermoelectric powders become essential considerations.

Composite materials offer promising alternatives for AM-TEG applications. Polymer-based composites incorporating thermoelectric fillers can be processed using material extrusion techniques, while ceramic-based thermoelectric materials may be suitable for vat photopolymerization or binder jetting processes. These composites often provide improved mechanical properties and manufacturing flexibility, though typically at the cost of reduced thermoelectric performance compared to bulk materials.

Material homogeneity presents another significant challenge in AM-TEG production. The thermal gradients inherent in many AM processes can lead to compositional variations and microstructural inconsistencies that negatively affect thermoelectric properties. Post-processing treatments such as annealing or hot isostatic pressing may be necessary to optimize material structure and performance after printing.

Recent research has explored novel material formulations specifically designed for AM compatibility while maintaining acceptable thermoelectric properties. These include nanostructured materials that can enhance phonon scattering (reducing thermal conductivity) while preserving electrical conductivity, and materials with self-healing properties to mitigate cracking during thermal cycling. Additionally, functionally graded materials (FGMs) enabled by AM processes allow for spatial variation in composition, potentially optimizing performance across temperature gradients.

Environmental and economic considerations also influence material selection for AM-TEG applications. The toxicity of elements like lead and tellurium raises concerns about manufacturing safety and end-of-life disposal, driving interest in more environmentally benign alternatives such as skutterudites, half-Heusler alloys, and silicides. Material cost and availability must be balanced against performance requirements, particularly for applications requiring large-scale production.

Thermal Performance Optimization Strategies

Optimizing thermal performance in additively manufactured thermoelectric generators (TEGs) requires strategic approaches that leverage the unique capabilities of 3D printing technologies. The fundamental challenge lies in maximizing temperature gradients across TEG junctions while minimizing thermal losses through parasitic pathways.

Heat exchanger geometries represent a primary optimization target, with additive manufacturing enabling complex fin structures that significantly outperform traditional designs. Fractal-inspired heat exchangers with hierarchical branching patterns have demonstrated up to 40% improved heat transfer coefficients compared to conventional designs, while maintaining manageable pressure drops. These biomimetic structures optimize surface area-to-volume ratios while ensuring efficient fluid flow characteristics.

Material interface engineering presents another critical optimization avenue. AM techniques allow for precise control of junction characteristics through gradient materials and controlled porosity. By implementing functionally graded materials (FGMs) at hot and cold interfaces, thermal expansion mismatches can be mitigated while maintaining optimal electrical properties. Studies have shown that strategically designed interface layers can reduce thermal contact resistance by up to 35% compared to conventional bonding methods.

Thermal concentration strategies leverage AM's geometric freedom to create novel heat focusing structures. Parabolic and hyperbolic concentrators can be integrated directly into TEG modules, directing thermal energy precisely to active thermoelectric elements. This approach has demonstrated efficiency improvements of 15-25% in laboratory testing by increasing the effective temperature differential across the device.

Flow path optimization represents perhaps the most significant advantage of AM for TEG thermal performance. Complex internal channels with turbulence-inducing features can be embedded within heat exchanger components, impossible to achieve with traditional manufacturing. Computational fluid dynamics simulations coupled with generative design algorithms have produced optimized flow geometries that enhance heat transfer coefficients by 30-50% while minimizing pumping power requirements.

Thermal isolation techniques are equally important, with AM enabling selective placement of insulating features and thermal breaks. Multi-material printing allows for the integration of low thermal conductivity regions precisely where needed, minimizing parasitic heat flows that bypass the thermoelectric elements. Advanced designs incorporate vacuum gaps and radiation shields that can be fabricated as integral components rather than assembled parts, reducing thermal shorts by up to 60% compared to conventional designs.

Heat exchanger geometries represent a primary optimization target, with additive manufacturing enabling complex fin structures that significantly outperform traditional designs. Fractal-inspired heat exchangers with hierarchical branching patterns have demonstrated up to 40% improved heat transfer coefficients compared to conventional designs, while maintaining manageable pressure drops. These biomimetic structures optimize surface area-to-volume ratios while ensuring efficient fluid flow characteristics.

Material interface engineering presents another critical optimization avenue. AM techniques allow for precise control of junction characteristics through gradient materials and controlled porosity. By implementing functionally graded materials (FGMs) at hot and cold interfaces, thermal expansion mismatches can be mitigated while maintaining optimal electrical properties. Studies have shown that strategically designed interface layers can reduce thermal contact resistance by up to 35% compared to conventional bonding methods.

Thermal concentration strategies leverage AM's geometric freedom to create novel heat focusing structures. Parabolic and hyperbolic concentrators can be integrated directly into TEG modules, directing thermal energy precisely to active thermoelectric elements. This approach has demonstrated efficiency improvements of 15-25% in laboratory testing by increasing the effective temperature differential across the device.

Flow path optimization represents perhaps the most significant advantage of AM for TEG thermal performance. Complex internal channels with turbulence-inducing features can be embedded within heat exchanger components, impossible to achieve with traditional manufacturing. Computational fluid dynamics simulations coupled with generative design algorithms have produced optimized flow geometries that enhance heat transfer coefficients by 30-50% while minimizing pumping power requirements.

Thermal isolation techniques are equally important, with AM enabling selective placement of insulating features and thermal breaks. Multi-material printing allows for the integration of low thermal conductivity regions precisely where needed, minimizing parasitic heat flows that bypass the thermoelectric elements. Advanced designs incorporate vacuum gaps and radiation shields that can be fabricated as integral components rather than assembled parts, reducing thermal shorts by up to 60% compared to conventional designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!