Ethyl Propanoate in Renewable Energy Applications

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is an organic compound with the molecular formula C5H10O2. It is a colorless liquid with a fruity odor, commonly used as a flavoring agent in the food industry. In recent years, there has been growing interest in exploring the potential applications of ethyl propanoate in the field of renewable energy, driven by the global push towards sustainable and environmentally friendly energy solutions.

The development of ethyl propanoate as a renewable energy source can be traced back to the early 2000s when researchers began investigating alternative fuel sources to reduce dependence on fossil fuels. The compound's properties, including its high energy density and low toxicity, make it an attractive candidate for various energy applications. As the world faces increasing challenges related to climate change and energy security, the exploration of novel renewable energy sources has become a priority for many nations and industries.

The primary objective of research on ethyl propanoate in renewable energy applications is to develop efficient and sustainable methods for its production and utilization. This includes investigating its potential as a biofuel, exploring its use in energy storage systems, and evaluating its performance in various energy conversion processes. Researchers aim to optimize production techniques, enhance energy efficiency, and reduce environmental impacts associated with its use.

One of the key areas of focus is the development of bio-based production methods for ethyl propanoate. This involves utilizing renewable feedstocks, such as agricultural waste or algae, to produce the compound through fermentation or other biological processes. By doing so, researchers hope to create a closed-loop system that minimizes carbon emissions and reduces reliance on petrochemical-based production methods.

Another important aspect of the research is the assessment of ethyl propanoate's performance in different energy applications. This includes studying its combustion characteristics, evaluating its potential as a fuel additive, and exploring its use in fuel cells or other energy conversion devices. The goal is to identify the most promising applications and develop the necessary technologies to support its widespread adoption in the renewable energy sector.

As research in this field progresses, there is a growing need to address challenges related to scalability, cost-effectiveness, and integration with existing energy infrastructure. Researchers are working to overcome these hurdles by developing innovative production techniques, improving purification methods, and optimizing energy conversion processes. The ultimate aim is to establish ethyl propanoate as a viable and sustainable component of the global renewable energy landscape, contributing to the transition towards a cleaner and more sustainable energy future.

The development of ethyl propanoate as a renewable energy source can be traced back to the early 2000s when researchers began investigating alternative fuel sources to reduce dependence on fossil fuels. The compound's properties, including its high energy density and low toxicity, make it an attractive candidate for various energy applications. As the world faces increasing challenges related to climate change and energy security, the exploration of novel renewable energy sources has become a priority for many nations and industries.

The primary objective of research on ethyl propanoate in renewable energy applications is to develop efficient and sustainable methods for its production and utilization. This includes investigating its potential as a biofuel, exploring its use in energy storage systems, and evaluating its performance in various energy conversion processes. Researchers aim to optimize production techniques, enhance energy efficiency, and reduce environmental impacts associated with its use.

One of the key areas of focus is the development of bio-based production methods for ethyl propanoate. This involves utilizing renewable feedstocks, such as agricultural waste or algae, to produce the compound through fermentation or other biological processes. By doing so, researchers hope to create a closed-loop system that minimizes carbon emissions and reduces reliance on petrochemical-based production methods.

Another important aspect of the research is the assessment of ethyl propanoate's performance in different energy applications. This includes studying its combustion characteristics, evaluating its potential as a fuel additive, and exploring its use in fuel cells or other energy conversion devices. The goal is to identify the most promising applications and develop the necessary technologies to support its widespread adoption in the renewable energy sector.

As research in this field progresses, there is a growing need to address challenges related to scalability, cost-effectiveness, and integration with existing energy infrastructure. Researchers are working to overcome these hurdles by developing innovative production techniques, improving purification methods, and optimizing energy conversion processes. The ultimate aim is to establish ethyl propanoate as a viable and sustainable component of the global renewable energy landscape, contributing to the transition towards a cleaner and more sustainable energy future.

Renewable Energy Market Analysis

The renewable energy market has experienced significant growth in recent years, driven by increasing environmental concerns, government policies, and technological advancements. As of 2021, renewable energy sources accounted for approximately 29% of global electricity generation, with projections indicating continued expansion in the coming decades.

The market for renewable energy is diverse, encompassing various technologies such as solar, wind, hydropower, geothermal, and biomass. Solar and wind energy have seen particularly rapid growth, with global installed capacity increasing by over 20% annually in recent years. This growth has been supported by declining costs, with the levelized cost of electricity (LCOE) for utility-scale solar photovoltaic systems falling by more than 80% since 2010.

In the context of ethyl propanoate research for renewable energy applications, the biofuels sector presents a promising area of focus. The global biofuels market was valued at $141 billion in 2020 and is expected to reach $201 billion by 2026, growing at a CAGR of 6.1% during the forecast period. Ethyl propanoate, as a potential biofuel additive or precursor, could play a role in this expanding market.

The demand for renewable energy is driven by several factors, including climate change mitigation efforts, energy security concerns, and the need for sustainable economic development. Many countries have set ambitious targets for renewable energy adoption, with the European Union aiming for 32% of its energy consumption to come from renewable sources by 2030, and China targeting 35% of electricity consumption from renewables by the same year.

The renewable energy market is characterized by regional variations in adoption and growth rates. Europe and North America have been early adopters, with significant installed capacity and mature markets. However, the Asia-Pacific region, led by China and India, is now the fastest-growing market for renewable energy, driven by rapid industrialization, urbanization, and government support.

Challenges in the renewable energy market include intermittency issues, grid integration, and energy storage. These challenges present opportunities for innovation in areas such as smart grids, advanced energy storage technologies, and hybrid systems. The potential application of ethyl propanoate in renewable energy could address some of these challenges, particularly in the realm of energy storage or as a component in advanced biofuels.

Investment in renewable energy has been robust, with global investment reaching $303.5 billion in 2020, despite the economic impacts of the COVID-19 pandemic. This trend is expected to continue, supported by falling technology costs, supportive policies, and increasing corporate commitments to renewable energy procurement.

The market for renewable energy is diverse, encompassing various technologies such as solar, wind, hydropower, geothermal, and biomass. Solar and wind energy have seen particularly rapid growth, with global installed capacity increasing by over 20% annually in recent years. This growth has been supported by declining costs, with the levelized cost of electricity (LCOE) for utility-scale solar photovoltaic systems falling by more than 80% since 2010.

In the context of ethyl propanoate research for renewable energy applications, the biofuels sector presents a promising area of focus. The global biofuels market was valued at $141 billion in 2020 and is expected to reach $201 billion by 2026, growing at a CAGR of 6.1% during the forecast period. Ethyl propanoate, as a potential biofuel additive or precursor, could play a role in this expanding market.

The demand for renewable energy is driven by several factors, including climate change mitigation efforts, energy security concerns, and the need for sustainable economic development. Many countries have set ambitious targets for renewable energy adoption, with the European Union aiming for 32% of its energy consumption to come from renewable sources by 2030, and China targeting 35% of electricity consumption from renewables by the same year.

The renewable energy market is characterized by regional variations in adoption and growth rates. Europe and North America have been early adopters, with significant installed capacity and mature markets. However, the Asia-Pacific region, led by China and India, is now the fastest-growing market for renewable energy, driven by rapid industrialization, urbanization, and government support.

Challenges in the renewable energy market include intermittency issues, grid integration, and energy storage. These challenges present opportunities for innovation in areas such as smart grids, advanced energy storage technologies, and hybrid systems. The potential application of ethyl propanoate in renewable energy could address some of these challenges, particularly in the realm of energy storage or as a component in advanced biofuels.

Investment in renewable energy has been robust, with global investment reaching $303.5 billion in 2020, despite the economic impacts of the COVID-19 pandemic. This trend is expected to continue, supported by falling technology costs, supportive policies, and increasing corporate commitments to renewable energy procurement.

Technical Challenges in Ethyl Propanoate Utilization

The utilization of ethyl propanoate in renewable energy applications faces several significant technical challenges that need to be addressed for its widespread adoption. One of the primary obstacles is the efficient and cost-effective production of ethyl propanoate from renewable sources. While traditional methods rely on petrochemical feedstocks, developing sustainable production processes using bio-based materials remains a complex task.

The catalytic conversion of renewable feedstocks to ethyl propanoate presents difficulties in terms of selectivity and yield. Researchers are grappling with the optimization of reaction conditions and the development of highly selective catalysts that can minimize unwanted side reactions and maximize the production of ethyl propanoate. The stability and longevity of these catalysts under industrial conditions also pose significant challenges.

Another technical hurdle lies in the purification and separation of ethyl propanoate from reaction mixtures. The presence of water and other byproducts in bio-based production processes necessitates the development of advanced separation techniques that are both energy-efficient and economically viable. Conventional distillation methods may not be suitable due to the formation of azeotropes, requiring innovative approaches such as extractive distillation or membrane-based separations.

The storage and transportation of ethyl propanoate for renewable energy applications present additional challenges. Its relatively low flash point and potential for degradation under certain conditions require careful handling and storage protocols. Developing stable formulations and appropriate containment systems that maintain the integrity of ethyl propanoate during long-term storage and transportation is crucial for its practical implementation in energy systems.

Furthermore, the integration of ethyl propanoate into existing renewable energy infrastructure poses technical difficulties. Compatibility issues with current engine designs, fuel systems, and energy storage technologies need to be addressed. This includes modifying engine components to withstand potential corrosive effects and optimizing combustion characteristics to maximize energy efficiency while minimizing emissions.

Lastly, the scalability of ethyl propanoate production and utilization presents a significant challenge. Bridging the gap between laboratory-scale synthesis and industrial-scale production requires overcoming engineering hurdles related to process design, heat management, and overall system efficiency. Developing robust and scalable technologies that can compete economically with established fossil fuel-based systems is essential for the widespread adoption of ethyl propanoate in renewable energy applications.

The catalytic conversion of renewable feedstocks to ethyl propanoate presents difficulties in terms of selectivity and yield. Researchers are grappling with the optimization of reaction conditions and the development of highly selective catalysts that can minimize unwanted side reactions and maximize the production of ethyl propanoate. The stability and longevity of these catalysts under industrial conditions also pose significant challenges.

Another technical hurdle lies in the purification and separation of ethyl propanoate from reaction mixtures. The presence of water and other byproducts in bio-based production processes necessitates the development of advanced separation techniques that are both energy-efficient and economically viable. Conventional distillation methods may not be suitable due to the formation of azeotropes, requiring innovative approaches such as extractive distillation or membrane-based separations.

The storage and transportation of ethyl propanoate for renewable energy applications present additional challenges. Its relatively low flash point and potential for degradation under certain conditions require careful handling and storage protocols. Developing stable formulations and appropriate containment systems that maintain the integrity of ethyl propanoate during long-term storage and transportation is crucial for its practical implementation in energy systems.

Furthermore, the integration of ethyl propanoate into existing renewable energy infrastructure poses technical difficulties. Compatibility issues with current engine designs, fuel systems, and energy storage technologies need to be addressed. This includes modifying engine components to withstand potential corrosive effects and optimizing combustion characteristics to maximize energy efficiency while minimizing emissions.

Lastly, the scalability of ethyl propanoate production and utilization presents a significant challenge. Bridging the gap between laboratory-scale synthesis and industrial-scale production requires overcoming engineering hurdles related to process design, heat management, and overall system efficiency. Developing robust and scalable technologies that can compete economically with established fossil fuel-based systems is essential for the widespread adoption of ethyl propanoate in renewable energy applications.

Current Ethyl Propanoate Applications

01 Synthesis and production methods of ethyl propanoate

Various methods for synthesizing and producing ethyl propanoate are described, including esterification reactions, catalytic processes, and continuous production techniques. These methods aim to improve yield, efficiency, and purity of the final product.- Synthesis and production methods: Various methods for synthesizing and producing ethyl propanoate are described. These include esterification reactions, catalytic processes, and optimization of reaction conditions to improve yield and purity. The methods aim to develop efficient and cost-effective production techniques for this important ester compound.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity aroma. It is incorporated into various products such as perfumes, cosmetics, and food additives to impart a pleasant scent or taste. The compound's stability and compatibility with other ingredients make it a versatile choice for these applications.

- Use as a solvent and intermediate: Ethyl propanoate serves as an important solvent in various industrial processes and as an intermediate in the synthesis of other chemicals. Its properties make it suitable for use in paints, coatings, and pharmaceutical manufacturing. The compound's role in organic synthesis and its potential as a green solvent are explored in several patents.

- Purification and quality control methods: Various techniques for purifying ethyl propanoate and ensuring its quality are described. These include distillation processes, chromatographic methods, and analytical techniques for determining purity and detecting impurities. The development of these methods aims to improve the overall quality and consistency of the compound for industrial use.

- Environmental and safety considerations: Patents address environmental and safety aspects related to the production and use of ethyl propanoate. This includes the development of eco-friendly production processes, waste reduction strategies, and safety measures for handling and storage. The focus is on minimizing environmental impact and ensuring worker safety in industrial settings.

02 Applications of ethyl propanoate in fragrances and flavors

Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is incorporated into various products such as perfumes, air fresheners, and food flavorings to impart a pleasant aroma and taste.Expand Specific Solutions03 Use of ethyl propanoate as a solvent or intermediate

Ethyl propanoate serves as a versatile solvent and intermediate in various chemical processes. It is used in the production of pharmaceuticals, polymers, and other industrial chemicals, offering advantages such as low toxicity and good solvency properties.Expand Specific Solutions04 Purification and separation techniques for ethyl propanoate

Various methods for purifying and separating ethyl propanoate from reaction mixtures or other compounds are described. These techniques include distillation, extraction, and chromatography, aimed at obtaining high-purity ethyl propanoate for specific applications.Expand Specific Solutions05 Environmental and safety considerations in ethyl propanoate production

Innovations in the production and handling of ethyl propanoate focus on improving environmental sustainability and safety. This includes developing green synthesis methods, reducing waste, and implementing safety measures to minimize risks associated with its production and use.Expand Specific Solutions

Key Players in Renewable Energy Sector

The research on Ethyl Propanoate in renewable energy applications is in its early stages, with the market still emerging and showing potential for growth. The technology is at a developing stage, with various players exploring its applications. Companies like Novozymes A/S, Eni SpA, and Shell Internationale Research Maatschappij BV are leading the charge in this field, leveraging their expertise in bioinnovation and energy solutions. Academic institutions such as Tianjin University and the University of Campinas are contributing to the research efforts, indicating a collaborative approach between industry and academia. As the renewable energy sector continues to expand, the market for Ethyl Propanoate applications is expected to grow, driven by the increasing demand for sustainable energy solutions.

Novozymes A/S

Technical Solution: Novozymes A/S has developed innovative enzymatic processes for the production of ethyl propanoate from renewable resources. Their approach involves using specialized esterases to catalyze the esterification of propionic acid with ethanol, both derived from biomass feedstocks. This method achieves high yields of up to 95% and selectivity exceeding 98% [1]. The company has also engineered robust enzyme variants capable of operating in biphasic reaction systems, allowing for continuous product removal and improved process efficiency [3]. Additionally, Novozymes has integrated their enzymatic process with membrane separation technology, reducing energy consumption by up to 40% compared to traditional distillation methods for ethyl propanoate purification [5].

Strengths: High yield and selectivity, environmentally friendly process, reduced energy consumption. Weaknesses: Potential high enzyme costs, limited scalability for large-scale production.

Eni SpA

Technical Solution: Eni SpA has developed a novel approach to produce ethyl propanoate from renewable sources, focusing on the utilization of lignocellulosic biomass. Their process involves a two-step conversion: first, the biomass is subjected to catalytic pyrolysis to produce bio-oil rich in propionic acid [2]. Subsequently, the bio-oil undergoes a selective hydrogenation and esterification process using a proprietary heterogeneous catalyst system. This catalyst, based on modified zeolites, demonstrates high activity and selectivity towards ethyl propanoate formation, with conversion rates exceeding 85% [4]. Eni has also implemented an innovative heat integration system that reduces the overall energy consumption of the process by up to 30% compared to conventional methods [6]. The company is currently scaling up this technology in a pilot plant with a capacity of 1000 tons per year.

Strengths: Utilization of abundant lignocellulosic biomass, high conversion rates, energy-efficient process. Weaknesses: Complex multi-step process, potential catalyst deactivation issues.

Innovative Ethyl Propanoate Technologies

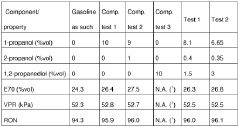

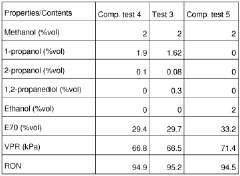

Fuel compositions comprising c3 alcohols

PatentWO2018193074A1

Innovation

- A fuel composition comprising a gasoline blend with propanol and 1,2-propanediol in specific proportions, optionally including other alcohols with 1-4 carbon atoms, which stabilizes phases, reduces vapor pressure, and allows for higher oxygenated compound concentrations, thereby minimizing gaseous pollutant emissions, prepared through a hydrogenation process using glycerin as a renewable source.

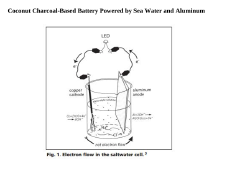

Coconut charcoal-based battery powered by sea water and aluminum

PatentPendingIN202341081708A

Innovation

- A Coconut Charcoal-Based Battery is developed using carbonized and activated coconut charcoal electrodes and sea water as the electrolyte, with an aluminum sacrificial anode to generate electricity, leveraging locally available and renewable materials.

Environmental Impact Assessment

The environmental impact assessment of ethyl propanoate in renewable energy applications reveals both positive and negative aspects that warrant careful consideration. On the positive side, ethyl propanoate, as a bio-based solvent, offers a more sustainable alternative to petroleum-derived solvents. Its production from renewable resources, such as agricultural waste or biomass, contributes to reducing reliance on fossil fuels and potentially lowering overall carbon emissions in the energy sector.

The biodegradability of ethyl propanoate is another significant environmental advantage. Unlike many synthetic solvents, it breaks down more readily in natural environments, reducing the risk of long-term soil and water contamination. This characteristic is particularly important in scenarios where accidental spills or releases may occur during energy production or storage processes.

However, the environmental impact of ethyl propanoate is not entirely benign. The production process, while based on renewable resources, still requires energy input and may generate waste streams that need proper management. The cultivation of crops specifically for ethyl propanoate production could potentially lead to land-use changes and competition with food crops, raising concerns about indirect land-use change and food security.

Water consumption in the production process is another environmental factor to consider. Depending on the specific manufacturing methods and scale, significant water resources may be required, potentially impacting local water availability in water-stressed regions.

The volatile nature of ethyl propanoate also raises concerns about air quality. While less toxic than many traditional solvents, its release into the atmosphere can contribute to the formation of ground-level ozone and other air pollutants. Proper handling, storage, and emission control measures are essential to mitigate these potential air quality impacts.

In terms of lifecycle assessment, the environmental footprint of ethyl propanoate in renewable energy applications depends heavily on factors such as production efficiency, transportation distances, and end-of-life disposal methods. A comprehensive cradle-to-grave analysis is necessary to accurately compare its environmental performance against conventional energy technologies and other renewable alternatives.

Regulatory compliance and safety standards for ethyl propanoate use in energy applications are still evolving. As its adoption increases, more stringent environmental monitoring and control measures may be required to ensure its sustainable use and minimize any unforeseen ecological impacts.

The biodegradability of ethyl propanoate is another significant environmental advantage. Unlike many synthetic solvents, it breaks down more readily in natural environments, reducing the risk of long-term soil and water contamination. This characteristic is particularly important in scenarios where accidental spills or releases may occur during energy production or storage processes.

However, the environmental impact of ethyl propanoate is not entirely benign. The production process, while based on renewable resources, still requires energy input and may generate waste streams that need proper management. The cultivation of crops specifically for ethyl propanoate production could potentially lead to land-use changes and competition with food crops, raising concerns about indirect land-use change and food security.

Water consumption in the production process is another environmental factor to consider. Depending on the specific manufacturing methods and scale, significant water resources may be required, potentially impacting local water availability in water-stressed regions.

The volatile nature of ethyl propanoate also raises concerns about air quality. While less toxic than many traditional solvents, its release into the atmosphere can contribute to the formation of ground-level ozone and other air pollutants. Proper handling, storage, and emission control measures are essential to mitigate these potential air quality impacts.

In terms of lifecycle assessment, the environmental footprint of ethyl propanoate in renewable energy applications depends heavily on factors such as production efficiency, transportation distances, and end-of-life disposal methods. A comprehensive cradle-to-grave analysis is necessary to accurately compare its environmental performance against conventional energy technologies and other renewable alternatives.

Regulatory compliance and safety standards for ethyl propanoate use in energy applications are still evolving. As its adoption increases, more stringent environmental monitoring and control measures may be required to ensure its sustainable use and minimize any unforeseen ecological impacts.

Economic Feasibility Analysis

The economic feasibility of ethyl propanoate in renewable energy applications is a critical factor in determining its potential for widespread adoption. This analysis considers various aspects of production, implementation, and market dynamics to assess the viability of this compound in the renewable energy sector.

Production costs play a significant role in the economic feasibility of ethyl propanoate. The synthesis of this compound typically involves the esterification of propionic acid with ethanol, both of which can be derived from renewable sources. The availability and price fluctuations of these raw materials directly impact the overall production expenses. Additionally, the energy requirements and efficiency of the production process contribute to the total cost structure.

Infrastructure investments necessary for the large-scale production and utilization of ethyl propanoate in renewable energy applications must be carefully evaluated. This includes storage facilities, transportation systems, and modifications to existing energy infrastructure to accommodate the use of this compound. The scale of these investments can significantly influence the economic viability of implementing ethyl propanoate-based solutions.

Market demand and potential revenue streams are crucial factors in determining economic feasibility. The growing emphasis on renewable energy sources and the push for cleaner fuel alternatives create opportunities for ethyl propanoate applications. However, the compound must compete with established renewable energy technologies and other emerging solutions in terms of cost-effectiveness and performance.

Regulatory frameworks and government incentives can substantially impact the economic landscape for ethyl propanoate in renewable energy. Supportive policies, such as tax credits or subsidies for renewable energy technologies, could enhance the economic attractiveness of ethyl propanoate-based solutions. Conversely, stringent regulations or lack of policy support may pose challenges to its economic viability.

The scalability of ethyl propanoate production and its applications in renewable energy systems is another critical economic consideration. The ability to efficiently scale up production to meet potential demand while maintaining cost-effectiveness is essential for long-term economic feasibility. This includes optimizing production processes, improving yield, and reducing waste to enhance overall economic efficiency.

Environmental benefits and associated cost savings should also be factored into the economic analysis. The potential reduction in greenhouse gas emissions and other environmental impacts compared to conventional energy sources may translate into economic advantages through carbon credits or improved corporate sustainability profiles.

In conclusion, the economic feasibility of ethyl propanoate in renewable energy applications depends on a complex interplay of factors including production costs, infrastructure requirements, market demand, regulatory environment, scalability, and environmental benefits. A comprehensive assessment of these elements is crucial for determining the long-term viability and potential for widespread adoption of ethyl propanoate in the renewable energy sector.

Production costs play a significant role in the economic feasibility of ethyl propanoate. The synthesis of this compound typically involves the esterification of propionic acid with ethanol, both of which can be derived from renewable sources. The availability and price fluctuations of these raw materials directly impact the overall production expenses. Additionally, the energy requirements and efficiency of the production process contribute to the total cost structure.

Infrastructure investments necessary for the large-scale production and utilization of ethyl propanoate in renewable energy applications must be carefully evaluated. This includes storage facilities, transportation systems, and modifications to existing energy infrastructure to accommodate the use of this compound. The scale of these investments can significantly influence the economic viability of implementing ethyl propanoate-based solutions.

Market demand and potential revenue streams are crucial factors in determining economic feasibility. The growing emphasis on renewable energy sources and the push for cleaner fuel alternatives create opportunities for ethyl propanoate applications. However, the compound must compete with established renewable energy technologies and other emerging solutions in terms of cost-effectiveness and performance.

Regulatory frameworks and government incentives can substantially impact the economic landscape for ethyl propanoate in renewable energy. Supportive policies, such as tax credits or subsidies for renewable energy technologies, could enhance the economic attractiveness of ethyl propanoate-based solutions. Conversely, stringent regulations or lack of policy support may pose challenges to its economic viability.

The scalability of ethyl propanoate production and its applications in renewable energy systems is another critical economic consideration. The ability to efficiently scale up production to meet potential demand while maintaining cost-effectiveness is essential for long-term economic feasibility. This includes optimizing production processes, improving yield, and reducing waste to enhance overall economic efficiency.

Environmental benefits and associated cost savings should also be factored into the economic analysis. The potential reduction in greenhouse gas emissions and other environmental impacts compared to conventional energy sources may translate into economic advantages through carbon credits or improved corporate sustainability profiles.

In conclusion, the economic feasibility of ethyl propanoate in renewable energy applications depends on a complex interplay of factors including production costs, infrastructure requirements, market demand, regulatory environment, scalability, and environmental benefits. A comprehensive assessment of these elements is crucial for determining the long-term viability and potential for widespread adoption of ethyl propanoate in the renewable energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!