How Ethyl Propanoate Affects Viscosity in Fluidic Systems

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Viscosity Effects: Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is an organic compound with significant implications for fluid dynamics and industrial applications. This ester, formed by the reaction between propionic acid and ethanol, has garnered attention in recent years due to its unique properties and potential to influence viscosity in fluidic systems.

The study of ethyl propanoate's effects on viscosity is rooted in the broader field of rheology, which examines the flow and deformation of matter. As industries continue to seek more efficient and environmentally friendly solutions for various processes, understanding the behavior of ethyl propanoate in fluid systems has become increasingly important.

Historically, the use of esters in industrial applications has been well-documented, with their ability to modify fluid properties being a key area of interest. Ethyl propanoate, in particular, has emerged as a compound of focus due to its relatively low toxicity, pleasant odor, and potential for biodegradability. These characteristics make it an attractive option for industries looking to optimize their processes while adhering to stricter environmental regulations.

The evolution of fluid dynamics research has led to a growing interest in how specific compounds can alter the viscosity of fluids. Viscosity, a measure of a fluid's resistance to flow, plays a crucial role in numerous industrial processes, from lubricant formulation to food processing. As such, the ability to fine-tune viscosity through the addition of compounds like ethyl propanoate presents exciting possibilities for process optimization and product development.

The primary objective of studying ethyl propanoate's effects on viscosity in fluidic systems is to gain a comprehensive understanding of its behavior under various conditions. This includes examining how factors such as temperature, pressure, and concentration influence the compound's impact on fluid viscosity. By elucidating these relationships, researchers aim to develop predictive models that can guide the design of more efficient fluidic systems across multiple industries.

Furthermore, this research seeks to explore the potential applications of ethyl propanoate as a viscosity modifier. This includes investigating its compatibility with different types of fluids, its stability under various operating conditions, and its long-term effects on system performance. The goal is to identify novel uses for ethyl propanoate that could lead to improvements in existing processes or the development of entirely new applications.

As we delve deeper into the study of ethyl propanoate's viscosity effects, it is essential to consider the broader implications of this research. The findings could potentially influence the development of new lubricants, coolants, and other functional fluids. Additionally, understanding the compound's behavior in fluidic systems may contribute to advancements in microfluidics, a field with applications ranging from medical diagnostics to environmental monitoring.

The study of ethyl propanoate's effects on viscosity is rooted in the broader field of rheology, which examines the flow and deformation of matter. As industries continue to seek more efficient and environmentally friendly solutions for various processes, understanding the behavior of ethyl propanoate in fluid systems has become increasingly important.

Historically, the use of esters in industrial applications has been well-documented, with their ability to modify fluid properties being a key area of interest. Ethyl propanoate, in particular, has emerged as a compound of focus due to its relatively low toxicity, pleasant odor, and potential for biodegradability. These characteristics make it an attractive option for industries looking to optimize their processes while adhering to stricter environmental regulations.

The evolution of fluid dynamics research has led to a growing interest in how specific compounds can alter the viscosity of fluids. Viscosity, a measure of a fluid's resistance to flow, plays a crucial role in numerous industrial processes, from lubricant formulation to food processing. As such, the ability to fine-tune viscosity through the addition of compounds like ethyl propanoate presents exciting possibilities for process optimization and product development.

The primary objective of studying ethyl propanoate's effects on viscosity in fluidic systems is to gain a comprehensive understanding of its behavior under various conditions. This includes examining how factors such as temperature, pressure, and concentration influence the compound's impact on fluid viscosity. By elucidating these relationships, researchers aim to develop predictive models that can guide the design of more efficient fluidic systems across multiple industries.

Furthermore, this research seeks to explore the potential applications of ethyl propanoate as a viscosity modifier. This includes investigating its compatibility with different types of fluids, its stability under various operating conditions, and its long-term effects on system performance. The goal is to identify novel uses for ethyl propanoate that could lead to improvements in existing processes or the development of entirely new applications.

As we delve deeper into the study of ethyl propanoate's viscosity effects, it is essential to consider the broader implications of this research. The findings could potentially influence the development of new lubricants, coolants, and other functional fluids. Additionally, understanding the compound's behavior in fluidic systems may contribute to advancements in microfluidics, a field with applications ranging from medical diagnostics to environmental monitoring.

Market Analysis for Ethyl Propanoate in Fluidic Systems

The market for ethyl propanoate in fluidic systems is experiencing significant growth, driven by its unique properties and versatile applications. This ester compound, known for its fruity aroma and solvent capabilities, has found increasing use in various industries, particularly in those involving fluid dynamics and viscosity control.

In the automotive sector, ethyl propanoate is gaining traction as an additive in lubricants and hydraulic fluids. Its ability to modify viscosity without compromising other fluid properties makes it valuable for improving engine efficiency and reducing wear. The growing emphasis on fuel economy and emission reduction in the automotive industry is expected to further boost the demand for ethyl propanoate in this sector.

The chemical processing industry represents another major market for ethyl propanoate in fluidic systems. Its use as a solvent and reactant in various chemical processes has led to increased adoption in manufacturing operations. The compound's low toxicity and biodegradability also align with the industry's shift towards more environmentally friendly practices, potentially expanding its market share.

In the pharmaceutical and cosmetics industries, ethyl propanoate is finding applications in formulation processes where viscosity control is crucial. Its compatibility with a wide range of ingredients and its ability to enhance product stability have made it a preferred choice in these sectors. The growing consumer demand for high-quality personal care products is likely to drive further growth in this market segment.

The food and beverage industry is another key market for ethyl propanoate, where it is used not only for its fruity flavor but also for its role in modifying the viscosity of certain food products. This dual functionality makes it particularly valuable in the development of new food textures and formulations, aligning with consumer trends for innovative food experiences.

Geographically, North America and Europe currently lead the market for ethyl propanoate in fluidic systems, owing to their advanced industrial sectors and stringent quality standards. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing adoption of advanced manufacturing processes.

The market is characterized by a mix of large chemical companies and specialized manufacturers. Key players are focusing on research and development to enhance the performance of ethyl propanoate in various fluidic applications, potentially opening new market opportunities. Collaborations between manufacturers and end-users are becoming more common, aiming to develop tailored solutions for specific industry needs.

In the automotive sector, ethyl propanoate is gaining traction as an additive in lubricants and hydraulic fluids. Its ability to modify viscosity without compromising other fluid properties makes it valuable for improving engine efficiency and reducing wear. The growing emphasis on fuel economy and emission reduction in the automotive industry is expected to further boost the demand for ethyl propanoate in this sector.

The chemical processing industry represents another major market for ethyl propanoate in fluidic systems. Its use as a solvent and reactant in various chemical processes has led to increased adoption in manufacturing operations. The compound's low toxicity and biodegradability also align with the industry's shift towards more environmentally friendly practices, potentially expanding its market share.

In the pharmaceutical and cosmetics industries, ethyl propanoate is finding applications in formulation processes where viscosity control is crucial. Its compatibility with a wide range of ingredients and its ability to enhance product stability have made it a preferred choice in these sectors. The growing consumer demand for high-quality personal care products is likely to drive further growth in this market segment.

The food and beverage industry is another key market for ethyl propanoate, where it is used not only for its fruity flavor but also for its role in modifying the viscosity of certain food products. This dual functionality makes it particularly valuable in the development of new food textures and formulations, aligning with consumer trends for innovative food experiences.

Geographically, North America and Europe currently lead the market for ethyl propanoate in fluidic systems, owing to their advanced industrial sectors and stringent quality standards. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing adoption of advanced manufacturing processes.

The market is characterized by a mix of large chemical companies and specialized manufacturers. Key players are focusing on research and development to enhance the performance of ethyl propanoate in various fluidic applications, potentially opening new market opportunities. Collaborations between manufacturers and end-users are becoming more common, aiming to develop tailored solutions for specific industry needs.

Current Challenges in Viscosity Control with Ethyl Propanoate

The control of viscosity in fluidic systems using ethyl propanoate presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the complex relationship between ethyl propanoate concentration and fluid viscosity. While it is known that ethyl propanoate can affect viscosity, the precise mechanisms and quantitative relationships are not fully understood across all types of fluidic systems.

Temperature sensitivity poses another major challenge. The effect of ethyl propanoate on viscosity can vary significantly with temperature changes, making it difficult to maintain consistent viscosity control across different operating conditions. This is particularly problematic in systems that experience wide temperature fluctuations or require precise temperature control.

The interaction between ethyl propanoate and other components in fluidic systems also presents complications. In many practical applications, fluids contain multiple additives and compounds, each potentially influencing viscosity. The presence of ethyl propanoate can lead to unexpected interactions, sometimes resulting in non-linear or unpredictable changes in viscosity.

Long-term stability is another area of concern. Over extended periods, the effectiveness of ethyl propanoate in controlling viscosity may diminish due to chemical degradation or evaporation. This can lead to gradual changes in fluid properties, potentially affecting system performance and requiring frequent adjustments or replacements.

Measurement and monitoring of viscosity in real-time present technical challenges, especially in systems where ethyl propanoate concentration may fluctuate. Current sensing technologies may not be sufficiently accurate or responsive to detect subtle changes in viscosity caused by variations in ethyl propanoate levels.

Environmental and safety considerations also pose challenges. Ethyl propanoate, while generally considered safe, can have environmental impacts if released in large quantities. Ensuring proper containment and disposal, particularly in large-scale industrial applications, adds complexity to system design and operation.

Lastly, the economic viability of using ethyl propanoate for viscosity control is a significant consideration. The cost of the compound, coupled with potential increased maintenance and monitoring requirements, may make it less attractive for certain applications compared to alternative viscosity control methods.

Temperature sensitivity poses another major challenge. The effect of ethyl propanoate on viscosity can vary significantly with temperature changes, making it difficult to maintain consistent viscosity control across different operating conditions. This is particularly problematic in systems that experience wide temperature fluctuations or require precise temperature control.

The interaction between ethyl propanoate and other components in fluidic systems also presents complications. In many practical applications, fluids contain multiple additives and compounds, each potentially influencing viscosity. The presence of ethyl propanoate can lead to unexpected interactions, sometimes resulting in non-linear or unpredictable changes in viscosity.

Long-term stability is another area of concern. Over extended periods, the effectiveness of ethyl propanoate in controlling viscosity may diminish due to chemical degradation or evaporation. This can lead to gradual changes in fluid properties, potentially affecting system performance and requiring frequent adjustments or replacements.

Measurement and monitoring of viscosity in real-time present technical challenges, especially in systems where ethyl propanoate concentration may fluctuate. Current sensing technologies may not be sufficiently accurate or responsive to detect subtle changes in viscosity caused by variations in ethyl propanoate levels.

Environmental and safety considerations also pose challenges. Ethyl propanoate, while generally considered safe, can have environmental impacts if released in large quantities. Ensuring proper containment and disposal, particularly in large-scale industrial applications, adds complexity to system design and operation.

Lastly, the economic viability of using ethyl propanoate for viscosity control is a significant consideration. The cost of the compound, coupled with potential increased maintenance and monitoring requirements, may make it less attractive for certain applications compared to alternative viscosity control methods.

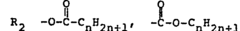

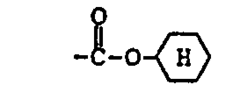

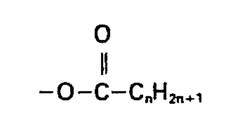

Existing Methods for Viscosity Adjustment Using Esters

01 Measurement and control of ethyl propanoate viscosity

Various methods and devices are used to measure and control the viscosity of ethyl propanoate in industrial processes. These include specialized viscometers, rheometers, and inline monitoring systems that can provide real-time data on the fluid's viscosity. Controlling viscosity is crucial for maintaining product quality and optimizing process efficiency in applications involving ethyl propanoate.- Measurement and control of ethyl propanoate viscosity: Various methods and devices are used to measure and control the viscosity of ethyl propanoate in industrial processes. These include specialized viscometers, rheometers, and inline monitoring systems that can provide real-time data on the fluid's viscosity. Controlling viscosity is crucial for maintaining product quality and optimizing process efficiency in applications involving ethyl propanoate.

- Ethyl propanoate as a solvent in chemical processes: Ethyl propanoate is utilized as a solvent in various chemical processes due to its favorable viscosity characteristics. Its low viscosity makes it suitable for use in reactions, extractions, and purifications where good solvent properties and ease of handling are required. The viscosity of ethyl propanoate can be adjusted by blending with other solvents to achieve desired flow properties for specific applications.

- Viscosity modification of ethyl propanoate-containing formulations: The viscosity of formulations containing ethyl propanoate can be modified using various additives and techniques. This includes the use of thickeners, polymers, or other viscosity modifiers to adjust the flow properties of the final product. Such modifications are important in industries like coatings, adhesives, and personal care products where the viscosity of ethyl propanoate-based formulations needs to be tailored for specific applications.

- Temperature dependence of ethyl propanoate viscosity: The viscosity of ethyl propanoate is known to vary with temperature. Understanding this temperature dependence is crucial for predicting and controlling the behavior of ethyl propanoate in various applications. Temperature-viscosity relationships are often studied and modeled to optimize processes involving this compound, particularly in industries where precise control of fluid properties is essential.

- Ethyl propanoate in lubricant formulations: Ethyl propanoate is used in certain lubricant formulations due to its viscosity characteristics. Its low viscosity can contribute to improved flow properties in lubricants, potentially enhancing their performance in specific applications. The viscosity of ethyl propanoate-containing lubricants may be further modified with additives to achieve desired tribological properties and temperature stability.

02 Ethyl propanoate as a solvent in chemical processes

Ethyl propanoate is utilized as a solvent in various chemical processes due to its favorable viscosity characteristics. Its low viscosity makes it suitable for use in reactions, extractions, and purifications where good solvent properties and ease of handling are required. The viscosity of ethyl propanoate can be adjusted by blending with other solvents to achieve desired flow properties for specific applications.Expand Specific Solutions03 Viscosity modification of ethyl propanoate-containing formulations

The viscosity of formulations containing ethyl propanoate can be modified using various additives and techniques. This is particularly important in the development of coatings, adhesives, and other industrial products where specific flow characteristics are required. Viscosity modifiers, such as polymers or inorganic particles, can be added to ethyl propanoate-based formulations to achieve desired rheological properties.Expand Specific Solutions04 Temperature dependence of ethyl propanoate viscosity

The viscosity of ethyl propanoate is known to be temperature-dependent, with viscosity generally decreasing as temperature increases. Understanding this relationship is crucial for predicting and controlling the behavior of ethyl propanoate in various applications, particularly in processes involving heat transfer or temperature changes. Temperature-viscosity correlations and models are used to account for these effects in process design and optimization.Expand Specific Solutions05 Ethyl propanoate in lubricant formulations

Ethyl propanoate is used as a component in certain lubricant formulations due to its viscosity characteristics and chemical properties. It can contribute to the overall viscosity profile of the lubricant and may offer benefits such as improved flow at low temperatures or enhanced solubility of additives. The viscosity of ethyl propanoate-containing lubricants is carefully controlled to meet specific performance requirements in various applications.Expand Specific Solutions

Key Industry Players in Fluidic System Additives

The competition landscape for "How Ethyl Propanoate Affects Viscosity in Fluidic Systems" is in its early development stage, with a relatively small market size but growing interest. The technology's maturity is still evolving, with major players like Halliburton Energy Services, Baker Hughes, and Schlumberger Technologies leading research efforts. These companies, along with ExxonMobil Chemical Patents and Weatherford Technology Holdings, are likely investing in understanding ethyl propanoate's impact on fluid viscosity for potential applications in the oil and gas industry. While the market is currently niche, increasing focus on optimizing fluidic systems in various industries may drive future growth and technological advancements in this area.

Baker Hughes Co.

Technical Solution: Baker Hughes has investigated the use of ethyl propanoate as a component in smart fluids for enhanced oil recovery (EOR) operations. Their research focuses on how ethyl propanoate affects the viscoelastic properties of polymer solutions used in EOR[1]. They have developed proprietary formulations that incorporate ethyl propanoate to optimize fluid performance in different reservoir types[2]. Baker Hughes has also explored the synergistic effects of ethyl propanoate with other additives to create adaptive fluid systems that respond to changes in downhole conditions, such as temperature and pressure variations[3].

Strengths: Innovative approach to smart fluid design, extensive field testing experience. Weaknesses: Primarily focused on oil and gas industry applications, which may limit applicability in other sectors.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced rheological models to study the effects of ethyl propanoate on fluid viscosity in oilfield applications. Their approach involves using high-precision rheometers to measure viscosity changes at various concentrations and temperatures[1]. They have also implemented computational fluid dynamics (CFD) simulations to predict the behavior of ethyl propanoate-containing fluids in complex downhole environments[2]. Schlumberger's research has shown that ethyl propanoate can act as a viscosity modifier, potentially improving flow characteristics in certain reservoir conditions[3].

Strengths: Comprehensive understanding of fluid behavior in oilfield conditions, advanced measurement techniques, and simulation capabilities. Weaknesses: May be primarily focused on oil and gas applications, potentially limiting broader industrial applications.

Critical Patents on Ethyl Propanoate in Viscosity Modification

Use of reactive diluents for epoxy resins, and epoxy balk compounds

PatentInactiveEP0159035A3

Innovation

- The use of reactive diluents like di-n-ethyl maleate, di-n-ethyl fumarate, or vinyl propionate, which are compatible with aliphatic or cycloaliphatic polyamines, reducing viscosity by 10-40% and participating in crosslinking reactions without volatile issues, thereby enhancing mechanical properties and reducing shrinkage.

Environmental Impact of Ethyl Propanoate Usage

The environmental impact of ethyl propanoate usage in fluidic systems is a critical consideration for industries employing this compound. Ethyl propanoate, also known as ethyl propionate, is an organic ester commonly used as a solvent and flavoring agent. Its application in fluidic systems, particularly for viscosity modification, necessitates a thorough examination of its ecological footprint.

Ethyl propanoate is generally considered to have a lower environmental impact compared to many other organic solvents. It is biodegradable and does not persist in the environment for extended periods. However, its production and use still contribute to carbon emissions and potential air quality issues. The manufacturing process of ethyl propanoate involves the reaction of propionic acid with ethanol, which requires energy input and may result in greenhouse gas emissions depending on the energy source used.

In aquatic environments, ethyl propanoate exhibits low toxicity to fish and other aquatic organisms. Its water solubility is moderate, which means that in case of accidental spills, it can dissolve and disperse in water bodies. While this reduces the risk of direct physical harm to aquatic life, it may still cause temporary changes in water chemistry and affect sensitive ecosystems.

The volatile nature of ethyl propanoate raises concerns about its contribution to air pollution. When used in open systems or during handling and transfer operations, it can evaporate and contribute to the formation of ground-level ozone and smog. This is particularly relevant in urban and industrial areas where air quality is already compromised.

Waste management is another crucial aspect of ethyl propanoate's environmental impact. Proper disposal methods must be employed to prevent contamination of soil and groundwater. Incineration is often used for disposal, which, while effective in destroying the compound, can lead to air emissions if not properly controlled.

In terms of long-term environmental effects, ethyl propanoate does not bioaccumulate in the food chain, which is a positive attribute. However, its production from petrochemical sources contributes to the depletion of non-renewable resources. There is growing interest in developing bio-based alternatives to ethyl propanoate, which could potentially reduce its overall environmental footprint.

The use of ethyl propanoate in fluidic systems may indirectly contribute to energy savings if it improves system efficiency. By optimizing viscosity, it can potentially reduce the energy required for fluid transport and processing. This indirect benefit should be weighed against the direct environmental impacts of its production and use.

Ethyl propanoate is generally considered to have a lower environmental impact compared to many other organic solvents. It is biodegradable and does not persist in the environment for extended periods. However, its production and use still contribute to carbon emissions and potential air quality issues. The manufacturing process of ethyl propanoate involves the reaction of propionic acid with ethanol, which requires energy input and may result in greenhouse gas emissions depending on the energy source used.

In aquatic environments, ethyl propanoate exhibits low toxicity to fish and other aquatic organisms. Its water solubility is moderate, which means that in case of accidental spills, it can dissolve and disperse in water bodies. While this reduces the risk of direct physical harm to aquatic life, it may still cause temporary changes in water chemistry and affect sensitive ecosystems.

The volatile nature of ethyl propanoate raises concerns about its contribution to air pollution. When used in open systems or during handling and transfer operations, it can evaporate and contribute to the formation of ground-level ozone and smog. This is particularly relevant in urban and industrial areas where air quality is already compromised.

Waste management is another crucial aspect of ethyl propanoate's environmental impact. Proper disposal methods must be employed to prevent contamination of soil and groundwater. Incineration is often used for disposal, which, while effective in destroying the compound, can lead to air emissions if not properly controlled.

In terms of long-term environmental effects, ethyl propanoate does not bioaccumulate in the food chain, which is a positive attribute. However, its production from petrochemical sources contributes to the depletion of non-renewable resources. There is growing interest in developing bio-based alternatives to ethyl propanoate, which could potentially reduce its overall environmental footprint.

The use of ethyl propanoate in fluidic systems may indirectly contribute to energy savings if it improves system efficiency. By optimizing viscosity, it can potentially reduce the energy required for fluid transport and processing. This indirect benefit should be weighed against the direct environmental impacts of its production and use.

Safety Regulations for Ester Additives in Fluidic Systems

The incorporation of ester additives, such as ethyl propanoate, in fluidic systems necessitates a comprehensive understanding of safety regulations to ensure proper handling, storage, and usage. These regulations are crucial for maintaining the integrity of the system and protecting personnel involved in its operation.

Regulatory bodies, including the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), have established guidelines for the safe use of ester additives in industrial settings. These guidelines cover aspects such as proper labeling, storage conditions, and handling procedures to minimize risks associated with flammability and potential health hazards.

Material Safety Data Sheets (MSDS) play a vital role in communicating safety information for ester additives. Manufacturers and users of ethyl propanoate and similar compounds must ensure that up-to-date MSDS are readily available to all personnel working with these substances. These documents provide critical information on physical and chemical properties, potential hazards, and appropriate emergency response procedures.

Personal Protective Equipment (PPE) requirements for handling ester additives in fluidic systems are typically outlined in safety regulations. This may include the use of chemical-resistant gloves, safety goggles, and appropriate respiratory protection when working with large quantities or in poorly ventilated areas. Proper training on the correct use of PPE is essential for maintaining a safe working environment.

Storage regulations for ester additives often specify the need for cool, dry, and well-ventilated areas away from sources of ignition. Containers must be properly sealed and labeled, with secondary containment measures in place to prevent accidental spills or leaks. Regular inspections of storage areas and containers are typically mandated to ensure compliance with safety standards.

Disposal of ester additives and contaminated materials must adhere to local, state, and federal environmental regulations. Proper disposal methods may include incineration or treatment at authorized waste management facilities. Companies must maintain accurate records of disposal activities to demonstrate compliance with regulatory requirements.

Emergency response plans are a critical component of safety regulations for ester additives in fluidic systems. These plans should outline procedures for addressing spills, fires, or other incidents involving these substances. Regular drills and training sessions are often required to ensure that personnel are prepared to respond effectively in emergency situations.

Monitoring and reporting requirements may be specified in safety regulations to track the use and potential environmental impact of ester additives. This can include periodic air quality assessments, wastewater testing, and documentation of any incidents or near-misses related to the handling of these substances.

By adhering to these comprehensive safety regulations, organizations can minimize risks associated with the use of ester additives like ethyl propanoate in fluidic systems, ensuring the protection of both personnel and the environment.

Regulatory bodies, including the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA), have established guidelines for the safe use of ester additives in industrial settings. These guidelines cover aspects such as proper labeling, storage conditions, and handling procedures to minimize risks associated with flammability and potential health hazards.

Material Safety Data Sheets (MSDS) play a vital role in communicating safety information for ester additives. Manufacturers and users of ethyl propanoate and similar compounds must ensure that up-to-date MSDS are readily available to all personnel working with these substances. These documents provide critical information on physical and chemical properties, potential hazards, and appropriate emergency response procedures.

Personal Protective Equipment (PPE) requirements for handling ester additives in fluidic systems are typically outlined in safety regulations. This may include the use of chemical-resistant gloves, safety goggles, and appropriate respiratory protection when working with large quantities or in poorly ventilated areas. Proper training on the correct use of PPE is essential for maintaining a safe working environment.

Storage regulations for ester additives often specify the need for cool, dry, and well-ventilated areas away from sources of ignition. Containers must be properly sealed and labeled, with secondary containment measures in place to prevent accidental spills or leaks. Regular inspections of storage areas and containers are typically mandated to ensure compliance with safety standards.

Disposal of ester additives and contaminated materials must adhere to local, state, and federal environmental regulations. Proper disposal methods may include incineration or treatment at authorized waste management facilities. Companies must maintain accurate records of disposal activities to demonstrate compliance with regulatory requirements.

Emergency response plans are a critical component of safety regulations for ester additives in fluidic systems. These plans should outline procedures for addressing spills, fires, or other incidents involving these substances. Regular drills and training sessions are often required to ensure that personnel are prepared to respond effectively in emergency situations.

Monitoring and reporting requirements may be specified in safety regulations to track the use and potential environmental impact of ester additives. This can include periodic air quality assessments, wastewater testing, and documentation of any incidents or near-misses related to the handling of these substances.

By adhering to these comprehensive safety regulations, organizations can minimize risks associated with the use of ester additives like ethyl propanoate in fluidic systems, ensuring the protection of both personnel and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!