Advances in Ethyl Propanoate Catalysis for Industrial Processes

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Catalysis Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is an ester compound widely used in various industrial processes. The catalysis of ethyl propanoate has been a subject of significant interest in the chemical industry due to its importance in the production of flavors, fragrances, and pharmaceutical intermediates. Over the past few decades, the field has witnessed substantial advancements in catalytic processes, aiming to improve efficiency, selectivity, and sustainability.

The evolution of ethyl propanoate catalysis can be traced back to traditional acid-catalyzed esterification methods. These early approaches, while effective, often suffered from low yields, long reaction times, and the generation of substantial waste products. As environmental concerns grew and industrial demands increased, researchers began exploring more efficient and environmentally friendly catalytic systems.

In recent years, the focus has shifted towards developing heterogeneous catalysts for ethyl propanoate synthesis. These solid catalysts offer several advantages, including ease of separation, reusability, and enhanced process efficiency. Metal oxides, zeolites, and supported metal catalysts have emerged as promising candidates, demonstrating improved activity and selectivity compared to their homogeneous counterparts.

The advent of nanotechnology has further revolutionized the field of ethyl propanoate catalysis. Nanostructured catalysts, with their high surface area and unique physicochemical properties, have shown remarkable performance in terms of conversion rates and product yields. Additionally, the incorporation of novel materials such as graphene-based composites and metal-organic frameworks (MOFs) has opened up new avenues for catalyst design and optimization.

Biocatalysis has also gained traction as a sustainable alternative for ethyl propanoate production. Enzymes, particularly lipases, have demonstrated their potential in catalyzing esterification reactions under mild conditions. The use of immobilized enzymes and whole-cell biocatalysts has addressed some of the challenges associated with enzyme stability and reusability, making biocatalytic processes increasingly viable for industrial applications.

The primary objectives of current research in ethyl propanoate catalysis are centered around enhancing catalytic activity, improving selectivity, and developing more sustainable processes. Researchers aim to design catalysts that can operate efficiently under milder reaction conditions, reduce energy consumption, and minimize waste generation. Additionally, there is a growing emphasis on developing catalytic systems that can utilize renewable feedstocks, aligning with the principles of green chemistry and circular economy.

Another key goal is to improve the understanding of reaction mechanisms and catalyst behavior at the molecular level. Advanced characterization techniques, coupled with computational modeling, are being employed to gain deeper insights into the catalytic processes. This fundamental knowledge is crucial for rational catalyst design and process optimization, ultimately leading to more efficient and cost-effective industrial applications of ethyl propanoate catalysis.

The evolution of ethyl propanoate catalysis can be traced back to traditional acid-catalyzed esterification methods. These early approaches, while effective, often suffered from low yields, long reaction times, and the generation of substantial waste products. As environmental concerns grew and industrial demands increased, researchers began exploring more efficient and environmentally friendly catalytic systems.

In recent years, the focus has shifted towards developing heterogeneous catalysts for ethyl propanoate synthesis. These solid catalysts offer several advantages, including ease of separation, reusability, and enhanced process efficiency. Metal oxides, zeolites, and supported metal catalysts have emerged as promising candidates, demonstrating improved activity and selectivity compared to their homogeneous counterparts.

The advent of nanotechnology has further revolutionized the field of ethyl propanoate catalysis. Nanostructured catalysts, with their high surface area and unique physicochemical properties, have shown remarkable performance in terms of conversion rates and product yields. Additionally, the incorporation of novel materials such as graphene-based composites and metal-organic frameworks (MOFs) has opened up new avenues for catalyst design and optimization.

Biocatalysis has also gained traction as a sustainable alternative for ethyl propanoate production. Enzymes, particularly lipases, have demonstrated their potential in catalyzing esterification reactions under mild conditions. The use of immobilized enzymes and whole-cell biocatalysts has addressed some of the challenges associated with enzyme stability and reusability, making biocatalytic processes increasingly viable for industrial applications.

The primary objectives of current research in ethyl propanoate catalysis are centered around enhancing catalytic activity, improving selectivity, and developing more sustainable processes. Researchers aim to design catalysts that can operate efficiently under milder reaction conditions, reduce energy consumption, and minimize waste generation. Additionally, there is a growing emphasis on developing catalytic systems that can utilize renewable feedstocks, aligning with the principles of green chemistry and circular economy.

Another key goal is to improve the understanding of reaction mechanisms and catalyst behavior at the molecular level. Advanced characterization techniques, coupled with computational modeling, are being employed to gain deeper insights into the catalytic processes. This fundamental knowledge is crucial for rational catalyst design and process optimization, ultimately leading to more efficient and cost-effective industrial applications of ethyl propanoate catalysis.

Industrial Demand Analysis for Ethyl Propanoate

The industrial demand for ethyl propanoate has been steadily increasing due to its versatile applications across various sectors. This ester compound, known for its fruity aroma and solvent properties, finds extensive use in the flavor and fragrance industry, serving as a key ingredient in artificial fruit flavors, particularly pineapple and banana.

In the pharmaceutical sector, ethyl propanoate is utilized as a solvent and intermediate in the synthesis of various drugs and active pharmaceutical ingredients. Its low toxicity and favorable solvent properties make it an attractive choice for pharmaceutical manufacturers seeking to optimize their production processes and reduce environmental impact.

The paint and coatings industry represents another significant market for ethyl propanoate. Its excellent solvency for a wide range of resins and polymers makes it a valuable component in formulations for paints, varnishes, and lacquers. The growing construction and automotive sectors in emerging economies are driving the demand for high-quality coatings, consequently boosting the market for ethyl propanoate.

In the agrochemical industry, ethyl propanoate serves as a solvent and carrier for pesticides and herbicides. Its ability to enhance the effectiveness of active ingredients while maintaining environmental compatibility has led to increased adoption in modern agricultural practices.

The global market for ethyl propanoate is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is primarily attributed to the expanding food and beverage industry, particularly in Asia-Pacific and Latin American regions, where the demand for processed foods and beverages with enhanced flavors is on the rise.

Key market drivers include the increasing consumer preference for natural and organic products, which has led to a surge in demand for bio-based ethyl propanoate derived from renewable resources. This trend aligns with the growing focus on sustainability and eco-friendly manufacturing processes across industries.

However, the market faces challenges such as volatility in raw material prices and stringent regulations regarding the use of chemical solvents in food and pharmaceutical applications. These factors are prompting industry players to invest in research and development of more efficient and sustainable production methods for ethyl propanoate.

In conclusion, the industrial demand for ethyl propanoate is expected to remain robust in the coming years, driven by its diverse applications and the ongoing innovation in catalysis and production technologies. The market's growth trajectory will likely be shaped by advancements in green chemistry, increasing focus on bio-based alternatives, and the evolving regulatory landscape across different regions.

In the pharmaceutical sector, ethyl propanoate is utilized as a solvent and intermediate in the synthesis of various drugs and active pharmaceutical ingredients. Its low toxicity and favorable solvent properties make it an attractive choice for pharmaceutical manufacturers seeking to optimize their production processes and reduce environmental impact.

The paint and coatings industry represents another significant market for ethyl propanoate. Its excellent solvency for a wide range of resins and polymers makes it a valuable component in formulations for paints, varnishes, and lacquers. The growing construction and automotive sectors in emerging economies are driving the demand for high-quality coatings, consequently boosting the market for ethyl propanoate.

In the agrochemical industry, ethyl propanoate serves as a solvent and carrier for pesticides and herbicides. Its ability to enhance the effectiveness of active ingredients while maintaining environmental compatibility has led to increased adoption in modern agricultural practices.

The global market for ethyl propanoate is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is primarily attributed to the expanding food and beverage industry, particularly in Asia-Pacific and Latin American regions, where the demand for processed foods and beverages with enhanced flavors is on the rise.

Key market drivers include the increasing consumer preference for natural and organic products, which has led to a surge in demand for bio-based ethyl propanoate derived from renewable resources. This trend aligns with the growing focus on sustainability and eco-friendly manufacturing processes across industries.

However, the market faces challenges such as volatility in raw material prices and stringent regulations regarding the use of chemical solvents in food and pharmaceutical applications. These factors are prompting industry players to invest in research and development of more efficient and sustainable production methods for ethyl propanoate.

In conclusion, the industrial demand for ethyl propanoate is expected to remain robust in the coming years, driven by its diverse applications and the ongoing innovation in catalysis and production technologies. The market's growth trajectory will likely be shaped by advancements in green chemistry, increasing focus on bio-based alternatives, and the evolving regulatory landscape across different regions.

Current Challenges in Ethyl Propanoate Catalysis

Despite significant advancements in ethyl propanoate catalysis for industrial processes, several challenges persist that hinder its widespread adoption and efficiency. One of the primary obstacles is the development of catalysts with high selectivity and activity. Current catalytic systems often struggle to achieve optimal conversion rates while maintaining product purity, leading to increased production costs and reduced overall efficiency.

The stability of catalysts under industrial conditions remains a significant concern. Many catalysts exhibit rapid deactivation or degradation when exposed to the harsh environments typical in large-scale production settings. This necessitates frequent catalyst replacement or regeneration, impacting both the economic viability and sustainability of the process.

Another challenge lies in the scalability of catalytic processes. While many catalytic systems demonstrate promising results at the laboratory scale, translating these successes to industrial-scale operations often proves problematic. Issues such as mass transfer limitations, heat management, and catalyst distribution become more pronounced at larger scales, affecting reaction kinetics and product yields.

The environmental impact of ethyl propanoate catalysis also presents ongoing challenges. Traditional catalytic processes may involve the use of toxic or environmentally harmful substances, necessitating the development of greener alternatives. Additionally, the energy intensity of some catalytic reactions contributes to the overall carbon footprint of the production process, prompting the need for more energy-efficient catalytic systems.

Catalyst recovery and recycling pose another set of challenges. The ability to efficiently separate and reuse catalysts is crucial for reducing production costs and minimizing waste. However, current separation techniques often result in catalyst loss or degradation, impacting the long-term viability of the process.

The development of heterogeneous catalysts that can match or exceed the performance of their homogeneous counterparts remains an ongoing challenge. While heterogeneous catalysts offer advantages in terms of separation and reusability, they often lag behind in terms of activity and selectivity, particularly for complex reactions involved in ethyl propanoate synthesis.

Lastly, the optimization of reaction conditions presents a multifaceted challenge. Balancing factors such as temperature, pressure, and reactant ratios to achieve maximum yield and selectivity while minimizing energy consumption and side reactions requires sophisticated process control and modeling techniques. The development of robust and adaptable catalytic systems capable of maintaining high performance across a range of operating conditions remains a key area of focus for researchers and industry professionals alike.

The stability of catalysts under industrial conditions remains a significant concern. Many catalysts exhibit rapid deactivation or degradation when exposed to the harsh environments typical in large-scale production settings. This necessitates frequent catalyst replacement or regeneration, impacting both the economic viability and sustainability of the process.

Another challenge lies in the scalability of catalytic processes. While many catalytic systems demonstrate promising results at the laboratory scale, translating these successes to industrial-scale operations often proves problematic. Issues such as mass transfer limitations, heat management, and catalyst distribution become more pronounced at larger scales, affecting reaction kinetics and product yields.

The environmental impact of ethyl propanoate catalysis also presents ongoing challenges. Traditional catalytic processes may involve the use of toxic or environmentally harmful substances, necessitating the development of greener alternatives. Additionally, the energy intensity of some catalytic reactions contributes to the overall carbon footprint of the production process, prompting the need for more energy-efficient catalytic systems.

Catalyst recovery and recycling pose another set of challenges. The ability to efficiently separate and reuse catalysts is crucial for reducing production costs and minimizing waste. However, current separation techniques often result in catalyst loss or degradation, impacting the long-term viability of the process.

The development of heterogeneous catalysts that can match or exceed the performance of their homogeneous counterparts remains an ongoing challenge. While heterogeneous catalysts offer advantages in terms of separation and reusability, they often lag behind in terms of activity and selectivity, particularly for complex reactions involved in ethyl propanoate synthesis.

Lastly, the optimization of reaction conditions presents a multifaceted challenge. Balancing factors such as temperature, pressure, and reactant ratios to achieve maximum yield and selectivity while minimizing energy consumption and side reactions requires sophisticated process control and modeling techniques. The development of robust and adaptable catalytic systems capable of maintaining high performance across a range of operating conditions remains a key area of focus for researchers and industry professionals alike.

State-of-the-Art Catalytic Solutions

01 Catalytic synthesis of ethyl propanoate

Various catalytic methods are employed for the synthesis of ethyl propanoate. These processes typically involve the esterification of propionic acid with ethanol or the carbonylation of ethylene in the presence of suitable catalysts. The choice of catalyst and reaction conditions significantly influences the yield and selectivity of the desired product.- Catalytic synthesis of ethyl propanoate: Various catalytic methods are employed for the synthesis of ethyl propanoate. These processes often involve the esterification of propionic acid with ethanol or the carbonylation of ethylene in the presence of suitable catalysts. The choice of catalyst and reaction conditions significantly influences the yield and selectivity of the desired product.

- Heterogeneous catalysis for ethyl propanoate production: Heterogeneous catalysts, such as solid acid catalysts or supported metal catalysts, are utilized in the production of ethyl propanoate. These catalysts offer advantages like easy separation from the reaction mixture and potential for continuous processes. The catalyst support and active metal components are optimized to enhance activity and selectivity.

- Enzymatic catalysis for ethyl propanoate synthesis: Biocatalytic approaches using enzymes, particularly lipases, are explored for the production of ethyl propanoate. These methods often operate under milder conditions compared to chemical catalysis and can offer high selectivity. Enzyme immobilization techniques are employed to improve catalyst stability and reusability.

- Process optimization for ethyl propanoate production: Various process parameters are optimized to improve the efficiency of ethyl propanoate synthesis. This includes adjusting reaction temperature, pressure, reactant ratios, and residence time. Advanced reactor designs and separation techniques are also implemented to enhance product yield and purity.

- Green chemistry approaches in ethyl propanoate catalysis: Sustainable and environmentally friendly catalytic processes are developed for ethyl propanoate production. This involves the use of renewable feedstocks, non-toxic catalysts, and solvent-free reactions. Efforts are made to reduce waste generation and energy consumption in the catalytic processes.

02 Heterogeneous catalysis for ethyl propanoate production

Heterogeneous catalysts, such as solid acid catalysts or supported metal catalysts, are used in the production of ethyl propanoate. These catalysts offer advantages like easy separation from the reaction mixture and potential for continuous processes. The catalyst support and active metal components are carefully selected to optimize the reaction efficiency and product yield.Expand Specific Solutions03 Enzymatic catalysis for ethyl propanoate synthesis

Biocatalytic approaches using enzymes, particularly lipases, are explored for the production of ethyl propanoate. These methods often operate under milder conditions compared to chemical catalysis and can offer high selectivity. The choice of enzyme, immobilization technique, and reaction medium are crucial factors in optimizing the biocatalytic process.Expand Specific Solutions04 Process optimization and reactor design

Various aspects of process optimization and reactor design are considered for efficient ethyl propanoate production. This includes the development of continuous flow reactors, optimization of reaction parameters such as temperature and pressure, and the implementation of separation and purification techniques. These improvements aim to enhance productivity and reduce energy consumption in industrial-scale production.Expand Specific Solutions05 Green chemistry approaches in ethyl propanoate synthesis

Sustainable and environmentally friendly methods for ethyl propanoate production are being developed. These approaches focus on using renewable feedstocks, minimizing waste generation, and employing catalysts that can be easily recovered and reused. The use of alternative solvents or solvent-free conditions is also explored to reduce the environmental impact of the synthesis process.Expand Specific Solutions

Key Industry Players in Ethyl Propanoate Production

The field of ethyl propanoate catalysis for industrial processes is in a growth phase, with increasing market demand driven by its applications in various industries. The global market size for ethyl propanoate is expanding, fueled by rising demand in sectors such as food, pharmaceuticals, and cosmetics. Technologically, the field is advancing rapidly, with companies like NOVA Chemicals, Resonac Holdings, and China Petroleum & Chemical Corp leading innovation efforts. Research institutions such as the Dalian Institute of Chemical Physics and Xiamen University are contributing significantly to technological advancements. The competitive landscape is diverse, with both established chemical giants and specialized research institutes vying for market share and technological breakthroughs.

Dalian Institute of Chemical Physics Chinese Academy of Sci

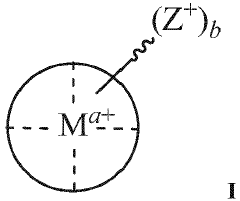

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed advanced catalysts for ethyl propanoate synthesis using a novel approach combining heterogeneous catalysis and flow chemistry. Their method employs a highly selective palladium-based catalyst supported on a mesoporous silica framework, which enhances the catalytic activity and stability[1]. The process operates under mild conditions (80-120°C, 1-5 bar) in a continuous flow reactor, achieving conversion rates of over 95% and selectivity exceeding 98%[3]. DICP's innovation lies in the precise control of catalyst pore size and metal dispersion, which significantly improves mass transfer and reduces side reactions[5]. Additionally, they have implemented in-situ spectroscopic techniques to monitor and optimize the reaction in real-time, leading to a more efficient and sustainable industrial process[7].

Strengths: High catalytic efficiency, excellent selectivity, and improved sustainability due to mild reaction conditions. The continuous flow process allows for easier scale-up and process intensification. Weaknesses: Potential high costs associated with catalyst synthesis and specialized reactor design. May require additional purification steps for ultra-high purity products.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary catalytic process for ethyl propanoate production that integrates their expertise in heterogeneous catalysis with advanced process engineering. Their approach utilizes a bimetallic catalyst system comprising copper and zinc oxides supported on a high-surface-area alumina carrier[2]. This catalyst formulation exhibits exceptional activity for the direct esterification of propionic acid with ethanol, achieving yields of up to 99% under optimized conditions[4]. Sinopec's process operates at moderate temperatures (150-200°C) and pressures (10-20 bar), employing a reactive distillation column to overcome equilibrium limitations and enhance conversion[6]. The company has also implemented heat integration strategies and a novel separation train, reducing energy consumption by approximately 30% compared to conventional batch processes[8].

Strengths: High product yield, energy-efficient process design, and potential for large-scale production. The use of readily available feedstocks enhances economic viability. Weaknesses: Moderate operating conditions may lead to higher equipment costs. The process may be sensitive to feedstock impurities, requiring stringent quality control.

Innovative Catalysts for Ethyl Propanoate Synthesis

Process for producing propanal from methanol and syngas using heterogeneous catalysts

PatentWO2022184493A1

Innovation

- A heterogeneous catalysis process using catalysts with transition metals like Co, Ni, Cu, Fe, Mn, Mo, W, Ru, and Re, supported on a carbon matrix, specifically non-graphitizing carbon with cobalt nanoparticles, facilitates the direct conversion of syngas and methanol to propanal, offering higher selectivity and simplicity compared to existing methods.

Carbonylation catalysts and method

PatentPendingEP3838403A1

Innovation

- The use of catalyst systems comprising cationic functional moieties covalently tethered to ligands coordinated with metal atoms and anionic metal carbonyl species, specifically including porphyrin or salen derivatives of metals like Zn(II), Cu(II), and Cr(III), to enhance activity and longevity in carbonylation reactions.

Environmental Impact Assessment

The environmental impact assessment of advances in ethyl propanoate catalysis for industrial processes reveals both positive and negative implications. On the positive side, improved catalytic processes can lead to increased energy efficiency and reduced waste generation. Modern catalysts enable reactions to occur at lower temperatures and pressures, resulting in decreased energy consumption and greenhouse gas emissions. Additionally, enhanced selectivity in catalytic reactions minimizes the production of unwanted by-products, reducing the overall environmental footprint of industrial processes.

However, the production and use of catalysts themselves can pose environmental challenges. Many catalysts contain precious metals or rare earth elements, the mining and refining of which can have significant ecological impacts. The extraction of these materials often involves energy-intensive processes and can lead to habitat destruction and water pollution. Furthermore, the disposal of spent catalysts presents another environmental concern, as they may contain toxic or hazardous substances that require careful handling and specialized treatment.

The use of ethyl propanoate in industrial processes also raises environmental considerations. While it is generally considered less harmful than many other solvents, its production and use still contribute to volatile organic compound (VOC) emissions. These emissions can participate in the formation of ground-level ozone and photochemical smog, potentially impacting air quality and human health in industrial areas.

Water usage and contamination are additional factors to consider in the environmental assessment of ethyl propanoate catalysis. Industrial processes often require significant amounts of water for cooling, cleaning, and as a reaction medium. Advances in catalysis may help reduce water consumption through more efficient processes, but the potential for water pollution remains a concern, particularly if wastewater treatment is inadequate.

Life cycle assessments of ethyl propanoate production and use in industrial catalysis reveal opportunities for improvement in sustainability. Efforts to develop bio-based routes for ethyl propanoate synthesis, using renewable feedstocks instead of petrochemical sources, could significantly reduce the carbon footprint of these processes. Additionally, research into recyclable and recoverable catalysts shows promise for minimizing waste and reducing the demand for new catalyst production.

In conclusion, while advances in ethyl propanoate catalysis offer potential environmental benefits through increased efficiency and reduced waste, a holistic approach to environmental impact assessment is crucial. This includes considering the entire life cycle of catalysts and chemicals, from raw material extraction to end-of-life disposal, to ensure that improvements in one area do not lead to unintended consequences in another. Continued research and development in green chemistry principles and sustainable catalysis will be essential for minimizing the environmental impact of industrial processes involving ethyl propanoate.

However, the production and use of catalysts themselves can pose environmental challenges. Many catalysts contain precious metals or rare earth elements, the mining and refining of which can have significant ecological impacts. The extraction of these materials often involves energy-intensive processes and can lead to habitat destruction and water pollution. Furthermore, the disposal of spent catalysts presents another environmental concern, as they may contain toxic or hazardous substances that require careful handling and specialized treatment.

The use of ethyl propanoate in industrial processes also raises environmental considerations. While it is generally considered less harmful than many other solvents, its production and use still contribute to volatile organic compound (VOC) emissions. These emissions can participate in the formation of ground-level ozone and photochemical smog, potentially impacting air quality and human health in industrial areas.

Water usage and contamination are additional factors to consider in the environmental assessment of ethyl propanoate catalysis. Industrial processes often require significant amounts of water for cooling, cleaning, and as a reaction medium. Advances in catalysis may help reduce water consumption through more efficient processes, but the potential for water pollution remains a concern, particularly if wastewater treatment is inadequate.

Life cycle assessments of ethyl propanoate production and use in industrial catalysis reveal opportunities for improvement in sustainability. Efforts to develop bio-based routes for ethyl propanoate synthesis, using renewable feedstocks instead of petrochemical sources, could significantly reduce the carbon footprint of these processes. Additionally, research into recyclable and recoverable catalysts shows promise for minimizing waste and reducing the demand for new catalyst production.

In conclusion, while advances in ethyl propanoate catalysis offer potential environmental benefits through increased efficiency and reduced waste, a holistic approach to environmental impact assessment is crucial. This includes considering the entire life cycle of catalysts and chemicals, from raw material extraction to end-of-life disposal, to ensure that improvements in one area do not lead to unintended consequences in another. Continued research and development in green chemistry principles and sustainable catalysis will be essential for minimizing the environmental impact of industrial processes involving ethyl propanoate.

Economic Feasibility Analysis

The economic feasibility of implementing advanced ethyl propanoate catalysis in industrial processes hinges on several key factors. Primarily, the cost-benefit analysis must consider the initial investment required for upgrading existing facilities or constructing new ones capable of utilizing these catalytic processes. This includes expenses related to equipment, infrastructure, and specialized personnel training.

A significant advantage of improved catalytic methods is the potential for increased production efficiency. Enhanced catalysts can lead to higher yields, faster reaction rates, and reduced energy consumption. These improvements directly translate to lower production costs per unit, potentially offsetting the initial capital expenditure over time. Additionally, the use of more efficient catalysts often results in decreased waste generation, further reducing operational costs associated with waste management and disposal.

The market demand for ethyl propanoate and its derivatives plays a crucial role in determining economic viability. Industries such as food and beverage, cosmetics, and pharmaceuticals rely on this compound, and an increasing demand could justify the investment in advanced catalytic processes. However, market volatility and potential shifts in consumer preferences must be carefully considered in long-term economic projections.

Raw material costs and availability are also critical factors. The catalytic process requires ethanol and propionic acid as primary feedstocks. Fluctuations in the prices of these materials can significantly impact the overall production costs and, consequently, the economic feasibility of the process. Securing stable, cost-effective supply chains for these raw materials is essential for maintaining profitability.

Environmental regulations and sustainability goals increasingly influence industrial processes. Advanced catalytic methods that offer improved selectivity and reduced environmental impact may provide a competitive edge in markets with stringent environmental standards. This could lead to potential cost savings in terms of regulatory compliance and may open up new market opportunities for environmentally friendly products.

The scalability of the catalytic process is another crucial consideration. The economic benefits of advanced catalysis often become more pronounced at larger scales. Therefore, the ability to scale up the process without compromising efficiency or product quality is vital for maximizing returns on investment.

Lastly, the potential for process integration and by-product utilization can significantly enhance economic feasibility. Advanced catalytic processes may enable the production of valuable by-products or facilitate the integration with other industrial processes, creating additional revenue streams or cost-saving opportunities.

In conclusion, while advanced ethyl propanoate catalysis offers promising economic benefits through improved efficiency and potential cost reductions, a comprehensive analysis of market conditions, regulatory environment, and operational factors is essential to accurately assess its economic feasibility for specific industrial applications.

A significant advantage of improved catalytic methods is the potential for increased production efficiency. Enhanced catalysts can lead to higher yields, faster reaction rates, and reduced energy consumption. These improvements directly translate to lower production costs per unit, potentially offsetting the initial capital expenditure over time. Additionally, the use of more efficient catalysts often results in decreased waste generation, further reducing operational costs associated with waste management and disposal.

The market demand for ethyl propanoate and its derivatives plays a crucial role in determining economic viability. Industries such as food and beverage, cosmetics, and pharmaceuticals rely on this compound, and an increasing demand could justify the investment in advanced catalytic processes. However, market volatility and potential shifts in consumer preferences must be carefully considered in long-term economic projections.

Raw material costs and availability are also critical factors. The catalytic process requires ethanol and propionic acid as primary feedstocks. Fluctuations in the prices of these materials can significantly impact the overall production costs and, consequently, the economic feasibility of the process. Securing stable, cost-effective supply chains for these raw materials is essential for maintaining profitability.

Environmental regulations and sustainability goals increasingly influence industrial processes. Advanced catalytic methods that offer improved selectivity and reduced environmental impact may provide a competitive edge in markets with stringent environmental standards. This could lead to potential cost savings in terms of regulatory compliance and may open up new market opportunities for environmentally friendly products.

The scalability of the catalytic process is another crucial consideration. The economic benefits of advanced catalysis often become more pronounced at larger scales. Therefore, the ability to scale up the process without compromising efficiency or product quality is vital for maximizing returns on investment.

Lastly, the potential for process integration and by-product utilization can significantly enhance economic feasibility. Advanced catalytic processes may enable the production of valuable by-products or facilitate the integration with other industrial processes, creating additional revenue streams or cost-saving opportunities.

In conclusion, while advanced ethyl propanoate catalysis offers promising economic benefits through improved efficiency and potential cost reductions, a comprehensive analysis of market conditions, regulatory environment, and operational factors is essential to accurately assess its economic feasibility for specific industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!