How Ethyl Propanoate Alters Shelf-Life in Packaged Foods

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate in Food Preservation: Background and Objectives

Ethyl propanoate, also known as ethyl propionate, has emerged as a significant compound in the field of food preservation, particularly in extending the shelf life of packaged foods. This ester, with its fruity aroma reminiscent of pineapples, has garnered attention for its potential to revolutionize food storage and distribution practices.

The journey of ethyl propanoate in food preservation began in the early 2000s when researchers started exploring natural compounds with antimicrobial properties. As concerns over synthetic preservatives grew, the food industry sought alternatives that could maintain food quality while meeting consumer demands for "clean label" products. Ethyl propanoate, being a naturally occurring substance in many fruits, presented itself as a promising candidate.

The primary objective of utilizing ethyl propanoate in food preservation is to inhibit microbial growth and delay oxidation processes, thereby extending the shelf life of packaged foods. This compound has shown particular efficacy in preserving baked goods, dairy products, and processed fruits. Its ability to function at low concentrations makes it an attractive option for manufacturers seeking to minimize additive usage while maximizing preservation effects.

Recent technological advancements have facilitated the incorporation of ethyl propanoate into various food packaging materials. This approach, known as active packaging, allows for the controlled release of the compound over time, providing continuous protection against spoilage. The development of nano-encapsulation techniques has further enhanced the stability and efficacy of ethyl propanoate in diverse food matrices.

The evolution of ethyl propanoate as a food preservative aligns with the broader trend towards sustainable and eco-friendly food packaging solutions. Its biodegradability and low environmental impact contribute to reducing food waste, a critical global issue. Moreover, the compound's natural origin addresses the growing consumer preference for clean-label products, positioning it as a key player in the future of food preservation technology.

As research continues, the focus is shifting towards understanding the synergistic effects of ethyl propanoate with other natural preservatives and its potential applications in novel food categories. The ongoing exploration of its mechanisms of action at the molecular level promises to unlock new possibilities in tailored preservation strategies for different food types.

The trajectory of ethyl propanoate in food preservation reflects a broader shift in the industry towards innovative, nature-inspired solutions. As we look to the future, the continued development and refinement of ethyl propanoate-based preservation techniques are expected to play a crucial role in addressing global food security challenges and meeting evolving consumer expectations for safe, high-quality, and minimally processed foods.

The journey of ethyl propanoate in food preservation began in the early 2000s when researchers started exploring natural compounds with antimicrobial properties. As concerns over synthetic preservatives grew, the food industry sought alternatives that could maintain food quality while meeting consumer demands for "clean label" products. Ethyl propanoate, being a naturally occurring substance in many fruits, presented itself as a promising candidate.

The primary objective of utilizing ethyl propanoate in food preservation is to inhibit microbial growth and delay oxidation processes, thereby extending the shelf life of packaged foods. This compound has shown particular efficacy in preserving baked goods, dairy products, and processed fruits. Its ability to function at low concentrations makes it an attractive option for manufacturers seeking to minimize additive usage while maximizing preservation effects.

Recent technological advancements have facilitated the incorporation of ethyl propanoate into various food packaging materials. This approach, known as active packaging, allows for the controlled release of the compound over time, providing continuous protection against spoilage. The development of nano-encapsulation techniques has further enhanced the stability and efficacy of ethyl propanoate in diverse food matrices.

The evolution of ethyl propanoate as a food preservative aligns with the broader trend towards sustainable and eco-friendly food packaging solutions. Its biodegradability and low environmental impact contribute to reducing food waste, a critical global issue. Moreover, the compound's natural origin addresses the growing consumer preference for clean-label products, positioning it as a key player in the future of food preservation technology.

As research continues, the focus is shifting towards understanding the synergistic effects of ethyl propanoate with other natural preservatives and its potential applications in novel food categories. The ongoing exploration of its mechanisms of action at the molecular level promises to unlock new possibilities in tailored preservation strategies for different food types.

The trajectory of ethyl propanoate in food preservation reflects a broader shift in the industry towards innovative, nature-inspired solutions. As we look to the future, the continued development and refinement of ethyl propanoate-based preservation techniques are expected to play a crucial role in addressing global food security challenges and meeting evolving consumer expectations for safe, high-quality, and minimally processed foods.

Market Analysis of Ethyl Propanoate in Food Packaging

The market for ethyl propanoate in food packaging has experienced significant growth in recent years, driven by increasing consumer demand for extended shelf life and improved food quality. This ester compound, known for its fruity aroma and flavor-enhancing properties, has found widespread application in the food industry as a preservative and flavor additive.

The global market for ethyl propanoate in food packaging is primarily segmented by application, including bakery products, beverages, dairy products, and processed foods. Among these, the processed foods segment holds the largest market share due to the compound's ability to extend shelf life and maintain flavor profiles in packaged ready-to-eat meals and snacks.

Geographically, North America and Europe dominate the market, owing to stringent food safety regulations and a well-established food processing industry. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid urbanization, changing dietary habits, and increasing disposable incomes.

Key market drivers include the growing demand for convenience foods, rising awareness of food safety, and the need for sustainable packaging solutions. Ethyl propanoate's ability to reduce food waste by extending shelf life aligns well with sustainability goals, making it an attractive option for food manufacturers and retailers alike.

The market faces challenges such as fluctuating raw material prices and regulatory hurdles in some regions. However, ongoing research and development efforts are focused on improving the efficacy and safety of ethyl propanoate, potentially expanding its applications and market reach.

Consumer trends towards clean label products and natural ingredients have led to increased demand for ethyl propanoate derived from natural sources. This has created opportunities for manufacturers to develop bio-based alternatives, potentially opening new market segments.

The competitive landscape of the ethyl propanoate market in food packaging is characterized by the presence of both large multinational corporations and smaller specialized chemical companies. Key players are investing in research and development to enhance product performance and expand their product portfolios.

Looking ahead, the market for ethyl propanoate in food packaging is projected to continue its growth trajectory. Factors such as increasing urbanization, rising demand for packaged foods in emerging economies, and ongoing innovations in food preservation technologies are expected to drive market expansion in the foreseeable future.

The global market for ethyl propanoate in food packaging is primarily segmented by application, including bakery products, beverages, dairy products, and processed foods. Among these, the processed foods segment holds the largest market share due to the compound's ability to extend shelf life and maintain flavor profiles in packaged ready-to-eat meals and snacks.

Geographically, North America and Europe dominate the market, owing to stringent food safety regulations and a well-established food processing industry. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid urbanization, changing dietary habits, and increasing disposable incomes.

Key market drivers include the growing demand for convenience foods, rising awareness of food safety, and the need for sustainable packaging solutions. Ethyl propanoate's ability to reduce food waste by extending shelf life aligns well with sustainability goals, making it an attractive option for food manufacturers and retailers alike.

The market faces challenges such as fluctuating raw material prices and regulatory hurdles in some regions. However, ongoing research and development efforts are focused on improving the efficacy and safety of ethyl propanoate, potentially expanding its applications and market reach.

Consumer trends towards clean label products and natural ingredients have led to increased demand for ethyl propanoate derived from natural sources. This has created opportunities for manufacturers to develop bio-based alternatives, potentially opening new market segments.

The competitive landscape of the ethyl propanoate market in food packaging is characterized by the presence of both large multinational corporations and smaller specialized chemical companies. Key players are investing in research and development to enhance product performance and expand their product portfolios.

Looking ahead, the market for ethyl propanoate in food packaging is projected to continue its growth trajectory. Factors such as increasing urbanization, rising demand for packaged foods in emerging economies, and ongoing innovations in food preservation technologies are expected to drive market expansion in the foreseeable future.

Current Applications and Challenges in Food Shelf-Life Extension

The current applications of ethyl propanoate in food shelf-life extension primarily focus on its use as a natural preservative and flavor enhancer. This compound, found naturally in fruits like pineapples and strawberries, has gained attention in the food industry due to its antimicrobial properties and pleasant fruity aroma. Many packaged food manufacturers are incorporating ethyl propanoate into their products to extend shelf life while maintaining a clean label approach.

One of the main applications of ethyl propanoate is in bakery products, where it helps prevent mold growth and maintain freshness. It is particularly effective in extending the shelf life of bread, pastries, and cakes. The compound's ability to inhibit microbial growth without significantly altering the taste or texture of baked goods has made it a popular choice among food producers seeking natural preservation methods.

In the beverage industry, ethyl propanoate is used to enhance flavor profiles and simultaneously extend product shelf life. It is commonly added to fruit juices, flavored waters, and soft drinks to provide a fruity note while also acting as a preservative. This dual functionality has made it an attractive option for beverage manufacturers looking to reduce the use of synthetic additives.

Despite its promising applications, the use of ethyl propanoate in food preservation faces several challenges. One of the primary concerns is achieving the right balance between effective preservation and maintaining optimal sensory qualities. While the compound can extend shelf life, excessive use may lead to off-flavors or overpowering fruity notes that could be undesirable in certain food products.

Another challenge lies in the stability of ethyl propanoate under various processing and storage conditions. The compound's effectiveness can be influenced by factors such as temperature, pH, and interaction with other food components. Ensuring consistent performance across different food matrices and environmental conditions remains a significant hurdle for food scientists and manufacturers.

The regulatory landscape also presents challenges for the widespread adoption of ethyl propanoate as a preservative. While it is generally recognized as safe (GRAS) by the FDA, regulations regarding its use and labeling can vary across different countries and regions. This regulatory complexity can complicate the formulation and marketing of products containing ethyl propanoate, especially for companies operating in multiple markets.

Furthermore, the cost-effectiveness of using ethyl propanoate compared to traditional preservatives is an ongoing consideration for food manufacturers. While it offers benefits in terms of natural labeling and consumer appeal, the production and incorporation of ethyl propanoate may be more expensive than synthetic alternatives. Balancing the cost with the perceived value and extended shelf life remains a challenge for many food companies.

One of the main applications of ethyl propanoate is in bakery products, where it helps prevent mold growth and maintain freshness. It is particularly effective in extending the shelf life of bread, pastries, and cakes. The compound's ability to inhibit microbial growth without significantly altering the taste or texture of baked goods has made it a popular choice among food producers seeking natural preservation methods.

In the beverage industry, ethyl propanoate is used to enhance flavor profiles and simultaneously extend product shelf life. It is commonly added to fruit juices, flavored waters, and soft drinks to provide a fruity note while also acting as a preservative. This dual functionality has made it an attractive option for beverage manufacturers looking to reduce the use of synthetic additives.

Despite its promising applications, the use of ethyl propanoate in food preservation faces several challenges. One of the primary concerns is achieving the right balance between effective preservation and maintaining optimal sensory qualities. While the compound can extend shelf life, excessive use may lead to off-flavors or overpowering fruity notes that could be undesirable in certain food products.

Another challenge lies in the stability of ethyl propanoate under various processing and storage conditions. The compound's effectiveness can be influenced by factors such as temperature, pH, and interaction with other food components. Ensuring consistent performance across different food matrices and environmental conditions remains a significant hurdle for food scientists and manufacturers.

The regulatory landscape also presents challenges for the widespread adoption of ethyl propanoate as a preservative. While it is generally recognized as safe (GRAS) by the FDA, regulations regarding its use and labeling can vary across different countries and regions. This regulatory complexity can complicate the formulation and marketing of products containing ethyl propanoate, especially for companies operating in multiple markets.

Furthermore, the cost-effectiveness of using ethyl propanoate compared to traditional preservatives is an ongoing consideration for food manufacturers. While it offers benefits in terms of natural labeling and consumer appeal, the production and incorporation of ethyl propanoate may be more expensive than synthetic alternatives. Balancing the cost with the perceived value and extended shelf life remains a challenge for many food companies.

Existing Ethyl Propanoate-Based Preservation Solutions

01 Storage conditions for ethyl propanoate

Proper storage conditions are crucial for extending the shelf life of ethyl propanoate. This includes controlling temperature, humidity, and light exposure. Storing the compound in a cool, dry place away from direct sunlight can significantly increase its longevity and maintain its chemical properties.- Storage conditions for ethyl propanoate: Proper storage conditions are crucial for extending the shelf life of ethyl propanoate. This includes maintaining appropriate temperature, humidity, and light exposure. Storing the compound in a cool, dry place away from direct sunlight can significantly increase its longevity and maintain its chemical properties.

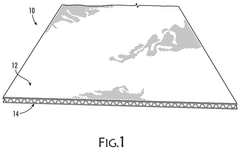

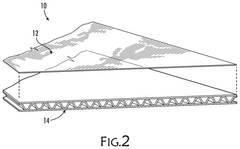

- Packaging materials for ethyl propanoate: The choice of packaging materials plays a vital role in preserving the shelf life of ethyl propanoate. Using inert materials that do not react with the compound, such as certain plastics or glass, can prevent degradation and contamination. Proper sealing techniques also help maintain the compound's purity and stability over time.

- Stabilizers and additives for ethyl propanoate: Incorporating stabilizers or additives into ethyl propanoate formulations can enhance its shelf life. These substances can prevent oxidation, hydrolysis, or other degradation processes that may occur over time. Careful selection of compatible stabilizers is essential to maintain the compound's effectiveness and safety.

- Quality control and monitoring of ethyl propanoate: Implementing rigorous quality control measures and regular monitoring of ethyl propanoate batches can help identify and address factors affecting shelf life. This may include periodic testing of chemical properties, purity levels, and stability under various conditions to ensure the compound remains within acceptable parameters throughout its intended shelf life.

- Manufacturing processes affecting ethyl propanoate shelf life: The manufacturing process of ethyl propanoate can significantly impact its shelf life. Optimizing production methods, purification techniques, and handling procedures can result in a more stable final product. Minimizing impurities and ensuring consistent quality during manufacturing contributes to extended shelf life and improved product reliability.

02 Packaging materials for ethyl propanoate

The choice of packaging material plays a vital role in preserving ethyl propanoate's shelf life. Using inert materials that do not react with the compound, such as certain plastics or glass, can prevent degradation and contamination. Proper sealing techniques also help maintain the compound's purity and extend its usable life.Expand Specific Solutions03 Stabilizers and additives for ethyl propanoate

Incorporating stabilizers or additives into ethyl propanoate formulations can significantly enhance its shelf life. These substances can prevent oxidation, hydrolysis, or other degradation processes that may occur over time. Careful selection of compatible stabilizers is essential to maintain the compound's intended properties and functionality.Expand Specific Solutions04 Quality control and monitoring of ethyl propanoate

Implementing robust quality control measures and regular monitoring of ethyl propanoate can help identify and address factors affecting its shelf life. This may include periodic testing of chemical properties, purity levels, and performance characteristics. Early detection of any changes can allow for timely interventions to extend the compound's usable life.Expand Specific Solutions05 Handling and transportation considerations

Proper handling and transportation procedures are essential for maintaining the shelf life of ethyl propanoate. This includes using appropriate containers, minimizing exposure to extreme temperatures or environmental conditions during transit, and following safety protocols to prevent contamination or degradation. Careful handling throughout the supply chain can significantly impact the compound's longevity.Expand Specific Solutions

Key Players in Food Additives and Packaging Industries

The competitive landscape for ethyl propanoate's impact on packaged food shelf-life is in a growth phase, with increasing market size due to rising demand for food preservation solutions. The technology's maturity is advancing, with major players like DuPont de Nemours, Cryovac LLC, and Frito-Lay North America actively developing and implementing related solutions. Research institutions such as the Indian Council of Agricultural Research and universities like Sabanci University are contributing to technological advancements. The market is characterized by a mix of established chemical companies, packaging specialists, and food manufacturers, indicating a diverse and competitive environment with potential for further innovation and market expansion.

Cryovac LLC

Technical Solution: Cryovac has pioneered a cryogenic packaging solution that incorporates ethyl propanoate to significantly extend the shelf-life of perishable foods. Their technology involves flash-freezing food products in an ethyl propanoate-enriched atmosphere, which forms microscopic ice crystals infused with the compound. As the product thaws, ethyl propanoate is gradually released, providing continuous antimicrobial and antioxidant protection[7]. Cryovac has also developed specialized packaging films that maintain the ethyl propanoate concentration within the package, ensuring long-term preservation effectiveness[8].

Strengths: Unique cryogenic approach combining freezing and ethyl propanoate preservation; suitable for a wide range of perishable foods. Weaknesses: Energy-intensive process; requires specialized storage and transportation conditions.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced packaging solutions incorporating ethyl propanoate to extend shelf-life in packaged foods. Their approach involves integrating ethyl propanoate into polymer matrices, creating active packaging materials that slowly release the compound over time. This controlled release mechanism helps maintain optimal concentrations of ethyl propanoate in the package headspace, effectively inhibiting microbial growth and oxidation processes[1]. DuPont's technology also includes a smart sensor system that monitors ethyl propanoate levels, ensuring consistent preservation throughout the product's shelf life[2].

Strengths: Innovative integration of ethyl propanoate into packaging materials; smart monitoring system for consistent preservation. Weaknesses: Potential higher cost of implementation; may require modifications to existing packaging processes.

Innovations in Ethyl Propanoate Synthesis and Application

Novel compound preservative formula based on ethyl lauroyl arginine and application mode suitable for preservation of chilled meat sausages

PatentActiveZA202109547A

Innovation

- A novel compound preservative formula based on ethyl lauroyl arginine, combined with Nisin and chitosan, is applied in various forms such as solutions, powders, emulsions, and solid lipid particles, to effectively inhibit microbial growth and extend the shelf life of chilled meat sausages.

Ethylene scavenging compositions with antimicrobial properties

PatentPendingUS20250136799A1

Innovation

- A composition with high ethylene scavenging ability and antimicrobial properties, comprising a base material like polyester combined with an ethylene scavenging agent and an antimicrobial agent, applied to storage containers to reduce ethylene levels and inhibit microbial growth, thereby extending the shelf life of produce.

Safety and Regulatory Considerations for Food Additives

The use of ethyl propanoate as a food additive to extend shelf life in packaged foods necessitates careful consideration of safety and regulatory aspects. Food additives are subject to stringent regulations to ensure consumer safety and maintain food quality. In the United States, the Food and Drug Administration (FDA) oversees the approval and use of food additives, including ethyl propanoate.

Ethyl propanoate is generally recognized as safe (GRAS) by the FDA when used in accordance with good manufacturing practices. However, its application in extending shelf life requires thorough evaluation to determine appropriate usage levels and potential interactions with different food matrices. Manufacturers must conduct comprehensive safety assessments, including toxicological studies and exposure assessments, to demonstrate the additive's safety at intended use levels.

Regulatory bodies worldwide have established acceptable daily intake (ADI) levels for ethyl propanoate. These levels are based on extensive scientific research and are designed to ensure that consumption remains well below any potential harmful threshold. Food producers must adhere to these guidelines and clearly label products containing ethyl propanoate in accordance with local regulations.

The European Food Safety Authority (EFSA) has also evaluated ethyl propanoate and established its own safety guidelines. Manufacturers exporting products containing this additive to the European Union must comply with EFSA regulations, which may differ from those in other regions. This highlights the importance of understanding and adhering to diverse international regulatory frameworks when using ethyl propanoate in globally distributed packaged foods.

Long-term studies on the effects of ethyl propanoate consumption are ongoing, as regulatory bodies continually review and update their guidelines based on emerging scientific evidence. Food producers must stay informed about any changes in regulations or safety assessments that may impact the use of ethyl propanoate as a shelf-life extender.

Additionally, the interaction between ethyl propanoate and packaging materials must be carefully evaluated to ensure no migration of harmful substances occurs. This involves testing the stability of the additive under various storage conditions and its potential to react with different packaging materials over time.

Manufacturers must also consider the impact of ethyl propanoate on the nutritional profile of packaged foods. While it may extend shelf life, it should not compromise the food's nutritional value or lead to the formation of potentially harmful compounds during storage. Comprehensive studies on the long-term effects of ethyl propanoate on food quality and safety are essential to maintain consumer trust and comply with regulatory standards.

Ethyl propanoate is generally recognized as safe (GRAS) by the FDA when used in accordance with good manufacturing practices. However, its application in extending shelf life requires thorough evaluation to determine appropriate usage levels and potential interactions with different food matrices. Manufacturers must conduct comprehensive safety assessments, including toxicological studies and exposure assessments, to demonstrate the additive's safety at intended use levels.

Regulatory bodies worldwide have established acceptable daily intake (ADI) levels for ethyl propanoate. These levels are based on extensive scientific research and are designed to ensure that consumption remains well below any potential harmful threshold. Food producers must adhere to these guidelines and clearly label products containing ethyl propanoate in accordance with local regulations.

The European Food Safety Authority (EFSA) has also evaluated ethyl propanoate and established its own safety guidelines. Manufacturers exporting products containing this additive to the European Union must comply with EFSA regulations, which may differ from those in other regions. This highlights the importance of understanding and adhering to diverse international regulatory frameworks when using ethyl propanoate in globally distributed packaged foods.

Long-term studies on the effects of ethyl propanoate consumption are ongoing, as regulatory bodies continually review and update their guidelines based on emerging scientific evidence. Food producers must stay informed about any changes in regulations or safety assessments that may impact the use of ethyl propanoate as a shelf-life extender.

Additionally, the interaction between ethyl propanoate and packaging materials must be carefully evaluated to ensure no migration of harmful substances occurs. This involves testing the stability of the additive under various storage conditions and its potential to react with different packaging materials over time.

Manufacturers must also consider the impact of ethyl propanoate on the nutritional profile of packaged foods. While it may extend shelf life, it should not compromise the food's nutritional value or lead to the formation of potentially harmful compounds during storage. Comprehensive studies on the long-term effects of ethyl propanoate on food quality and safety are essential to maintain consumer trust and comply with regulatory standards.

Environmental Impact of Ethyl Propanoate in Food Packaging

The environmental impact of ethyl propanoate in food packaging is a crucial consideration as the food industry seeks to balance shelf-life extension with sustainability. Ethyl propanoate, a naturally occurring ester, is increasingly used as a food preservative and flavoring agent in packaged foods. While it offers benefits in terms of prolonging shelf life, its widespread use raises questions about potential environmental consequences.

One of the primary environmental concerns associated with ethyl propanoate is its production process. The compound is typically synthesized through the esterification of propionic acid with ethanol, both of which are derived from petrochemical sources. This reliance on fossil fuels contributes to carbon emissions and resource depletion, raising sustainability issues in the manufacturing phase.

Furthermore, the disposal of packaging materials containing ethyl propanoate presents challenges. Although the compound is biodegradable, its presence in food packaging may complicate recycling processes. Recycling facilities may need to adapt their methods to effectively handle materials treated with this preservative, potentially increasing the energy and resource requirements of recycling operations.

The release of ethyl propanoate into the environment during the packaging lifecycle is another area of concern. While the compound is generally considered to have low toxicity, its accumulation in soil and water systems could potentially impact local ecosystems. Studies have shown that ethyl propanoate can affect the growth and behavior of certain microorganisms, which may have cascading effects on biodiversity and nutrient cycles in affected areas.

On the positive side, the use of ethyl propanoate in food packaging can indirectly contribute to reducing food waste. By extending the shelf life of packaged foods, it helps minimize the amount of spoiled food that ends up in landfills. This reduction in food waste can lead to decreased methane emissions from decomposing organic matter and conserve the resources used in food production and distribution.

The environmental impact of ethyl propanoate also extends to transportation and storage. Its effectiveness in preserving food quality may allow for less energy-intensive storage conditions and potentially reduce the frequency of transportation required for perishable goods. This could result in lower greenhouse gas emissions associated with the cold chain and food distribution networks.

As the food industry continues to explore innovative packaging solutions, there is growing interest in developing more sustainable alternatives to traditional preservatives like ethyl propanoate. Research into bio-based production methods and natural preservatives derived from renewable sources could potentially mitigate some of the environmental concerns associated with synthetic compounds.

One of the primary environmental concerns associated with ethyl propanoate is its production process. The compound is typically synthesized through the esterification of propionic acid with ethanol, both of which are derived from petrochemical sources. This reliance on fossil fuels contributes to carbon emissions and resource depletion, raising sustainability issues in the manufacturing phase.

Furthermore, the disposal of packaging materials containing ethyl propanoate presents challenges. Although the compound is biodegradable, its presence in food packaging may complicate recycling processes. Recycling facilities may need to adapt their methods to effectively handle materials treated with this preservative, potentially increasing the energy and resource requirements of recycling operations.

The release of ethyl propanoate into the environment during the packaging lifecycle is another area of concern. While the compound is generally considered to have low toxicity, its accumulation in soil and water systems could potentially impact local ecosystems. Studies have shown that ethyl propanoate can affect the growth and behavior of certain microorganisms, which may have cascading effects on biodiversity and nutrient cycles in affected areas.

On the positive side, the use of ethyl propanoate in food packaging can indirectly contribute to reducing food waste. By extending the shelf life of packaged foods, it helps minimize the amount of spoiled food that ends up in landfills. This reduction in food waste can lead to decreased methane emissions from decomposing organic matter and conserve the resources used in food production and distribution.

The environmental impact of ethyl propanoate also extends to transportation and storage. Its effectiveness in preserving food quality may allow for less energy-intensive storage conditions and potentially reduce the frequency of transportation required for perishable goods. This could result in lower greenhouse gas emissions associated with the cold chain and food distribution networks.

As the food industry continues to explore innovative packaging solutions, there is growing interest in developing more sustainable alternatives to traditional preservatives like ethyl propanoate. Research into bio-based production methods and natural preservatives derived from renewable sources could potentially mitigate some of the environmental concerns associated with synthetic compounds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!