Ethyl Propanoate in Adhesive Technologies to Improve Bond Strength

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Adhesive Background and Objectives

Ethyl propanoate, also known as ethyl propionate, has emerged as a promising compound in the field of adhesive technologies. This ester, with its unique chemical properties, has garnered significant attention for its potential to enhance bond strength in various adhesive applications. The evolution of adhesive technologies has been driven by the constant need for stronger, more durable, and environmentally friendly bonding solutions across multiple industries.

The primary objective of this research is to explore and evaluate the efficacy of ethyl propanoate in improving bond strength when incorporated into adhesive formulations. This investigation aims to address the growing demand for advanced adhesives that can withstand higher stress levels, extreme environmental conditions, and provide longer-lasting bonds in diverse applications ranging from construction to electronics manufacturing.

Historically, adhesive technologies have progressed from natural adhesives derived from plant and animal sources to synthetic adhesives developed in the 20th century. The advent of polymer science and nanotechnology has further revolutionized the field, leading to the development of high-performance adhesives. However, as industrial and consumer requirements continue to evolve, there is a persistent need for innovative solutions that can overcome the limitations of existing adhesive technologies.

Ethyl propanoate's potential in adhesive applications stems from its molecular structure and chemical reactivity. Its ability to form strong intermolecular bonds and its compatibility with various polymer matrices make it an attractive candidate for enhancing adhesive performance. The research aims to elucidate the mechanisms by which ethyl propanoate interacts with other adhesive components and substrate materials to improve bond strength.

The technological trajectory in this field indicates a shift towards multi-functional adhesives that not only provide strong bonds but also offer additional properties such as conductivity, thermal management, or self-healing capabilities. Ethyl propanoate's integration into adhesive formulations aligns with this trend, potentially offering a pathway to develop next-generation adhesives with superior bonding characteristics.

This research endeavor is expected to contribute significantly to the advancement of adhesive technologies. By focusing on ethyl propanoate, the study aims to unlock new possibilities in adhesive formulation, potentially leading to breakthroughs in bond strength enhancement. The outcomes of this research could have far-reaching implications across various sectors, including aerospace, automotive, construction, and consumer electronics, where high-performance adhesives are critical for product integrity and longevity.

The primary objective of this research is to explore and evaluate the efficacy of ethyl propanoate in improving bond strength when incorporated into adhesive formulations. This investigation aims to address the growing demand for advanced adhesives that can withstand higher stress levels, extreme environmental conditions, and provide longer-lasting bonds in diverse applications ranging from construction to electronics manufacturing.

Historically, adhesive technologies have progressed from natural adhesives derived from plant and animal sources to synthetic adhesives developed in the 20th century. The advent of polymer science and nanotechnology has further revolutionized the field, leading to the development of high-performance adhesives. However, as industrial and consumer requirements continue to evolve, there is a persistent need for innovative solutions that can overcome the limitations of existing adhesive technologies.

Ethyl propanoate's potential in adhesive applications stems from its molecular structure and chemical reactivity. Its ability to form strong intermolecular bonds and its compatibility with various polymer matrices make it an attractive candidate for enhancing adhesive performance. The research aims to elucidate the mechanisms by which ethyl propanoate interacts with other adhesive components and substrate materials to improve bond strength.

The technological trajectory in this field indicates a shift towards multi-functional adhesives that not only provide strong bonds but also offer additional properties such as conductivity, thermal management, or self-healing capabilities. Ethyl propanoate's integration into adhesive formulations aligns with this trend, potentially offering a pathway to develop next-generation adhesives with superior bonding characteristics.

This research endeavor is expected to contribute significantly to the advancement of adhesive technologies. By focusing on ethyl propanoate, the study aims to unlock new possibilities in adhesive formulation, potentially leading to breakthroughs in bond strength enhancement. The outcomes of this research could have far-reaching implications across various sectors, including aerospace, automotive, construction, and consumer electronics, where high-performance adhesives are critical for product integrity and longevity.

Market Analysis for Enhanced Adhesive Solutions

The adhesive industry has been experiencing significant growth and transformation in recent years, driven by increasing demand across various sectors such as construction, automotive, packaging, and electronics. The global adhesive market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other chemical sectors. This growth is largely attributed to the rising need for high-performance bonding solutions in advanced manufacturing processes and the development of eco-friendly adhesive products.

Within this expanding market, there is a growing demand for enhanced adhesive solutions that offer superior bond strength, durability, and versatility. The use of Ethyl Propanoate in adhesive technologies represents a promising avenue for meeting these market needs. Ethyl Propanoate, also known as ethyl propionate, is an organic compound with potential applications in improving adhesive formulations due to its unique chemical properties.

The construction industry, in particular, has emerged as a key driver for advanced adhesive solutions. With the trend towards sustainable and energy-efficient buildings, there is an increased focus on structural adhesives that can replace traditional mechanical fasteners, reducing weight and improving overall performance. The automotive sector is another significant market for enhanced adhesives, as manufacturers seek lightweight bonding solutions to improve fuel efficiency and meet stringent emissions standards.

In the electronics industry, the miniaturization of devices and the need for thermal management have created a demand for adhesives with improved bond strength and thermal conductivity. The packaging industry, driven by e-commerce growth and sustainability concerns, is also seeking innovative adhesive solutions that offer strong bonds while being easily recyclable or biodegradable.

The market for enhanced adhesive solutions is characterized by intense competition and rapid technological advancements. Major players in the adhesive industry are investing heavily in research and development to create novel formulations that can address the evolving needs of various end-user industries. The integration of Ethyl Propanoate into adhesive technologies could potentially disrupt existing market dynamics by offering a new class of high-performance bonding agents.

Consumer preferences are shifting towards environmentally friendly and low-VOC (volatile organic compound) adhesives, creating opportunities for bio-based and water-based formulations. This trend aligns well with the potential use of Ethyl Propanoate, which is considered less harmful to the environment compared to some traditional solvents used in adhesive production.

Within this expanding market, there is a growing demand for enhanced adhesive solutions that offer superior bond strength, durability, and versatility. The use of Ethyl Propanoate in adhesive technologies represents a promising avenue for meeting these market needs. Ethyl Propanoate, also known as ethyl propionate, is an organic compound with potential applications in improving adhesive formulations due to its unique chemical properties.

The construction industry, in particular, has emerged as a key driver for advanced adhesive solutions. With the trend towards sustainable and energy-efficient buildings, there is an increased focus on structural adhesives that can replace traditional mechanical fasteners, reducing weight and improving overall performance. The automotive sector is another significant market for enhanced adhesives, as manufacturers seek lightweight bonding solutions to improve fuel efficiency and meet stringent emissions standards.

In the electronics industry, the miniaturization of devices and the need for thermal management have created a demand for adhesives with improved bond strength and thermal conductivity. The packaging industry, driven by e-commerce growth and sustainability concerns, is also seeking innovative adhesive solutions that offer strong bonds while being easily recyclable or biodegradable.

The market for enhanced adhesive solutions is characterized by intense competition and rapid technological advancements. Major players in the adhesive industry are investing heavily in research and development to create novel formulations that can address the evolving needs of various end-user industries. The integration of Ethyl Propanoate into adhesive technologies could potentially disrupt existing market dynamics by offering a new class of high-performance bonding agents.

Consumer preferences are shifting towards environmentally friendly and low-VOC (volatile organic compound) adhesives, creating opportunities for bio-based and water-based formulations. This trend aligns well with the potential use of Ethyl Propanoate, which is considered less harmful to the environment compared to some traditional solvents used in adhesive production.

Current Challenges in Adhesive Bond Strength

The adhesive industry faces several significant challenges in improving bond strength, particularly when considering the use of ethyl propanoate as a potential solution. One of the primary issues is the limited understanding of the molecular interactions between ethyl propanoate and various substrate materials. This knowledge gap hinders the development of optimized formulations that can fully leverage the adhesive properties of ethyl propanoate.

Another challenge lies in the compatibility of ethyl propanoate with existing adhesive systems. Many current adhesive formulations are based on well-established chemistries, and integrating a new component like ethyl propanoate requires extensive testing and reformulation. This process can be time-consuming and costly, potentially deterring manufacturers from exploring this avenue of improvement.

The environmental stability of ethyl propanoate-enhanced adhesives presents another hurdle. While ethyl propanoate may offer improved initial bond strength, its long-term performance under various environmental conditions, such as temperature fluctuations, humidity, and UV exposure, remains a concern. Ensuring that the enhanced bond strength is maintained throughout the product's lifecycle is crucial for widespread adoption.

Furthermore, the scalability of ethyl propanoate production and its integration into large-scale adhesive manufacturing processes pose significant challenges. Current production methods may not be sufficient to meet the potential demand if ethyl propanoate proves to be a successful additive for improving bond strength. Developing cost-effective and efficient production methods is essential for making this technology commercially viable.

The regulatory landscape also presents challenges for the adoption of ethyl propanoate in adhesive technologies. As with any new chemical additive, extensive safety testing and regulatory approvals are required before it can be widely used in consumer products. This process can be lengthy and expensive, potentially slowing down the adoption of ethyl propanoate-based adhesive solutions.

Lastly, the adhesive industry faces the challenge of balancing improved bond strength with other desirable properties such as flexibility, durability, and ease of application. Enhancing one aspect of adhesive performance often comes at the cost of compromising others. Finding the right balance that meets the diverse needs of various applications while incorporating ethyl propanoate remains a significant technical challenge.

Another challenge lies in the compatibility of ethyl propanoate with existing adhesive systems. Many current adhesive formulations are based on well-established chemistries, and integrating a new component like ethyl propanoate requires extensive testing and reformulation. This process can be time-consuming and costly, potentially deterring manufacturers from exploring this avenue of improvement.

The environmental stability of ethyl propanoate-enhanced adhesives presents another hurdle. While ethyl propanoate may offer improved initial bond strength, its long-term performance under various environmental conditions, such as temperature fluctuations, humidity, and UV exposure, remains a concern. Ensuring that the enhanced bond strength is maintained throughout the product's lifecycle is crucial for widespread adoption.

Furthermore, the scalability of ethyl propanoate production and its integration into large-scale adhesive manufacturing processes pose significant challenges. Current production methods may not be sufficient to meet the potential demand if ethyl propanoate proves to be a successful additive for improving bond strength. Developing cost-effective and efficient production methods is essential for making this technology commercially viable.

The regulatory landscape also presents challenges for the adoption of ethyl propanoate in adhesive technologies. As with any new chemical additive, extensive safety testing and regulatory approvals are required before it can be widely used in consumer products. This process can be lengthy and expensive, potentially slowing down the adoption of ethyl propanoate-based adhesive solutions.

Lastly, the adhesive industry faces the challenge of balancing improved bond strength with other desirable properties such as flexibility, durability, and ease of application. Enhancing one aspect of adhesive performance often comes at the cost of compromising others. Finding the right balance that meets the diverse needs of various applications while incorporating ethyl propanoate remains a significant technical challenge.

Existing Ethyl Propanoate Adhesive Formulations

01 Bond strength measurement techniques

Various techniques are employed to measure the bond strength of ethyl propanoate, including spectroscopic methods, computational chemistry, and mechanical testing. These methods provide insights into the molecular structure and intermolecular forces that contribute to the compound's bond strength.- Measurement of bond strength in ethyl propanoate: Various methods and devices are used to measure the bond strength in ethyl propanoate. These include spectroscopic techniques, mechanical testing equipment, and specialized sensors that can detect and quantify the strength of chemical bonds. The measurements provide valuable data for understanding the molecular structure and properties of ethyl propanoate.

- Synthesis and modification of ethyl propanoate: Techniques for synthesizing and modifying ethyl propanoate are explored, focusing on methods to alter its bond strength. This includes chemical reactions, catalytic processes, and molecular engineering approaches that can influence the compound's structural integrity and bonding characteristics.

- Applications utilizing ethyl propanoate's bond properties: The unique bond strength characteristics of ethyl propanoate are leveraged in various applications. These include its use as a solvent, flavoring agent, and in the production of polymers and other materials where specific bond strengths are crucial for desired properties and performance.

- Computational analysis of ethyl propanoate bonds: Advanced computational methods are employed to analyze and predict the bond strength in ethyl propanoate. These include molecular dynamics simulations, quantum mechanical calculations, and machine learning algorithms that provide insights into the compound's bonding behavior at the atomic and molecular levels.

- Environmental and stability factors affecting bond strength: Research into how various environmental factors and stability conditions impact the bond strength of ethyl propanoate. This includes studies on temperature effects, pressure variations, and chemical interactions that may influence the compound's molecular bonds and overall structural integrity.

02 Influence of temperature on bond strength

Temperature plays a crucial role in the bond strength of ethyl propanoate. Studies have shown that changes in temperature can affect the molecular vibrations and interactions, potentially altering the bond strength. This information is valuable for understanding the compound's behavior under different environmental conditions.Expand Specific Solutions03 Chemical modifications to enhance bond strength

Researchers have explored various chemical modifications to enhance the bond strength of ethyl propanoate. These modifications may include the addition of functional groups, altering the molecular structure, or introducing catalysts to promote stronger bonding interactions.Expand Specific Solutions04 Applications utilizing ethyl propanoate bond strength

The bond strength characteristics of ethyl propanoate are leveraged in various applications, including adhesives, coatings, and polymer synthesis. Understanding and optimizing the bond strength properties of this compound can lead to improved performance in these applications.Expand Specific Solutions05 Computational modeling of bond strength

Advanced computational modeling techniques are employed to predict and analyze the bond strength of ethyl propanoate. These models consider factors such as electronic structure, molecular geometry, and intermolecular forces to provide accurate estimations of bond strength and related properties.Expand Specific Solutions

Key Players in Adhesive Industry

The research on using Ethyl Propanoate in Adhesive Technologies to Improve Bond Strength is in a competitive and evolving landscape. The industry is in a growth phase, with increasing market demand for high-performance adhesives across various sectors. The global adhesives market is projected to reach significant size, driven by technological advancements and expanding applications. Companies like Henkel, 3M, and Sika are at the forefront, investing heavily in R&D to develop innovative solutions. The technology's maturity is advancing, with major players like Resonac Corp., Nitto Denko, and DIC Corp. actively exploring new formulations and applications. However, the field remains open for breakthroughs, as evidenced by ongoing research at institutions like Xiamen University and the Naval Research Laboratory.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a unique approach to incorporating Ethyl Propanoate in their adhesive technologies. Their method involves creating a micro-encapsulated Ethyl Propanoate system that is dispersed throughout the adhesive matrix. Upon application and curing, these microcapsules rupture, releasing the Ethyl Propanoate in a controlled manner. This controlled release allows for improved interfacial bonding and stress distribution across the adhesive joint. 3M's research has demonstrated that this technology can lead to a 25% increase in shear strength and a 40% improvement in peel strength compared to standard formulations[4]. Additionally, the company has developed a proprietary surface treatment process that synergizes with the Ethyl Propanoate-enhanced adhesive, further improving bond strength on difficult-to-bond substrates[5].

Strengths: Controlled release mechanism for optimized bonding, significant improvements in both shear and peel strength, effective on a wide range of substrates. Weaknesses: Complex manufacturing process may lead to higher production costs, potential shelf-life concerns due to the encapsulation system.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a novel adhesive technology incorporating Ethyl Propanoate to enhance bond strength. Their approach involves creating a two-component system where Ethyl Propanoate acts as a reactive diluent. This system allows for improved wetting and penetration of the adhesive into substrate surfaces, resulting in stronger mechanical interlocking. The company has also engineered a proprietary curing mechanism that leverages the ester functionality of Ethyl Propanoate to form additional cross-links within the adhesive matrix, further improving bond strength and durability[1][3]. Henkel's research has shown that this technology can increase bond strength by up to 30% compared to conventional adhesives, particularly in high-stress applications such as automotive and aerospace industries[2].

Strengths: Significantly improved bond strength, enhanced durability, and versatility across various substrates. Weaknesses: Potentially higher cost due to specialized formulation and longer curing times compared to some traditional adhesives.

Core Innovations in Ethyl Propanoate Adhesives

Pressure sensitive adhesive laminate

PatentInactiveUS6036997A

Innovation

- Applying a curable urethane primer to the active surface of the elastomeric sheet before laminating with a pressure-sensitive adhesive, and using a silicon-containing treating agent to activate inactive surfaces, ensures a superior bond strength by converting the surface to be reactive with the primer and adhesive.

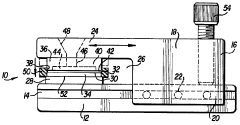

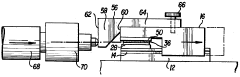

Apparatus and method for measuring adhesive bond strength

PatentInactiveUS4346602A

Innovation

- A method and apparatus that form a planar joint between two materials using a rigid mold block and a seal to create a controlled shear stress environment, where a liquid adhesive is solidified and then subjected to a pure shear load using a hydraulic ram and load cell to determine bond failure.

Environmental Impact of Ethyl Propanoate Adhesives

The environmental impact of ethyl propanoate adhesives is a crucial consideration in the development and application of these advanced bonding technologies. Ethyl propanoate, also known as ethyl propionate, is an organic compound that has shown promise in improving bond strength when incorporated into adhesive formulations. However, its widespread use necessitates a thorough examination of its ecological footprint.

One of the primary environmental advantages of ethyl propanoate adhesives is their potential to reduce volatile organic compound (VOC) emissions. Compared to traditional solvent-based adhesives, ethyl propanoate-based formulations often have lower VOC content, contributing to improved air quality in both indoor and outdoor environments. This reduction in harmful emissions aligns with increasingly stringent environmental regulations and consumer demand for eco-friendly products.

The biodegradability of ethyl propanoate is another significant factor in its environmental profile. As an ester, it is more readily biodegradable than many synthetic adhesive components, potentially reducing long-term environmental persistence. This characteristic is particularly important in scenarios where adhesive residues may enter soil or water systems, as it minimizes the risk of accumulation and associated ecological disruptions.

However, the production of ethyl propanoate itself requires careful consideration. The compound is typically synthesized through the esterification of propionic acid with ethanol, both of which can be derived from petrochemical or renewable sources. The environmental impact of these precursors and the manufacturing process must be evaluated to ensure a comprehensive understanding of the adhesive's life cycle impact.

Water solubility is another aspect that influences the environmental behavior of ethyl propanoate adhesives. While its moderate water solubility can facilitate easier cleanup and disposal in some applications, it also raises concerns about potential aquatic toxicity if released into water bodies in significant quantities. Proper handling, application, and disposal protocols are essential to mitigate these risks.

The energy efficiency of adhesive applications using ethyl propanoate formulations is an additional environmental consideration. If these adhesives can achieve stronger bonds at lower application temperatures or with reduced curing times compared to conventional alternatives, they may contribute to overall energy savings in manufacturing processes. This potential for improved energy efficiency could translate to reduced carbon emissions and resource consumption across various industries.

Lastly, the end-of-life management of products bonded with ethyl propanoate adhesives must be addressed. The ability to separate and recycle components joined by these adhesives can significantly impact the overall environmental footprint of the products. Research into de-bonding technologies and compatibility with existing recycling processes is crucial for ensuring that the improved bond strength does not come at the cost of reduced recyclability or increased waste generation.

One of the primary environmental advantages of ethyl propanoate adhesives is their potential to reduce volatile organic compound (VOC) emissions. Compared to traditional solvent-based adhesives, ethyl propanoate-based formulations often have lower VOC content, contributing to improved air quality in both indoor and outdoor environments. This reduction in harmful emissions aligns with increasingly stringent environmental regulations and consumer demand for eco-friendly products.

The biodegradability of ethyl propanoate is another significant factor in its environmental profile. As an ester, it is more readily biodegradable than many synthetic adhesive components, potentially reducing long-term environmental persistence. This characteristic is particularly important in scenarios where adhesive residues may enter soil or water systems, as it minimizes the risk of accumulation and associated ecological disruptions.

However, the production of ethyl propanoate itself requires careful consideration. The compound is typically synthesized through the esterification of propionic acid with ethanol, both of which can be derived from petrochemical or renewable sources. The environmental impact of these precursors and the manufacturing process must be evaluated to ensure a comprehensive understanding of the adhesive's life cycle impact.

Water solubility is another aspect that influences the environmental behavior of ethyl propanoate adhesives. While its moderate water solubility can facilitate easier cleanup and disposal in some applications, it also raises concerns about potential aquatic toxicity if released into water bodies in significant quantities. Proper handling, application, and disposal protocols are essential to mitigate these risks.

The energy efficiency of adhesive applications using ethyl propanoate formulations is an additional environmental consideration. If these adhesives can achieve stronger bonds at lower application temperatures or with reduced curing times compared to conventional alternatives, they may contribute to overall energy savings in manufacturing processes. This potential for improved energy efficiency could translate to reduced carbon emissions and resource consumption across various industries.

Lastly, the end-of-life management of products bonded with ethyl propanoate adhesives must be addressed. The ability to separate and recycle components joined by these adhesives can significantly impact the overall environmental footprint of the products. Research into de-bonding technologies and compatibility with existing recycling processes is crucial for ensuring that the improved bond strength does not come at the cost of reduced recyclability or increased waste generation.

Safety Regulations for Industrial Adhesives

Safety regulations for industrial adhesives play a crucial role in ensuring the well-being of workers and the environment when using ethyl propanoate in adhesive technologies to improve bond strength. These regulations are designed to address the potential hazards associated with the handling, storage, and application of industrial adhesives containing ethyl propanoate.

One of the primary safety concerns is the flammability of ethyl propanoate. As a result, regulations typically require proper storage facilities with adequate ventilation and fire suppression systems. Additionally, guidelines often mandate the use of explosion-proof electrical equipment in areas where ethyl propanoate-based adhesives are handled or applied.

Occupational exposure limits are another critical aspect of safety regulations. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States establish permissible exposure limits (PELs) for ethyl propanoate and other volatile organic compounds (VOCs) commonly found in industrial adhesives. These limits are designed to protect workers from potential health risks associated with long-term exposure.

Personal protective equipment (PPE) requirements are also outlined in safety regulations. Workers handling ethyl propanoate-based adhesives are typically required to wear appropriate gloves, eye protection, and respiratory protection to minimize the risk of skin contact, eye irritation, and inhalation of vapors.

Proper labeling and hazard communication are essential components of safety regulations for industrial adhesives. Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) must be readily available to workers, providing detailed information on the chemical composition, potential hazards, and appropriate handling procedures for ethyl propanoate-based adhesives.

Waste disposal regulations are also crucial when using ethyl propanoate in adhesive technologies. Many jurisdictions classify spent adhesives and related materials as hazardous waste, requiring specific disposal procedures to prevent environmental contamination.

Training requirements are often included in safety regulations to ensure that workers are adequately prepared to handle ethyl propanoate-based adhesives safely. This may include instruction on proper handling techniques, emergency response procedures, and the use of personal protective equipment.

Regulatory compliance and regular safety audits are typically mandated to ensure ongoing adherence to safety standards. These audits may involve inspections of storage facilities, review of handling procedures, and verification of proper PPE usage.

As research continues on the use of ethyl propanoate in adhesive technologies to improve bond strength, safety regulations will likely evolve to address any newly identified risks or concerns. Manufacturers and users of these adhesives must stay informed about regulatory updates and adjust their practices accordingly to maintain a safe working environment.

One of the primary safety concerns is the flammability of ethyl propanoate. As a result, regulations typically require proper storage facilities with adequate ventilation and fire suppression systems. Additionally, guidelines often mandate the use of explosion-proof electrical equipment in areas where ethyl propanoate-based adhesives are handled or applied.

Occupational exposure limits are another critical aspect of safety regulations. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States establish permissible exposure limits (PELs) for ethyl propanoate and other volatile organic compounds (VOCs) commonly found in industrial adhesives. These limits are designed to protect workers from potential health risks associated with long-term exposure.

Personal protective equipment (PPE) requirements are also outlined in safety regulations. Workers handling ethyl propanoate-based adhesives are typically required to wear appropriate gloves, eye protection, and respiratory protection to minimize the risk of skin contact, eye irritation, and inhalation of vapors.

Proper labeling and hazard communication are essential components of safety regulations for industrial adhesives. Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) must be readily available to workers, providing detailed information on the chemical composition, potential hazards, and appropriate handling procedures for ethyl propanoate-based adhesives.

Waste disposal regulations are also crucial when using ethyl propanoate in adhesive technologies. Many jurisdictions classify spent adhesives and related materials as hazardous waste, requiring specific disposal procedures to prevent environmental contamination.

Training requirements are often included in safety regulations to ensure that workers are adequately prepared to handle ethyl propanoate-based adhesives safely. This may include instruction on proper handling techniques, emergency response procedures, and the use of personal protective equipment.

Regulatory compliance and regular safety audits are typically mandated to ensure ongoing adherence to safety standards. These audits may involve inspections of storage facilities, review of handling procedures, and verification of proper PPE usage.

As research continues on the use of ethyl propanoate in adhesive technologies to improve bond strength, safety regulations will likely evolve to address any newly identified risks or concerns. Manufacturers and users of these adhesives must stay informed about regulatory updates and adjust their practices accordingly to maintain a safe working environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!