Biocatalytic Transformations Involving Ethyl Propanoate in Biorefineries

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biocatalysis Background

Biocatalysis, a field at the intersection of biology and chemistry, has emerged as a powerful tool in the development of sustainable and efficient processes for biorefineries. This approach harnesses the catalytic power of enzymes to perform chemical transformations under mild conditions, offering numerous advantages over traditional chemical catalysis.

The history of biocatalysis dates back to ancient times when fermentation processes were used to produce food and beverages. However, it wasn't until the late 19th and early 20th centuries that the scientific understanding of enzymes and their potential in industrial applications began to take shape. The discovery of penicillin and its large-scale production in the 1940s marked a significant milestone in the field of biocatalysis.

In recent decades, advancements in molecular biology, protein engineering, and process technology have revolutionized biocatalysis, enabling its application in various industries, including pharmaceuticals, fine chemicals, and biofuels. The ability to engineer enzymes for improved stability, selectivity, and activity has greatly expanded the scope of biocatalytic transformations.

Biorefineries, which aim to convert biomass into value-added products, have become a key focus area for biocatalysis. These facilities seek to maximize the utilization of renewable resources while minimizing waste and environmental impact. Biocatalytic processes play a crucial role in biorefineries by enabling the efficient conversion of complex biomolecules into desired products under environmentally friendly conditions.

Ethyl propanoate, a common ester used in various industries, has gained attention as a potential platform chemical in biorefineries. Its production and transformation through biocatalytic routes offer several advantages over traditional chemical methods. Enzymes such as lipases and esterases can catalyze the synthesis and hydrolysis of ethyl propanoate with high selectivity and efficiency.

The use of biocatalysts in ethyl propanoate transformations aligns with the principles of green chemistry, as it reduces the need for harsh reaction conditions and toxic solvents. Additionally, the high specificity of enzymes can lead to improved product purity and reduced waste generation, addressing key challenges in biorefinery operations.

As research in this field progresses, new enzyme discovery and engineering techniques are continually expanding the toolbox of biocatalysts available for ethyl propanoate transformations. This ongoing development promises to unlock novel pathways for the production of valuable chemicals and materials from renewable resources, furthering the goals of sustainable industrial processes and circular bioeconomy.

The history of biocatalysis dates back to ancient times when fermentation processes were used to produce food and beverages. However, it wasn't until the late 19th and early 20th centuries that the scientific understanding of enzymes and their potential in industrial applications began to take shape. The discovery of penicillin and its large-scale production in the 1940s marked a significant milestone in the field of biocatalysis.

In recent decades, advancements in molecular biology, protein engineering, and process technology have revolutionized biocatalysis, enabling its application in various industries, including pharmaceuticals, fine chemicals, and biofuels. The ability to engineer enzymes for improved stability, selectivity, and activity has greatly expanded the scope of biocatalytic transformations.

Biorefineries, which aim to convert biomass into value-added products, have become a key focus area for biocatalysis. These facilities seek to maximize the utilization of renewable resources while minimizing waste and environmental impact. Biocatalytic processes play a crucial role in biorefineries by enabling the efficient conversion of complex biomolecules into desired products under environmentally friendly conditions.

Ethyl propanoate, a common ester used in various industries, has gained attention as a potential platform chemical in biorefineries. Its production and transformation through biocatalytic routes offer several advantages over traditional chemical methods. Enzymes such as lipases and esterases can catalyze the synthesis and hydrolysis of ethyl propanoate with high selectivity and efficiency.

The use of biocatalysts in ethyl propanoate transformations aligns with the principles of green chemistry, as it reduces the need for harsh reaction conditions and toxic solvents. Additionally, the high specificity of enzymes can lead to improved product purity and reduced waste generation, addressing key challenges in biorefinery operations.

As research in this field progresses, new enzyme discovery and engineering techniques are continually expanding the toolbox of biocatalysts available for ethyl propanoate transformations. This ongoing development promises to unlock novel pathways for the production of valuable chemicals and materials from renewable resources, furthering the goals of sustainable industrial processes and circular bioeconomy.

Market Analysis

The market for biocatalytic transformations involving ethyl propanoate in biorefineries is experiencing significant growth, driven by the increasing demand for sustainable and eco-friendly production processes in various industries. Ethyl propanoate, also known as ethyl propionate, is a versatile compound used in flavors, fragrances, solvents, and as a precursor for other chemicals. The shift towards bio-based production methods has created new opportunities for this compound in the biorefinery sector.

The global biorefinery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2030. Within this broader market, the segment focusing on biocatalytic transformations is gaining traction due to its potential for improved efficiency and reduced environmental impact. The use of enzymes and microorganisms to catalyze the production or transformation of ethyl propanoate aligns well with the principles of green chemistry and circular economy.

Key industries driving the demand for biocatalytic processes involving ethyl propanoate include food and beverage, cosmetics, pharmaceuticals, and agrochemicals. The food and beverage sector, in particular, shows strong growth potential as consumers increasingly prefer natural flavors and ingredients. Ethyl propanoate's fruity aroma makes it a popular choice in this industry.

Geographically, North America and Europe currently lead the market for biocatalytic transformations in biorefineries, owing to their advanced biotechnology sectors and stringent environmental regulations. However, Asia-Pacific is emerging as a rapidly growing market, fueled by increasing industrialization and a rising focus on sustainable technologies in countries like China and India.

The market is characterized by a mix of established chemical companies diversifying into bio-based production and innovative biotech startups specializing in enzyme engineering and fermentation technologies. Collaborations between academic institutions and industry players are also driving advancements in this field, leading to more efficient and cost-effective biocatalytic processes.

Challenges in the market include the need for further optimization of biocatalytic processes to compete with traditional chemical synthesis methods in terms of yield and cost-effectiveness. Additionally, scaling up these processes from laboratory to industrial levels presents technical and economic hurdles that need to be addressed.

Despite these challenges, the market outlook remains positive. The growing emphasis on sustainability, coupled with advancements in enzyme engineering and process technologies, is expected to drive continued innovation and adoption of biocatalytic transformations involving ethyl propanoate in biorefineries. This trend is likely to create new market opportunities and reshape the competitive landscape in the coming years.

The global biorefinery market is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 10% through 2030. Within this broader market, the segment focusing on biocatalytic transformations is gaining traction due to its potential for improved efficiency and reduced environmental impact. The use of enzymes and microorganisms to catalyze the production or transformation of ethyl propanoate aligns well with the principles of green chemistry and circular economy.

Key industries driving the demand for biocatalytic processes involving ethyl propanoate include food and beverage, cosmetics, pharmaceuticals, and agrochemicals. The food and beverage sector, in particular, shows strong growth potential as consumers increasingly prefer natural flavors and ingredients. Ethyl propanoate's fruity aroma makes it a popular choice in this industry.

Geographically, North America and Europe currently lead the market for biocatalytic transformations in biorefineries, owing to their advanced biotechnology sectors and stringent environmental regulations. However, Asia-Pacific is emerging as a rapidly growing market, fueled by increasing industrialization and a rising focus on sustainable technologies in countries like China and India.

The market is characterized by a mix of established chemical companies diversifying into bio-based production and innovative biotech startups specializing in enzyme engineering and fermentation technologies. Collaborations between academic institutions and industry players are also driving advancements in this field, leading to more efficient and cost-effective biocatalytic processes.

Challenges in the market include the need for further optimization of biocatalytic processes to compete with traditional chemical synthesis methods in terms of yield and cost-effectiveness. Additionally, scaling up these processes from laboratory to industrial levels presents technical and economic hurdles that need to be addressed.

Despite these challenges, the market outlook remains positive. The growing emphasis on sustainability, coupled with advancements in enzyme engineering and process technologies, is expected to drive continued innovation and adoption of biocatalytic transformations involving ethyl propanoate in biorefineries. This trend is likely to create new market opportunities and reshape the competitive landscape in the coming years.

Technical Challenges

The biocatalytic transformation of ethyl propanoate in biorefineries faces several technical challenges that need to be addressed for efficient and sustainable production. One of the primary obstacles is the limited stability of enzymes under industrial conditions. Enzymes used in these transformations often degrade or lose activity when exposed to high temperatures, extreme pH levels, or organic solvents commonly found in biorefinery processes.

Another significant challenge is the low catalytic efficiency of enzymes for ethyl propanoate transformations. Many naturally occurring enzymes exhibit suboptimal activity and selectivity towards this substrate, resulting in slow reaction rates and reduced yields. This necessitates the development of improved biocatalysts through protein engineering or directed evolution techniques.

The presence of inhibitory compounds in biorefinery feedstocks poses a substantial hurdle for biocatalytic processes. Lignocellulosic biomass, a common feedstock in biorefineries, contains various inhibitors such as phenolic compounds and furans that can significantly impair enzyme activity and stability. Overcoming this inhibition is crucial for maintaining high catalytic performance and process efficiency.

Scale-up and process integration present additional technical challenges. Transitioning from laboratory-scale experiments to industrial-scale production often encounters issues related to mass transfer limitations, heat dissipation, and maintaining optimal reaction conditions in large bioreactors. Integrating biocatalytic transformations into existing biorefinery processes while ensuring compatibility with upstream and downstream operations is also a complex task.

The recovery and recycling of enzymes represent another technical hurdle. Efficient methods for separating and reusing biocatalysts are essential for improving the economic viability of these processes. However, developing effective immobilization techniques or membrane-based separation systems that maintain enzyme activity and stability remains challenging.

Furthermore, controlling the stereoselectivity of biocatalytic reactions involving ethyl propanoate is crucial for producing high-value chiral compounds. Achieving high enantioselectivity while maintaining high conversion rates often requires fine-tuning of reaction conditions and enzyme properties, which can be technically demanding.

Lastly, the development of robust and scalable enzyme production systems is a significant challenge. Establishing efficient expression hosts and optimizing fermentation processes for large-scale enzyme production are essential for ensuring a stable and cost-effective supply of biocatalysts for industrial applications in biorefineries.

Another significant challenge is the low catalytic efficiency of enzymes for ethyl propanoate transformations. Many naturally occurring enzymes exhibit suboptimal activity and selectivity towards this substrate, resulting in slow reaction rates and reduced yields. This necessitates the development of improved biocatalysts through protein engineering or directed evolution techniques.

The presence of inhibitory compounds in biorefinery feedstocks poses a substantial hurdle for biocatalytic processes. Lignocellulosic biomass, a common feedstock in biorefineries, contains various inhibitors such as phenolic compounds and furans that can significantly impair enzyme activity and stability. Overcoming this inhibition is crucial for maintaining high catalytic performance and process efficiency.

Scale-up and process integration present additional technical challenges. Transitioning from laboratory-scale experiments to industrial-scale production often encounters issues related to mass transfer limitations, heat dissipation, and maintaining optimal reaction conditions in large bioreactors. Integrating biocatalytic transformations into existing biorefinery processes while ensuring compatibility with upstream and downstream operations is also a complex task.

The recovery and recycling of enzymes represent another technical hurdle. Efficient methods for separating and reusing biocatalysts are essential for improving the economic viability of these processes. However, developing effective immobilization techniques or membrane-based separation systems that maintain enzyme activity and stability remains challenging.

Furthermore, controlling the stereoselectivity of biocatalytic reactions involving ethyl propanoate is crucial for producing high-value chiral compounds. Achieving high enantioselectivity while maintaining high conversion rates often requires fine-tuning of reaction conditions and enzyme properties, which can be technically demanding.

Lastly, the development of robust and scalable enzyme production systems is a significant challenge. Establishing efficient expression hosts and optimizing fermentation processes for large-scale enzyme production are essential for ensuring a stable and cost-effective supply of biocatalysts for industrial applications in biorefineries.

Current Solutions

01 Synthesis and production methods

Various methods for synthesizing and producing ethyl propanoate are described. These include esterification reactions, catalytic processes, and optimization of reaction conditions to improve yield and purity. The methods aim to enhance efficiency and reduce costs in industrial production of this ester.- Synthesis methods for ethyl propanoate: Various methods for synthesizing ethyl propanoate are described, including esterification reactions between propionic acid and ethanol, as well as catalytic processes using different catalysts and reaction conditions. These methods aim to improve yield, selectivity, and efficiency in the production of ethyl propanoate.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is employed in the formulation of various perfumes, cosmetics, and food flavorings. The compound's low toxicity and pleasant aroma make it a popular choice for these applications.

- Use as a solvent and intermediate: Ethyl propanoate serves as an important solvent in various industrial processes, particularly in the production of paints, inks, and adhesives. It is also used as a chemical intermediate in the synthesis of other compounds, including pharmaceuticals and agrochemicals.

- Purification and separation techniques: Various methods for purifying and separating ethyl propanoate from reaction mixtures or other compounds are described. These techniques include distillation, extraction, and chromatography, aimed at obtaining high-purity ethyl propanoate for industrial and research applications.

- Environmental and safety considerations: Research and development efforts focus on improving the environmental impact and safety aspects of ethyl propanoate production and use. This includes developing greener synthesis methods, reducing waste generation, and implementing safer handling procedures in industrial settings.

02 Applications in flavor and fragrance industry

Ethyl propanoate is widely used in the flavor and fragrance industry due to its fruity aroma. It is employed in creating artificial fruit flavors, particularly for pineapple and strawberry notes. The compound is also utilized in perfumery to add fresh, fruity accents to various fragrances.Expand Specific Solutions03 Use as a solvent and intermediate

Ethyl propanoate serves as a versatile solvent in various industrial applications, including paints, coatings, and adhesives. It is also used as an intermediate in the synthesis of other chemicals and pharmaceutical compounds, demonstrating its importance in chemical manufacturing processes.Expand Specific Solutions04 Purification and quality control

Methods for purifying ethyl propanoate and ensuring its quality are described. These include distillation techniques, chromatographic separation, and analytical methods for determining purity and identifying impurities. Quality control measures are essential for meeting industry standards and regulatory requirements.Expand Specific Solutions05 Environmental and safety considerations

Research and development efforts focus on improving the environmental profile and safety aspects of ethyl propanoate production and use. This includes developing green synthesis methods, reducing waste generation, and implementing safety measures for handling and storage of the compound in industrial settings.Expand Specific Solutions

Industry Leaders

The biocatalytic transformations involving ethyl propanoate in biorefineries represent an emerging field with significant potential for sustainable chemical production. The industry is in its early growth stage, characterized by ongoing research and development efforts. While the market size is still relatively small, it is expected to expand as bio-based alternatives gain traction. Companies like Novozymes, BASF, and Braskem are at the forefront, leveraging their expertise in enzymes and biotechnology to develop innovative solutions. Academic institutions such as Zhejiang University and the University of Campinas are contributing valuable research. The technology is progressing but still evolving, with opportunities for further optimization and scale-up to enhance commercial viability.

Novozymes A/S

Technical Solution: Novozymes A/S has developed advanced enzyme technologies for biocatalytic transformations involving ethyl propanoate in biorefineries. Their approach utilizes engineered esterases and lipases to catalyze the hydrolysis of ethyl propanoate into propionic acid and ethanol [1]. These enzymes are optimized for high activity and stability under biorefinery conditions, including elevated temperatures and varying pH levels. Novozymes has also implemented immobilization techniques to enhance enzyme reusability and operational stability [3]. Their process integrates seamlessly with existing biorefinery infrastructure, allowing for efficient production of valuable chemicals from renewable feedstocks [5].

Strengths: High enzyme efficiency and stability, seamless integration with existing biorefinery processes. Weaknesses: Potential high costs associated with enzyme production and immobilization.

BASF Corp.

Technical Solution: BASF Corp. has developed a comprehensive approach to biocatalytic transformations involving ethyl propanoate in biorefineries. Their strategy combines chemical catalysis with biocatalysis, utilizing a hybrid process that maximizes efficiency and yield [2]. BASF's method employs specially designed heterogeneous catalysts for the initial conversion of biomass to ethyl propanoate, followed by enzymatic hydrolysis using tailored lipases [4]. This two-step process allows for better control over reaction conditions and product selectivity. Additionally, BASF has implemented advanced separation technologies to purify the resulting propionic acid and ethanol, ensuring high-quality end products [6].

Strengths: Hybrid approach combining chemical and biological catalysis, high product purity. Weaknesses: Complex process may require specialized equipment and expertise.

Key Innovations

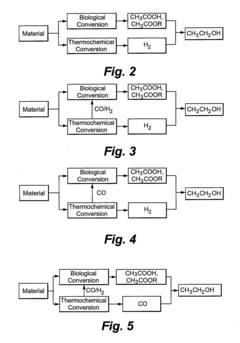

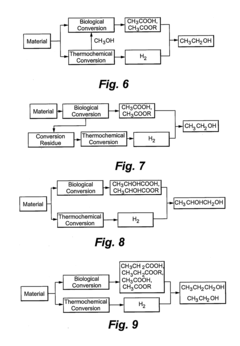

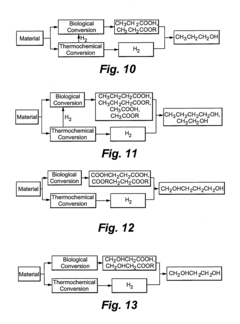

Energy efficient methods to produce products

PatentInactiveUS20130189752A1

Innovation

- A method combining biological and thermochemical conversion processes to produce intermediates, where biological processes convert carbohydrate substances and thermochemical processes convert non-carbohydrate substances, then reacting these intermediates to form the final product, thereby enhancing energy and mass transfer efficiency.

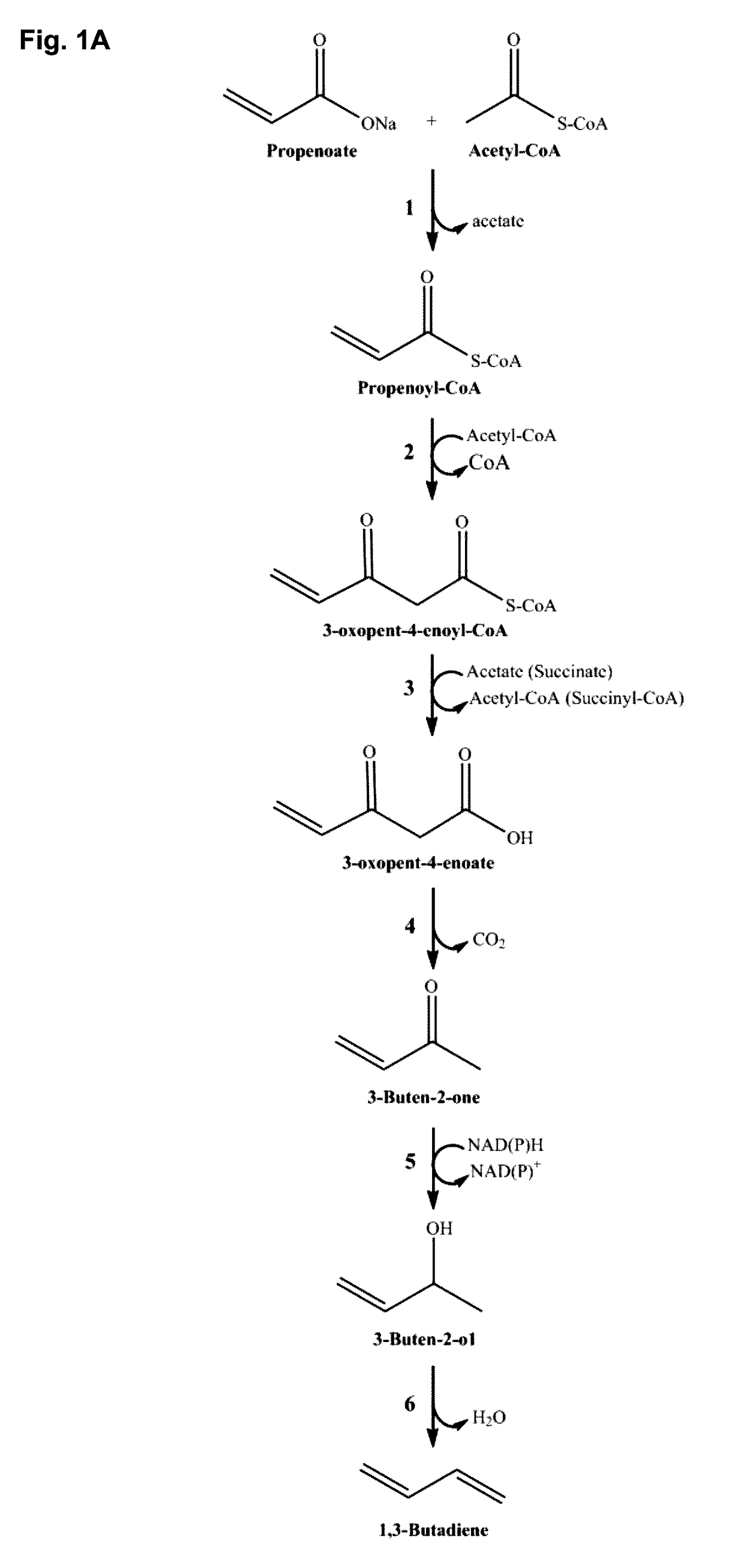

Polypeptides for carbon-carbon bond formation and uses thereof

PatentActiveUS20170159031A1

Innovation

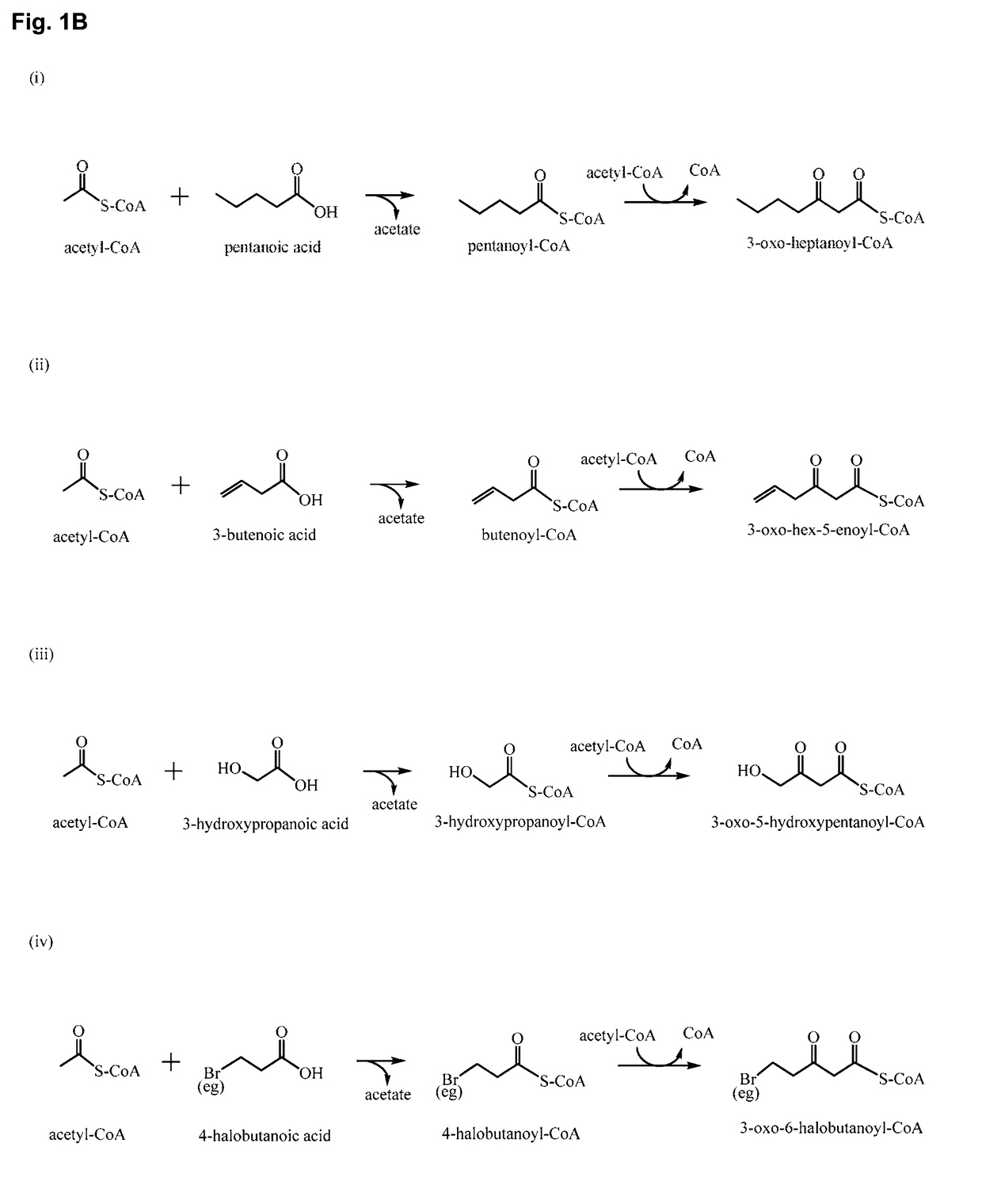

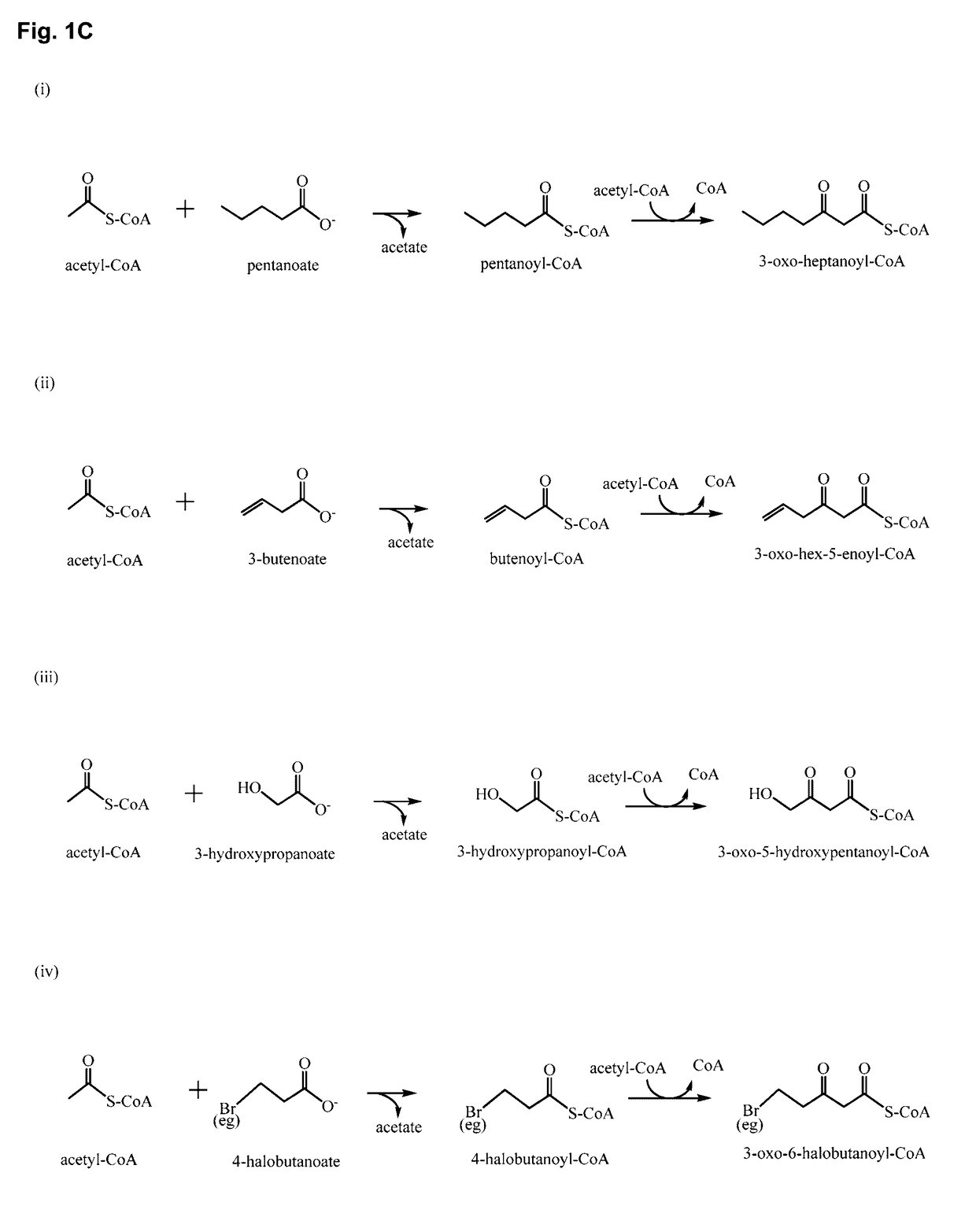

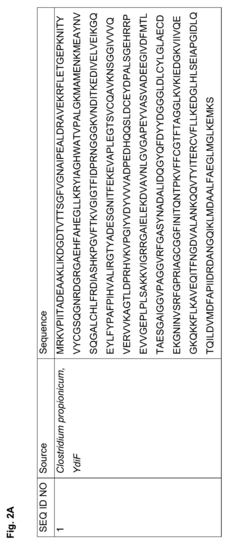

- Development of polypeptides with dual CoA transferase and β-ketothiolase activities, classified under EC 2.8.3., which can catalyze CoA transfer and Claisen condensation to produce 3-keto-acyl-CoA esters from acetyl-CoA with alkanoic, alkenoic, hydroxy-, or halo-acids, enabling the production of longer chain 3-keto acids and derivatives.

Sustainability Impact

The integration of biocatalytic transformations involving ethyl propanoate in biorefineries presents significant sustainability impacts across multiple dimensions. From an environmental perspective, these processes offer substantial benefits in terms of reduced energy consumption and greenhouse gas emissions compared to traditional chemical synthesis methods. The use of enzymes as catalysts allows for milder reaction conditions, typically at ambient temperatures and pressures, leading to lower energy requirements and a smaller carbon footprint.

Furthermore, biocatalytic transformations often exhibit higher selectivity and specificity, resulting in fewer by-products and waste streams. This increased efficiency not only reduces the environmental burden associated with waste disposal but also improves resource utilization, aligning with circular economy principles. The biodegradability of enzymes and their ability to operate in aqueous environments further contribute to the overall environmental sustainability of these processes.

From an economic standpoint, the implementation of biocatalytic transformations can lead to cost savings in several areas. The reduced energy requirements and improved atom economy translate to lower operational costs for biorefineries. Additionally, the high selectivity of enzymatic reactions often results in simpler downstream processing and purification steps, further reducing production costs and resource consumption.

The use of renewable feedstocks, such as biomass-derived ethyl propanoate, in these transformations supports the transition towards a bio-based economy. This shift away from fossil fuel-dependent processes enhances the long-term sustainability of the chemical industry and contributes to energy security by diversifying raw material sources.

In terms of social sustainability, the development and implementation of biocatalytic processes can drive innovation and create high-skilled job opportunities in the biotechnology and biorefinery sectors. This can contribute to rural development and economic diversification in regions where biorefineries are established.

However, it is important to consider potential challenges and trade-offs. The production of enzymes and their immobilization may have associated environmental impacts that need to be carefully assessed through comprehensive life cycle analyses. Additionally, the scalability and long-term stability of biocatalytic processes must be addressed to ensure their viability in industrial settings.

Overall, the integration of biocatalytic transformations involving ethyl propanoate in biorefineries offers a promising pathway towards more sustainable chemical production. By harnessing the power of enzymes and renewable resources, these processes have the potential to significantly reduce environmental impacts, improve economic efficiency, and contribute to the development of a more sustainable and resilient chemical industry.

Furthermore, biocatalytic transformations often exhibit higher selectivity and specificity, resulting in fewer by-products and waste streams. This increased efficiency not only reduces the environmental burden associated with waste disposal but also improves resource utilization, aligning with circular economy principles. The biodegradability of enzymes and their ability to operate in aqueous environments further contribute to the overall environmental sustainability of these processes.

From an economic standpoint, the implementation of biocatalytic transformations can lead to cost savings in several areas. The reduced energy requirements and improved atom economy translate to lower operational costs for biorefineries. Additionally, the high selectivity of enzymatic reactions often results in simpler downstream processing and purification steps, further reducing production costs and resource consumption.

The use of renewable feedstocks, such as biomass-derived ethyl propanoate, in these transformations supports the transition towards a bio-based economy. This shift away from fossil fuel-dependent processes enhances the long-term sustainability of the chemical industry and contributes to energy security by diversifying raw material sources.

In terms of social sustainability, the development and implementation of biocatalytic processes can drive innovation and create high-skilled job opportunities in the biotechnology and biorefinery sectors. This can contribute to rural development and economic diversification in regions where biorefineries are established.

However, it is important to consider potential challenges and trade-offs. The production of enzymes and their immobilization may have associated environmental impacts that need to be carefully assessed through comprehensive life cycle analyses. Additionally, the scalability and long-term stability of biocatalytic processes must be addressed to ensure their viability in industrial settings.

Overall, the integration of biocatalytic transformations involving ethyl propanoate in biorefineries offers a promising pathway towards more sustainable chemical production. By harnessing the power of enzymes and renewable resources, these processes have the potential to significantly reduce environmental impacts, improve economic efficiency, and contribute to the development of a more sustainable and resilient chemical industry.

Regulatory Framework

The regulatory framework surrounding biocatalytic transformations involving ethyl propanoate in biorefineries is complex and multifaceted, encompassing various aspects of environmental protection, product safety, and industrial processes. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) provide guidelines and recommendations for sustainable biorefinery practices, including the use of biocatalysts.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating biorefineries and their processes. The Toxic Substances Control Act (TSCA) and the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) are key pieces of legislation that govern the use of biocatalysts and the production of bio-based chemicals. The EPA's Renewable Fuel Standard (RFS) program also impacts biorefineries by setting requirements for the production and use of renewable fuels.

The European Union has established a comprehensive regulatory framework for biorefineries and biocatalytic processes. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation is particularly relevant, as it requires manufacturers and importers to assess and manage the risks associated with the substances they produce or import. The EU's Renewable Energy Directive (RED) and its successor, RED II, set targets for renewable energy use and provide sustainability criteria for biofuels and bioliquids.

Specific to biocatalytic transformations involving ethyl propanoate, regulations focus on ensuring the safety and quality of the final products, as well as the environmental impact of the production process. Good Manufacturing Practices (GMP) and Good Laboratory Practices (GLP) are essential standards that biorefineries must adhere to, particularly when producing materials for food, pharmaceutical, or cosmetic applications.

Waste management and disposal regulations are also critical for biorefineries. In many jurisdictions, the by-products and waste streams from biocatalytic processes must be carefully managed to comply with local and national environmental regulations. This often includes requirements for proper treatment and disposal of organic waste and potentially hazardous materials.

As the field of biocatalysis continues to evolve, regulatory frameworks are likely to adapt to address new challenges and opportunities. Emerging areas of focus include the regulation of genetically modified organisms (GMOs) used as biocatalysts, the development of standards for bio-based products, and the implementation of circular economy principles in biorefinery operations. Policymakers and industry stakeholders are working to strike a balance between fostering innovation in biocatalytic technologies and ensuring the safety and sustainability of biorefinery processes.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating biorefineries and their processes. The Toxic Substances Control Act (TSCA) and the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) are key pieces of legislation that govern the use of biocatalysts and the production of bio-based chemicals. The EPA's Renewable Fuel Standard (RFS) program also impacts biorefineries by setting requirements for the production and use of renewable fuels.

The European Union has established a comprehensive regulatory framework for biorefineries and biocatalytic processes. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation is particularly relevant, as it requires manufacturers and importers to assess and manage the risks associated with the substances they produce or import. The EU's Renewable Energy Directive (RED) and its successor, RED II, set targets for renewable energy use and provide sustainability criteria for biofuels and bioliquids.

Specific to biocatalytic transformations involving ethyl propanoate, regulations focus on ensuring the safety and quality of the final products, as well as the environmental impact of the production process. Good Manufacturing Practices (GMP) and Good Laboratory Practices (GLP) are essential standards that biorefineries must adhere to, particularly when producing materials for food, pharmaceutical, or cosmetic applications.

Waste management and disposal regulations are also critical for biorefineries. In many jurisdictions, the by-products and waste streams from biocatalytic processes must be carefully managed to comply with local and national environmental regulations. This often includes requirements for proper treatment and disposal of organic waste and potentially hazardous materials.

As the field of biocatalysis continues to evolve, regulatory frameworks are likely to adapt to address new challenges and opportunities. Emerging areas of focus include the regulation of genetically modified organisms (GMOs) used as biocatalysts, the development of standards for bio-based products, and the implementation of circular economy principles in biorefinery operations. Policymakers and industry stakeholders are working to strike a balance between fostering innovation in biocatalytic technologies and ensuring the safety and sustainability of biorefinery processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!