Thermoelectric Generator Monitoring And Fault Detection Techniques

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821. This phenomenon, where a temperature difference between two dissimilar electrical conductors produces a voltage difference, forms the fundamental principle of thermoelectric generation. The technology remained largely theoretical until the mid-20th century when semiconductor materials revolutionized the field, enabling practical applications of TEGs.

The development trajectory of TEG technology has been characterized by continuous improvements in conversion efficiency, material performance, and system integration. Early TEGs exhibited efficiencies below 1%, limiting their practical utility. However, advancements in material science, particularly the development of bismuth telluride (Bi2Te3) compounds in the 1950s and 1960s, pushed efficiencies to 5-8% range, making commercial applications viable for specific use cases.

Recent technological innovations have focused on nanostructured materials, quantum well structures, and advanced manufacturing techniques to enhance the figure of merit (ZT) - the key performance indicator for thermoelectric materials. The current state-of-the-art materials achieve ZT values approaching 2.0, with laboratory demonstrations exceeding this threshold under controlled conditions.

The primary technical objective in TEG monitoring and fault detection is to develop robust, real-time systems capable of detecting performance degradation, predicting failures, and optimizing operational parameters across diverse application environments. This includes creating sensor networks that can accurately measure temperature gradients, electrical output, and material degradation with minimal impact on system performance.

Another critical goal is establishing standardized testing protocols and performance metrics specifically tailored for TEG systems, enabling consistent evaluation across different technologies and applications. This standardization would facilitate more accurate comparisons between emerging solutions and accelerate industry-wide adoption of best practices.

Long-term objectives include developing self-diagnostic capabilities within TEG systems, implementing machine learning algorithms for predictive maintenance, and creating integrated monitoring solutions that can adapt to changing environmental conditions. These advancements aim to extend TEG operational lifetimes, reduce maintenance costs, and improve overall system reliability.

The evolution of TEG technology is increasingly focused on sustainability, with research directed toward reducing dependence on rare or toxic materials while maintaining or improving performance characteristics. This trend aligns with global initiatives for cleaner energy technologies and circular economy principles, positioning TEGs as a potentially significant contributor to sustainable energy portfolios.

The development trajectory of TEG technology has been characterized by continuous improvements in conversion efficiency, material performance, and system integration. Early TEGs exhibited efficiencies below 1%, limiting their practical utility. However, advancements in material science, particularly the development of bismuth telluride (Bi2Te3) compounds in the 1950s and 1960s, pushed efficiencies to 5-8% range, making commercial applications viable for specific use cases.

Recent technological innovations have focused on nanostructured materials, quantum well structures, and advanced manufacturing techniques to enhance the figure of merit (ZT) - the key performance indicator for thermoelectric materials. The current state-of-the-art materials achieve ZT values approaching 2.0, with laboratory demonstrations exceeding this threshold under controlled conditions.

The primary technical objective in TEG monitoring and fault detection is to develop robust, real-time systems capable of detecting performance degradation, predicting failures, and optimizing operational parameters across diverse application environments. This includes creating sensor networks that can accurately measure temperature gradients, electrical output, and material degradation with minimal impact on system performance.

Another critical goal is establishing standardized testing protocols and performance metrics specifically tailored for TEG systems, enabling consistent evaluation across different technologies and applications. This standardization would facilitate more accurate comparisons between emerging solutions and accelerate industry-wide adoption of best practices.

Long-term objectives include developing self-diagnostic capabilities within TEG systems, implementing machine learning algorithms for predictive maintenance, and creating integrated monitoring solutions that can adapt to changing environmental conditions. These advancements aim to extend TEG operational lifetimes, reduce maintenance costs, and improve overall system reliability.

The evolution of TEG technology is increasingly focused on sustainability, with research directed toward reducing dependence on rare or toxic materials while maintaining or improving performance characteristics. This trend aligns with global initiatives for cleaner energy technologies and circular economy principles, positioning TEGs as a potentially significant contributor to sustainable energy portfolios.

Market Demand Analysis for TEG Monitoring Solutions

The global market for Thermoelectric Generator (TEG) monitoring solutions is experiencing significant growth, driven primarily by increasing deployment of TEGs across multiple industries. Current market analysis indicates a robust demand trajectory, with the oil and gas sector representing the largest market segment, where TEGs are extensively used in remote locations for powering critical monitoring equipment and communication systems.

The renewable energy sector presents another substantial market opportunity, as TEGs are increasingly integrated into solar and wind power systems to harvest waste heat and improve overall energy efficiency. This integration creates a parallel demand for sophisticated monitoring solutions that can ensure optimal performance and early fault detection in these hybrid energy systems.

Industrial manufacturing represents the fastest-growing segment for TEG monitoring solutions, with an increasing focus on energy recovery from industrial processes. As manufacturers implement TEGs to capture waste heat from furnaces, kilns, and other high-temperature processes, the need for reliable monitoring systems becomes critical to ensure continuous operation and maximize energy recovery.

Market research reveals that end-users are primarily seeking monitoring solutions that offer real-time performance tracking, predictive maintenance capabilities, and seamless integration with existing industrial control systems. The ability to detect performance degradation before catastrophic failure occurs represents a particularly high-value proposition, as it directly impacts operational continuity and maintenance costs.

Geographically, North America currently leads the market for TEG monitoring solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate, driven by rapid industrialization in countries like China and India, coupled with increasing adoption of renewable energy technologies.

A significant market trend is the growing demand for wireless and IoT-enabled monitoring solutions that can operate in remote or hazardous environments. These solutions offer advantages in terms of installation flexibility, reduced maintenance requirements, and the ability to integrate with cloud-based analytics platforms for advanced diagnostics.

Customer feedback indicates that key purchasing factors include reliability in harsh environments, ease of installation and configuration, battery life for wireless systems, and total cost of ownership. Additionally, there is increasing demand for monitoring solutions that can handle multiple TEG units simultaneously, providing centralized management capabilities for large-scale deployments.

The market is also witnessing a shift toward monitoring systems that incorporate machine learning algorithms for more accurate fault prediction and performance optimization, reflecting the broader industry trend toward data-driven operational intelligence and automated decision support systems.

The renewable energy sector presents another substantial market opportunity, as TEGs are increasingly integrated into solar and wind power systems to harvest waste heat and improve overall energy efficiency. This integration creates a parallel demand for sophisticated monitoring solutions that can ensure optimal performance and early fault detection in these hybrid energy systems.

Industrial manufacturing represents the fastest-growing segment for TEG monitoring solutions, with an increasing focus on energy recovery from industrial processes. As manufacturers implement TEGs to capture waste heat from furnaces, kilns, and other high-temperature processes, the need for reliable monitoring systems becomes critical to ensure continuous operation and maximize energy recovery.

Market research reveals that end-users are primarily seeking monitoring solutions that offer real-time performance tracking, predictive maintenance capabilities, and seamless integration with existing industrial control systems. The ability to detect performance degradation before catastrophic failure occurs represents a particularly high-value proposition, as it directly impacts operational continuity and maintenance costs.

Geographically, North America currently leads the market for TEG monitoring solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate, driven by rapid industrialization in countries like China and India, coupled with increasing adoption of renewable energy technologies.

A significant market trend is the growing demand for wireless and IoT-enabled monitoring solutions that can operate in remote or hazardous environments. These solutions offer advantages in terms of installation flexibility, reduced maintenance requirements, and the ability to integrate with cloud-based analytics platforms for advanced diagnostics.

Customer feedback indicates that key purchasing factors include reliability in harsh environments, ease of installation and configuration, battery life for wireless systems, and total cost of ownership. Additionally, there is increasing demand for monitoring solutions that can handle multiple TEG units simultaneously, providing centralized management capabilities for large-scale deployments.

The market is also witnessing a shift toward monitoring systems that incorporate machine learning algorithms for more accurate fault prediction and performance optimization, reflecting the broader industry trend toward data-driven operational intelligence and automated decision support systems.

Current State and Challenges in TEG Fault Detection

Thermoelectric Generator (TEG) fault detection currently faces significant challenges despite advancements in monitoring technologies. The global landscape shows varying levels of technological maturity, with research institutions in North America, Europe, and East Asia leading development efforts. Current detection systems primarily rely on conventional methods such as temperature differential monitoring, electrical output analysis, and visual inspections, which often fail to provide early warning of degradation or impending failures.

A major technical challenge in TEG fault detection is the complex relationship between environmental conditions and TEG performance. Temperature fluctuations, thermal cycling, and varying heat sources create noise in monitoring data, making it difficult to distinguish between normal operational variations and actual fault conditions. This complexity is compounded by the lack of standardized testing protocols across the industry, resulting in inconsistent fault detection methodologies.

Material degradation monitoring presents another significant obstacle. The gradual deterioration of thermoelectric materials due to oxidation, thermal stress, and mechanical fatigue occurs subtly over extended periods, making early detection particularly challenging. Current sensors often lack the sensitivity to detect microscopic changes in material properties before significant performance degradation occurs.

Interconnection failures between thermoelectric couples represent approximately 40% of TEG system failures according to recent industry data. These connection points are vulnerable to thermal expansion stresses and mechanical vibration, yet existing monitoring systems struggle to isolate these specific failure modes from overall performance metrics.

Data integration challenges further complicate fault detection efforts. Most TEG installations generate substantial monitoring data across multiple parameters, but the industry lacks sophisticated algorithms capable of correlating these diverse data streams to identify fault patterns. Machine learning approaches show promise but remain in early development stages, with limited training datasets available for algorithm development.

Remote monitoring capabilities for distributed TEG installations remain underdeveloped, particularly for applications in remote or harsh environments. Wireless sensor networks face power constraints and communication reliability issues, while edge computing solutions for real-time fault analysis are still emerging technologies in this domain.

Cost-effectiveness represents a significant barrier to widespread implementation of advanced monitoring systems. The economic justification for sophisticated fault detection in small-scale TEG applications remains challenging, creating a technological divide between high-value industrial applications and smaller distributed energy harvesting systems.

A major technical challenge in TEG fault detection is the complex relationship between environmental conditions and TEG performance. Temperature fluctuations, thermal cycling, and varying heat sources create noise in monitoring data, making it difficult to distinguish between normal operational variations and actual fault conditions. This complexity is compounded by the lack of standardized testing protocols across the industry, resulting in inconsistent fault detection methodologies.

Material degradation monitoring presents another significant obstacle. The gradual deterioration of thermoelectric materials due to oxidation, thermal stress, and mechanical fatigue occurs subtly over extended periods, making early detection particularly challenging. Current sensors often lack the sensitivity to detect microscopic changes in material properties before significant performance degradation occurs.

Interconnection failures between thermoelectric couples represent approximately 40% of TEG system failures according to recent industry data. These connection points are vulnerable to thermal expansion stresses and mechanical vibration, yet existing monitoring systems struggle to isolate these specific failure modes from overall performance metrics.

Data integration challenges further complicate fault detection efforts. Most TEG installations generate substantial monitoring data across multiple parameters, but the industry lacks sophisticated algorithms capable of correlating these diverse data streams to identify fault patterns. Machine learning approaches show promise but remain in early development stages, with limited training datasets available for algorithm development.

Remote monitoring capabilities for distributed TEG installations remain underdeveloped, particularly for applications in remote or harsh environments. Wireless sensor networks face power constraints and communication reliability issues, while edge computing solutions for real-time fault analysis are still emerging technologies in this domain.

Cost-effectiveness represents a significant barrier to widespread implementation of advanced monitoring systems. The economic justification for sophisticated fault detection in small-scale TEG applications remains challenging, creating a technological divide between high-value industrial applications and smaller distributed energy harvesting systems.

Current TEG Fault Detection Methodologies

01 Real-time monitoring systems for thermoelectric generators

Advanced monitoring systems that provide real-time data on thermoelectric generator performance. These systems continuously track operational parameters such as temperature differentials, voltage output, and power generation efficiency. Real-time monitoring enables early detection of performance degradation and potential failures, allowing for timely maintenance interventions. These systems often incorporate data logging capabilities for trend analysis and performance optimization.- Real-time monitoring systems for thermoelectric generators: Real-time monitoring systems are implemented to continuously track the performance of thermoelectric generators. These systems collect data on various parameters such as temperature differentials, voltage output, and power generation efficiency. By monitoring these parameters in real-time, operators can quickly identify deviations from normal operating conditions and take corrective actions before failures occur. These monitoring systems often include data logging capabilities and can be integrated with broader power management systems.

- Fault detection algorithms and diagnostic techniques: Advanced algorithms and diagnostic techniques are employed to detect and identify faults in thermoelectric generator systems. These algorithms analyze patterns in operational data to recognize anomalies that may indicate developing problems. Machine learning and statistical methods are used to improve fault detection accuracy and reduce false alarms. Diagnostic techniques can pinpoint specific components that are failing or operating outside optimal parameters, enabling targeted maintenance and repairs.

- Temperature sensing and thermal management: Temperature sensing systems are critical for monitoring thermoelectric generators, as these devices operate based on temperature differentials. Multiple temperature sensors are strategically placed to measure hot and cold side temperatures, as well as ambient conditions. Thermal management systems use this data to optimize performance and prevent overheating. Abnormal temperature readings can indicate issues such as heat sink fouling, thermal interface material degradation, or changes in heat source characteristics.

- Remote monitoring and wireless communication systems: Remote monitoring capabilities allow thermoelectric generator systems to be observed and controlled from distant locations. Wireless communication technologies enable data transmission from generators in remote or hazardous environments to central monitoring stations. These systems can send alerts and status updates via cellular networks, satellite communications, or local wireless protocols. Remote monitoring reduces the need for on-site inspections and allows for faster response to potential issues, particularly for generators deployed in hard-to-reach locations.

- Predictive maintenance and reliability enhancement: Predictive maintenance approaches use historical and real-time data to forecast potential failures before they occur. By analyzing performance trends and degradation patterns, these systems can estimate remaining useful life of components and schedule maintenance activities optimally. This approach minimizes downtime and extends the operational life of thermoelectric generators. Reliability enhancement techniques include redundant components, automatic switchover mechanisms, and self-healing capabilities that can compensate for partial failures in the system.

02 Fault detection algorithms and diagnostic techniques

Specialized algorithms and diagnostic techniques designed to identify and classify various types of faults in thermoelectric generator systems. These methods analyze patterns in operational data to detect anomalies indicative of specific failure modes. Machine learning and statistical analysis techniques are employed to improve fault classification accuracy and reduce false alarms. Advanced diagnostic approaches can differentiate between mechanical failures, electrical issues, and thermal coupling problems.Expand Specific Solutions03 Temperature sensing and thermal management for fault prevention

Systems focused on temperature monitoring and thermal management to prevent thermoelectric generator failures. These solutions employ temperature sensors at critical points to detect overheating and thermal imbalances that could lead to device degradation. Thermal management strategies include active cooling systems, heat flow optimization, and protective shutdown mechanisms when temperature thresholds are exceeded. Maintaining optimal temperature differentials is crucial for both performance and longevity of thermoelectric generators.Expand Specific Solutions04 Integrated monitoring and control systems

Comprehensive systems that combine monitoring capabilities with automated control functions for thermoelectric generators. These integrated solutions not only detect faults but also implement corrective actions to maintain optimal operation. Control algorithms adjust operating parameters based on real-time monitoring data to maximize efficiency and prevent failures. These systems often feature user interfaces that provide operators with system status information and alert notifications when issues are detected.Expand Specific Solutions05 Remote monitoring and wireless fault detection

Wireless and remote monitoring solutions that enable off-site tracking of thermoelectric generator performance and fault conditions. These systems utilize wireless communication technologies to transmit operational data to centralized monitoring stations or cloud-based platforms. Remote monitoring capabilities allow for efficient management of distributed thermoelectric generator installations and enable predictive maintenance strategies. Mobile applications and web interfaces provide convenient access to system status information and historical performance data.Expand Specific Solutions

Key Industry Players in TEG Monitoring Systems

Thermoelectric Generator Monitoring and Fault Detection Techniques market is currently in a growth phase, with increasing adoption across automotive, energy, and industrial sectors. The market is estimated to reach $350-400 million by 2025, driven by demand for reliable energy harvesting solutions. Technology maturity varies across applications, with companies at different development stages. Toyota, DENSO, and Bosch lead in automotive applications with advanced fault prediction systems. State Grid Corp. of China and EDF focus on grid-scale implementations, while KELK specializes in high-precision thermoelectric modules. Sony and Panasonic are advancing consumer applications, with emerging players like Yanmar and Caterpillar developing industrial monitoring solutions that integrate AI-based predictive maintenance capabilities.

Toyota Motor Corp.

Technical Solution: Toyota has developed a specialized TEG monitoring system primarily focused on automotive waste heat recovery applications. Their approach centers on a distributed sensor network that monitors not only electrical output parameters but also the thermal conditions across the entire exhaust system integration. Toyota's fault detection methodology employs a combination of threshold-based alerts and trend analysis algorithms that account for varying driving conditions and engine loads. The system incorporates dedicated microcontrollers that perform real-time analysis of TEG performance metrics, comparing them against expected values derived from comprehensive thermal models. Toyota's solution features adaptive baseline adjustments that compensate for normal degradation over the vehicle's lifetime, distinguishing between expected performance changes and actual fault conditions. Their monitoring system integrates with the vehicle's onboard diagnostic system, providing drivers and service technicians with actionable information about TEG health and efficiency through standardized diagnostic interfaces.

Strengths: Highly optimized for automotive applications, excellent integration with vehicle diagnostic systems, and sophisticated compensation for varying operating conditions. Weaknesses: Limited applicability to non-automotive TEG applications and relatively high component cost when considered for aftermarket implementation.

State Grid Corp. of China

Technical Solution: State Grid has developed an extensive TEG monitoring framework specifically designed for distributed energy harvesting applications within power transmission infrastructure. Their system employs a hierarchical monitoring architecture that aggregates data from thousands of individual TEG units deployed across the power grid. The monitoring solution incorporates both wired and wireless sensor networks depending on installation location and accessibility requirements. State Grid's fault detection approach utilizes comparative analytics that evaluate performance across similar TEG units operating under comparable conditions, enabling the identification of underperforming units with high sensitivity. Their system features automated environmental compensation algorithms that adjust performance expectations based on ambient conditions, seasonal variations, and load patterns. The monitoring platform integrates with State Grid's broader grid management systems, allowing operators to prioritize maintenance activities based on both TEG performance degradation and the criticality of the installation location to overall grid operations.

Strengths: Massive scalability for thousands of monitoring points, sophisticated comparative analytics across similar units, and excellent integration with broader grid management systems. Weaknesses: Heavy customization toward power grid applications limits versatility for other industries, and significant infrastructure requirements for full implementation.

Core Patents and Research in TEG Monitoring

Thermoelectric generating system

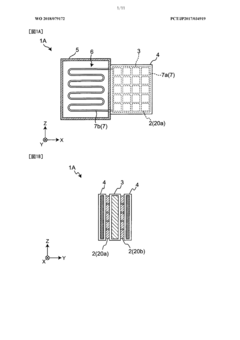

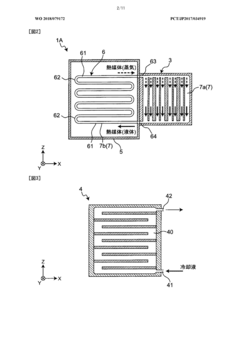

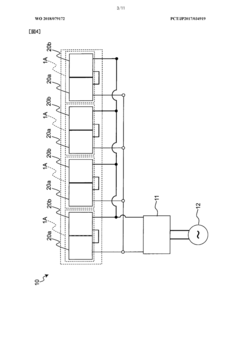

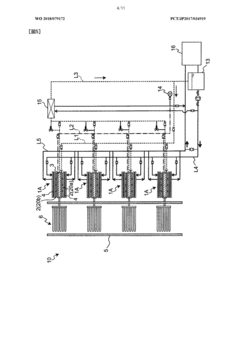

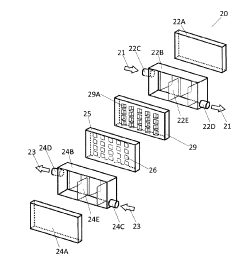

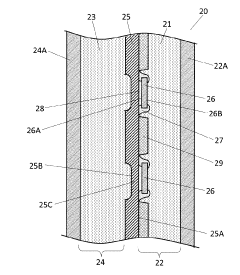

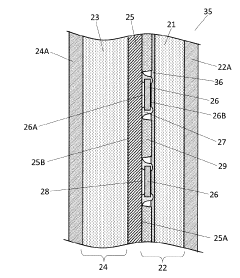

PatentWO2018079172A1

Innovation

- The proposed thermoelectric power generation device includes a heating section with a heat medium flow path, a cooling unit with a coolant flow path, and sensors to detect power generation output, heat medium pressure or temperature, and coolant temperature, allowing for the storage of normal state relationships to detect abnormalities based on deviations from these conditions.

Power generator

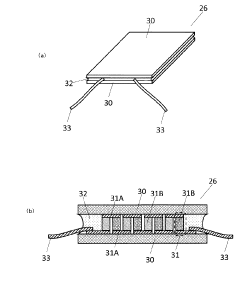

PatentInactiveJP2016015860A

Innovation

- A power generation device with separate flow paths for different mediums, a heat transfer body, and thermoelectric modules mounted on one heat transfer surface, where the thermoelectric modules are fixed on one side and have an exposed surface in direct contact with a medium to reduce mechanical stress and enhance heat transfer efficiency.

Reliability and Efficiency Metrics for TEG Systems

Reliability and efficiency metrics serve as critical performance indicators for thermoelectric generator (TEG) systems, providing quantitative measures to evaluate system health, operational effectiveness, and long-term sustainability. The primary reliability metrics include Mean Time Between Failures (MTBF), which typically ranges from 15,000 to 30,000 hours for industrial TEG applications, and Mean Time To Repair (MTTR), averaging 2-8 hours depending on system complexity and accessibility. Failure Rate (λ) calculations, expressed as failures per million hours, enable predictive maintenance scheduling and risk assessment across the TEG lifecycle.

Efficiency metrics focus on conversion performance, with the Figure of Merit (ZT) remaining the fundamental parameter for thermoelectric material evaluation. Current commercial TEG systems operate at ZT values between 0.8 and 1.2, with laboratory prototypes achieving up to 2.0 under controlled conditions. Power conversion efficiency, typically ranging from 3% to 8% in field applications, represents the ratio of electrical output to thermal input and varies significantly with temperature differential and load conditions.

Temperature-related metrics include the Seebeck coefficient stability (measured in μV/K) and thermal cycling resilience, which quantifies performance degradation after repeated heating-cooling cycles. Advanced TEG systems maintain Seebeck coefficient stability within ±2% over 10,000 operational hours and demonstrate less than 5% performance degradation after 1,000 thermal cycles.

Operational metrics encompass power density (W/cm²), specific power (W/kg), and response time to load variations. Modern TEG systems achieve power densities of 0.2-1.0 W/cm² and specific power ratings of 0.1-0.5 W/kg, with response times under varying loads typically measured in seconds to minutes depending on thermal mass and circuit design.

Economic efficiency metrics include Levelized Cost of Energy (LCOE), installation costs per watt, and maintenance costs as a percentage of capital expenditure. Current TEG systems demonstrate LCOE values of $0.10-0.30 per kWh, with installation costs ranging from $5-15 per watt and annual maintenance costs between 2-5% of initial investment.

Standardized testing protocols such as ASTM E2557 and IEC 62108 provide frameworks for consistent measurement and reporting of these metrics across different TEG technologies and applications. These standards enable meaningful benchmarking between systems and support evidence-based decision-making for technology selection and deployment strategies in various industrial contexts.

Efficiency metrics focus on conversion performance, with the Figure of Merit (ZT) remaining the fundamental parameter for thermoelectric material evaluation. Current commercial TEG systems operate at ZT values between 0.8 and 1.2, with laboratory prototypes achieving up to 2.0 under controlled conditions. Power conversion efficiency, typically ranging from 3% to 8% in field applications, represents the ratio of electrical output to thermal input and varies significantly with temperature differential and load conditions.

Temperature-related metrics include the Seebeck coefficient stability (measured in μV/K) and thermal cycling resilience, which quantifies performance degradation after repeated heating-cooling cycles. Advanced TEG systems maintain Seebeck coefficient stability within ±2% over 10,000 operational hours and demonstrate less than 5% performance degradation after 1,000 thermal cycles.

Operational metrics encompass power density (W/cm²), specific power (W/kg), and response time to load variations. Modern TEG systems achieve power densities of 0.2-1.0 W/cm² and specific power ratings of 0.1-0.5 W/kg, with response times under varying loads typically measured in seconds to minutes depending on thermal mass and circuit design.

Economic efficiency metrics include Levelized Cost of Energy (LCOE), installation costs per watt, and maintenance costs as a percentage of capital expenditure. Current TEG systems demonstrate LCOE values of $0.10-0.30 per kWh, with installation costs ranging from $5-15 per watt and annual maintenance costs between 2-5% of initial investment.

Standardized testing protocols such as ASTM E2557 and IEC 62108 provide frameworks for consistent measurement and reporting of these metrics across different TEG technologies and applications. These standards enable meaningful benchmarking between systems and support evidence-based decision-making for technology selection and deployment strategies in various industrial contexts.

Environmental Impact and Sustainability Considerations

Thermoelectric generators (TEGs) offer significant environmental advantages compared to conventional power generation technologies, primarily due to their zero-emission operation during electricity production. The absence of moving parts eliminates the need for lubricants and reduces maintenance waste, while their ability to convert waste heat into usable electricity improves overall system efficiency and reduces carbon footprints across industrial applications. When properly monitored and maintained through advanced fault detection techniques, TEGs can achieve operational lifespans exceeding 25 years, substantially reducing electronic waste compared to technologies requiring frequent replacement.

Life cycle assessment (LCA) studies indicate that the environmental impact of TEGs is heavily concentrated in the manufacturing phase, particularly in the extraction and processing of semiconductor materials like bismuth telluride. Advanced monitoring systems that extend TEG lifespan effectively amortize these initial environmental costs over longer operational periods. Furthermore, early fault detection prevents catastrophic failures that might otherwise render entire modules unrepairable, supporting circular economy principles through component-level repair rather than complete replacement.

The environmental benefits of TEGs are particularly pronounced in remote applications where they replace diesel generators. In these scenarios, effective monitoring systems ensure optimal performance while preventing fuel-intensive maintenance trips, creating a dual environmental benefit. Recent research indicates that a well-monitored 1kW TEG system can offset approximately 4-6 tons of CO2 annually when replacing diesel generation in remote locations.

Water conservation represents another significant environmental advantage of TEG technology. Unlike conventional thermal power generation requiring substantial cooling water, TEGs operate without water consumption. This makes them particularly valuable in water-stressed regions, where monitoring systems that optimize performance based on available heat gradients can maximize electricity production without increasing water demand.

End-of-life considerations for TEG systems present both challenges and opportunities. The semiconductor materials contain valuable and sometimes toxic elements that require proper recycling. Advanced monitoring systems that track material degradation can provide valuable data for recycling processes, potentially improving recovery rates of critical materials. Recent innovations in non-destructive testing techniques allow for more precise assessment of remaining useful life, supporting decisions about refurbishment versus recycling and further enhancing the sustainability profile of TEG technology.

Life cycle assessment (LCA) studies indicate that the environmental impact of TEGs is heavily concentrated in the manufacturing phase, particularly in the extraction and processing of semiconductor materials like bismuth telluride. Advanced monitoring systems that extend TEG lifespan effectively amortize these initial environmental costs over longer operational periods. Furthermore, early fault detection prevents catastrophic failures that might otherwise render entire modules unrepairable, supporting circular economy principles through component-level repair rather than complete replacement.

The environmental benefits of TEGs are particularly pronounced in remote applications where they replace diesel generators. In these scenarios, effective monitoring systems ensure optimal performance while preventing fuel-intensive maintenance trips, creating a dual environmental benefit. Recent research indicates that a well-monitored 1kW TEG system can offset approximately 4-6 tons of CO2 annually when replacing diesel generation in remote locations.

Water conservation represents another significant environmental advantage of TEG technology. Unlike conventional thermal power generation requiring substantial cooling water, TEGs operate without water consumption. This makes them particularly valuable in water-stressed regions, where monitoring systems that optimize performance based on available heat gradients can maximize electricity production without increasing water demand.

End-of-life considerations for TEG systems present both challenges and opportunities. The semiconductor materials contain valuable and sometimes toxic elements that require proper recycling. Advanced monitoring systems that track material degradation can provide valuable data for recycling processes, potentially improving recovery rates of critical materials. Recent innovations in non-destructive testing techniques allow for more precise assessment of remaining useful life, supporting decisions about refurbishment versus recycling and further enhancing the sustainability profile of TEG technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!