How Ethyl Propanoate Affects Polysaccharide Structures

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate and Polysaccharide Interaction Background

Ethyl propanoate, also known as ethyl propionate, is an organic compound with the molecular formula C5H10O2. It is a colorless liquid with a fruity odor, commonly used as a flavoring agent in the food industry. In recent years, researchers have become increasingly interested in studying the interactions between ethyl propanoate and polysaccharides, as these interactions can significantly impact the structure and properties of various materials.

Polysaccharides are complex carbohydrates composed of long chains of monosaccharide units linked by glycosidic bonds. They play crucial roles in numerous biological processes and are widely used in various industries, including food, pharmaceuticals, and materials science. The interaction between ethyl propanoate and polysaccharides has gained attention due to its potential applications in modifying the properties of polysaccharide-based materials.

The study of ethyl propanoate's effects on polysaccharide structures is rooted in the broader field of polymer science and carbohydrate chemistry. Researchers have been exploring how small organic molecules, such as ethyl propanoate, can influence the conformational changes and intermolecular interactions of polysaccharides. This area of research has implications for developing novel materials with tailored properties and improving existing products in various industries.

One of the key aspects of this interaction is the potential for ethyl propanoate to act as a plasticizer for polysaccharides. Plasticizers are substances that can increase the flexibility and workability of polymers by reducing the intermolecular forces between polymer chains. The ability of ethyl propanoate to interact with polysaccharides in this manner could lead to the development of more flexible and processable biopolymer-based materials.

Furthermore, the interaction between ethyl propanoate and polysaccharides has implications for the food industry, particularly in the area of flavor encapsulation and controlled release. The ability of polysaccharides to form complexes with small molecules like ethyl propanoate could be exploited to create novel delivery systems for flavors and aromas in food products.

As research in this field progresses, scientists are employing a variety of analytical techniques to study the molecular-level interactions between ethyl propanoate and polysaccharides. These include spectroscopic methods, such as nuclear magnetic resonance (NMR) and Fourier-transform infrared spectroscopy (FTIR), as well as computational modeling approaches to simulate and predict the behavior of these complex systems.

Polysaccharides are complex carbohydrates composed of long chains of monosaccharide units linked by glycosidic bonds. They play crucial roles in numerous biological processes and are widely used in various industries, including food, pharmaceuticals, and materials science. The interaction between ethyl propanoate and polysaccharides has gained attention due to its potential applications in modifying the properties of polysaccharide-based materials.

The study of ethyl propanoate's effects on polysaccharide structures is rooted in the broader field of polymer science and carbohydrate chemistry. Researchers have been exploring how small organic molecules, such as ethyl propanoate, can influence the conformational changes and intermolecular interactions of polysaccharides. This area of research has implications for developing novel materials with tailored properties and improving existing products in various industries.

One of the key aspects of this interaction is the potential for ethyl propanoate to act as a plasticizer for polysaccharides. Plasticizers are substances that can increase the flexibility and workability of polymers by reducing the intermolecular forces between polymer chains. The ability of ethyl propanoate to interact with polysaccharides in this manner could lead to the development of more flexible and processable biopolymer-based materials.

Furthermore, the interaction between ethyl propanoate and polysaccharides has implications for the food industry, particularly in the area of flavor encapsulation and controlled release. The ability of polysaccharides to form complexes with small molecules like ethyl propanoate could be exploited to create novel delivery systems for flavors and aromas in food products.

As research in this field progresses, scientists are employing a variety of analytical techniques to study the molecular-level interactions between ethyl propanoate and polysaccharides. These include spectroscopic methods, such as nuclear magnetic resonance (NMR) and Fourier-transform infrared spectroscopy (FTIR), as well as computational modeling approaches to simulate and predict the behavior of these complex systems.

Market Applications of Modified Polysaccharides

The modification of polysaccharides through interactions with ethyl propanoate has opened up a wide range of market applications across various industries. These modified polysaccharides exhibit enhanced properties and functionalities, making them valuable in sectors such as food and beverage, pharmaceuticals, cosmetics, and industrial materials.

In the food industry, modified polysaccharides have found extensive use as thickeners, stabilizers, and emulsifiers. The altered structures resulting from ethyl propanoate treatment can improve texture, mouthfeel, and shelf-life of various food products. For instance, in dairy products, these modified polysaccharides can enhance creaminess and prevent syneresis, leading to improved consumer acceptance and product quality.

The pharmaceutical sector has also benefited significantly from these modified polysaccharides. They serve as effective drug delivery systems, offering controlled release properties and improved bioavailability of active pharmaceutical ingredients. The structural changes induced by ethyl propanoate can create more porous matrices, allowing for better encapsulation and targeted release of drugs.

Cosmetics and personal care products have embraced modified polysaccharides for their unique rheological properties and skin-feel characteristics. These materials can act as natural film-formers, moisturizers, and texture modifiers in a variety of formulations, from creams and lotions to hair care products. The ethyl propanoate-induced modifications can enhance the polysaccharides' ability to form stable emulsions and improve their sensory attributes.

In the realm of industrial materials, modified polysaccharides have found applications in areas such as paper manufacturing, textiles, and adhesives. The structural changes can improve the strength and durability of paper products, enhance the dyeing properties of textiles, and increase the bonding capabilities of adhesives. These modifications have led to more sustainable and eco-friendly alternatives in various industrial processes.

The biomedical field has also seen significant advancements with the use of these modified polysaccharides. They have been employed in tissue engineering scaffolds, wound dressings, and as components in biocompatible implants. The altered structures can promote better cell adhesion, controlled degradation rates, and improved mechanical properties, making them suitable for a wide range of biomedical applications.

As sustainability becomes increasingly important, modified polysaccharides are gaining traction in the development of biodegradable packaging materials. The structural changes induced by ethyl propanoate can enhance barrier properties and mechanical strength, making these materials viable alternatives to traditional petroleum-based plastics in certain applications.

In the food industry, modified polysaccharides have found extensive use as thickeners, stabilizers, and emulsifiers. The altered structures resulting from ethyl propanoate treatment can improve texture, mouthfeel, and shelf-life of various food products. For instance, in dairy products, these modified polysaccharides can enhance creaminess and prevent syneresis, leading to improved consumer acceptance and product quality.

The pharmaceutical sector has also benefited significantly from these modified polysaccharides. They serve as effective drug delivery systems, offering controlled release properties and improved bioavailability of active pharmaceutical ingredients. The structural changes induced by ethyl propanoate can create more porous matrices, allowing for better encapsulation and targeted release of drugs.

Cosmetics and personal care products have embraced modified polysaccharides for their unique rheological properties and skin-feel characteristics. These materials can act as natural film-formers, moisturizers, and texture modifiers in a variety of formulations, from creams and lotions to hair care products. The ethyl propanoate-induced modifications can enhance the polysaccharides' ability to form stable emulsions and improve their sensory attributes.

In the realm of industrial materials, modified polysaccharides have found applications in areas such as paper manufacturing, textiles, and adhesives. The structural changes can improve the strength and durability of paper products, enhance the dyeing properties of textiles, and increase the bonding capabilities of adhesives. These modifications have led to more sustainable and eco-friendly alternatives in various industrial processes.

The biomedical field has also seen significant advancements with the use of these modified polysaccharides. They have been employed in tissue engineering scaffolds, wound dressings, and as components in biocompatible implants. The altered structures can promote better cell adhesion, controlled degradation rates, and improved mechanical properties, making them suitable for a wide range of biomedical applications.

As sustainability becomes increasingly important, modified polysaccharides are gaining traction in the development of biodegradable packaging materials. The structural changes induced by ethyl propanoate can enhance barrier properties and mechanical strength, making these materials viable alternatives to traditional petroleum-based plastics in certain applications.

Current Challenges in Polysaccharide Modification

The modification of polysaccharide structures presents several significant challenges in the field of carbohydrate chemistry and materials science. One of the primary obstacles is the complex and diverse nature of polysaccharides themselves. These macromolecules exhibit a wide range of structural variations, including differences in monosaccharide composition, glycosidic linkages, and branching patterns. This inherent complexity makes it difficult to develop universal modification strategies that can be applied across different types of polysaccharides.

Another major challenge lies in achieving selective and controlled modifications. Polysaccharides often contain multiple reactive functional groups, such as hydroxyl, carboxyl, and amino groups. Targeting specific sites for modification while leaving others untouched requires highly selective chemistry and precise reaction conditions. This becomes particularly challenging when attempting to modify internal regions of the polysaccharide chain, as opposed to more accessible terminal units.

The preservation of the native polysaccharide structure during modification processes is also a significant concern. Many modification techniques involve harsh reaction conditions or reagents that can lead to unintended structural changes, such as chain degradation or alteration of the glycosidic linkages. Maintaining the integrity of the polysaccharide backbone while introducing desired modifications is crucial for retaining the original properties and functions of the material.

Scale-up and reproducibility of polysaccharide modifications present additional challenges. Reactions that work well at laboratory scale may encounter difficulties when translated to industrial production. Factors such as mixing efficiency, heat transfer, and reagent distribution can significantly impact the outcome of modifications at larger scales. Ensuring consistent and reproducible results across different batches and scales is essential for commercial applications.

The characterization of modified polysaccharides poses its own set of challenges. Traditional analytical techniques may not always be suitable for accurately determining the degree and location of modifications within complex polysaccharide structures. Advanced analytical methods, such as NMR spectroscopy and mass spectrometry, are often required but can be time-consuming and expensive.

Environmental and safety concerns also play a role in the challenges faced in polysaccharide modification. Many traditional modification techniques rely on organic solvents or toxic reagents, which are not aligned with the principles of green chemistry. Developing eco-friendly and sustainable modification methods that minimize environmental impact and health risks is an ongoing challenge in the field.

In the context of using ethyl propanoate to affect polysaccharide structures, specific challenges may include controlling the extent of esterification, ensuring uniform modification across the polysaccharide chain, and preventing unwanted side reactions or degradation. The volatility and flammability of ethyl propanoate also necessitate careful handling and safety precautions during the modification process.

Another major challenge lies in achieving selective and controlled modifications. Polysaccharides often contain multiple reactive functional groups, such as hydroxyl, carboxyl, and amino groups. Targeting specific sites for modification while leaving others untouched requires highly selective chemistry and precise reaction conditions. This becomes particularly challenging when attempting to modify internal regions of the polysaccharide chain, as opposed to more accessible terminal units.

The preservation of the native polysaccharide structure during modification processes is also a significant concern. Many modification techniques involve harsh reaction conditions or reagents that can lead to unintended structural changes, such as chain degradation or alteration of the glycosidic linkages. Maintaining the integrity of the polysaccharide backbone while introducing desired modifications is crucial for retaining the original properties and functions of the material.

Scale-up and reproducibility of polysaccharide modifications present additional challenges. Reactions that work well at laboratory scale may encounter difficulties when translated to industrial production. Factors such as mixing efficiency, heat transfer, and reagent distribution can significantly impact the outcome of modifications at larger scales. Ensuring consistent and reproducible results across different batches and scales is essential for commercial applications.

The characterization of modified polysaccharides poses its own set of challenges. Traditional analytical techniques may not always be suitable for accurately determining the degree and location of modifications within complex polysaccharide structures. Advanced analytical methods, such as NMR spectroscopy and mass spectrometry, are often required but can be time-consuming and expensive.

Environmental and safety concerns also play a role in the challenges faced in polysaccharide modification. Many traditional modification techniques rely on organic solvents or toxic reagents, which are not aligned with the principles of green chemistry. Developing eco-friendly and sustainable modification methods that minimize environmental impact and health risks is an ongoing challenge in the field.

In the context of using ethyl propanoate to affect polysaccharide structures, specific challenges may include controlling the extent of esterification, ensuring uniform modification across the polysaccharide chain, and preventing unwanted side reactions or degradation. The volatility and flammability of ethyl propanoate also necessitate careful handling and safety precautions during the modification process.

Existing Methods for Ethyl Propanoate-Polysaccharide Modification

01 Synthesis of ethyl propanoate-modified polysaccharides

Methods for synthesizing polysaccharide structures modified with ethyl propanoate groups. This involves esterification reactions between polysaccharides and ethyl propanoate or its derivatives to create novel materials with altered properties.- Synthesis of ethyl propanoate-modified polysaccharides: Methods for synthesizing polysaccharide structures modified with ethyl propanoate groups. This involves esterification reactions between polysaccharides and ethyl propanoate or its derivatives to create novel materials with altered properties.

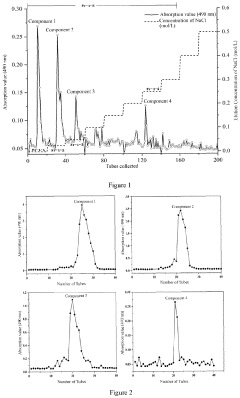

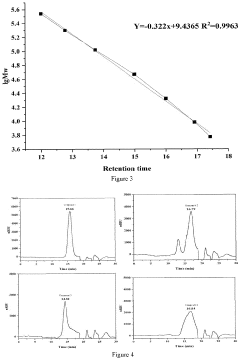

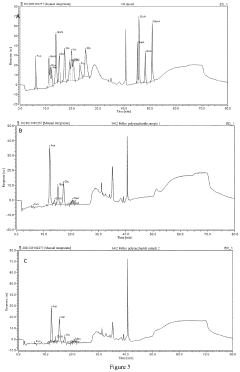

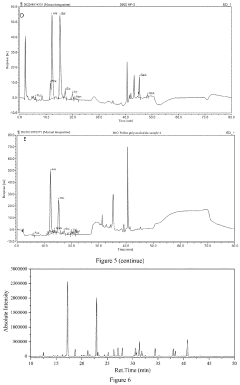

- Characterization of ethyl propanoate polysaccharide structures: Techniques for analyzing and characterizing the structural features of ethyl propanoate-modified polysaccharides. This includes spectroscopic methods, chromatography, and other analytical approaches to determine composition, degree of substitution, and molecular weight.

- Applications of ethyl propanoate polysaccharide structures: Various applications of ethyl propanoate-modified polysaccharides in fields such as drug delivery, food technology, and materials science. These modified structures can exhibit improved solubility, stability, or functional properties compared to unmodified polysaccharides.

- Biodegradability and environmental impact: Studies on the biodegradability and environmental impact of ethyl propanoate polysaccharide structures. This includes investigations into their decomposition pathways, potential for eco-friendly applications, and comparison with conventional synthetic polymers.

- Ethyl propanoate polysaccharide derivatives and modifications: Development of various derivatives and further modifications of ethyl propanoate polysaccharide structures. This includes chemical alterations, crosslinking, or grafting with other molecules to create new materials with enhanced or tailored properties for specific applications.

02 Characterization of ethyl propanoate polysaccharide structures

Techniques for analyzing and characterizing the structural features of ethyl propanoate-modified polysaccharides. This includes spectroscopic methods, chromatography, and other analytical approaches to determine composition, degree of substitution, and molecular weight.Expand Specific Solutions03 Applications of ethyl propanoate polysaccharide structures

Various applications of ethyl propanoate-modified polysaccharides in fields such as drug delivery, food technology, and materials science. These modified structures may exhibit improved solubility, stability, or functional properties compared to unmodified polysaccharides.Expand Specific Solutions04 Biodegradability and environmental impact

Studies on the biodegradability and environmental impact of ethyl propanoate polysaccharide structures. This includes investigations into their decomposition pathways, potential ecological effects, and comparison with conventional synthetic polymers.Expand Specific Solutions05 Optimization of ethyl propanoate polysaccharide production

Strategies for optimizing the production of ethyl propanoate-modified polysaccharides, including process improvements, scaling up synthesis, and enhancing yield and purity. This may involve enzymatic approaches, novel catalysts, or innovative reaction conditions.Expand Specific Solutions

Key Players in Polysaccharide Research and Industry

The competitive landscape for research on "How Ethyl Propanoate Affects Polysaccharide Structures" is in its early stages, with potential for significant growth. The market size is currently modest but expanding as interest in polysaccharide modifications grows across various industries. Technologically, the field is still developing, with academic institutions like Zhejiang University and Washington State University leading fundamental research. Companies such as DSM IP Assets BV, Novozymes A/S, and BASF Corp. are likely at the forefront of applied research and development, leveraging their expertise in enzymes and industrial bioproducts to explore practical applications of ethyl propanoate's effects on polysaccharide structures.

Zhejiang University

Technical Solution: Zhejiang University has developed a novel approach to study the effects of ethyl propanoate on polysaccharide structures. Their research focuses on the interaction between ethyl propanoate and various polysaccharides, such as cellulose, starch, and pectin. The team has employed advanced spectroscopic techniques, including Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR), to analyze the structural changes induced by ethyl propanoate[1]. They have also utilized molecular dynamics simulations to model the interactions at the atomic level, providing insights into the mechanism of ethyl propanoate's influence on polysaccharide conformations[3]. Their findings suggest that ethyl propanoate can alter the hydrogen bonding network within polysaccharides, potentially affecting their physical properties and functionality in various applications.

Strengths: Comprehensive approach combining experimental and computational methods. Weaknesses: May be limited to specific types of polysaccharides and require further validation in complex biological systems.

DSM IP Assets BV

Technical Solution: DSM IP Assets BV has developed a proprietary technology to leverage the effects of ethyl propanoate on polysaccharide structures for industrial applications. Their approach involves the controlled modification of polysaccharides using ethyl propanoate as a reagent in a patented process[2]. This method allows for the tailoring of polysaccharide properties, such as solubility, viscosity, and film-forming capabilities. DSM's research has shown that ethyl propanoate can selectively esterify hydroxyl groups on polysaccharides, leading to altered physicochemical properties[4]. The company has successfully applied this technology in the development of novel food ingredients, pharmaceutical excipients, and biomaterials with enhanced functionality[5]. Their process is scalable and has been optimized for industrial production, ensuring consistent quality and performance of the modified polysaccharides.

Strengths: Industrial-scale application and patented technology. Weaknesses: May be limited to specific polysaccharide modifications and potentially high production costs.

Core Innovations in Polysaccharide Structural Analysis

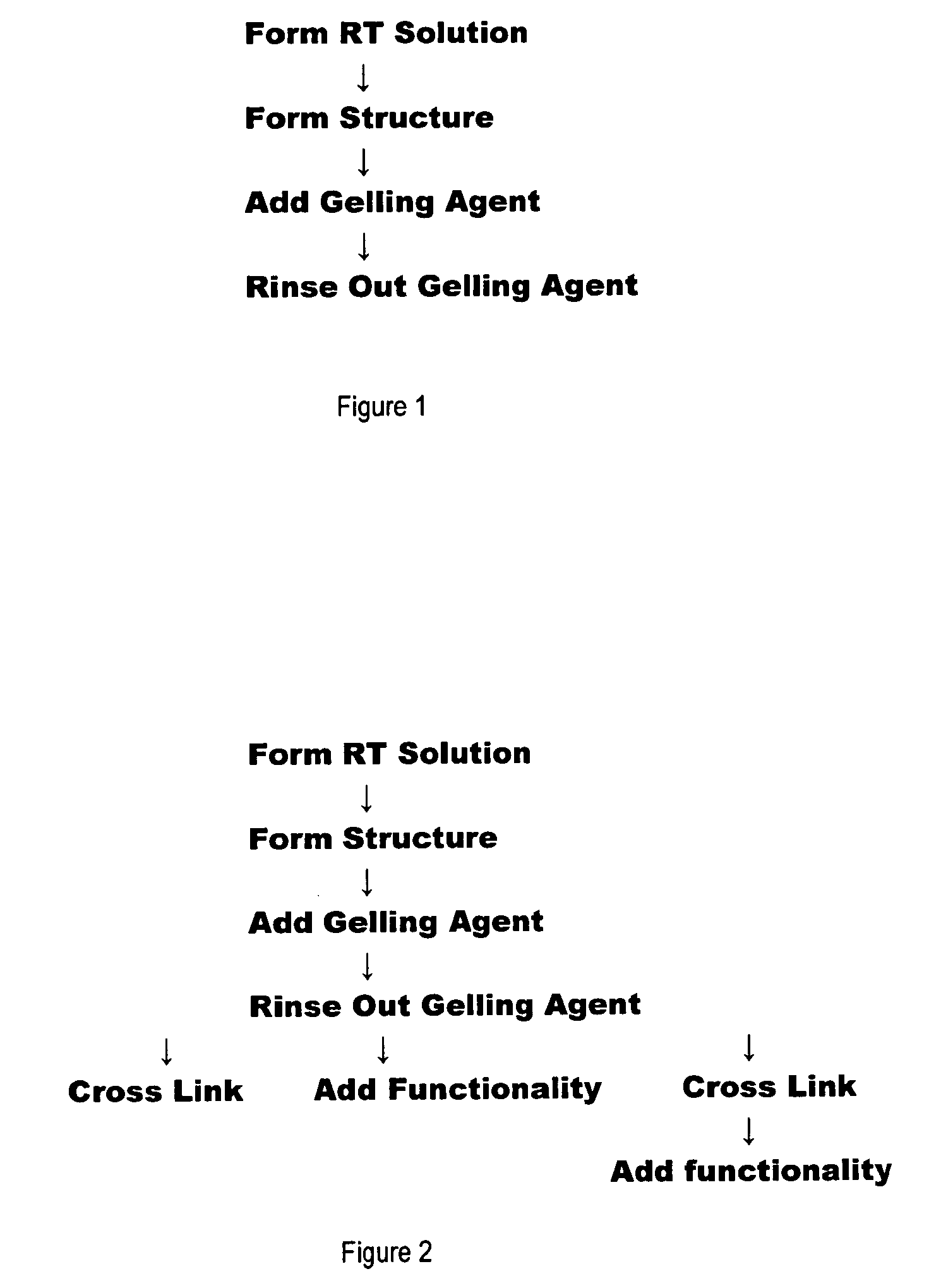

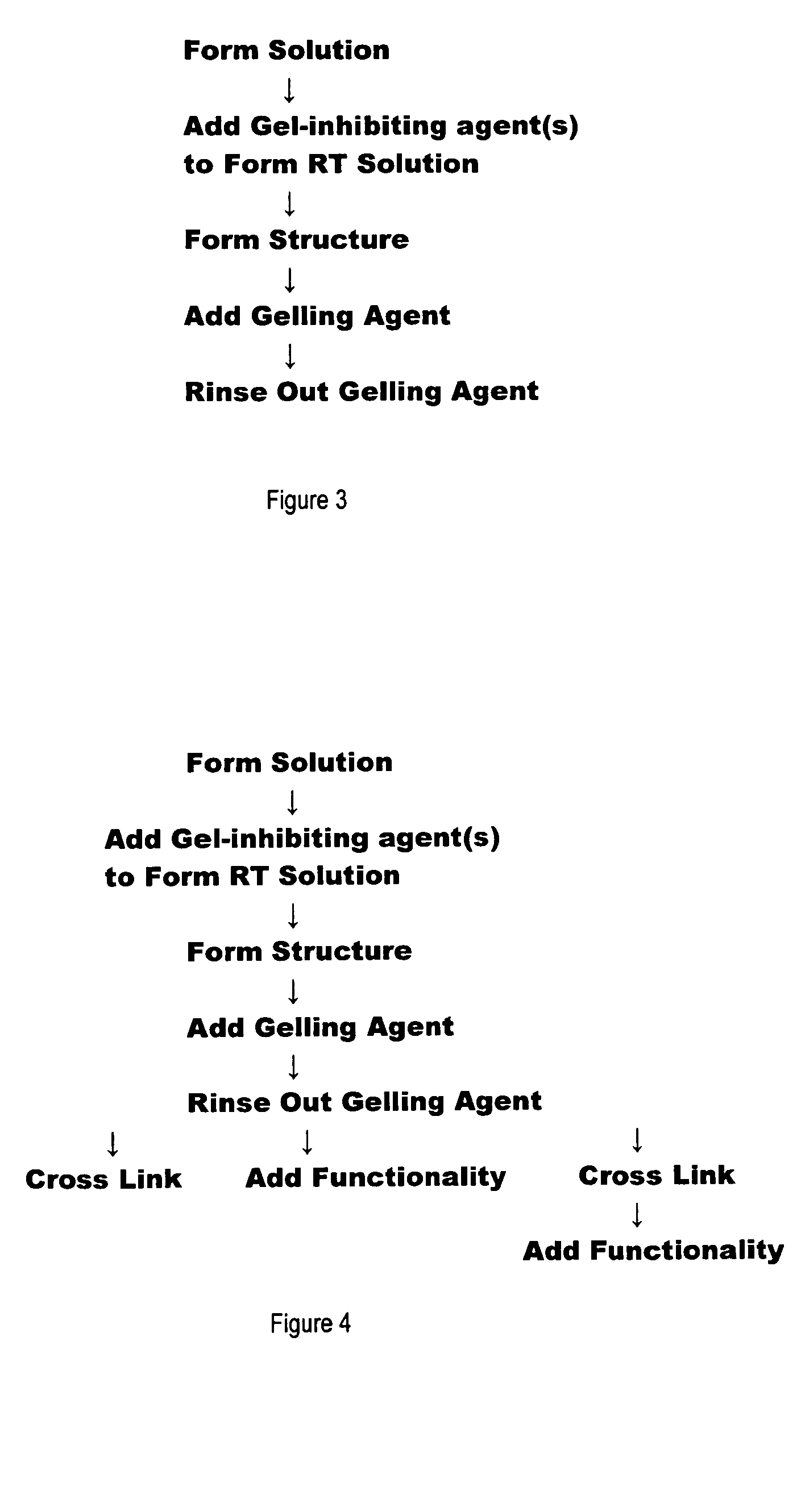

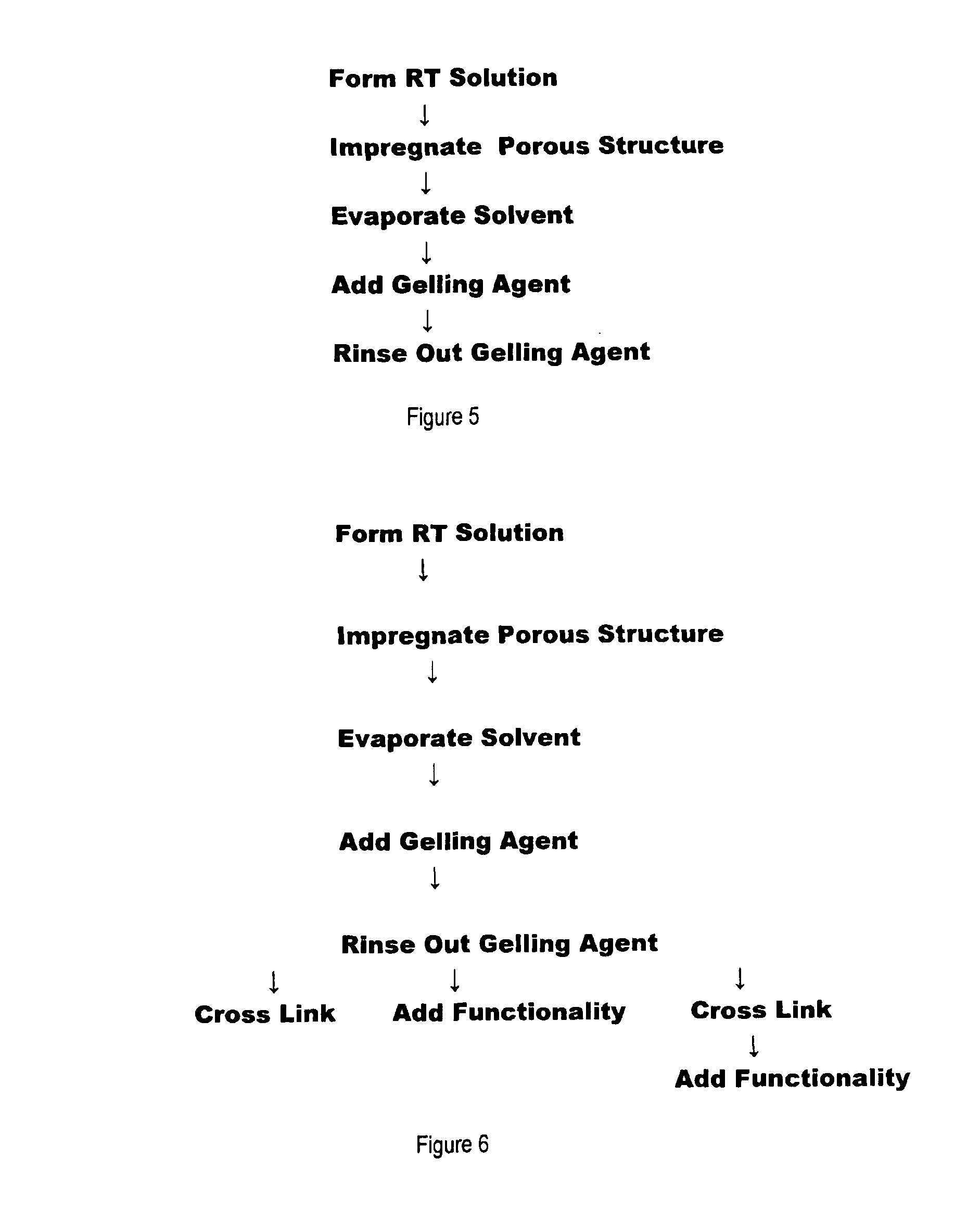

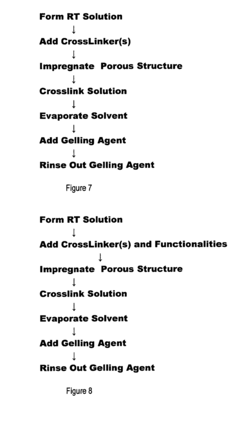

Method of forming polysaccharide structures

PatentInactiveUS7807823B2

Innovation

- A method involving the formation of a room temperature stable agarose solution using gel-inhibiting agents, which allows for coating porous materials without blocking pores, enabling both convective and diffusive flow, and the creation of beads and gels at or near room temperature.

Pollen polysaccharide and the separation method and application

PatentPendingEP4311835A1

Innovation

- The extraction and purification of pollen polysaccharides from oilseed rape pollen, specifically polysaccharides with defined structural units and molecular weights, which are then used to enhance plant growth promotion and stress resistance.

Environmental Impact of Ethyl Propanoate Usage

The environmental impact of ethyl propanoate usage in relation to polysaccharide structures is a complex issue that warrants careful consideration. Ethyl propanoate, also known as ethyl propionate, is an organic compound commonly used as a solvent and flavoring agent in various industries. When examining its effects on polysaccharide structures, it is crucial to assess the broader environmental implications.

One primary concern is the potential release of ethyl propanoate into aquatic ecosystems. As a volatile organic compound, it can contaminate water bodies through industrial effluents or accidental spills. This contamination may lead to alterations in the natural polysaccharide structures present in aquatic environments, such as those found in algae and other microorganisms. These changes could disrupt the delicate balance of aquatic ecosystems, affecting biodiversity and food chains.

Furthermore, the production and disposal of ethyl propanoate can contribute to air pollution. During manufacturing processes, volatile organic compounds (VOCs) may be released into the atmosphere, potentially leading to the formation of ground-level ozone and smog. These air quality issues can indirectly impact terrestrial ecosystems, including plants that rely on polysaccharide structures for their cellular integrity and function.

Soil contamination is another environmental concern associated with ethyl propanoate usage. When the compound seeps into soil, it can interact with soil microorganisms and affect their ability to produce and maintain polysaccharide structures. This interaction may have cascading effects on soil health, nutrient cycling, and the overall stability of terrestrial ecosystems.

The persistence of ethyl propanoate in the environment is an important factor to consider. While it is generally considered to have low persistence due to its volatility and biodegradability, repeated or large-scale releases could lead to accumulation in certain environmental compartments. This accumulation may result in long-term effects on polysaccharide structures in various organisms, potentially altering ecosystem dynamics over time.

It is also essential to consider the indirect environmental impacts of ethyl propanoate production. The manufacturing process requires energy and raw materials, contributing to resource depletion and greenhouse gas emissions. These broader environmental consequences can indirectly affect polysaccharide structures through climate change and habitat alterations.

To mitigate these environmental impacts, it is crucial to implement proper handling, storage, and disposal practices for ethyl propanoate. Additionally, exploring alternative compounds or processes that have less impact on polysaccharide structures and the environment should be a priority for industries relying on this chemical. Ongoing research and monitoring of the long-term effects of ethyl propanoate on ecosystems and biodiversity are necessary to fully understand and address its environmental implications.

One primary concern is the potential release of ethyl propanoate into aquatic ecosystems. As a volatile organic compound, it can contaminate water bodies through industrial effluents or accidental spills. This contamination may lead to alterations in the natural polysaccharide structures present in aquatic environments, such as those found in algae and other microorganisms. These changes could disrupt the delicate balance of aquatic ecosystems, affecting biodiversity and food chains.

Furthermore, the production and disposal of ethyl propanoate can contribute to air pollution. During manufacturing processes, volatile organic compounds (VOCs) may be released into the atmosphere, potentially leading to the formation of ground-level ozone and smog. These air quality issues can indirectly impact terrestrial ecosystems, including plants that rely on polysaccharide structures for their cellular integrity and function.

Soil contamination is another environmental concern associated with ethyl propanoate usage. When the compound seeps into soil, it can interact with soil microorganisms and affect their ability to produce and maintain polysaccharide structures. This interaction may have cascading effects on soil health, nutrient cycling, and the overall stability of terrestrial ecosystems.

The persistence of ethyl propanoate in the environment is an important factor to consider. While it is generally considered to have low persistence due to its volatility and biodegradability, repeated or large-scale releases could lead to accumulation in certain environmental compartments. This accumulation may result in long-term effects on polysaccharide structures in various organisms, potentially altering ecosystem dynamics over time.

It is also essential to consider the indirect environmental impacts of ethyl propanoate production. The manufacturing process requires energy and raw materials, contributing to resource depletion and greenhouse gas emissions. These broader environmental consequences can indirectly affect polysaccharide structures through climate change and habitat alterations.

To mitigate these environmental impacts, it is crucial to implement proper handling, storage, and disposal practices for ethyl propanoate. Additionally, exploring alternative compounds or processes that have less impact on polysaccharide structures and the environment should be a priority for industries relying on this chemical. Ongoing research and monitoring of the long-term effects of ethyl propanoate on ecosystems and biodiversity are necessary to fully understand and address its environmental implications.

Scalability of Ethyl Propanoate-Based Processes

The scalability of ethyl propanoate-based processes for modifying polysaccharide structures presents both opportunities and challenges in industrial applications. As the demand for tailored polysaccharides grows across various sectors, including food, pharmaceuticals, and materials science, the ability to scale up these processes becomes crucial for commercial viability.

One of the primary advantages of ethyl propanoate-based processes is their relatively low cost and wide availability of raw materials. Ethyl propanoate can be synthesized from renewable resources, making it an attractive option for large-scale production. Additionally, its low toxicity and biodegradability align well with increasing environmental regulations, potentially simplifying the scaling process from a regulatory standpoint.

However, several technical hurdles must be addressed to achieve efficient large-scale production. The reaction kinetics between ethyl propanoate and polysaccharides can be complex, often requiring precise control of temperature, pH, and concentration. As the scale increases, maintaining uniform reaction conditions throughout larger vessels becomes more challenging, potentially leading to inconsistent product quality.

Mass transfer limitations also become more pronounced at larger scales, particularly when dealing with high-molecular-weight polysaccharides. This can result in longer reaction times or incomplete modifications, necessitating the development of advanced mixing technologies or novel reactor designs to ensure efficient contact between the reagents.

Another consideration for scalability is the separation and purification of the modified polysaccharides. Traditional methods such as precipitation or dialysis may become impractical or cost-prohibitive at industrial scales. Innovative separation techniques, such as membrane filtration or chromatographic methods, may need to be adapted or developed to handle larger volumes efficiently.

The energy requirements for heating, cooling, and mixing in large-scale reactors also present a significant challenge. Optimizing energy efficiency while maintaining process control is essential for the economic viability of scaled-up operations. This may involve the implementation of heat recovery systems or the use of alternative energy sources to reduce operational costs.

Lastly, the stability and shelf-life of ethyl propanoate and the modified polysaccharides must be carefully considered in large-scale production. Storage and transportation of larger quantities of materials may require specialized facilities and handling procedures to maintain product integrity and safety.

In conclusion, while ethyl propanoate-based processes show promise for scalability in modifying polysaccharide structures, successful implementation will require addressing several technical and operational challenges. Continued research and development efforts focused on process optimization, reactor design, and separation technologies will be crucial in realizing the full potential of these processes at industrial scales.

One of the primary advantages of ethyl propanoate-based processes is their relatively low cost and wide availability of raw materials. Ethyl propanoate can be synthesized from renewable resources, making it an attractive option for large-scale production. Additionally, its low toxicity and biodegradability align well with increasing environmental regulations, potentially simplifying the scaling process from a regulatory standpoint.

However, several technical hurdles must be addressed to achieve efficient large-scale production. The reaction kinetics between ethyl propanoate and polysaccharides can be complex, often requiring precise control of temperature, pH, and concentration. As the scale increases, maintaining uniform reaction conditions throughout larger vessels becomes more challenging, potentially leading to inconsistent product quality.

Mass transfer limitations also become more pronounced at larger scales, particularly when dealing with high-molecular-weight polysaccharides. This can result in longer reaction times or incomplete modifications, necessitating the development of advanced mixing technologies or novel reactor designs to ensure efficient contact between the reagents.

Another consideration for scalability is the separation and purification of the modified polysaccharides. Traditional methods such as precipitation or dialysis may become impractical or cost-prohibitive at industrial scales. Innovative separation techniques, such as membrane filtration or chromatographic methods, may need to be adapted or developed to handle larger volumes efficiently.

The energy requirements for heating, cooling, and mixing in large-scale reactors also present a significant challenge. Optimizing energy efficiency while maintaining process control is essential for the economic viability of scaled-up operations. This may involve the implementation of heat recovery systems or the use of alternative energy sources to reduce operational costs.

Lastly, the stability and shelf-life of ethyl propanoate and the modified polysaccharides must be carefully considered in large-scale production. Storage and transportation of larger quantities of materials may require specialized facilities and handling procedures to maintain product integrity and safety.

In conclusion, while ethyl propanoate-based processes show promise for scalability in modifying polysaccharide structures, successful implementation will require addressing several technical and operational challenges. Continued research and development efforts focused on process optimization, reactor design, and separation technologies will be crucial in realizing the full potential of these processes at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!