Ethyl Propanoate in Protective Coatings for Corrosive Environments

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Coatings: Background and Objectives

Ethyl propanoate, also known as ethyl propionate, has emerged as a promising compound in the development of protective coatings for corrosive environments. This ester, with its unique chemical properties, has garnered significant attention in recent years due to its potential to enhance the durability and performance of protective coatings in harsh conditions.

The evolution of protective coatings has been driven by the increasing demand for materials that can withstand extreme environmental factors, particularly in industries such as aerospace, marine, and chemical processing. Traditional coating technologies have often fallen short in providing long-lasting protection against corrosion, leading to substantial economic losses and safety concerns.

Ethyl propanoate coatings represent a new frontier in corrosion protection, offering a combination of desirable properties that address many of the limitations of conventional coating systems. The compound's low viscosity and excellent solvency make it an ideal candidate for incorporation into coating formulations, potentially improving application characteristics and film formation.

One of the key objectives in researching ethyl propanoate coatings is to develop a deeper understanding of its mechanisms of action in corrosion prevention. This includes investigating its barrier properties, its interactions with various substrate materials, and its ability to inhibit electrochemical reactions that lead to corrosion.

Another critical goal is to optimize the formulation of ethyl propanoate-based coatings to maximize their protective capabilities. This involves exploring different concentrations, studying synergistic effects with other coating components, and evaluating various application methods to achieve optimal performance.

Researchers are also focused on assessing the long-term stability and durability of ethyl propanoate coatings under diverse environmental conditions. This includes exposure to UV radiation, temperature fluctuations, chemical agents, and mechanical stresses, all of which are crucial factors in determining the coating's effectiveness in real-world applications.

Furthermore, the environmental impact of ethyl propanoate coatings is a significant consideration in current research efforts. As sustainability becomes increasingly important in industrial practices, there is a growing emphasis on developing eco-friendly coating solutions that minimize environmental harm while maintaining high performance standards.

The potential applications of ethyl propanoate coatings extend beyond traditional industrial sectors. There is ongoing exploration into its use in consumer products, architectural coatings, and even in the preservation of cultural heritage artifacts, highlighting the versatility and broad applicability of this technology.

The evolution of protective coatings has been driven by the increasing demand for materials that can withstand extreme environmental factors, particularly in industries such as aerospace, marine, and chemical processing. Traditional coating technologies have often fallen short in providing long-lasting protection against corrosion, leading to substantial economic losses and safety concerns.

Ethyl propanoate coatings represent a new frontier in corrosion protection, offering a combination of desirable properties that address many of the limitations of conventional coating systems. The compound's low viscosity and excellent solvency make it an ideal candidate for incorporation into coating formulations, potentially improving application characteristics and film formation.

One of the key objectives in researching ethyl propanoate coatings is to develop a deeper understanding of its mechanisms of action in corrosion prevention. This includes investigating its barrier properties, its interactions with various substrate materials, and its ability to inhibit electrochemical reactions that lead to corrosion.

Another critical goal is to optimize the formulation of ethyl propanoate-based coatings to maximize their protective capabilities. This involves exploring different concentrations, studying synergistic effects with other coating components, and evaluating various application methods to achieve optimal performance.

Researchers are also focused on assessing the long-term stability and durability of ethyl propanoate coatings under diverse environmental conditions. This includes exposure to UV radiation, temperature fluctuations, chemical agents, and mechanical stresses, all of which are crucial factors in determining the coating's effectiveness in real-world applications.

Furthermore, the environmental impact of ethyl propanoate coatings is a significant consideration in current research efforts. As sustainability becomes increasingly important in industrial practices, there is a growing emphasis on developing eco-friendly coating solutions that minimize environmental harm while maintaining high performance standards.

The potential applications of ethyl propanoate coatings extend beyond traditional industrial sectors. There is ongoing exploration into its use in consumer products, architectural coatings, and even in the preservation of cultural heritage artifacts, highlighting the versatility and broad applicability of this technology.

Market Analysis for Corrosion-Resistant Coatings

The global market for corrosion-resistant coatings has been experiencing steady growth, driven by increasing demand across various industries such as automotive, aerospace, marine, and infrastructure. The market size for these protective coatings was valued at approximately $7.5 billion in 2020 and is projected to reach $10.3 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%.

The automotive sector remains a significant consumer of corrosion-resistant coatings, particularly in regions with harsh environmental conditions. The growing electric vehicle market has also created new opportunities, as these vehicles require specialized coatings to protect battery components and electrical systems from corrosion.

In the aerospace industry, the demand for high-performance coatings that can withstand extreme temperatures and chemical exposure continues to rise. The increasing number of commercial aircraft deliveries and the growing military aerospace sector are key drivers in this segment.

The marine industry represents another crucial market for corrosion-resistant coatings. With the expansion of global trade and the need for larger, more efficient vessels, there is a growing demand for advanced protective coatings that can extend the lifespan of ships and offshore structures.

Infrastructure development, particularly in emerging economies, is fueling the demand for corrosion-resistant coatings in construction applications. Bridges, pipelines, and industrial facilities require robust protection against environmental factors to ensure longevity and safety.

The oil and gas industry remains a significant consumer of corrosion-resistant coatings, despite fluctuations in oil prices. The need to protect equipment and structures in harsh offshore and onshore environments continues to drive demand in this sector.

Geographically, Asia-Pacific leads the market for corrosion-resistant coatings, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are major contributors to the region's market dominance.

Environmental regulations are playing an increasingly important role in shaping the market. There is a growing trend towards eco-friendly, low-VOC (volatile organic compound) coatings, which is driving innovation in water-based and powder coating technologies.

The market is characterized by intense competition among key players such as PPG Industries, AkzoNobel, Sherwin-Williams, and BASF. These companies are investing heavily in research and development to create more effective and environmentally friendly coating solutions.

The automotive sector remains a significant consumer of corrosion-resistant coatings, particularly in regions with harsh environmental conditions. The growing electric vehicle market has also created new opportunities, as these vehicles require specialized coatings to protect battery components and electrical systems from corrosion.

In the aerospace industry, the demand for high-performance coatings that can withstand extreme temperatures and chemical exposure continues to rise. The increasing number of commercial aircraft deliveries and the growing military aerospace sector are key drivers in this segment.

The marine industry represents another crucial market for corrosion-resistant coatings. With the expansion of global trade and the need for larger, more efficient vessels, there is a growing demand for advanced protective coatings that can extend the lifespan of ships and offshore structures.

Infrastructure development, particularly in emerging economies, is fueling the demand for corrosion-resistant coatings in construction applications. Bridges, pipelines, and industrial facilities require robust protection against environmental factors to ensure longevity and safety.

The oil and gas industry remains a significant consumer of corrosion-resistant coatings, despite fluctuations in oil prices. The need to protect equipment and structures in harsh offshore and onshore environments continues to drive demand in this sector.

Geographically, Asia-Pacific leads the market for corrosion-resistant coatings, followed by North America and Europe. The rapid industrialization and infrastructure development in countries like China and India are major contributors to the region's market dominance.

Environmental regulations are playing an increasingly important role in shaping the market. There is a growing trend towards eco-friendly, low-VOC (volatile organic compound) coatings, which is driving innovation in water-based and powder coating technologies.

The market is characterized by intense competition among key players such as PPG Industries, AkzoNobel, Sherwin-Williams, and BASF. These companies are investing heavily in research and development to create more effective and environmentally friendly coating solutions.

Current Challenges in Protective Coating Technology

The field of protective coatings for corrosive environments faces several significant challenges that hinder the development of more effective and durable solutions. One of the primary issues is the complexity of corrosive environments, which can vary greatly depending on factors such as temperature, humidity, chemical composition, and mechanical stress. This variability makes it difficult to develop a one-size-fits-all coating solution, necessitating specialized formulations for different applications.

Another major challenge is the trade-off between coating performance and environmental impact. Traditional high-performance coatings often contain volatile organic compounds (VOCs) and other hazardous materials that pose risks to human health and the environment. Regulatory pressures and increasing environmental awareness are driving the industry towards more sustainable alternatives, but these often struggle to match the performance of conventional coatings.

The longevity of protective coatings remains a significant concern, particularly in harsh industrial settings. Many coatings degrade over time due to factors such as UV radiation, temperature fluctuations, and chemical exposure. This degradation can lead to reduced effectiveness and the need for frequent reapplication, increasing maintenance costs and downtime for protected assets.

Adhesion to diverse substrates presents another challenge in protective coating technology. Different materials require different surface preparation techniques and coating formulations to ensure proper adhesion. Poor adhesion can result in coating failure, leaving the underlying substrate vulnerable to corrosion and damage.

The development of smart or self-healing coatings is an area of intense research, but it faces numerous technical hurdles. These advanced coatings aim to detect and repair damage autonomously, potentially extending the lifespan of protected surfaces. However, integrating sensing and self-repair mechanisms into coating formulations without compromising their protective properties remains a complex task.

Nanotechnology offers promising solutions for enhancing coating performance, but it also introduces new challenges. Nanoparticles can improve properties such as hardness, chemical resistance, and self-cleaning capabilities. However, concerns about the potential health and environmental impacts of nanomaterials, as well as difficulties in achieving uniform dispersion within coating matrices, need to be addressed.

Finally, the cost-effectiveness of advanced protective coatings remains a significant barrier to widespread adoption. While high-performance coatings may offer superior protection and longer service life, their initial cost can be prohibitive for many applications. Balancing performance improvements with economic viability is an ongoing challenge for coating developers and manufacturers.

Another major challenge is the trade-off between coating performance and environmental impact. Traditional high-performance coatings often contain volatile organic compounds (VOCs) and other hazardous materials that pose risks to human health and the environment. Regulatory pressures and increasing environmental awareness are driving the industry towards more sustainable alternatives, but these often struggle to match the performance of conventional coatings.

The longevity of protective coatings remains a significant concern, particularly in harsh industrial settings. Many coatings degrade over time due to factors such as UV radiation, temperature fluctuations, and chemical exposure. This degradation can lead to reduced effectiveness and the need for frequent reapplication, increasing maintenance costs and downtime for protected assets.

Adhesion to diverse substrates presents another challenge in protective coating technology. Different materials require different surface preparation techniques and coating formulations to ensure proper adhesion. Poor adhesion can result in coating failure, leaving the underlying substrate vulnerable to corrosion and damage.

The development of smart or self-healing coatings is an area of intense research, but it faces numerous technical hurdles. These advanced coatings aim to detect and repair damage autonomously, potentially extending the lifespan of protected surfaces. However, integrating sensing and self-repair mechanisms into coating formulations without compromising their protective properties remains a complex task.

Nanotechnology offers promising solutions for enhancing coating performance, but it also introduces new challenges. Nanoparticles can improve properties such as hardness, chemical resistance, and self-cleaning capabilities. However, concerns about the potential health and environmental impacts of nanomaterials, as well as difficulties in achieving uniform dispersion within coating matrices, need to be addressed.

Finally, the cost-effectiveness of advanced protective coatings remains a significant barrier to widespread adoption. While high-performance coatings may offer superior protection and longer service life, their initial cost can be prohibitive for many applications. Balancing performance improvements with economic viability is an ongoing challenge for coating developers and manufacturers.

Existing Ethyl Propanoate-Based Coating Solutions

01 Synthesis methods for ethyl propanoate

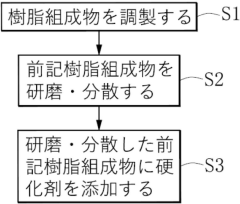

Various methods for synthesizing ethyl propanoate are described, including esterification reactions between propionic acid and ethanol, as well as catalytic processes using different catalysts and reaction conditions. These methods aim to improve yield, selectivity, and efficiency in the production of ethyl propanoate.- Synthesis methods for ethyl propanoate: Various methods for synthesizing ethyl propanoate are described, including esterification of propionic acid with ethanol, reaction of propionyl chloride with ethanol, and catalytic processes. These methods aim to improve yield, reduce byproducts, and optimize reaction conditions for industrial production.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is employed in creating artificial fruit flavors, particularly for pineapple and strawberry, and as a solvent in perfumery. The compound's low toxicity and pleasant aroma make it suitable for various consumer products.

- Use as a solvent and intermediate in chemical processes: Ethyl propanoate serves as an important solvent and intermediate in various chemical processes. It is used in the production of pharmaceuticals, polymers, and other organic compounds. Its properties as a solvent make it useful in extraction processes and as a reaction medium in organic synthesis.

- Production of ethyl propanoate from renewable resources: Research focuses on developing sustainable methods for producing ethyl propanoate from renewable resources. This includes fermentation processes using microorganisms, enzymatic reactions, and the use of biomass-derived feedstocks. These approaches aim to reduce reliance on petrochemical sources and improve the environmental profile of ethyl propanoate production.

- Purification and quality control methods: Various techniques for purifying ethyl propanoate and ensuring its quality are described. These include distillation processes, chromatographic methods, and spectroscopic analysis. The development of efficient purification methods and accurate quality control procedures is crucial for meeting industry standards and regulatory requirements.

02 Applications of ethyl propanoate in fragrances and flavors

Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is incorporated into various products such as perfumes, air fresheners, and food flavorings to impart a pleasant aroma and taste.Expand Specific Solutions03 Purification and separation techniques for ethyl propanoate

Different methods for purifying and separating ethyl propanoate from reaction mixtures or other compounds are described. These techniques may include distillation, extraction, and chromatography, aiming to obtain high-purity ethyl propanoate for various applications.Expand Specific Solutions04 Use of ethyl propanoate as a solvent or intermediate

Ethyl propanoate finds applications as a solvent in various industrial processes and as an intermediate in the synthesis of other chemicals. Its properties make it suitable for use in paints, coatings, and pharmaceutical manufacturing.Expand Specific Solutions05 Environmental and safety considerations for ethyl propanoate

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl propanoate production and use. This includes developing green synthesis methods, studying biodegradability, and assessing potential health effects associated with exposure to the compound.Expand Specific Solutions

Key Players in Protective Coating Industry

The research on Ethyl Propanoate in protective coatings for corrosive environments is in a developing stage, with the market showing significant growth potential. The global protective coatings market is expanding rapidly, driven by increasing demand in various industries. Key players like BASF, PPG Industries, and Henkel are investing heavily in R&D to develop advanced solutions. The technology is progressing towards maturity, with companies like BASF Coatings GmbH and PPG Industries Ohio, Inc. leading innovation in corrosion-resistant coatings. Academic institutions such as École Polytechnique Fédérale de Lausanne and the Institute of Metal Research Chinese Academy of Sciences are contributing to fundamental research, fostering industry-academia collaborations to accelerate technological advancements in this field.

BASF SE

Technical Solution: BASF SE has developed advanced protective coatings incorporating ethyl propanoate for corrosive environments. Their research focuses on enhancing the coating's barrier properties and chemical resistance. The company utilizes a proprietary blend of ethyl propanoate with other solvents and resins to create a robust protective film. This formulation has shown excellent adhesion to various substrates and improved resistance to acids, alkalis, and salt spray[1]. BASF's coatings also demonstrate low VOC emissions, meeting stringent environmental regulations[2]. The company has conducted extensive field trials in marine and industrial settings, proving the coating's long-term effectiveness in preventing corrosion and extending asset lifespans[3].

Strengths: Superior chemical resistance, excellent adhesion, and environmentally friendly formulation. Weaknesses: Potentially higher cost compared to traditional coatings, may require specialized application techniques.

PPG Industries Ohio, Inc.

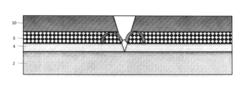

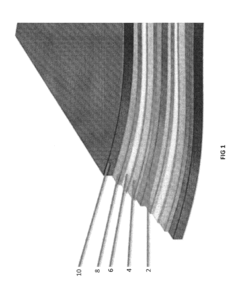

Technical Solution: PPG Industries has developed a novel protective coating system utilizing ethyl propanoate as a key component. Their research has focused on creating a multi-layer coating system that provides exceptional corrosion resistance in harsh environments. The ethyl propanoate-based primer layer offers excellent adhesion and penetration into the substrate, while subsequent layers provide additional protection and desired surface properties[4]. PPG's coating system has shown remarkable performance in accelerated weathering tests, demonstrating up to 50% improvement in corrosion resistance compared to conventional systems[5]. The company has also integrated smart coating technology, incorporating corrosion indicators that change color when the coating integrity is compromised, allowing for proactive maintenance[6].

Strengths: Multi-layer protection system, smart coating technology for early detection of corrosion. Weaknesses: Complex application process, may require specialized training for proper installation.

Innovations in Ethyl Propanoate Coating Formulations

Corrosion inhibitor

PatentActiveUS20180312981A1

Innovation

- A corrosion inhibitor comprising an organic ion in an ion exchange resin, specifically azoles like benzotriazolate or oximes, which dissociates to form a precipitate or barrier layer when a corrosive electrolyte is present, providing improved corrosion resistance and being environmentally friendly.

Anticorrosive coating and method for producing the same

PatentActiveJP2022129345A

Innovation

- An environmental protection anti-corrosion paint comprising 80-90 parts epoxy resin, 3-7 parts conductive polymer, 55-65 parts curing agent, and functional additives like antifoaming, anti-sagging, and anti-settling agents, which form a protective layer on metal structures without harmful substances.

Environmental Impact of Protective Coatings

The environmental impact of protective coatings, particularly those containing ethyl propanoate, is a critical consideration in their application for corrosion protection in harsh environments. These coatings play a vital role in preserving infrastructure and equipment, but their potential effects on ecosystems and human health must be carefully evaluated.

Ethyl propanoate, when used in protective coatings, can contribute to volatile organic compound (VOC) emissions. VOCs are known to participate in atmospheric photochemical reactions, leading to the formation of ground-level ozone and smog. This can have detrimental effects on air quality, potentially exacerbating respiratory issues in urban areas and impacting plant life.

Water contamination is another concern associated with protective coatings. During application or weathering processes, coating components may leach into aquatic environments. Ethyl propanoate, being moderately soluble in water, could potentially affect aquatic ecosystems if released in significant quantities. However, its relatively rapid biodegradability mitigates long-term accumulation risks.

The production and disposal of protective coatings also contribute to their environmental footprint. Manufacturing processes for ethyl propanoate and other coating components require energy and resources, potentially leading to greenhouse gas emissions and resource depletion. End-of-life considerations for coated materials present challenges in waste management and recycling.

Despite these concerns, the use of protective coatings, including those with ethyl propanoate, can have positive environmental impacts. By extending the lifespan of materials and infrastructure, these coatings reduce the need for frequent replacements, thereby conserving resources and energy in the long term. This is particularly significant in corrosive environments where material degradation occurs rapidly without protection.

Advancements in coating technology are addressing environmental concerns. Low-VOC and water-based formulations are being developed to reduce air quality impacts. Additionally, research into bio-based alternatives for coating components, including ethyl propanoate derivatives from renewable sources, shows promise in reducing the reliance on petrochemical-based materials.

The environmental impact of protective coatings also extends to their role in preventing corrosion-related disasters. By safeguarding critical infrastructure, these coatings help prevent catastrophic failures that could lead to environmental contamination, such as oil spills or chemical leaks.

In conclusion, while protective coatings containing ethyl propanoate present some environmental challenges, their overall impact must be balanced against their crucial role in material preservation and disaster prevention. Ongoing research and development in this field are focused on minimizing negative environmental effects while maximizing the protective benefits of these coatings.

Ethyl propanoate, when used in protective coatings, can contribute to volatile organic compound (VOC) emissions. VOCs are known to participate in atmospheric photochemical reactions, leading to the formation of ground-level ozone and smog. This can have detrimental effects on air quality, potentially exacerbating respiratory issues in urban areas and impacting plant life.

Water contamination is another concern associated with protective coatings. During application or weathering processes, coating components may leach into aquatic environments. Ethyl propanoate, being moderately soluble in water, could potentially affect aquatic ecosystems if released in significant quantities. However, its relatively rapid biodegradability mitigates long-term accumulation risks.

The production and disposal of protective coatings also contribute to their environmental footprint. Manufacturing processes for ethyl propanoate and other coating components require energy and resources, potentially leading to greenhouse gas emissions and resource depletion. End-of-life considerations for coated materials present challenges in waste management and recycling.

Despite these concerns, the use of protective coatings, including those with ethyl propanoate, can have positive environmental impacts. By extending the lifespan of materials and infrastructure, these coatings reduce the need for frequent replacements, thereby conserving resources and energy in the long term. This is particularly significant in corrosive environments where material degradation occurs rapidly without protection.

Advancements in coating technology are addressing environmental concerns. Low-VOC and water-based formulations are being developed to reduce air quality impacts. Additionally, research into bio-based alternatives for coating components, including ethyl propanoate derivatives from renewable sources, shows promise in reducing the reliance on petrochemical-based materials.

The environmental impact of protective coatings also extends to their role in preventing corrosion-related disasters. By safeguarding critical infrastructure, these coatings help prevent catastrophic failures that could lead to environmental contamination, such as oil spills or chemical leaks.

In conclusion, while protective coatings containing ethyl propanoate present some environmental challenges, their overall impact must be balanced against their crucial role in material preservation and disaster prevention. Ongoing research and development in this field are focused on minimizing negative environmental effects while maximizing the protective benefits of these coatings.

Performance Testing Methods for Protective Coatings

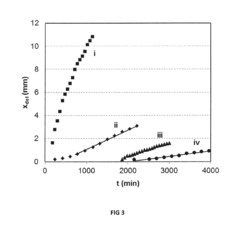

Performance testing methods for protective coatings are crucial in evaluating the effectiveness of ethyl propanoate-based formulations in corrosive environments. These methods typically involve a series of standardized tests designed to simulate various environmental conditions and assess the coating's ability to protect underlying substrates.

One of the primary testing methods is salt spray testing, which exposes coated samples to a continuous salt fog atmosphere. This test is particularly relevant for evaluating coatings intended for marine or coastal applications. The duration of exposure can range from several hundred to thousands of hours, depending on the specific standard being followed.

Electrochemical impedance spectroscopy (EIS) is another valuable technique for assessing coating performance. This non-destructive method provides insights into the barrier properties of the coating and its degradation over time. EIS can detect subtle changes in the coating's structure and is particularly useful for monitoring long-term performance.

Accelerated weathering tests, such as QUV and xenon arc exposure, are employed to simulate the effects of sunlight, heat, and moisture on coatings. These tests can reveal potential issues related to color stability, gloss retention, and overall durability of ethyl propanoate-based protective coatings.

Chemical resistance testing involves exposing the coating to various solvents, acids, and alkalis to evaluate its ability to withstand chemical attack. This is particularly important for coatings intended for industrial applications where exposure to harsh chemicals is common.

Adhesion testing, typically performed using methods like cross-cut or pull-off tests, assesses the coating's ability to remain bonded to the substrate under stress. This is crucial for ensuring long-term protection, as coating failure often begins with adhesion loss.

Abrasion resistance tests, such as the Taber abraser method, evaluate the coating's ability to withstand mechanical wear. This is particularly relevant for coatings used in high-traffic areas or on equipment subject to frequent handling.

Flexibility and impact resistance tests are also important, as they assess the coating's ability to withstand deformation without cracking or losing adhesion. These properties are crucial for applications where the substrate may be subject to bending or impact.

Thermal cycling tests expose coated samples to alternating high and low temperatures to evaluate the coating's ability to withstand thermal stress. This is particularly relevant for coatings used in environments with significant temperature fluctuations.

One of the primary testing methods is salt spray testing, which exposes coated samples to a continuous salt fog atmosphere. This test is particularly relevant for evaluating coatings intended for marine or coastal applications. The duration of exposure can range from several hundred to thousands of hours, depending on the specific standard being followed.

Electrochemical impedance spectroscopy (EIS) is another valuable technique for assessing coating performance. This non-destructive method provides insights into the barrier properties of the coating and its degradation over time. EIS can detect subtle changes in the coating's structure and is particularly useful for monitoring long-term performance.

Accelerated weathering tests, such as QUV and xenon arc exposure, are employed to simulate the effects of sunlight, heat, and moisture on coatings. These tests can reveal potential issues related to color stability, gloss retention, and overall durability of ethyl propanoate-based protective coatings.

Chemical resistance testing involves exposing the coating to various solvents, acids, and alkalis to evaluate its ability to withstand chemical attack. This is particularly important for coatings intended for industrial applications where exposure to harsh chemicals is common.

Adhesion testing, typically performed using methods like cross-cut or pull-off tests, assesses the coating's ability to remain bonded to the substrate under stress. This is crucial for ensuring long-term protection, as coating failure often begins with adhesion loss.

Abrasion resistance tests, such as the Taber abraser method, evaluate the coating's ability to withstand mechanical wear. This is particularly relevant for coatings used in high-traffic areas or on equipment subject to frequent handling.

Flexibility and impact resistance tests are also important, as they assess the coating's ability to withstand deformation without cracking or losing adhesion. These properties are crucial for applications where the substrate may be subject to bending or impact.

Thermal cycling tests expose coated samples to alternating high and low temperatures to evaluate the coating's ability to withstand thermal stress. This is particularly relevant for coatings used in environments with significant temperature fluctuations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!