Ethyl Propanoate in Biodegradable Polymer Synthesis

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is an organic compound with the molecular formula C5H10O2. It is a colorless liquid with a fruity odor, commonly used as a flavoring agent in the food industry. In recent years, this ester has gained significant attention in the field of biodegradable polymer synthesis due to its potential as a sustainable and environmentally friendly building block.

The development of biodegradable polymers has become increasingly important in addressing the global plastic pollution crisis. Traditional petroleum-based plastics persist in the environment for hundreds of years, causing severe ecological damage. Biodegradable polymers, on the other hand, can decompose naturally under specific conditions, offering a promising solution to this pressing issue.

Ethyl propanoate has emerged as a promising candidate for biodegradable polymer synthesis due to its unique chemical properties and renewable sourcing potential. It can be derived from bio-based feedstocks, making it an attractive option for sustainable polymer production. The ester's structure allows for various polymerization reactions, enabling the creation of diverse polymer architectures with tailored properties.

The primary objective of research on ethyl propanoate in biodegradable polymer synthesis is to develop novel materials that combine excellent mechanical properties, biodegradability, and eco-friendliness. Scientists aim to explore different polymerization techniques, such as ring-opening polymerization and condensation polymerization, to create a wide range of polymer structures using ethyl propanoate as a key monomer or co-monomer.

Another crucial goal is to optimize the synthesis processes to achieve high yields and purity while minimizing environmental impact. This includes investigating catalysts that can enhance reaction efficiency and selectivity, as well as exploring green chemistry principles to reduce waste and energy consumption during production.

Researchers are also focused on understanding the degradation mechanisms of ethyl propanoate-based polymers under various environmental conditions. This knowledge is essential for designing materials with controlled biodegradation rates suitable for specific applications, ranging from packaging to biomedical devices.

Furthermore, the research aims to evaluate the overall life cycle impact of ethyl propanoate-based biodegradable polymers, from raw material sourcing to end-of-life disposal. This comprehensive assessment will help determine the true environmental benefits of these materials compared to conventional plastics and other biodegradable alternatives.

As the field progresses, there is a growing emphasis on scaling up production processes and improving the economic viability of ethyl propanoate-based biodegradable polymers. This involves optimizing synthesis routes, exploring cost-effective feedstock options, and developing efficient manufacturing techniques that can compete with traditional plastic production methods.

The development of biodegradable polymers has become increasingly important in addressing the global plastic pollution crisis. Traditional petroleum-based plastics persist in the environment for hundreds of years, causing severe ecological damage. Biodegradable polymers, on the other hand, can decompose naturally under specific conditions, offering a promising solution to this pressing issue.

Ethyl propanoate has emerged as a promising candidate for biodegradable polymer synthesis due to its unique chemical properties and renewable sourcing potential. It can be derived from bio-based feedstocks, making it an attractive option for sustainable polymer production. The ester's structure allows for various polymerization reactions, enabling the creation of diverse polymer architectures with tailored properties.

The primary objective of research on ethyl propanoate in biodegradable polymer synthesis is to develop novel materials that combine excellent mechanical properties, biodegradability, and eco-friendliness. Scientists aim to explore different polymerization techniques, such as ring-opening polymerization and condensation polymerization, to create a wide range of polymer structures using ethyl propanoate as a key monomer or co-monomer.

Another crucial goal is to optimize the synthesis processes to achieve high yields and purity while minimizing environmental impact. This includes investigating catalysts that can enhance reaction efficiency and selectivity, as well as exploring green chemistry principles to reduce waste and energy consumption during production.

Researchers are also focused on understanding the degradation mechanisms of ethyl propanoate-based polymers under various environmental conditions. This knowledge is essential for designing materials with controlled biodegradation rates suitable for specific applications, ranging from packaging to biomedical devices.

Furthermore, the research aims to evaluate the overall life cycle impact of ethyl propanoate-based biodegradable polymers, from raw material sourcing to end-of-life disposal. This comprehensive assessment will help determine the true environmental benefits of these materials compared to conventional plastics and other biodegradable alternatives.

As the field progresses, there is a growing emphasis on scaling up production processes and improving the economic viability of ethyl propanoate-based biodegradable polymers. This involves optimizing synthesis routes, exploring cost-effective feedstock options, and developing efficient manufacturing techniques that can compete with traditional plastic production methods.

Market Analysis for Biodegradable Polymers

The market for biodegradable polymers has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The global biodegradable polymer market was valued at approximately $6.5 billion in 2021 and is projected to reach $25.4 billion by 2030, growing at a CAGR of 14.5% during the forecast period.

The packaging industry remains the largest consumer of biodegradable polymers, accounting for over 60% of the market share. This sector's demand is fueled by the shift towards sustainable packaging solutions in response to consumer preferences and government regulations. The food and beverage industry, in particular, has been a major adopter of biodegradable packaging materials.

Agriculture is another key application area for biodegradable polymers, with growing demand for biodegradable mulch films and controlled-release fertilizers. The medical sector also shows promising growth potential, particularly in the development of biodegradable implants and drug delivery systems.

Regionally, Europe leads the biodegradable polymer market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and India.

Key market players include NatureWorks LLC, BASF SE, Novamont S.p.A., and Total Corbion PLA. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of biodegradable polymers. Collaborations between polymer manufacturers and end-user industries are becoming increasingly common to develop tailored solutions for specific applications.

The integration of ethyl propanoate in biodegradable polymer synthesis represents an emerging trend in the market. This compound has shown potential in improving the properties of certain biodegradable polymers, particularly in terms of flexibility and degradation rates. As research in this area progresses, it is expected to open up new opportunities for product development and market expansion.

However, challenges remain in the widespread adoption of biodegradable polymers. The higher cost compared to conventional plastics continues to be a significant barrier, especially in price-sensitive markets. Additionally, concerns about the performance and durability of biodegradable polymers in certain applications need to be addressed through ongoing research and development efforts.

The packaging industry remains the largest consumer of biodegradable polymers, accounting for over 60% of the market share. This sector's demand is fueled by the shift towards sustainable packaging solutions in response to consumer preferences and government regulations. The food and beverage industry, in particular, has been a major adopter of biodegradable packaging materials.

Agriculture is another key application area for biodegradable polymers, with growing demand for biodegradable mulch films and controlled-release fertilizers. The medical sector also shows promising growth potential, particularly in the development of biodegradable implants and drug delivery systems.

Regionally, Europe leads the biodegradable polymer market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and India.

Key market players include NatureWorks LLC, BASF SE, Novamont S.p.A., and Total Corbion PLA. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of biodegradable polymers. Collaborations between polymer manufacturers and end-user industries are becoming increasingly common to develop tailored solutions for specific applications.

The integration of ethyl propanoate in biodegradable polymer synthesis represents an emerging trend in the market. This compound has shown potential in improving the properties of certain biodegradable polymers, particularly in terms of flexibility and degradation rates. As research in this area progresses, it is expected to open up new opportunities for product development and market expansion.

However, challenges remain in the widespread adoption of biodegradable polymers. The higher cost compared to conventional plastics continues to be a significant barrier, especially in price-sensitive markets. Additionally, concerns about the performance and durability of biodegradable polymers in certain applications need to be addressed through ongoing research and development efforts.

Current Challenges in Biodegradable Polymer Synthesis

The synthesis of biodegradable polymers, particularly those involving ethyl propanoate, faces several significant challenges in the current research landscape. One of the primary obstacles is achieving precise control over the polymer's molecular weight and distribution. This control is crucial for tailoring the material properties to specific applications, yet it remains difficult due to the complex nature of polymerization reactions involving ethyl propanoate and other monomers.

Another major challenge lies in the optimization of reaction conditions. The synthesis of biodegradable polymers often requires careful balancing of temperature, pressure, and catalyst concentrations. In the case of ethyl propanoate-based polymers, finding the ideal conditions that promote high conversion rates while maintaining the desired polymer structure can be particularly demanding. Researchers must navigate a delicate equilibrium to avoid side reactions or premature chain termination.

The selection and development of suitable catalysts present another hurdle. Catalysts play a vital role in the polymerization process, influencing reaction kinetics and polymer properties. For ethyl propanoate polymerization, identifying catalysts that are both highly efficient and environmentally benign remains an ongoing challenge. The quest for green catalysts that can operate under mild conditions without compromising polymer quality is a key focus area.

Scalability and cost-effectiveness of the synthesis process pose significant challenges for industrial applications. While laboratory-scale production may yield promising results, translating these processes to large-scale manufacturing often encounters unforeseen difficulties. Issues such as heat transfer, mixing efficiency, and reaction time management become more pronounced at industrial scales, particularly when dealing with ethyl propanoate-based systems.

The purification and characterization of the resulting polymers also present technical challenges. Removing residual monomers, catalysts, and other impurities from the final product is crucial for ensuring the polymer's quality and biodegradability. However, developing efficient purification methods that do not compromise the polymer's properties or increase production costs significantly is an ongoing area of research.

Lastly, ensuring consistent biodegradability across different environmental conditions remains a complex challenge. The degradation rate and pathways of ethyl propanoate-based polymers can vary significantly depending on factors such as temperature, humidity, and microbial activity. Developing polymers that maintain their structural integrity during use but degrade predictably and safely in various environments is a delicate balancing act that continues to challenge researchers in the field.

Another major challenge lies in the optimization of reaction conditions. The synthesis of biodegradable polymers often requires careful balancing of temperature, pressure, and catalyst concentrations. In the case of ethyl propanoate-based polymers, finding the ideal conditions that promote high conversion rates while maintaining the desired polymer structure can be particularly demanding. Researchers must navigate a delicate equilibrium to avoid side reactions or premature chain termination.

The selection and development of suitable catalysts present another hurdle. Catalysts play a vital role in the polymerization process, influencing reaction kinetics and polymer properties. For ethyl propanoate polymerization, identifying catalysts that are both highly efficient and environmentally benign remains an ongoing challenge. The quest for green catalysts that can operate under mild conditions without compromising polymer quality is a key focus area.

Scalability and cost-effectiveness of the synthesis process pose significant challenges for industrial applications. While laboratory-scale production may yield promising results, translating these processes to large-scale manufacturing often encounters unforeseen difficulties. Issues such as heat transfer, mixing efficiency, and reaction time management become more pronounced at industrial scales, particularly when dealing with ethyl propanoate-based systems.

The purification and characterization of the resulting polymers also present technical challenges. Removing residual monomers, catalysts, and other impurities from the final product is crucial for ensuring the polymer's quality and biodegradability. However, developing efficient purification methods that do not compromise the polymer's properties or increase production costs significantly is an ongoing area of research.

Lastly, ensuring consistent biodegradability across different environmental conditions remains a complex challenge. The degradation rate and pathways of ethyl propanoate-based polymers can vary significantly depending on factors such as temperature, humidity, and microbial activity. Developing polymers that maintain their structural integrity during use but degrade predictably and safely in various environments is a delicate balancing act that continues to challenge researchers in the field.

Existing Ethyl Propanoate Synthesis Methods

01 Synthesis of ethyl propanoate

Ethyl propanoate can be synthesized through various methods, including esterification of propionic acid with ethanol, or by the reaction of ethyl alcohol with propionyl chloride. These processes often involve catalysts and specific reaction conditions to optimize yield and purity.- Synthesis of ethyl propanoate: Ethyl propanoate can be synthesized through various methods, including the esterification of propionic acid with ethanol. This process typically involves catalysts and specific reaction conditions to optimize yield and purity. The synthesis may also be carried out using alternative starting materials or through enzymatic processes.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is commonly employed as a flavoring agent in food products and as a fragrance component in perfumes and cosmetics. The compound's low toxicity and pleasant aroma make it a versatile ingredient in various consumer products.

- Use as a solvent and intermediate: Ethyl propanoate serves as an effective solvent for various organic compounds and is used in industrial applications. It also acts as an intermediate in the synthesis of other chemicals, pharmaceuticals, and agrochemicals. Its properties make it suitable for use in paints, coatings, and cleaning formulations.

- Production methods and process improvements: Research focuses on developing more efficient and sustainable methods for producing ethyl propanoate. This includes optimizing reaction conditions, exploring new catalysts, and implementing continuous flow processes. Efforts are also directed towards improving yield, reducing waste, and minimizing energy consumption in the production process.

- Environmental and safety considerations: As ethyl propanoate is used in various consumer products and industrial applications, there is ongoing research into its environmental impact and safety profile. Studies focus on biodegradability, ecotoxicity, and potential health effects. Efforts are made to develop safer handling procedures and to assess the compound's long-term environmental fate.

02 Applications in flavor and fragrance industry

Ethyl propanoate is widely used in the flavor and fragrance industry due to its fruity, rum-like odor. It is often incorporated into artificial fruit flavors, particularly for pineapple and strawberry, and is used in perfumery to create various scent profiles.Expand Specific Solutions03 Use as a solvent and intermediate

Ethyl propanoate serves as an important solvent in various industrial applications, including paints, inks, and coatings. It is also used as an intermediate in the production of pharmaceuticals, agrochemicals, and other organic compounds.Expand Specific Solutions04 Production methods and process optimization

Various methods for the production of ethyl propanoate have been developed, focusing on improving yield, reducing byproducts, and enhancing process efficiency. These include continuous flow reactors, enzymatic processes, and the use of novel catalysts.Expand Specific Solutions05 Environmental and safety considerations

Research has been conducted on developing more environmentally friendly production methods for ethyl propanoate, as well as assessing its safety profile for various applications. This includes studies on biodegradability, toxicity, and potential alternatives for certain uses.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The research on Ethyl Propanoate in Biodegradable Polymer Synthesis is in an emerging stage, with growing market potential due to increasing environmental concerns. The global biodegradable polymers market is expanding rapidly, driven by sustainability initiatives and regulatory pressures. Key players like Novozymes, LG Chem, and DuPont are at the forefront of this technology, leveraging their expertise in bioinnovation and materials science. The field is characterized by a mix of established chemical companies and specialized biotech firms, indicating a competitive landscape with diverse approaches to biodegradable polymer development. While the technology is advancing, it is still evolving, with ongoing research focused on improving performance, cost-effectiveness, and scalability of biodegradable polymer production using ethyl propanoate.

Novozymes A/S

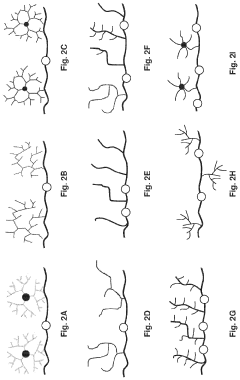

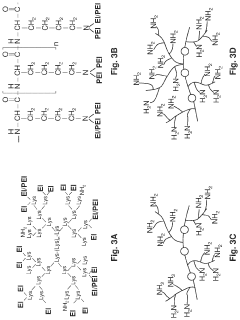

Technical Solution: Novozymes A/S has developed an innovative enzymatic approach for the synthesis of biodegradable polymers incorporating ethyl propanoate. Their process utilizes specialized lipases to catalyze the polymerization of ethyl propanoate with other monomers, resulting in polyesters with enhanced biodegradability[1]. The company has optimized enzyme formulations to achieve high conversion rates and control over polymer molecular weight distribution. Their technology enables the production of polymers with tailored properties, such as adjustable degradation rates and mechanical characteristics, suitable for various applications including packaging and biomedical devices[2].

Strengths: Eco-friendly enzymatic process, precise control over polymer properties, and versatility in applications. Weaknesses: Potentially higher production costs compared to traditional chemical synthesis methods and limited scalability for large-volume production.

LG Chem Ltd.

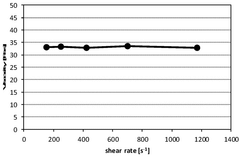

Technical Solution: LG Chem Ltd. has developed a proprietary technology for incorporating ethyl propanoate into biodegradable polymer synthesis, focusing on improving the thermal and mechanical properties of the resulting materials. Their approach involves the copolymerization of ethyl propanoate with other bio-based monomers, creating a range of biodegradable plastics with enhanced flexibility and durability[3]. The company has also implemented a reactive extrusion process that allows for efficient large-scale production of these polymers. LG Chem's biodegradable polymers containing ethyl propanoate have shown promising results in applications such as food packaging and agricultural films, with controlled degradation rates in various environmental conditions[4].

Strengths: Improved material properties, scalable production process, and diverse application potential. Weaknesses: Potential challenges in achieving cost-competitiveness with conventional plastics and ensuring consistent biodegradation across different environments.

Innovations in Ethyl Propanoate Applications

Biodegradable Polymer and Use Thereof

PatentInactiveUS20200392289A1

Innovation

- A biodegradable polymer comprising two or more cationic components separated by biodegradable bonds, covalently attached to biomolecules, which can form covalent or non-covalent linkages with bioactive agents for targeted delivery and treatment.

Biodegradable polymer blend and method for its preparation

PatentActiveNZ761901B

Innovation

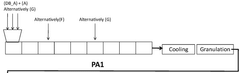

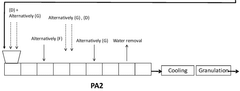

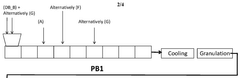

- The biodegradable polymer blend incorporates a unique combination of lactic acid-based polymers (A), thermoplastic starch (B), and polyhydroxyalkanoates (D) in a specific blending sequence.

- The method involves a strategic blending process where components A and B are mixed prior to the addition of component D, potentially allowing for better compatibility and dispersion.

- The blend allows for the optional addition of plasticizers (F) for PLAs and/or PHAs at various stages of the blending process, providing flexibility in tailoring the final properties.

Environmental Impact Assessment

The environmental impact assessment of ethyl propanoate in biodegradable polymer synthesis reveals both positive and negative aspects that warrant careful consideration. On the positive side, the use of ethyl propanoate as a precursor in biodegradable polymer production aligns with sustainable chemistry principles, potentially reducing reliance on petroleum-based materials and mitigating long-term plastic pollution.

Biodegradable polymers synthesized using ethyl propanoate can significantly decrease the accumulation of plastic waste in landfills and oceans, as these materials break down more readily under natural conditions. This characteristic contributes to reduced environmental persistence and lower risks to wildlife and ecosystems compared to conventional plastics.

However, the production process of ethyl propanoate itself requires careful scrutiny. While it can be derived from renewable resources, such as biomass fermentation, industrial-scale production may still involve energy-intensive processes and potential chemical waste. The environmental footprint of ethyl propanoate synthesis must be thoroughly evaluated to ensure that the benefits of biodegradable polymers are not offset by the impacts of their precursor production.

Water consumption and potential contamination during the manufacturing process are additional concerns that need to be addressed. Proper wastewater treatment and recycling systems should be implemented to minimize the environmental impact on local water resources.

The biodegradation of polymers synthesized with ethyl propanoate may release byproducts into the environment. While these are generally expected to be less harmful than those from conventional plastics, comprehensive studies on their long-term effects on soil and aquatic ecosystems are necessary to confirm their environmental safety.

Life cycle assessments (LCAs) comparing ethyl propanoate-based biodegradable polymers with traditional plastics and other biodegradable alternatives are crucial. These assessments should consider factors such as raw material sourcing, energy consumption, greenhouse gas emissions, and end-of-life scenarios to provide a holistic view of the environmental impact.

The potential for these biodegradable polymers to reduce microplastic pollution is a significant environmental benefit. However, public education and proper waste management infrastructure are essential to ensure that these materials are disposed of correctly and can biodegrade under appropriate conditions.

In conclusion, while ethyl propanoate-based biodegradable polymers show promise in reducing environmental pollution, a comprehensive and ongoing assessment of their full life cycle impact is necessary to maximize their benefits and mitigate any potential negative consequences.

Biodegradable polymers synthesized using ethyl propanoate can significantly decrease the accumulation of plastic waste in landfills and oceans, as these materials break down more readily under natural conditions. This characteristic contributes to reduced environmental persistence and lower risks to wildlife and ecosystems compared to conventional plastics.

However, the production process of ethyl propanoate itself requires careful scrutiny. While it can be derived from renewable resources, such as biomass fermentation, industrial-scale production may still involve energy-intensive processes and potential chemical waste. The environmental footprint of ethyl propanoate synthesis must be thoroughly evaluated to ensure that the benefits of biodegradable polymers are not offset by the impacts of their precursor production.

Water consumption and potential contamination during the manufacturing process are additional concerns that need to be addressed. Proper wastewater treatment and recycling systems should be implemented to minimize the environmental impact on local water resources.

The biodegradation of polymers synthesized with ethyl propanoate may release byproducts into the environment. While these are generally expected to be less harmful than those from conventional plastics, comprehensive studies on their long-term effects on soil and aquatic ecosystems are necessary to confirm their environmental safety.

Life cycle assessments (LCAs) comparing ethyl propanoate-based biodegradable polymers with traditional plastics and other biodegradable alternatives are crucial. These assessments should consider factors such as raw material sourcing, energy consumption, greenhouse gas emissions, and end-of-life scenarios to provide a holistic view of the environmental impact.

The potential for these biodegradable polymers to reduce microplastic pollution is a significant environmental benefit. However, public education and proper waste management infrastructure are essential to ensure that these materials are disposed of correctly and can biodegrade under appropriate conditions.

In conclusion, while ethyl propanoate-based biodegradable polymers show promise in reducing environmental pollution, a comprehensive and ongoing assessment of their full life cycle impact is necessary to maximize their benefits and mitigate any potential negative consequences.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in the development and adoption of sustainable polymer technologies, including those involving ethyl propanoate in biodegradable polymer synthesis. This framework encompasses a complex web of international, national, and regional regulations that govern the production, use, and disposal of biodegradable materials.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradability and compostability. ISO 17088, for instance, specifies requirements for compostable plastics, while ASTM D6400 provides a standard specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities.

In the European Union, the regulatory landscape is shaped by directives such as the EU Packaging and Packaging Waste Directive (94/62/EC) and the Single-Use Plastics Directive (EU) 2019/904. These regulations aim to reduce the environmental impact of plastics and promote the use of biodegradable alternatives. The European Committee for Standardization (CEN) has also developed standards like EN 13432 for packaging recoverable through composting and biodegradation.

In the United States, the regulatory framework is more fragmented, with oversight shared between federal agencies like the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). The FDA regulates biodegradable materials used in food packaging, while the EPA oversees waste management and environmental impact aspects. Additionally, several states have enacted their own regulations on biodegradable plastics, such as California's strict labeling requirements for compostable products.

The regulatory landscape also includes certification schemes and eco-labels that help consumers identify genuinely biodegradable products. Examples include the "OK compost" label in Europe and the Biodegradable Products Institute (BPI) certification in North America. These certifications ensure that products meet specific standards for biodegradability and environmental safety.

For researchers and manufacturers working on ethyl propanoate in biodegradable polymer synthesis, navigating this regulatory framework is essential. Compliance with relevant standards and regulations is crucial for market acceptance and environmental credibility. Moreover, understanding the regulatory landscape can guide research and development efforts, ensuring that new biodegradable polymers meet the necessary criteria for certification and market approval.

As the field of biodegradable materials continues to evolve, regulatory frameworks are likely to adapt and expand. Ongoing discussions about the need for more harmonized global standards and the potential for stricter regulations on biodegradable claims highlight the dynamic nature of this regulatory landscape. Researchers and industry stakeholders must stay informed about these developments to ensure continued compliance and to contribute to the advancement of sustainable polymer technologies.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for biodegradability and compostability. ISO 17088, for instance, specifies requirements for compostable plastics, while ASTM D6400 provides a standard specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities.

In the European Union, the regulatory landscape is shaped by directives such as the EU Packaging and Packaging Waste Directive (94/62/EC) and the Single-Use Plastics Directive (EU) 2019/904. These regulations aim to reduce the environmental impact of plastics and promote the use of biodegradable alternatives. The European Committee for Standardization (CEN) has also developed standards like EN 13432 for packaging recoverable through composting and biodegradation.

In the United States, the regulatory framework is more fragmented, with oversight shared between federal agencies like the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). The FDA regulates biodegradable materials used in food packaging, while the EPA oversees waste management and environmental impact aspects. Additionally, several states have enacted their own regulations on biodegradable plastics, such as California's strict labeling requirements for compostable products.

The regulatory landscape also includes certification schemes and eco-labels that help consumers identify genuinely biodegradable products. Examples include the "OK compost" label in Europe and the Biodegradable Products Institute (BPI) certification in North America. These certifications ensure that products meet specific standards for biodegradability and environmental safety.

For researchers and manufacturers working on ethyl propanoate in biodegradable polymer synthesis, navigating this regulatory framework is essential. Compliance with relevant standards and regulations is crucial for market acceptance and environmental credibility. Moreover, understanding the regulatory landscape can guide research and development efforts, ensuring that new biodegradable polymers meet the necessary criteria for certification and market approval.

As the field of biodegradable materials continues to evolve, regulatory frameworks are likely to adapt and expand. Ongoing discussions about the need for more harmonized global standards and the potential for stricter regulations on biodegradable claims highlight the dynamic nature of this regulatory landscape. Researchers and industry stakeholders must stay informed about these developments to ensure continued compliance and to contribute to the advancement of sustainable polymer technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!