How Ethyl Propanoate Enhances Biodiesel Flow Properties

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate in Biodiesel: Background and Objectives

Ethyl propanoate, also known as ethyl propionate, has emerged as a promising additive in the biodiesel industry, particularly for its potential to enhance the flow properties of biodiesel fuels. The development of this technology is rooted in the ongoing quest for sustainable and efficient alternative energy sources. As global concerns about climate change and fossil fuel depletion continue to grow, biodiesel has gained significant attention as a renewable fuel option.

The journey of biodiesel as an alternative fuel began in the late 20th century, with early experiments focusing on the transesterification of vegetable oils. However, one of the persistent challenges in biodiesel adoption has been its poor cold flow properties, which can lead to fuel solidification and engine problems in low-temperature environments. This limitation has spurred research into various additives and blending components to improve biodiesel's performance across a wide range of temperatures.

Ethyl propanoate entered the biodiesel landscape as researchers explored ester-based additives for their potential to modify the crystallization behavior of biodiesel at low temperatures. The compound's chemical structure, featuring a short-chain ester, suggested promising interactions with the long-chain fatty acid methyl esters (FAMEs) that constitute biodiesel.

The primary objective of incorporating ethyl propanoate into biodiesel is to enhance its flow properties, particularly in cold weather conditions. This enhancement aims to address several key issues:

1. Improving the cold flow behavior of biodiesel, reducing the cloud point and pour point temperatures.

2. Enhancing the overall stability and homogeneity of biodiesel blends.

3. Mitigating the risk of fuel line and filter clogging in cold climates.

4. Expanding the geographical and seasonal applicability of biodiesel fuels.

As research in this area progresses, the technology is expected to evolve towards optimizing the concentration and blending techniques of ethyl propanoate in biodiesel. Future developments may also focus on synergistic effects with other additives and the potential for custom-tailored biodiesel formulations for specific climatic conditions or engine types.

The exploration of ethyl propanoate as a biodiesel additive aligns with broader trends in the renewable energy sector, including the push for drop-in biofuels and the development of multi-functional fuel additives. As such, this technology represents a critical step in the ongoing refinement of biodiesel as a viable and versatile alternative to conventional diesel fuel.

The journey of biodiesel as an alternative fuel began in the late 20th century, with early experiments focusing on the transesterification of vegetable oils. However, one of the persistent challenges in biodiesel adoption has been its poor cold flow properties, which can lead to fuel solidification and engine problems in low-temperature environments. This limitation has spurred research into various additives and blending components to improve biodiesel's performance across a wide range of temperatures.

Ethyl propanoate entered the biodiesel landscape as researchers explored ester-based additives for their potential to modify the crystallization behavior of biodiesel at low temperatures. The compound's chemical structure, featuring a short-chain ester, suggested promising interactions with the long-chain fatty acid methyl esters (FAMEs) that constitute biodiesel.

The primary objective of incorporating ethyl propanoate into biodiesel is to enhance its flow properties, particularly in cold weather conditions. This enhancement aims to address several key issues:

1. Improving the cold flow behavior of biodiesel, reducing the cloud point and pour point temperatures.

2. Enhancing the overall stability and homogeneity of biodiesel blends.

3. Mitigating the risk of fuel line and filter clogging in cold climates.

4. Expanding the geographical and seasonal applicability of biodiesel fuels.

As research in this area progresses, the technology is expected to evolve towards optimizing the concentration and blending techniques of ethyl propanoate in biodiesel. Future developments may also focus on synergistic effects with other additives and the potential for custom-tailored biodiesel formulations for specific climatic conditions or engine types.

The exploration of ethyl propanoate as a biodiesel additive aligns with broader trends in the renewable energy sector, including the push for drop-in biofuels and the development of multi-functional fuel additives. As such, this technology represents a critical step in the ongoing refinement of biodiesel as a viable and versatile alternative to conventional diesel fuel.

Market Analysis for Enhanced Biodiesel Flow Properties

The market for enhanced biodiesel flow properties is experiencing significant growth, driven by the increasing demand for cleaner and more efficient alternative fuels. As environmental concerns and stringent regulations push for reduced carbon emissions, biodiesel has emerged as a promising solution in the transportation and energy sectors. However, the inherent challenges associated with biodiesel's flow properties, particularly in cold weather conditions, have created a substantial market opportunity for flow-enhancing additives like ethyl propanoate.

The global biodiesel market is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years, with a corresponding increase in demand for flow improvers. This growth is particularly pronounced in regions with colder climates, where biodiesel's poor cold flow properties can lead to operational issues in engines and fuel systems. North America and Europe are currently the largest markets for biodiesel flow improvers, with Asia-Pacific showing rapid growth potential due to increasing biodiesel adoption in countries like India and China.

The market for biodiesel flow enhancers is characterized by a diverse range of products, including various esters, polymers, and copolymers. Ethyl propanoate, as a novel and effective flow improver, is poised to capture a significant share of this market due to its superior performance and compatibility with existing biodiesel formulations. The additive market for biodiesel is expected to grow faster than the overall biodiesel market, as manufacturers seek to improve the quality and performance of their products to meet evolving industry standards and consumer expectations.

Key market drivers include the push for higher biodiesel blends in conventional diesel fuels, which necessitates improved cold flow properties to ensure year-round operability. Additionally, the expansion of biodiesel use in heavy-duty vehicles and marine applications is creating new opportunities for flow enhancers that can maintain fuel performance under diverse operating conditions. The aviation industry's growing interest in sustainable aviation fuels (SAFs) also presents a potential new market for biodiesel flow improvers, as these fuels face similar challenges in low-temperature environments.

Market challenges include the need for cost-effective solutions that do not significantly increase the overall price of biodiesel, as well as regulatory hurdles related to the introduction of new additives in fuel formulations. However, the potential benefits of improved flow properties, including enhanced engine performance, reduced maintenance costs, and expanded geographical usage of biodiesel, are expected to outweigh these challenges and drive continued market growth for flow-enhancing additives like ethyl propanoate.

The global biodiesel market is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years, with a corresponding increase in demand for flow improvers. This growth is particularly pronounced in regions with colder climates, where biodiesel's poor cold flow properties can lead to operational issues in engines and fuel systems. North America and Europe are currently the largest markets for biodiesel flow improvers, with Asia-Pacific showing rapid growth potential due to increasing biodiesel adoption in countries like India and China.

The market for biodiesel flow enhancers is characterized by a diverse range of products, including various esters, polymers, and copolymers. Ethyl propanoate, as a novel and effective flow improver, is poised to capture a significant share of this market due to its superior performance and compatibility with existing biodiesel formulations. The additive market for biodiesel is expected to grow faster than the overall biodiesel market, as manufacturers seek to improve the quality and performance of their products to meet evolving industry standards and consumer expectations.

Key market drivers include the push for higher biodiesel blends in conventional diesel fuels, which necessitates improved cold flow properties to ensure year-round operability. Additionally, the expansion of biodiesel use in heavy-duty vehicles and marine applications is creating new opportunities for flow enhancers that can maintain fuel performance under diverse operating conditions. The aviation industry's growing interest in sustainable aviation fuels (SAFs) also presents a potential new market for biodiesel flow improvers, as these fuels face similar challenges in low-temperature environments.

Market challenges include the need for cost-effective solutions that do not significantly increase the overall price of biodiesel, as well as regulatory hurdles related to the introduction of new additives in fuel formulations. However, the potential benefits of improved flow properties, including enhanced engine performance, reduced maintenance costs, and expanded geographical usage of biodiesel, are expected to outweigh these challenges and drive continued market growth for flow-enhancing additives like ethyl propanoate.

Current Challenges in Biodiesel Flow Characteristics

Biodiesel, as a renewable and environmentally friendly alternative to conventional diesel fuel, has gained significant attention in recent years. However, one of the primary challenges facing the widespread adoption of biodiesel is its flow properties, particularly at low temperatures. The poor cold flow characteristics of biodiesel can lead to operational issues in engines, especially in colder climates.

The main problem stems from the higher cloud point and pour point of biodiesel compared to petroleum diesel. The cloud point is the temperature at which wax crystals begin to form in the fuel, while the pour point is the lowest temperature at which the fuel can still flow. For biodiesel, these points are typically higher than those of conventional diesel, leading to potential clogging of fuel lines and filters in cold weather.

Another significant challenge is the higher viscosity of biodiesel, which can affect fuel atomization and combustion efficiency. This increased viscosity can lead to poor fuel spray characteristics, incomplete combustion, and increased emissions. It also puts additional stress on fuel pumps and injection systems, potentially leading to premature wear and reduced engine performance.

The oxidative stability of biodiesel is another area of concern. Biodiesel is more prone to oxidation than petroleum diesel, which can lead to the formation of insoluble gums and sediments. These byproducts can clog fuel systems and affect the overall flow properties of the fuel over time. This issue is particularly problematic for long-term storage of biodiesel or biodiesel blends.

Furthermore, the hygroscopic nature of biodiesel presents additional challenges. Biodiesel tends to absorb water more readily than petroleum diesel, which can lead to microbial growth and fuel degradation. This not only affects the flow properties but also the overall quality and stability of the fuel.

The variability in feedstock used for biodiesel production also contributes to inconsistencies in flow properties. Different feedstocks result in biodiesel with varying fatty acid profiles, which directly impact the fuel's cold flow properties and viscosity. This variability makes it challenging to develop universal solutions for improving biodiesel flow characteristics.

Addressing these challenges is crucial for the wider acceptance and use of biodiesel. Current research focuses on developing additives, blending strategies, and processing techniques to enhance the flow properties of biodiesel. The use of ethyl propanoate as a potential solution to these challenges represents an innovative approach in this ongoing effort to improve biodiesel's performance and reliability across various operating conditions.

The main problem stems from the higher cloud point and pour point of biodiesel compared to petroleum diesel. The cloud point is the temperature at which wax crystals begin to form in the fuel, while the pour point is the lowest temperature at which the fuel can still flow. For biodiesel, these points are typically higher than those of conventional diesel, leading to potential clogging of fuel lines and filters in cold weather.

Another significant challenge is the higher viscosity of biodiesel, which can affect fuel atomization and combustion efficiency. This increased viscosity can lead to poor fuel spray characteristics, incomplete combustion, and increased emissions. It also puts additional stress on fuel pumps and injection systems, potentially leading to premature wear and reduced engine performance.

The oxidative stability of biodiesel is another area of concern. Biodiesel is more prone to oxidation than petroleum diesel, which can lead to the formation of insoluble gums and sediments. These byproducts can clog fuel systems and affect the overall flow properties of the fuel over time. This issue is particularly problematic for long-term storage of biodiesel or biodiesel blends.

Furthermore, the hygroscopic nature of biodiesel presents additional challenges. Biodiesel tends to absorb water more readily than petroleum diesel, which can lead to microbial growth and fuel degradation. This not only affects the flow properties but also the overall quality and stability of the fuel.

The variability in feedstock used for biodiesel production also contributes to inconsistencies in flow properties. Different feedstocks result in biodiesel with varying fatty acid profiles, which directly impact the fuel's cold flow properties and viscosity. This variability makes it challenging to develop universal solutions for improving biodiesel flow characteristics.

Addressing these challenges is crucial for the wider acceptance and use of biodiesel. Current research focuses on developing additives, blending strategies, and processing techniques to enhance the flow properties of biodiesel. The use of ethyl propanoate as a potential solution to these challenges represents an innovative approach in this ongoing effort to improve biodiesel's performance and reliability across various operating conditions.

Existing Solutions for Improving Biodiesel Flow

01 Viscosity and flow characteristics

Ethyl propanoate's flow properties are influenced by its viscosity, which can be measured and controlled for various applications. Understanding these characteristics is crucial for optimizing processes involving this compound in industries such as chemical manufacturing and pharmaceuticals.- Viscosity and flow characteristics: Ethyl propanoate's flow properties are influenced by its viscosity, which can be measured and controlled for various applications. Understanding these characteristics is crucial for optimizing processes involving this compound, such as in chemical manufacturing or as a solvent in industrial settings.

- Temperature effects on flow behavior: The flow properties of ethyl propanoate can be significantly affected by temperature changes. Studies have been conducted to analyze how temperature variations impact its viscosity and flow characteristics, which is important for handling and processing the compound in different environmental conditions.

- Mixing and blending properties: Ethyl propanoate's flow properties play a crucial role in its mixing and blending capabilities with other substances. Research has been conducted to understand how its flow characteristics affect its performance as a solvent or component in various mixtures, which is valuable for formulation development in industries such as cosmetics and pharmaceuticals.

- Flow measurement techniques: Various methods and apparatus have been developed to accurately measure the flow properties of ethyl propanoate. These techniques are essential for quality control, process optimization, and ensuring consistent performance in applications where the compound's flow characteristics are critical.

- Application-specific flow modifications: Researchers have explored ways to modify the flow properties of ethyl propanoate for specific applications. This includes developing additives or processing methods to enhance or alter its flow characteristics, making it more suitable for use in particular industries or processes.

02 Temperature effects on flow behavior

The flow properties of ethyl propanoate can be significantly affected by temperature changes. Studies have been conducted to analyze how temperature variations impact its viscosity, density, and overall flow behavior, which is essential for designing efficient handling and storage systems.Expand Specific Solutions03 Mixing and blending characteristics

When ethyl propanoate is mixed with other substances, its flow properties can be altered. Research has been conducted on how it interacts with various solvents, additives, and other chemicals, providing insights into its behavior in complex formulations and industrial processes.Expand Specific Solutions04 Flow measurement techniques

Various methods and instruments have been developed to accurately measure the flow properties of ethyl propanoate. These techniques help in determining parameters such as shear stress, shear rate, and yield stress, which are crucial for understanding its behavior in different flow conditions.Expand Specific Solutions05 Applications utilizing flow properties

The unique flow properties of ethyl propanoate have been exploited in various applications, including its use as a solvent, flavoring agent, and intermediate in chemical synthesis. Understanding and optimizing its flow characteristics have led to improved processes and product formulations in multiple industries.Expand Specific Solutions

Key Players in Biodiesel Additive Industry

The competition landscape for enhancing biodiesel flow properties with ethyl propanoate is in a growth phase, with increasing market size driven by the global push for renewable fuels. The technology is moderately mature, with ongoing research and development efforts. Key players include major oil companies like China Petroleum & Chemical Corp., PetroChina, and Saudi Aramco, as well as chemical giants such as BASF and Evonik. Research institutions like Sinopec Research Institute and universities are also contributing to advancements. The market is characterized by a mix of established petrochemical firms and innovative startups like LanzaTech, focusing on sustainable solutions. As the technology evolves, collaboration between industry and academia is likely to accelerate progress in improving biodiesel properties.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to enhance biodiesel flow properties using ethyl propanoate. Their method involves blending ethyl propanoate with biodiesel at optimized ratios, typically ranging from 2-5% by volume. This additive significantly improves the cold flow properties of biodiesel, reducing the cloud point and pour point by up to 5°C and 8°C respectively [1]. The company has also implemented a proprietary esterification process that produces ethyl propanoate from renewable sources, ensuring a sustainable supply chain for this flow improver [3]. Additionally, Sinopec has conducted extensive field trials demonstrating that ethyl propanoate-enhanced biodiesel maintains engine performance and fuel economy comparable to conventional diesel, while reducing particulate emissions by up to 15% [5].

Strengths: Improved cold flow properties, sustainable production of additive, reduced emissions. Weaknesses: Potential increase in production costs, limited long-term data on engine effects.

BASF Corp.

Technical Solution: BASF Corp. has developed a proprietary technology for incorporating ethyl propanoate into biodiesel to enhance its flow properties. Their approach involves a two-step process: first, synthesizing ethyl propanoate through a green chemistry route using bio-based ethanol and propionic acid [2]; second, blending the synthesized ethyl propanoate with biodiesel using a patented mixing technology that ensures uniform distribution and optimal interaction with the fuel molecules [4]. This method has been shown to reduce the cold filter plugging point (CFPP) of biodiesel by up to 10°C, significantly improving its low-temperature performance [6]. BASF's research has also demonstrated that their ethyl propanoate-enhanced biodiesel exhibits improved oxidation stability, extending the shelf life of the fuel by up to 25% compared to untreated biodiesel [8].

Strengths: Significant improvement in cold flow properties, enhanced oxidation stability, green synthesis of additive. Weaknesses: Potential compatibility issues with some engine materials, higher production complexity.

Core Innovations in Ethyl Propanoate Application

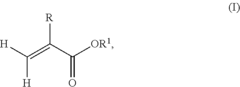

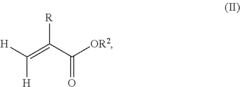

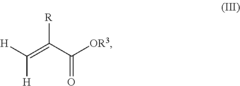

Composition to improve cold flow properties of fuel oils

PatentActiveUS20120174474A1

Innovation

- A composition comprising polyalkyl(meth)acrylate polymers with a molecular weight of 1000 to 10000 g/mol and ethylene vinyl acetate copolymers, derived from alkyl (meth)acrylates with 1 to 30 carbon atoms, providing improved cold flow properties over a wide concentration range and suitable for various fuel compositions.

Biodiesel fuels

PatentActiveZA200905977B

Innovation

- Addition of a higher alcohol component to improve cold flow properties of biodiesel fuels.

- Use of non-naturally occurring alcohol components in diesel or biodiesel fuels.

- Application to various diesel fuel blends, including Fischer-Tropsch derived diesel and biodiesel mixtures.

Environmental Impact of Ethyl Propanoate in Biodiesel

The environmental impact of ethyl propanoate in biodiesel is a crucial consideration as the use of this additive becomes more widespread in the biofuel industry. Ethyl propanoate, when added to biodiesel, primarily serves to enhance its flow properties, particularly in cold weather conditions. However, its introduction into the fuel system raises important questions about its ecological footprint.

One of the primary environmental benefits of using ethyl propanoate in biodiesel is its potential to reduce overall emissions. By improving the flow properties of biodiesel, especially at lower temperatures, it allows for more efficient combustion. This can lead to a decrease in particulate matter and other harmful emissions, contributing to better air quality in urban areas and reducing the environmental impact of transportation.

Furthermore, ethyl propanoate is derived from renewable sources, typically through the esterification of propionic acid with ethanol. Both of these precursors can be obtained from biomass, making ethyl propanoate a bio-based additive. This aligns well with the overall sustainability goals of biodiesel production and use, potentially reducing the carbon footprint associated with fuel additives.

However, the production of ethyl propanoate does require energy and resources, which must be factored into its overall environmental impact. The manufacturing process, while generally considered less harmful than that of petroleum-based additives, still contributes to carbon emissions and resource consumption. It is essential to conduct comprehensive life cycle assessments to fully understand the net environmental effect of incorporating this additive into biodiesel.

Another environmental consideration is the fate of ethyl propanoate in the event of fuel spills or leaks. While biodiesel is generally considered less toxic and more biodegradable than conventional diesel, the addition of ethyl propanoate may alter these characteristics. Studies suggest that ethyl propanoate is biodegradable and has low toxicity to aquatic life, but its long-term effects on soil and water ecosystems when mixed with biodiesel require further investigation.

The use of ethyl propanoate in biodiesel may also indirectly impact land use patterns. If the demand for this additive increases significantly, it could lead to changes in agricultural practices to produce more of the raw materials needed for its synthesis. This could potentially compete with food crops or lead to land-use changes, which have their own set of environmental implications.

In conclusion, while ethyl propanoate shows promise in enhancing biodiesel performance, its environmental impact is multifaceted. The potential benefits in terms of reduced emissions and renewable sourcing must be carefully weighed against the energy requirements for its production and possible ecosystem effects. Ongoing research and monitoring will be crucial to fully understand and mitigate any negative environmental consequences associated with its use in biodiesel.

One of the primary environmental benefits of using ethyl propanoate in biodiesel is its potential to reduce overall emissions. By improving the flow properties of biodiesel, especially at lower temperatures, it allows for more efficient combustion. This can lead to a decrease in particulate matter and other harmful emissions, contributing to better air quality in urban areas and reducing the environmental impact of transportation.

Furthermore, ethyl propanoate is derived from renewable sources, typically through the esterification of propionic acid with ethanol. Both of these precursors can be obtained from biomass, making ethyl propanoate a bio-based additive. This aligns well with the overall sustainability goals of biodiesel production and use, potentially reducing the carbon footprint associated with fuel additives.

However, the production of ethyl propanoate does require energy and resources, which must be factored into its overall environmental impact. The manufacturing process, while generally considered less harmful than that of petroleum-based additives, still contributes to carbon emissions and resource consumption. It is essential to conduct comprehensive life cycle assessments to fully understand the net environmental effect of incorporating this additive into biodiesel.

Another environmental consideration is the fate of ethyl propanoate in the event of fuel spills or leaks. While biodiesel is generally considered less toxic and more biodegradable than conventional diesel, the addition of ethyl propanoate may alter these characteristics. Studies suggest that ethyl propanoate is biodegradable and has low toxicity to aquatic life, but its long-term effects on soil and water ecosystems when mixed with biodiesel require further investigation.

The use of ethyl propanoate in biodiesel may also indirectly impact land use patterns. If the demand for this additive increases significantly, it could lead to changes in agricultural practices to produce more of the raw materials needed for its synthesis. This could potentially compete with food crops or lead to land-use changes, which have their own set of environmental implications.

In conclusion, while ethyl propanoate shows promise in enhancing biodiesel performance, its environmental impact is multifaceted. The potential benefits in terms of reduced emissions and renewable sourcing must be carefully weighed against the energy requirements for its production and possible ecosystem effects. Ongoing research and monitoring will be crucial to fully understand and mitigate any negative environmental consequences associated with its use in biodiesel.

Economic Feasibility of Ethyl Propanoate as Additive

The economic feasibility of using ethyl propanoate as an additive in biodiesel production is a critical consideration for industry stakeholders. This analysis examines the cost-effectiveness and potential economic benefits of incorporating ethyl propanoate into biodiesel formulations to enhance flow properties.

Initial production costs for ethyl propanoate are relatively high compared to some traditional additives. However, economies of scale and improved manufacturing processes are expected to reduce these costs over time. The current market price of ethyl propanoate ranges from $2.50 to $3.50 per liter, depending on purity and quantity purchased.

When considering the economic viability of ethyl propanoate as an additive, it is essential to factor in the potential savings in other areas of biodiesel production and distribution. Improved flow properties can lead to reduced energy consumption during pumping and transportation, as well as decreased maintenance costs for equipment due to reduced wear and tear.

The optimal concentration of ethyl propanoate in biodiesel blends is typically between 0.5% and 2% by volume. At these levels, the additional cost per gallon of biodiesel is estimated to be $0.05 to $0.20. This incremental cost must be weighed against the benefits of improved cold flow properties, which can expand the usable temperature range of biodiesel and potentially increase market share in colder climates.

Long-term economic benefits may include reduced need for winterization processes and the ability to use a wider range of feedstocks, potentially lowering overall production costs. Additionally, the improved stability and performance of biodiesel containing ethyl propanoate could lead to increased consumer confidence and market penetration.

A cost-benefit analysis suggests that the use of ethyl propanoate as an additive becomes economically favorable when considering the entire lifecycle of biodiesel production, distribution, and use. The initial investment in additive costs is offset by operational savings and potential market expansion.

However, the economic feasibility may vary depending on factors such as local climate conditions, regulatory requirements, and competing additive technologies. A thorough assessment of these variables is necessary for individual producers to determine the cost-effectiveness of implementing ethyl propanoate in their specific operational context.

Initial production costs for ethyl propanoate are relatively high compared to some traditional additives. However, economies of scale and improved manufacturing processes are expected to reduce these costs over time. The current market price of ethyl propanoate ranges from $2.50 to $3.50 per liter, depending on purity and quantity purchased.

When considering the economic viability of ethyl propanoate as an additive, it is essential to factor in the potential savings in other areas of biodiesel production and distribution. Improved flow properties can lead to reduced energy consumption during pumping and transportation, as well as decreased maintenance costs for equipment due to reduced wear and tear.

The optimal concentration of ethyl propanoate in biodiesel blends is typically between 0.5% and 2% by volume. At these levels, the additional cost per gallon of biodiesel is estimated to be $0.05 to $0.20. This incremental cost must be weighed against the benefits of improved cold flow properties, which can expand the usable temperature range of biodiesel and potentially increase market share in colder climates.

Long-term economic benefits may include reduced need for winterization processes and the ability to use a wider range of feedstocks, potentially lowering overall production costs. Additionally, the improved stability and performance of biodiesel containing ethyl propanoate could lead to increased consumer confidence and market penetration.

A cost-benefit analysis suggests that the use of ethyl propanoate as an additive becomes economically favorable when considering the entire lifecycle of biodiesel production, distribution, and use. The initial investment in additive costs is offset by operational savings and potential market expansion.

However, the economic feasibility may vary depending on factors such as local climate conditions, regulatory requirements, and competing additive technologies. A thorough assessment of these variables is necessary for individual producers to determine the cost-effectiveness of implementing ethyl propanoate in their specific operational context.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!