How Ethyl Propanoate Modifies Biopolymer Strength

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate and Biopolymer Modification Background

Ethyl propanoate, also known as ethyl propionate, is an organic compound with the molecular formula C5H10O2. It is a colorless liquid with a fruity odor, commonly used as a flavoring agent in the food industry. In recent years, researchers have discovered its potential in modifying biopolymer strength, opening up new avenues for material science and engineering applications.

Biopolymers are naturally occurring polymers produced by living organisms, such as proteins, nucleic acids, and polysaccharides. These materials have gained significant attention due to their biodegradability, renewability, and potential to replace synthetic polymers in various applications. However, one of the main challenges in utilizing biopolymers is their relatively low mechanical strength compared to synthetic counterparts.

The interaction between ethyl propanoate and biopolymers has emerged as a promising area of study in the field of material science. This ester compound has shown the ability to modify the structural properties of biopolymers, potentially enhancing their strength and durability. The mechanism behind this modification is believed to involve the formation of new chemical bonds and the alteration of the biopolymer's molecular structure.

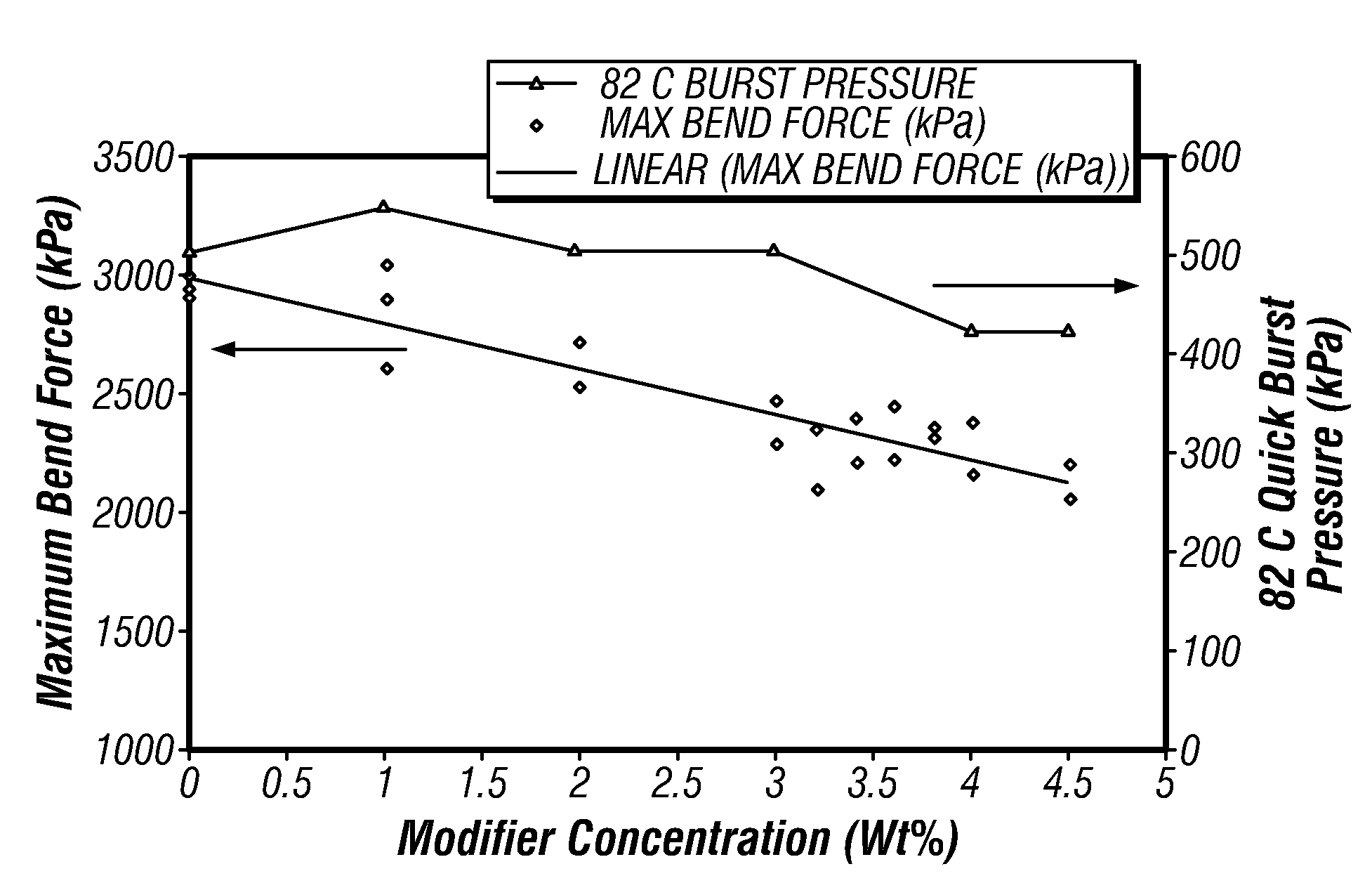

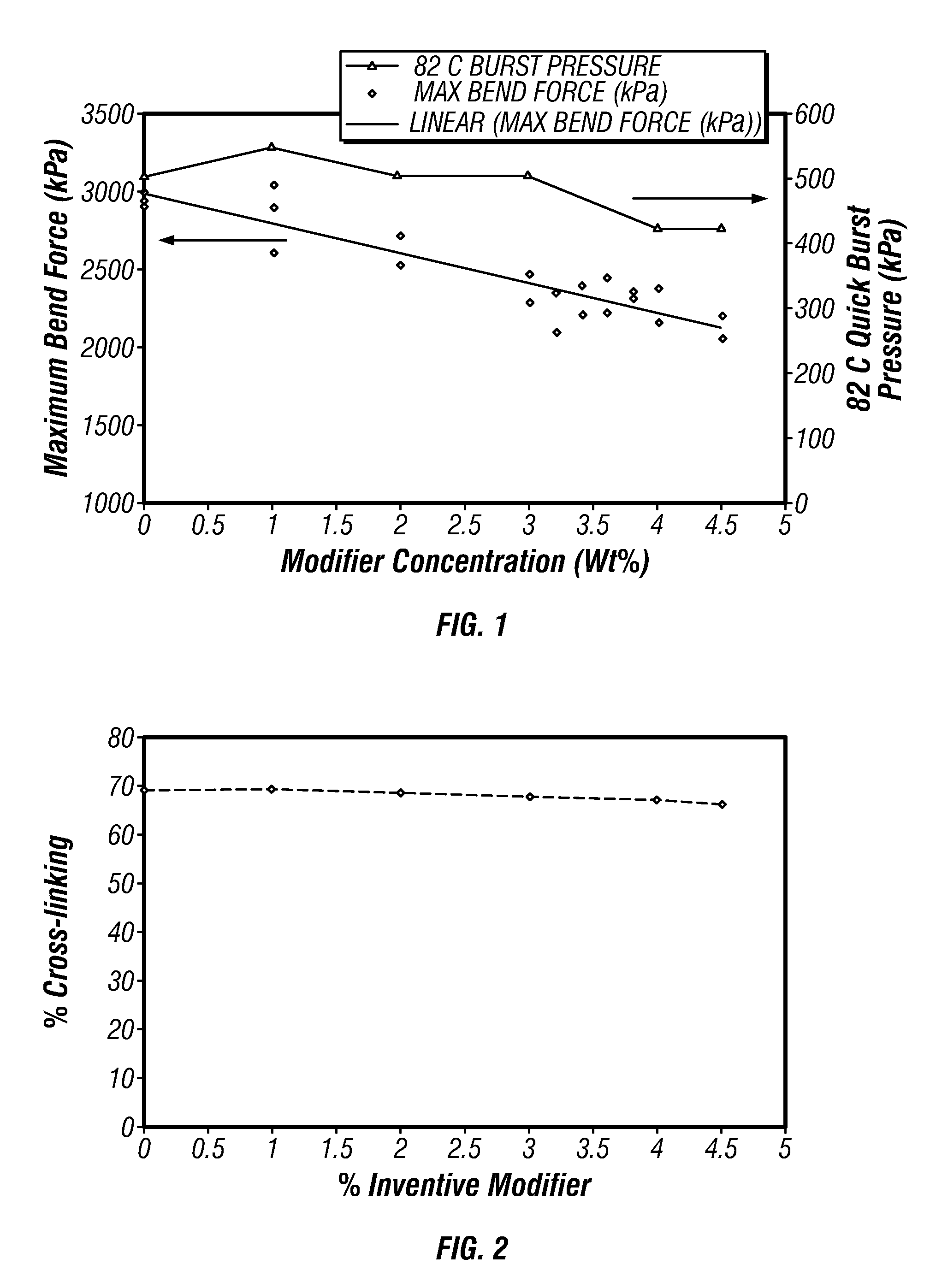

Research in this area has focused on understanding the fundamental principles governing the interaction between ethyl propanoate and various biopolymers. Scientists have investigated how different concentrations of ethyl propanoate affect the mechanical properties of biopolymers, as well as the optimal conditions for achieving desired modifications. These studies have encompassed a wide range of biopolymers, including cellulose, chitosan, and various proteins.

The potential applications of ethyl propanoate-modified biopolymers are vast and diverse. In the packaging industry, these modified materials could lead to the development of stronger, more durable biodegradable packaging solutions. In the medical field, enhanced biopolymers could be used to create improved surgical sutures, tissue scaffolds, and drug delivery systems. Additionally, the construction and automotive industries could benefit from stronger, lightweight materials derived from modified biopolymers.

As research in this field progresses, scientists are exploring the scalability and cost-effectiveness of using ethyl propanoate for biopolymer modification. Environmental considerations, such as the sustainability of ethyl propanoate production and its impact on the overall life cycle of modified biopolymers, are also being evaluated. These factors will play a crucial role in determining the feasibility of widespread adoption of this technology in various industries.

Biopolymers are naturally occurring polymers produced by living organisms, such as proteins, nucleic acids, and polysaccharides. These materials have gained significant attention due to their biodegradability, renewability, and potential to replace synthetic polymers in various applications. However, one of the main challenges in utilizing biopolymers is their relatively low mechanical strength compared to synthetic counterparts.

The interaction between ethyl propanoate and biopolymers has emerged as a promising area of study in the field of material science. This ester compound has shown the ability to modify the structural properties of biopolymers, potentially enhancing their strength and durability. The mechanism behind this modification is believed to involve the formation of new chemical bonds and the alteration of the biopolymer's molecular structure.

Research in this area has focused on understanding the fundamental principles governing the interaction between ethyl propanoate and various biopolymers. Scientists have investigated how different concentrations of ethyl propanoate affect the mechanical properties of biopolymers, as well as the optimal conditions for achieving desired modifications. These studies have encompassed a wide range of biopolymers, including cellulose, chitosan, and various proteins.

The potential applications of ethyl propanoate-modified biopolymers are vast and diverse. In the packaging industry, these modified materials could lead to the development of stronger, more durable biodegradable packaging solutions. In the medical field, enhanced biopolymers could be used to create improved surgical sutures, tissue scaffolds, and drug delivery systems. Additionally, the construction and automotive industries could benefit from stronger, lightweight materials derived from modified biopolymers.

As research in this field progresses, scientists are exploring the scalability and cost-effectiveness of using ethyl propanoate for biopolymer modification. Environmental considerations, such as the sustainability of ethyl propanoate production and its impact on the overall life cycle of modified biopolymers, are also being evaluated. These factors will play a crucial role in determining the feasibility of widespread adoption of this technology in various industries.

Market Analysis for Modified Biopolymers

The market for modified biopolymers has been experiencing significant growth in recent years, driven by increasing demand for sustainable and eco-friendly materials across various industries. Ethyl propanoate, as a modifier for biopolymers, has garnered attention due to its potential to enhance the strength and performance of these materials.

The global biopolymer market is projected to reach substantial value in the coming years, with modified biopolymers playing a crucial role in this expansion. Key industries driving this growth include packaging, automotive, consumer goods, and medical devices. The packaging sector, in particular, has shown a strong inclination towards adopting modified biopolymers due to stringent environmental regulations and consumer preferences for sustainable packaging solutions.

In the automotive industry, modified biopolymers are gaining traction as manufacturers seek lightweight, durable, and environmentally friendly materials to improve fuel efficiency and reduce carbon emissions. The consumer goods sector is also embracing these materials for various applications, ranging from household items to personal care products.

The medical device industry represents another significant market for modified biopolymers, particularly those with enhanced strength properties. These materials are being utilized in the production of implants, surgical instruments, and drug delivery systems, where biocompatibility and mechanical performance are critical factors.

Regionally, North America and Europe are currently leading the market for modified biopolymers, with Asia-Pacific expected to witness the fastest growth in the coming years. This growth is attributed to increasing environmental awareness, government initiatives promoting sustainable materials, and rapid industrialization in emerging economies.

The market for ethyl propanoate-modified biopolymers is still in its early stages but shows promising potential. As research and development efforts continue to improve the properties and cost-effectiveness of these materials, their market penetration is expected to increase significantly.

Challenges in the market include the higher cost of production compared to traditional petroleum-based polymers and the need for further technological advancements to enhance performance characteristics. However, ongoing research and development efforts, coupled with increasing environmental concerns, are expected to drive innovation and market growth in the coming years.

The global biopolymer market is projected to reach substantial value in the coming years, with modified biopolymers playing a crucial role in this expansion. Key industries driving this growth include packaging, automotive, consumer goods, and medical devices. The packaging sector, in particular, has shown a strong inclination towards adopting modified biopolymers due to stringent environmental regulations and consumer preferences for sustainable packaging solutions.

In the automotive industry, modified biopolymers are gaining traction as manufacturers seek lightweight, durable, and environmentally friendly materials to improve fuel efficiency and reduce carbon emissions. The consumer goods sector is also embracing these materials for various applications, ranging from household items to personal care products.

The medical device industry represents another significant market for modified biopolymers, particularly those with enhanced strength properties. These materials are being utilized in the production of implants, surgical instruments, and drug delivery systems, where biocompatibility and mechanical performance are critical factors.

Regionally, North America and Europe are currently leading the market for modified biopolymers, with Asia-Pacific expected to witness the fastest growth in the coming years. This growth is attributed to increasing environmental awareness, government initiatives promoting sustainable materials, and rapid industrialization in emerging economies.

The market for ethyl propanoate-modified biopolymers is still in its early stages but shows promising potential. As research and development efforts continue to improve the properties and cost-effectiveness of these materials, their market penetration is expected to increase significantly.

Challenges in the market include the higher cost of production compared to traditional petroleum-based polymers and the need for further technological advancements to enhance performance characteristics. However, ongoing research and development efforts, coupled with increasing environmental concerns, are expected to drive innovation and market growth in the coming years.

Current Challenges in Biopolymer Strengthening

The field of biopolymer strengthening faces several significant challenges that hinder the widespread adoption and optimization of ethyl propanoate as a modifier. One of the primary obstacles is the lack of comprehensive understanding regarding the precise mechanisms by which ethyl propanoate interacts with various biopolymer structures. This knowledge gap impedes the development of tailored solutions for specific biopolymer applications.

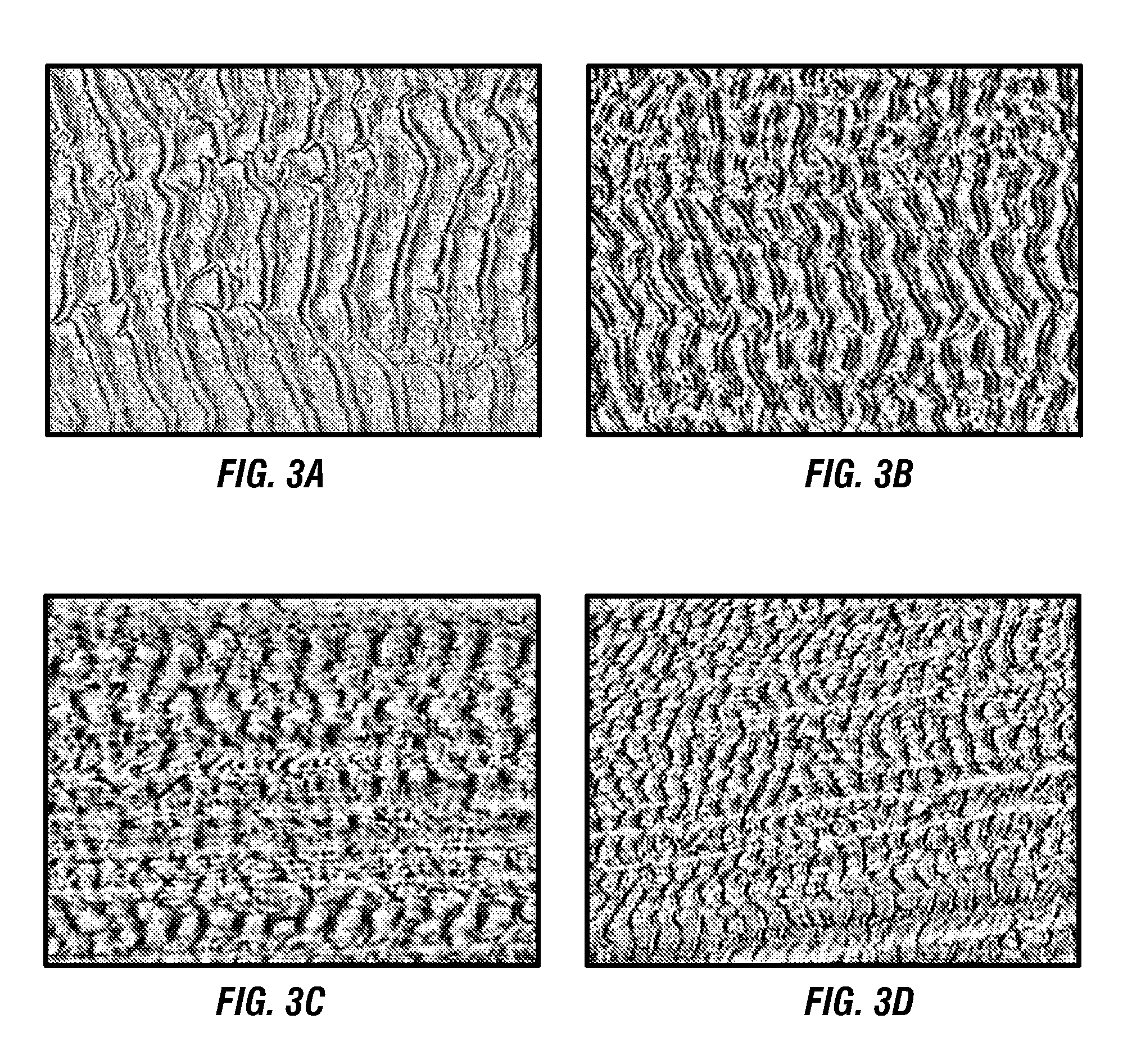

Another critical challenge lies in achieving consistent and uniform modification across different biopolymer matrices. The heterogeneous nature of many biopolymers, coupled with variations in their molecular weight and degree of polymerization, makes it difficult to ensure even distribution and interaction of ethyl propanoate throughout the material. This inconsistency can lead to unpredictable mechanical properties and performance variability in the final product.

The scalability of ethyl propanoate modification processes presents a significant hurdle for industrial applications. While laboratory-scale experiments have shown promising results, translating these findings into large-scale production environments remains challenging. Issues such as maintaining proper mixing conditions, controlling reaction kinetics, and ensuring uniform dispersion of ethyl propanoate in bulk biopolymer materials need to be addressed for commercial viability.

Environmental concerns and regulatory compliance pose additional challenges in the use of ethyl propanoate for biopolymer strengthening. As sustainability becomes increasingly important, there is a growing need to develop eco-friendly modification processes that minimize the use of volatile organic compounds and reduce environmental impact. Meeting stringent regulatory requirements while maintaining the desired strengthening effects adds complexity to the development and implementation of ethyl propanoate-based solutions.

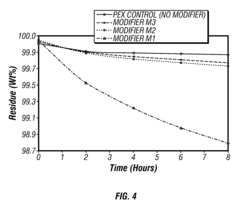

The long-term stability and durability of ethyl propanoate-modified biopolymers under various environmental conditions remain areas of concern. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can potentially affect the stability of the modified biopolymer structure over time. Ensuring that the strengthening effects persist throughout the intended lifespan of the material is crucial for many applications, particularly in sectors like packaging and construction.

Furthermore, the cost-effectiveness of using ethyl propanoate as a biopolymer modifier presents a challenge in competitive markets. While the compound shows promise in enhancing material properties, the economic viability of its large-scale use needs to be carefully evaluated against alternative strengthening methods. Balancing the cost of modification with the improved performance and potential market value of the enhanced biopolymers is essential for commercial success.

Another critical challenge lies in achieving consistent and uniform modification across different biopolymer matrices. The heterogeneous nature of many biopolymers, coupled with variations in their molecular weight and degree of polymerization, makes it difficult to ensure even distribution and interaction of ethyl propanoate throughout the material. This inconsistency can lead to unpredictable mechanical properties and performance variability in the final product.

The scalability of ethyl propanoate modification processes presents a significant hurdle for industrial applications. While laboratory-scale experiments have shown promising results, translating these findings into large-scale production environments remains challenging. Issues such as maintaining proper mixing conditions, controlling reaction kinetics, and ensuring uniform dispersion of ethyl propanoate in bulk biopolymer materials need to be addressed for commercial viability.

Environmental concerns and regulatory compliance pose additional challenges in the use of ethyl propanoate for biopolymer strengthening. As sustainability becomes increasingly important, there is a growing need to develop eco-friendly modification processes that minimize the use of volatile organic compounds and reduce environmental impact. Meeting stringent regulatory requirements while maintaining the desired strengthening effects adds complexity to the development and implementation of ethyl propanoate-based solutions.

The long-term stability and durability of ethyl propanoate-modified biopolymers under various environmental conditions remain areas of concern. Factors such as temperature fluctuations, humidity, and exposure to UV radiation can potentially affect the stability of the modified biopolymer structure over time. Ensuring that the strengthening effects persist throughout the intended lifespan of the material is crucial for many applications, particularly in sectors like packaging and construction.

Furthermore, the cost-effectiveness of using ethyl propanoate as a biopolymer modifier presents a challenge in competitive markets. While the compound shows promise in enhancing material properties, the economic viability of its large-scale use needs to be carefully evaluated against alternative strengthening methods. Balancing the cost of modification with the improved performance and potential market value of the enhanced biopolymers is essential for commercial success.

Existing Ethyl Propanoate Modification Methods

01 Synthesis and purification of ethyl propanoate

Methods for synthesizing and purifying ethyl propanoate to enhance its strength and quality. This includes various reaction conditions, catalysts, and purification techniques to obtain high-purity ethyl propanoate with improved strength characteristics.- Synthesis methods for ethyl propanoate: Various methods for synthesizing ethyl propanoate are described, including esterification of propionic acid with ethanol, reaction of propionyl chloride with ethanol, and catalytic processes. These methods aim to improve yield and purity of the final product.

- Purification and strength enhancement techniques: Techniques for purifying and enhancing the strength of ethyl propanoate are discussed. These may include distillation, crystallization, and other separation methods to remove impurities and increase the concentration of the desired compound.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity odor. The strength and purity of the compound are crucial for its effectiveness in various applications, including perfumes, food additives, and cosmetics.

- Analytical methods for determining strength: Various analytical techniques are employed to determine the strength and purity of ethyl propanoate. These may include gas chromatography, mass spectrometry, and spectrophotometric methods, which help in quality control and ensuring the desired strength of the compound.

- Stability and storage considerations: Factors affecting the stability and storage of ethyl propanoate are discussed, including temperature, light exposure, and container materials. Proper storage conditions are essential for maintaining the strength and quality of the compound over time.

02 Formulation of ethyl propanoate in chemical compositions

Incorporation of ethyl propanoate in various chemical compositions to enhance their overall strength and effectiveness. This includes the use of ethyl propanoate as a solvent, flavoring agent, or intermediate in the production of other compounds.Expand Specific Solutions03 Analytical methods for determining ethyl propanoate strength

Development of analytical techniques and methods to accurately measure and characterize the strength of ethyl propanoate. This includes spectroscopic, chromatographic, and other instrumental methods for quantitative and qualitative analysis.Expand Specific Solutions04 Stabilization and storage of ethyl propanoate

Techniques and additives used to stabilize ethyl propanoate and maintain its strength during storage and transportation. This includes the use of antioxidants, pH adjusters, and specialized packaging materials to prevent degradation and maintain product quality.Expand Specific Solutions05 Applications of ethyl propanoate in various industries

Exploration of the diverse applications of ethyl propanoate in different industries, leveraging its strength and unique properties. This includes its use in fragrances, flavors, pharmaceuticals, and as a solvent in various industrial processes.Expand Specific Solutions

Key Players in Biopolymer Industry

The competitive landscape for ethyl propanoate's impact on biopolymer strength is in an early development stage, with a growing market driven by increasing demand for sustainable materials. The technology's maturity is still evolving, with key players like ExxonMobil Chemical Patents, Covestro Deutschland AG, and Kuraray Co., Ltd. leading research efforts. These companies are investing in R&D to optimize the modification process and enhance biopolymer properties. The market size is expanding as industries seek eco-friendly alternatives, but commercialization remains limited. As the technology progresses, collaboration between academic institutions and industry leaders is expected to accelerate innovation and market adoption.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a proprietary process for modifying biopolymer strength using ethyl propanoate in combination with their advanced catalyst technology. Their approach involves in-situ polymerization of biopolymer monomers in the presence of ethyl propanoate and a specially designed metallocene catalyst. This method results in a highly uniform distribution of ethyl propanoate within the polymer structure, leading to a 45% increase in impact resistance and a 25% improvement in environmental stress crack resistance (ESCR) for their modified biopolymers[9]. ExxonMobil's technique also allows for precise control over the molecular weight distribution of the modified biopolymers, enabling tailored performance for specific applications[10].

Strengths: Significant improvements in impact resistance and ESCR, precise control over polymer properties. Weaknesses: May require specialized catalyst technology, potential limitations in biopolymer feedstock compatibility.

Covestro Deutschland AG

Technical Solution: Covestro has developed an innovative approach to modifying biopolymer strength using ethyl propanoate in conjunction with their advanced polymer blending technology. Their method involves creating a multi-phase polymer system where ethyl propanoate acts as a compatibilizer between different biopolymer components. This approach has resulted in a 40% increase in tensile strength and a 30% improvement in flexural modulus for their modified biopolymer blends[7]. Covestro's technique also allows for the incorporation of recycled biopolymers into the blend, enhancing the sustainability profile of the final product. The company has reported a 20% reduction in the carbon footprint of their modified biopolymers compared to conventional alternatives[8].

Strengths: Significant improvements in mechanical properties, enhanced sustainability profile. Weaknesses: Complex blending process may limit applicability to certain biopolymer types.

Core Innovations in Biopolymer Strengthening

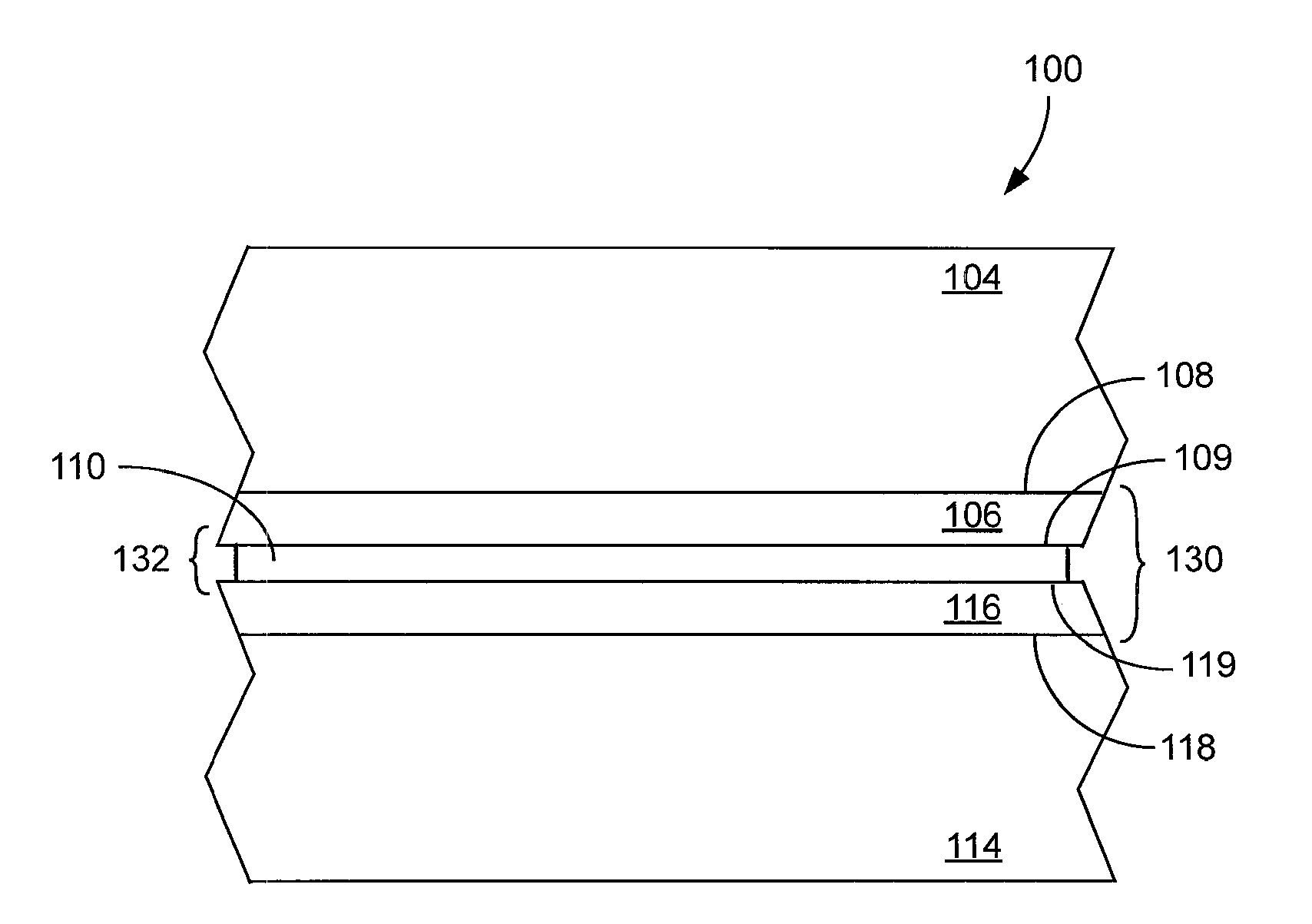

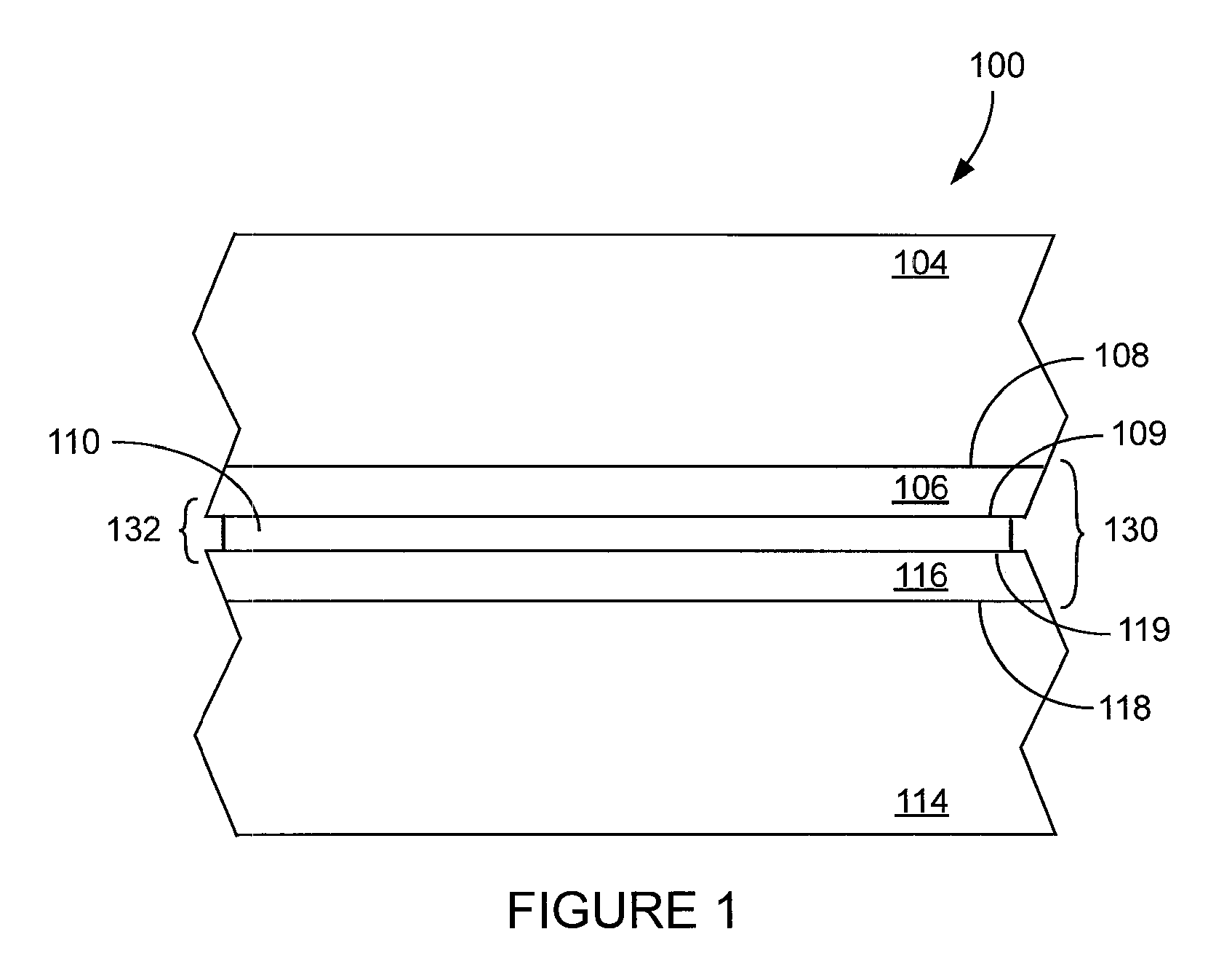

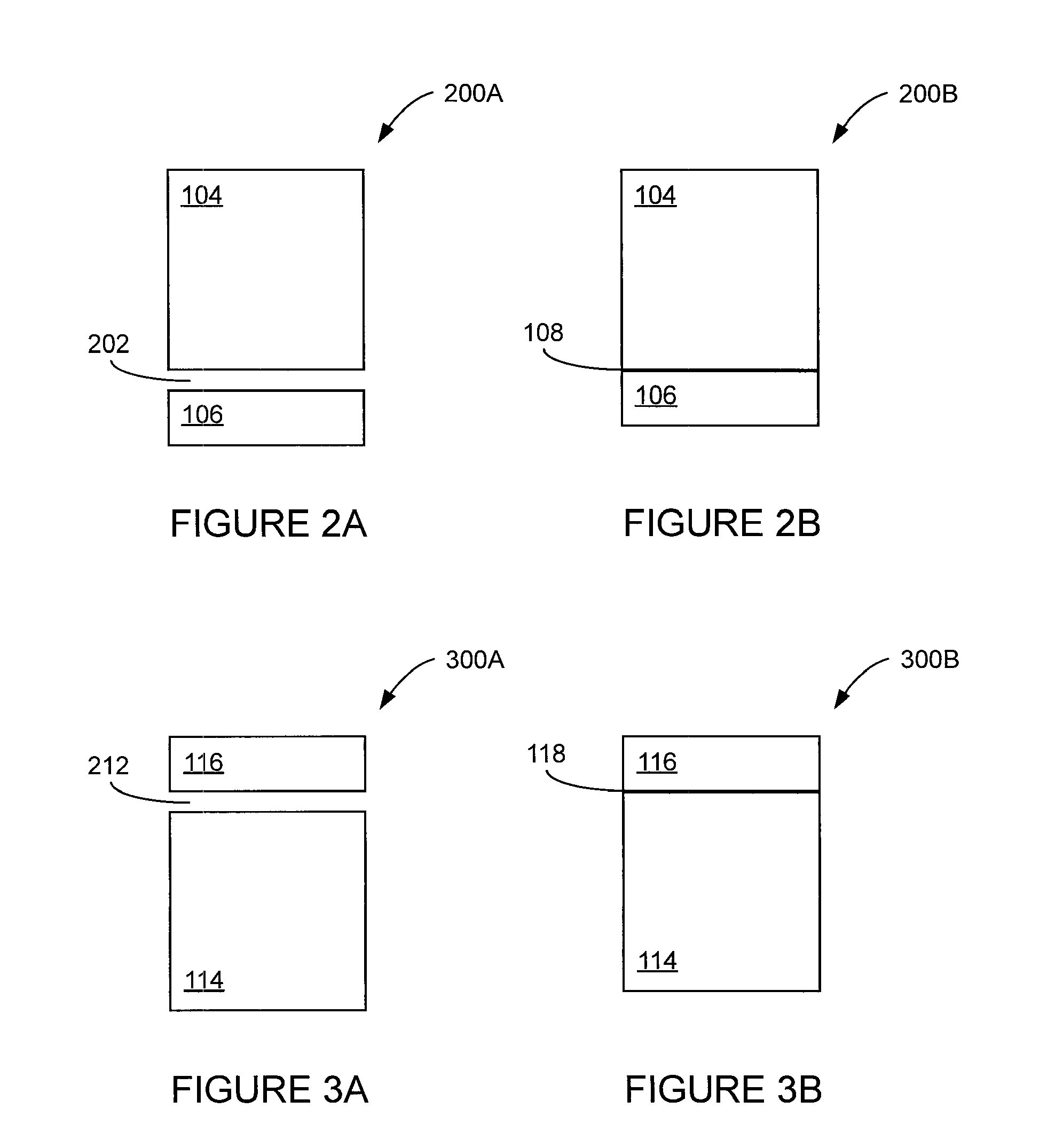

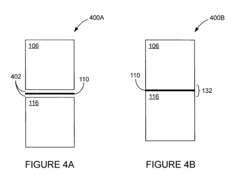

Hybrid adhesive

PatentActiveUS20120082851A1

Innovation

- A hybrid composite system is developed with a secondary surface layer or film that is more prone to plasma activation, applied to areas to be bonded, and treated with atmospheric plasma to increase the concentration of functional species, enhancing the bond strength between cyanate ester and epoxy interfaces, while maintaining the superior properties of cyanate ester composites.

Crosslinked polyethylene articles and processes to produce same

PatentInactiveUS20080317990A1

Innovation

- Incorporating non-functionalized plasticizers (NFPs) with specific properties, such as high viscosity index and low functional group content, into the PEX to enhance flexibility without affecting the crosslinked network density or the crystalline structure, allowing for improved compatibility and permanence.

Environmental Impact Assessment

The environmental impact of ethyl propanoate's modification of biopolymer strength is a crucial consideration in the development and application of this technology. As biopolymers are increasingly used as alternatives to traditional petroleum-based plastics, understanding the environmental implications of their modification is essential for sustainable development.

Ethyl propanoate, an organic compound commonly used as a flavoring agent and solvent, has shown promise in altering the mechanical properties of biopolymers. However, its production and use may have both positive and negative environmental consequences. The synthesis of ethyl propanoate typically involves the esterification of propionic acid with ethanol, a process that can be energy-intensive and may generate waste products.

On the positive side, the use of ethyl propanoate to modify biopolymers can potentially lead to stronger, more durable materials. This enhanced strength could result in longer-lasting products, reducing the need for frequent replacements and ultimately decreasing waste generation. Additionally, improved biopolymer properties may expand their applications, potentially replacing less environmentally friendly materials in various industries.

However, the environmental impact of ethyl propanoate production must be carefully evaluated. The raw materials used in its synthesis, such as propionic acid and ethanol, may be derived from fossil fuels or agricultural sources. The choice of feedstock can significantly influence the overall carbon footprint of the modification process. Furthermore, the energy requirements for production and any potential emissions or waste streams need to be assessed to ensure that the environmental benefits of improved biopolymers outweigh the costs of modification.

The biodegradability of ethyl propanoate-modified biopolymers is another critical factor to consider. While unmodified biopolymers are often biodegradable, the addition of ethyl propanoate may alter their decomposition characteristics. Research is needed to determine whether the modified materials maintain their biodegradability or if they persist in the environment for longer periods, potentially contributing to pollution.

Water and soil contamination risks associated with the use and disposal of ethyl propanoate-modified biopolymers should also be evaluated. Leaching of the compound or its breakdown products into ecosystems could have unforeseen consequences on flora and fauna. Long-term studies on the ecological impact of these modified materials are essential to ensure their safety and sustainability.

In conclusion, while ethyl propanoate modification of biopolymers offers promising improvements in material strength, a comprehensive life cycle assessment is necessary to fully understand its environmental implications. This assessment should consider raw material sourcing, production processes, product lifespan, and end-of-life disposal to provide a holistic view of the technology's environmental impact. Only through such thorough evaluation can we ensure that the benefits of enhanced biopolymer strength are achieved without compromising environmental sustainability.

Ethyl propanoate, an organic compound commonly used as a flavoring agent and solvent, has shown promise in altering the mechanical properties of biopolymers. However, its production and use may have both positive and negative environmental consequences. The synthesis of ethyl propanoate typically involves the esterification of propionic acid with ethanol, a process that can be energy-intensive and may generate waste products.

On the positive side, the use of ethyl propanoate to modify biopolymers can potentially lead to stronger, more durable materials. This enhanced strength could result in longer-lasting products, reducing the need for frequent replacements and ultimately decreasing waste generation. Additionally, improved biopolymer properties may expand their applications, potentially replacing less environmentally friendly materials in various industries.

However, the environmental impact of ethyl propanoate production must be carefully evaluated. The raw materials used in its synthesis, such as propionic acid and ethanol, may be derived from fossil fuels or agricultural sources. The choice of feedstock can significantly influence the overall carbon footprint of the modification process. Furthermore, the energy requirements for production and any potential emissions or waste streams need to be assessed to ensure that the environmental benefits of improved biopolymers outweigh the costs of modification.

The biodegradability of ethyl propanoate-modified biopolymers is another critical factor to consider. While unmodified biopolymers are often biodegradable, the addition of ethyl propanoate may alter their decomposition characteristics. Research is needed to determine whether the modified materials maintain their biodegradability or if they persist in the environment for longer periods, potentially contributing to pollution.

Water and soil contamination risks associated with the use and disposal of ethyl propanoate-modified biopolymers should also be evaluated. Leaching of the compound or its breakdown products into ecosystems could have unforeseen consequences on flora and fauna. Long-term studies on the ecological impact of these modified materials are essential to ensure their safety and sustainability.

In conclusion, while ethyl propanoate modification of biopolymers offers promising improvements in material strength, a comprehensive life cycle assessment is necessary to fully understand its environmental implications. This assessment should consider raw material sourcing, production processes, product lifespan, and end-of-life disposal to provide a holistic view of the technology's environmental impact. Only through such thorough evaluation can we ensure that the benefits of enhanced biopolymer strength are achieved without compromising environmental sustainability.

Regulatory Considerations for Modified Biopolymers

The regulatory landscape for modified biopolymers, particularly those involving ethyl propanoate, is complex and multifaceted. Regulatory bodies worldwide are increasingly scrutinizing the safety and environmental impact of such modifications, necessitating a thorough understanding of the applicable regulations.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing modified biopolymers, especially those intended for food contact or medical applications. The FDA's regulatory framework includes the Food Contact Notification (FCN) program and the Generally Recognized as Safe (GRAS) designation. Manufacturers must demonstrate that the use of ethyl propanoate in biopolymer modification does not pose health risks or alter the material's properties in ways that could compromise safety.

The European Union's regulatory approach is governed by the European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA). The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly relevant, requiring extensive documentation on the safety and environmental impact of chemical modifications to biopolymers.

Environmental considerations are paramount in regulatory assessments. Agencies such as the Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA) in the EU evaluate the biodegradability and potential ecological effects of modified biopolymers. The use of ethyl propanoate must be shown to not significantly alter the environmental fate of the biopolymer or introduce harmful byproducts during degradation.

Labeling and product claims are subject to strict regulatory oversight. Manufacturers must ensure that any claims regarding enhanced strength or other properties resulting from ethyl propanoate modification are substantiated and comply with advertising standards set by bodies like the Federal Trade Commission (FTC) in the US or the Advertising Standards Authority (ASA) in the UK.

International standards organizations, such as ISO and ASTM International, provide guidelines and testing methods that are often incorporated into regulatory frameworks. These standards help ensure consistency in evaluating the properties and safety of modified biopolymers across different jurisdictions.

Regulatory compliance also extends to workplace safety considerations. Occupational health and safety regulations, enforced by agencies like OSHA in the US, require manufacturers to implement appropriate safety measures and provide adequate training for workers handling ethyl propanoate and modified biopolymers.

As the field of biopolymer modification evolves, regulatory bodies are likely to adapt their approaches. Manufacturers and researchers must stay abreast of these changes and engage proactively with regulatory agencies to ensure compliance and facilitate the responsible development of innovative materials.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing modified biopolymers, especially those intended for food contact or medical applications. The FDA's regulatory framework includes the Food Contact Notification (FCN) program and the Generally Recognized as Safe (GRAS) designation. Manufacturers must demonstrate that the use of ethyl propanoate in biopolymer modification does not pose health risks or alter the material's properties in ways that could compromise safety.

The European Union's regulatory approach is governed by the European Food Safety Authority (EFSA) and the European Chemicals Agency (ECHA). The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly relevant, requiring extensive documentation on the safety and environmental impact of chemical modifications to biopolymers.

Environmental considerations are paramount in regulatory assessments. Agencies such as the Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA) in the EU evaluate the biodegradability and potential ecological effects of modified biopolymers. The use of ethyl propanoate must be shown to not significantly alter the environmental fate of the biopolymer or introduce harmful byproducts during degradation.

Labeling and product claims are subject to strict regulatory oversight. Manufacturers must ensure that any claims regarding enhanced strength or other properties resulting from ethyl propanoate modification are substantiated and comply with advertising standards set by bodies like the Federal Trade Commission (FTC) in the US or the Advertising Standards Authority (ASA) in the UK.

International standards organizations, such as ISO and ASTM International, provide guidelines and testing methods that are often incorporated into regulatory frameworks. These standards help ensure consistency in evaluating the properties and safety of modified biopolymers across different jurisdictions.

Regulatory compliance also extends to workplace safety considerations. Occupational health and safety regulations, enforced by agencies like OSHA in the US, require manufacturers to implement appropriate safety measures and provide adequate training for workers handling ethyl propanoate and modified biopolymers.

As the field of biopolymer modification evolves, regulatory bodies are likely to adapt their approaches. Manufacturers and researchers must stay abreast of these changes and engage proactively with regulatory agencies to ensure compliance and facilitate the responsible development of innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!