Life-Cycle Assessment For TEG-Boosted Energy-Saving Retrofits

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Energy-Saving Goals

Thermoelectric generators (TEGs) represent a significant advancement in waste heat recovery technology, with roots dating back to the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect. This phenomenon, which enables direct conversion of temperature differences into electrical voltage, has evolved substantially over the past two centuries. Modern TEG technology has progressed from simple metallic junctions to sophisticated semiconductor-based devices with enhanced efficiency and durability.

The evolution of TEG technology has been marked by several key milestones, including the development of bismuth telluride-based materials in the mid-20th century, which significantly improved conversion efficiency. Recent advancements have focused on nanostructured materials and quantum well structures that further enhance the figure of merit (ZT), a critical parameter determining thermoelectric performance. Current research trends indicate a continued push toward higher ZT values through novel material compositions and manufacturing techniques.

In the context of energy-saving retrofits, TEGs offer a compelling solution for harvesting waste heat from existing industrial processes, building systems, and transportation infrastructure. The primary technical goal of TEG-boosted retrofits is to capture thermal energy that would otherwise be lost to the environment and convert it into usable electricity, thereby improving overall system efficiency without requiring complete infrastructure replacement.

Specific technical objectives include achieving conversion efficiencies exceeding 10% in practical applications, developing modular and scalable TEG systems adaptable to various retrofit scenarios, and ensuring long-term reliability with minimal maintenance requirements. Additionally, there is a focus on reducing the environmental impact of TEG manufacturing and deployment, aligning with broader sustainability goals.

The integration of TEGs into existing energy systems presents unique technical challenges, including thermal interface management, electrical integration with existing power systems, and optimization of heat flow paths. These challenges necessitate innovative approaches to system design and implementation that balance performance with practical constraints such as space limitations and cost considerations.

From a life-cycle perspective, TEG-boosted retrofits aim to achieve net positive energy balance, where the energy generated over the system lifetime substantially exceeds the energy invested in manufacturing, installation, and maintenance. This requires careful consideration of material selection, manufacturing processes, and end-of-life management to maximize environmental benefits and economic returns.

As global energy efficiency standards become increasingly stringent, TEG technology represents a promising pathway for extracting additional value from existing infrastructure while contributing to carbon reduction targets. The technical trajectory suggests continued improvements in both material performance and system integration capabilities, potentially enabling more widespread adoption across diverse applications.

The evolution of TEG technology has been marked by several key milestones, including the development of bismuth telluride-based materials in the mid-20th century, which significantly improved conversion efficiency. Recent advancements have focused on nanostructured materials and quantum well structures that further enhance the figure of merit (ZT), a critical parameter determining thermoelectric performance. Current research trends indicate a continued push toward higher ZT values through novel material compositions and manufacturing techniques.

In the context of energy-saving retrofits, TEGs offer a compelling solution for harvesting waste heat from existing industrial processes, building systems, and transportation infrastructure. The primary technical goal of TEG-boosted retrofits is to capture thermal energy that would otherwise be lost to the environment and convert it into usable electricity, thereby improving overall system efficiency without requiring complete infrastructure replacement.

Specific technical objectives include achieving conversion efficiencies exceeding 10% in practical applications, developing modular and scalable TEG systems adaptable to various retrofit scenarios, and ensuring long-term reliability with minimal maintenance requirements. Additionally, there is a focus on reducing the environmental impact of TEG manufacturing and deployment, aligning with broader sustainability goals.

The integration of TEGs into existing energy systems presents unique technical challenges, including thermal interface management, electrical integration with existing power systems, and optimization of heat flow paths. These challenges necessitate innovative approaches to system design and implementation that balance performance with practical constraints such as space limitations and cost considerations.

From a life-cycle perspective, TEG-boosted retrofits aim to achieve net positive energy balance, where the energy generated over the system lifetime substantially exceeds the energy invested in manufacturing, installation, and maintenance. This requires careful consideration of material selection, manufacturing processes, and end-of-life management to maximize environmental benefits and economic returns.

As global energy efficiency standards become increasingly stringent, TEG technology represents a promising pathway for extracting additional value from existing infrastructure while contributing to carbon reduction targets. The technical trajectory suggests continued improvements in both material performance and system integration capabilities, potentially enabling more widespread adoption across diverse applications.

Market Analysis for TEG-Based Retrofit Solutions

The global market for thermoelectric generator (TEG) based retrofit solutions is experiencing significant growth, driven by increasing energy efficiency demands and sustainability initiatives across various industries. The current market size for TEG technologies is estimated at $640 million in 2023, with projections indicating growth to reach approximately $1.2 billion by 2030, representing a compound annual growth rate of 9.4% during the forecast period.

Industrial sectors constitute the largest market segment for TEG-based retrofit solutions, accounting for roughly 42% of the total market share. This dominance stems from the abundant waste heat available in manufacturing processes, particularly in energy-intensive industries such as steel, cement, and chemical production. The automotive sector follows closely, representing approximately 35% of the market, where TEG systems are increasingly being integrated into vehicle exhaust systems to recover waste heat and improve fuel efficiency.

Regional analysis reveals North America and Europe as leading markets for TEG retrofit solutions, collectively accounting for over 60% of global market value. This dominance is attributed to stringent energy efficiency regulations, substantial government incentives for green technologies, and higher awareness of sustainability practices. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated growth rate of 12.3% annually, driven by rapid industrialization in China and India coupled with increasing environmental concerns.

Customer segmentation analysis indicates three primary buyer categories: large industrial corporations seeking to reduce operational costs and carbon footprints, medium-sized manufacturers aiming to comply with increasingly stringent environmental regulations, and forward-thinking property developers incorporating energy-efficient solutions into commercial and residential buildings.

Market barriers include the relatively high initial investment costs for TEG systems, with current payback periods ranging from 3-7 years depending on application and scale. Technical limitations such as conversion efficiency constraints (typically 5-8% for commercial systems) also present challenges to widespread adoption. Additionally, lack of awareness about TEG technology benefits and limited technical expertise for installation and maintenance in emerging markets remain significant obstacles.

Growth opportunities are emerging in several sectors, particularly in data centers where waste heat recovery could significantly reduce cooling costs, and in remote power applications where TEG systems can provide reliable power from various heat sources. The building retrofit market also presents substantial potential, especially as energy efficiency standards for existing structures become more stringent globally.

Industrial sectors constitute the largest market segment for TEG-based retrofit solutions, accounting for roughly 42% of the total market share. This dominance stems from the abundant waste heat available in manufacturing processes, particularly in energy-intensive industries such as steel, cement, and chemical production. The automotive sector follows closely, representing approximately 35% of the market, where TEG systems are increasingly being integrated into vehicle exhaust systems to recover waste heat and improve fuel efficiency.

Regional analysis reveals North America and Europe as leading markets for TEG retrofit solutions, collectively accounting for over 60% of global market value. This dominance is attributed to stringent energy efficiency regulations, substantial government incentives for green technologies, and higher awareness of sustainability practices. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated growth rate of 12.3% annually, driven by rapid industrialization in China and India coupled with increasing environmental concerns.

Customer segmentation analysis indicates three primary buyer categories: large industrial corporations seeking to reduce operational costs and carbon footprints, medium-sized manufacturers aiming to comply with increasingly stringent environmental regulations, and forward-thinking property developers incorporating energy-efficient solutions into commercial and residential buildings.

Market barriers include the relatively high initial investment costs for TEG systems, with current payback periods ranging from 3-7 years depending on application and scale. Technical limitations such as conversion efficiency constraints (typically 5-8% for commercial systems) also present challenges to widespread adoption. Additionally, lack of awareness about TEG technology benefits and limited technical expertise for installation and maintenance in emerging markets remain significant obstacles.

Growth opportunities are emerging in several sectors, particularly in data centers where waste heat recovery could significantly reduce cooling costs, and in remote power applications where TEG systems can provide reliable power from various heat sources. The building retrofit market also presents substantial potential, especially as energy efficiency standards for existing structures become more stringent globally.

Current TEG Implementation Challenges

Despite the promising potential of thermoelectric generators (TEGs) in energy-saving retrofits, several significant implementation challenges currently hinder their widespread adoption. The primary obstacle remains the relatively low conversion efficiency of commercial TEG modules, typically ranging between 3-8% under optimal conditions. This efficiency limitation necessitates larger TEG arrays to generate meaningful power outputs, consequently increasing system costs and installation complexity.

Material constraints present another substantial challenge. High-performance thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about resource availability, environmental impact, and regulatory compliance. The development of alternative materials with comparable performance using earth-abundant elements remains an active but unresolved research area.

Thermal management issues significantly affect TEG performance in retrofit applications. Ensuring consistent temperature differentials across TEG modules requires sophisticated heat transfer systems that can maintain performance under variable operating conditions. Inadequate thermal interface management often leads to performance degradation over time, with thermal cycling causing mechanical stress that reduces system reliability and operational lifespan.

Cost-effectiveness represents perhaps the most formidable barrier to widespread implementation. Current TEG systems typically have high initial costs, with estimates ranging from $5-20 per watt of generating capacity depending on application specifications. This translates to lengthy payback periods that often exceed 5-10 years, making economic justification difficult for many potential applications without additional incentives or value propositions.

Integration challenges with existing infrastructure further complicate implementation. Retrofitting TEGs into established systems requires customized designs that accommodate spatial constraints, existing thermal flows, and electrical integration requirements. The lack of standardized integration approaches increases engineering costs and creates barriers to scalable deployment across different applications.

Durability and maintenance considerations also present ongoing challenges. TEG systems must withstand harsh operating environments, including high temperatures, thermal cycling, vibration, and potential chemical exposure. Current data on long-term reliability in field conditions remains limited, creating uncertainty for potential adopters regarding maintenance requirements and total lifecycle costs.

Lastly, knowledge gaps among engineers, installers, and end-users regarding TEG technology applications and benefits create adoption barriers. The relative novelty of TEG applications in energy-saving retrofits means that expertise is concentrated among specialists, limiting the technology's diffusion through conventional engineering and construction channels.

Material constraints present another substantial challenge. High-performance thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about resource availability, environmental impact, and regulatory compliance. The development of alternative materials with comparable performance using earth-abundant elements remains an active but unresolved research area.

Thermal management issues significantly affect TEG performance in retrofit applications. Ensuring consistent temperature differentials across TEG modules requires sophisticated heat transfer systems that can maintain performance under variable operating conditions. Inadequate thermal interface management often leads to performance degradation over time, with thermal cycling causing mechanical stress that reduces system reliability and operational lifespan.

Cost-effectiveness represents perhaps the most formidable barrier to widespread implementation. Current TEG systems typically have high initial costs, with estimates ranging from $5-20 per watt of generating capacity depending on application specifications. This translates to lengthy payback periods that often exceed 5-10 years, making economic justification difficult for many potential applications without additional incentives or value propositions.

Integration challenges with existing infrastructure further complicate implementation. Retrofitting TEGs into established systems requires customized designs that accommodate spatial constraints, existing thermal flows, and electrical integration requirements. The lack of standardized integration approaches increases engineering costs and creates barriers to scalable deployment across different applications.

Durability and maintenance considerations also present ongoing challenges. TEG systems must withstand harsh operating environments, including high temperatures, thermal cycling, vibration, and potential chemical exposure. Current data on long-term reliability in field conditions remains limited, creating uncertainty for potential adopters regarding maintenance requirements and total lifecycle costs.

Lastly, knowledge gaps among engineers, installers, and end-users regarding TEG technology applications and benefits create adoption barriers. The relative novelty of TEG applications in energy-saving retrofits means that expertise is concentrated among specialists, limiting the technology's diffusion through conventional engineering and construction channels.

Current TEG Retrofit Integration Methods

01 Waste heat recovery systems using TEGs

Thermoelectric generators can be utilized to recover waste heat from various sources such as industrial processes, vehicle exhaust systems, and household appliances. These systems convert thermal energy that would otherwise be lost into usable electricity, thereby improving overall energy efficiency. The recovered energy can be used to power auxiliary systems or fed back into the main power grid, reducing the need for additional energy consumption.- Waste heat recovery systems using TEGs: Thermoelectric generators can be integrated into systems that capture and convert waste heat from industrial processes, vehicle exhaust, or other heat-generating operations into usable electricity. These systems improve overall energy efficiency by harvesting thermal energy that would otherwise be lost to the environment, thereby reducing primary energy consumption and associated costs. The recovered electrical energy can be used to power auxiliary systems or fed back into the main power grid.

- TEG integration with renewable energy sources: Thermoelectric generators can be combined with other renewable energy technologies such as solar panels or biomass systems to create hybrid energy solutions. These integrated systems enhance overall efficiency by utilizing multiple energy conversion pathways. For example, TEGs can capture heat from solar collectors that would otherwise be wasted, effectively increasing the total energy output from the same installation footprint and improving the cost-effectiveness of renewable energy systems.

- Advanced TEG materials and structures: Innovations in thermoelectric materials and device structures have led to significant improvements in conversion efficiency. Novel semiconductor materials, nanostructured elements, and advanced manufacturing techniques enable TEGs to generate more electricity from the same temperature differential. These improvements include enhanced figure of merit (ZT) values, reduced thermal conductivity while maintaining electrical conductivity, and optimized contact interfaces that minimize energy losses during conversion.

- Smart power management systems for TEGs: Intelligent control and power management systems maximize the energy output from thermoelectric generators under varying temperature conditions. These systems include advanced DC-DC converters, maximum power point tracking algorithms, and energy storage solutions that optimize electricity generation and utilization. By dynamically adjusting to changing thermal gradients and load requirements, these management systems ensure that TEGs operate at peak efficiency regardless of environmental conditions.

- Portable and wearable TEG applications: Compact thermoelectric generators can be incorporated into portable devices and wearable technology to harvest body heat or environmental temperature differentials. These applications enable energy-saving by reducing reliance on traditional batteries or grid power. Miniaturized TEGs can power sensors, medical devices, or consumer electronics using otherwise wasted thermal energy, extending operational lifetimes and reducing the need for frequent battery replacements or recharging.

02 Integration of TEGs with renewable energy systems

Thermoelectric generators can be integrated with other renewable energy systems such as solar panels or biomass systems to create hybrid energy solutions. These integrated systems can enhance overall energy efficiency by utilizing multiple energy sources simultaneously. For example, TEGs can capture heat from solar panels that would otherwise contribute to decreased efficiency, converting this waste heat into additional electrical power.Expand Specific Solutions03 Advanced TEG materials and designs

Innovations in thermoelectric materials and device designs have led to significant improvements in conversion efficiency. Novel semiconductor materials, nanostructured elements, and advanced manufacturing techniques have enhanced the Seebeck effect and reduced thermal conductivity, resulting in higher energy conversion rates. These advancements make TEGs more viable for widespread energy-saving applications by improving their power output and cost-effectiveness.Expand Specific Solutions04 Portable and wearable TEG applications

Miniaturized thermoelectric generators can be incorporated into portable devices and wearable technology to harvest body heat or environmental temperature differentials. These applications enable self-powered electronic devices that reduce or eliminate the need for conventional battery charging, resulting in energy savings. Wearable TEGs can power health monitoring devices, mobile electronics, and IoT sensors using only the temperature difference between the human body and the surrounding environment.Expand Specific Solutions05 Smart control systems for TEG optimization

Intelligent control systems can maximize the energy-saving potential of thermoelectric generators by dynamically adjusting their operation based on temperature differentials, load requirements, and other environmental factors. These systems employ sensors, microcontrollers, and power management circuits to ensure TEGs operate at their optimal efficiency points. Advanced algorithms can predict thermal conditions and adjust the system accordingly, further enhancing energy recovery and reducing overall power consumption.Expand Specific Solutions

Key Industry Players in TEG Energy Harvesting

The Life-Cycle Assessment (LCA) for TEG-boosted energy-saving retrofits market is currently in an early growth phase, characterized by increasing adoption as organizations seek sustainable energy solutions. The global market size is expanding, driven by stringent environmental regulations and rising energy costs, with projections indicating significant growth potential. Technologically, the field shows moderate maturity with companies like State Grid Corp. of China, Shanghai Power Equipment Research Institute, and China Electric Power Research Institute leading research and implementation. Automotive manufacturers including Toyota, Jaguar Land Rover, and Dongfeng are exploring TEG applications for vehicle efficiency, while energy giants such as Saudi Aramco and Weichai Power are investing in industrial applications. Academic institutions like MIT and Sichuan University are advancing fundamental research, creating a dynamic ecosystem poised for innovation and commercial expansion.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute has developed comprehensive TEG-based waste heat recovery systems specifically designed for power plant applications with detailed lifecycle assessment methodologies. Their approach focuses on capturing low and medium-grade waste heat from various power generation processes, including cooling water systems and flue gas streams. CEPRI's lifecycle assessment framework quantifies environmental benefits across manufacturing, installation, operation, and end-of-life phases, demonstrating that their TEG systems achieve carbon payback within 1.5-2.5 years of operation in typical coal-fired power plants. Their segmented TEG module design optimizes performance across varying temperature gradients, achieving system-level conversion efficiencies of 3-6% depending on heat source characteristics. CEPRI has developed specialized heat exchanger configurations that minimize thermal resistance while maintaining durability in corrosive environments common in power generation facilities. Their integrated monitoring system provides real-time performance data and predictive maintenance capabilities, extending operational lifespans by an estimated 20-30% compared to conventional TEG implementations.

Strengths: CEPRI's deep understanding of power generation systems enables highly optimized TEG integration with minimal impact on primary operations. Their systems demonstrate excellent durability in harsh industrial environments with minimal maintenance requirements. Weaknesses: Higher initial capital costs compared to simpler waste heat recovery methods, and optimal performance requires sophisticated control systems that increase implementation complexity.

Toshiba Corp.

Technical Solution: Toshiba has developed advanced TEG systems specifically designed for building HVAC retrofits with comprehensive lifecycle assessment methodologies. Their approach focuses on low-temperature differential TEG modules that can harvest energy from temperature gradients as low as 20°C, making them suitable for integration with existing building systems. Toshiba's lifecycle assessment framework evaluates environmental impacts across manufacturing, installation, operation, and decommissioning phases, demonstrating net positive environmental benefits within 3-4 years of operation in typical commercial building applications. Their proprietary thin-film TEG technology achieves higher power density than conventional bulk thermoelectric materials while reducing material requirements by approximately 60%. Toshiba's integrated energy management system optimizes TEG performance based on building operational patterns, increasing overall system efficiency by an estimated 15-20% compared to static implementations. Their modular design approach enables scalable deployment with minimal disruption to existing building operations.

Strengths: Toshiba's specialized focus on building applications has resulted in systems optimized for the unique thermal characteristics of HVAC environments. Their thin-film technology significantly reduces material requirements and associated environmental impacts. Weaknesses: Lower conversion efficiency compared to high-temperature differential systems, requiring larger installation footprints to achieve meaningful energy recovery.

Critical TEG Efficiency Innovations

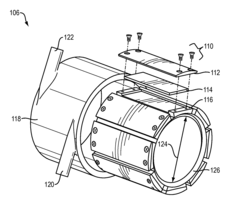

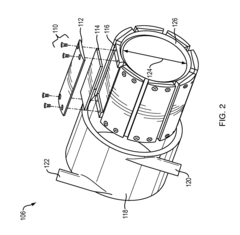

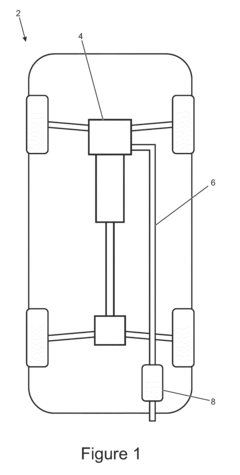

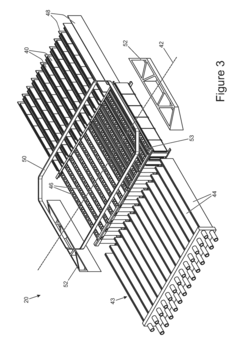

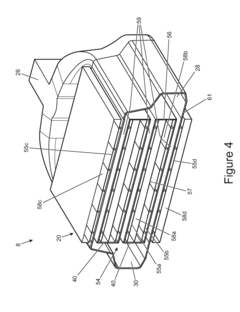

Thermoelectric generator sleeve for a catalytic converter

PatentActiveUS20160155922A1

Innovation

- A thermoelectric generator (TEG) sleeve system comprising a TEG layer with a silicon-based nanostructure, a thermal conductance layer, and a cooling layer, including a heat sink and thermal insulation, designed for easy mounting on a catalytic converter to convert exhaust gas heat into electrical energy.

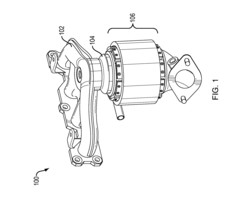

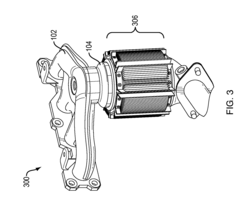

Energy recovery unit for vehicle use

PatentActiveUS20190088846A1

Innovation

- An energy recovery unit with a valve arrangement that alternates the direction of exhaust gas flow across the thermoelectric generator, utilizing two bypass ducts and valve actuators to control the flow, creating a more even temperature profile and preventing overheating, thereby improving system performance and extending the lifespan of the TEGs.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for TEG-boosted energy-saving retrofits requires a comprehensive methodology that captures the full spectrum of environmental effects throughout the technology's lifecycle. This framework must integrate both direct impacts from thermoelectric generator (TEG) manufacturing and installation, as well as the indirect environmental benefits achieved through energy recovery and efficiency improvements.

The assessment begins with a boundary definition phase that clearly delineates the scope of analysis, including temporal boundaries (covering pre-installation, operational life, and end-of-life stages) and spatial boundaries (encompassing manufacturing facilities, installation sites, and affected ecosystems). This ensures all relevant environmental interactions are captured without unnecessary complexity.

Material flow analysis forms the second critical component, tracking raw materials from extraction through processing, manufacturing, use, and eventual disposal or recycling. Special attention must be paid to rare earth elements and other critical materials often used in TEG production, as these present unique environmental challenges regarding extraction impacts and recycling potential.

Energy accounting methodologies constitute the third framework element, measuring both embodied energy in TEG components and the operational energy savings achieved through waste heat recovery. This net energy analysis provides crucial data for determining the technology's energy payback period and long-term environmental value proposition.

Emissions profiling represents another essential framework component, quantifying greenhouse gas emissions, air pollutants, and other environmental releases across the TEG lifecycle. This includes manufacturing emissions, potential reductions during operation, and end-of-life processing impacts. The framework employs standardized metrics like Global Warming Potential (GWP) and Acidification Potential to enable comparative assessments.

Water impact assessment methodologies track consumption and pollution throughout the TEG lifecycle, with particular focus on manufacturing processes that may involve significant water usage or potential contamination risks. This component addresses both quantity and quality dimensions of water resource impacts.

The framework concludes with an ecosystem impact evaluation that examines potential effects on biodiversity, habitat disruption, and ecosystem services. While TEG retrofits typically have minimal direct ecosystem impacts compared to large-scale energy infrastructure, the framework nevertheless incorporates these considerations for comprehensive assessment.

Integration with existing environmental management systems and reporting frameworks (such as ISO 14040/14044 standards) ensures compatibility with organizational sustainability initiatives and regulatory compliance requirements, enhancing the practical utility of assessment outcomes.

The assessment begins with a boundary definition phase that clearly delineates the scope of analysis, including temporal boundaries (covering pre-installation, operational life, and end-of-life stages) and spatial boundaries (encompassing manufacturing facilities, installation sites, and affected ecosystems). This ensures all relevant environmental interactions are captured without unnecessary complexity.

Material flow analysis forms the second critical component, tracking raw materials from extraction through processing, manufacturing, use, and eventual disposal or recycling. Special attention must be paid to rare earth elements and other critical materials often used in TEG production, as these present unique environmental challenges regarding extraction impacts and recycling potential.

Energy accounting methodologies constitute the third framework element, measuring both embodied energy in TEG components and the operational energy savings achieved through waste heat recovery. This net energy analysis provides crucial data for determining the technology's energy payback period and long-term environmental value proposition.

Emissions profiling represents another essential framework component, quantifying greenhouse gas emissions, air pollutants, and other environmental releases across the TEG lifecycle. This includes manufacturing emissions, potential reductions during operation, and end-of-life processing impacts. The framework employs standardized metrics like Global Warming Potential (GWP) and Acidification Potential to enable comparative assessments.

Water impact assessment methodologies track consumption and pollution throughout the TEG lifecycle, with particular focus on manufacturing processes that may involve significant water usage or potential contamination risks. This component addresses both quantity and quality dimensions of water resource impacts.

The framework concludes with an ecosystem impact evaluation that examines potential effects on biodiversity, habitat disruption, and ecosystem services. While TEG retrofits typically have minimal direct ecosystem impacts compared to large-scale energy infrastructure, the framework nevertheless incorporates these considerations for comprehensive assessment.

Integration with existing environmental management systems and reporting frameworks (such as ISO 14040/14044 standards) ensures compatibility with organizational sustainability initiatives and regulatory compliance requirements, enhancing the practical utility of assessment outcomes.

Cost-Benefit Analysis of TEG Retrofits

The economic viability of Thermoelectric Generator (TEG) retrofits represents a critical factor in their adoption across various sectors. Initial investment costs for TEG systems include hardware components (thermoelectric modules, heat exchangers, thermal interface materials), installation labor, and system integration expenses. These upfront costs typically range from $200-$800 per kilowatt of capacity, depending on application scale and complexity.

Operational benefits manifest through multiple revenue streams. Primary among these is energy cost reduction, with TEG systems capable of generating 5-15% energy savings in industrial applications by converting waste heat into usable electricity. For a medium-sized manufacturing facility, this can translate to annual savings of $10,000-$50,000, depending on energy prices and waste heat availability.

Maintenance requirements for TEG systems are minimal compared to conventional power generation technologies, with no moving parts and estimated annual maintenance costs of only 1-3% of the initial investment. The durability of modern TEG modules extends to 10-15 years of operational life, allowing for extended return periods.

Payback periods vary significantly across applications. In high-temperature industrial environments with continuous operations, ROI can be achieved within 2-4 years. Commercial building applications typically show longer payback periods of 5-7 years, while residential implementations may require 7-10 years to reach break-even, absent subsidies or incentives.

Government incentives substantially improve the economic equation. Many jurisdictions offer tax credits (10-30% of installation costs), grants, or accelerated depreciation schedules for clean energy technologies. Carbon credit markets provide additional revenue potential, with TEG retrofits potentially generating 0.4-0.7 tons of CO2 equivalent offsets per MWh of electricity generated.

Sensitivity analysis reveals that TEG retrofit economics are most influenced by waste heat availability, energy prices, and installation costs. A 20% increase in energy prices can reduce payback periods by 15-25%, while technological improvements reducing installation costs by 30% could accelerate ROI by up to 2 years across most applications.

Financing options including energy service company (ESCO) models, green bonds, and performance contracting can mitigate upfront cost barriers. These mechanisms allow organizations to implement TEG retrofits with minimal initial capital outlay, paying for the improvements through realized energy savings over time.

Operational benefits manifest through multiple revenue streams. Primary among these is energy cost reduction, with TEG systems capable of generating 5-15% energy savings in industrial applications by converting waste heat into usable electricity. For a medium-sized manufacturing facility, this can translate to annual savings of $10,000-$50,000, depending on energy prices and waste heat availability.

Maintenance requirements for TEG systems are minimal compared to conventional power generation technologies, with no moving parts and estimated annual maintenance costs of only 1-3% of the initial investment. The durability of modern TEG modules extends to 10-15 years of operational life, allowing for extended return periods.

Payback periods vary significantly across applications. In high-temperature industrial environments with continuous operations, ROI can be achieved within 2-4 years. Commercial building applications typically show longer payback periods of 5-7 years, while residential implementations may require 7-10 years to reach break-even, absent subsidies or incentives.

Government incentives substantially improve the economic equation. Many jurisdictions offer tax credits (10-30% of installation costs), grants, or accelerated depreciation schedules for clean energy technologies. Carbon credit markets provide additional revenue potential, with TEG retrofits potentially generating 0.4-0.7 tons of CO2 equivalent offsets per MWh of electricity generated.

Sensitivity analysis reveals that TEG retrofit economics are most influenced by waste heat availability, energy prices, and installation costs. A 20% increase in energy prices can reduce payback periods by 15-25%, while technological improvements reducing installation costs by 30% could accelerate ROI by up to 2 years across most applications.

Financing options including energy service company (ESCO) models, green bonds, and performance contracting can mitigate upfront cost barriers. These mechanisms allow organizations to implement TEG retrofits with minimal initial capital outlay, paying for the improvements through realized energy savings over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!