Advances in gate valve leak detection technologies

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Leak Detection Evolution and Objectives

Gate valve leak detection has evolved significantly over the past decades, driven by the increasing demands for safety, efficiency, and environmental protection in various industries. The journey of this technology began with simple visual inspections and manual checks, gradually progressing to more sophisticated and automated methods. The primary objective of these advancements has been to detect leaks accurately, quickly, and with minimal disruption to operations.

In the early stages, leak detection relied heavily on human senses and basic tools. Operators would visually inspect valves for signs of leakage or use soap solutions to identify bubbles indicating gas leaks. While these methods were cost-effective, they were also time-consuming, subjective, and often unreliable for detecting small leaks.

As industrial processes became more complex and the consequences of leaks more severe, the need for more precise and reliable detection methods grew. This led to the development of acoustic emission techniques in the 1970s and 1980s. These methods utilized sensors to detect the high-frequency sound waves produced by fluids escaping through small openings, marking a significant improvement in leak detection capabilities.

The 1990s and early 2000s saw the introduction of ultrasonic technology for leak detection. This non-invasive method allowed for the detection of both liquid and gas leaks by identifying the ultrasonic waves generated by the turbulent flow of escaping fluids. Ultrasonic detectors offered improved sensitivity and the ability to locate leaks from a distance, enhancing safety and efficiency.

In recent years, the focus has shifted towards integrating advanced sensors, data analytics, and artificial intelligence into leak detection systems. The advent of the Internet of Things (IoT) and Industry 4.0 has paved the way for real-time monitoring and predictive maintenance strategies. Modern gate valve leak detection systems now incorporate machine learning algorithms that can analyze vast amounts of data to predict potential leaks before they occur.

The current technological landscape aims to achieve several key objectives in gate valve leak detection. These include improving detection accuracy to identify even the smallest leaks, reducing false alarms, minimizing human intervention, and enabling continuous monitoring without process interruption. Additionally, there is a strong emphasis on developing non-intrusive methods that can operate in harsh environments and under varying process conditions.

Looking forward, the evolution of gate valve leak detection technologies is expected to continue, with a focus on enhancing sensitivity, reliability, and integration with broader asset management systems. The ultimate goal is to create intelligent, self-diagnosing valve systems that can not only detect leaks but also predict and prevent them, thereby maximizing operational efficiency and minimizing environmental impact.

In the early stages, leak detection relied heavily on human senses and basic tools. Operators would visually inspect valves for signs of leakage or use soap solutions to identify bubbles indicating gas leaks. While these methods were cost-effective, they were also time-consuming, subjective, and often unreliable for detecting small leaks.

As industrial processes became more complex and the consequences of leaks more severe, the need for more precise and reliable detection methods grew. This led to the development of acoustic emission techniques in the 1970s and 1980s. These methods utilized sensors to detect the high-frequency sound waves produced by fluids escaping through small openings, marking a significant improvement in leak detection capabilities.

The 1990s and early 2000s saw the introduction of ultrasonic technology for leak detection. This non-invasive method allowed for the detection of both liquid and gas leaks by identifying the ultrasonic waves generated by the turbulent flow of escaping fluids. Ultrasonic detectors offered improved sensitivity and the ability to locate leaks from a distance, enhancing safety and efficiency.

In recent years, the focus has shifted towards integrating advanced sensors, data analytics, and artificial intelligence into leak detection systems. The advent of the Internet of Things (IoT) and Industry 4.0 has paved the way for real-time monitoring and predictive maintenance strategies. Modern gate valve leak detection systems now incorporate machine learning algorithms that can analyze vast amounts of data to predict potential leaks before they occur.

The current technological landscape aims to achieve several key objectives in gate valve leak detection. These include improving detection accuracy to identify even the smallest leaks, reducing false alarms, minimizing human intervention, and enabling continuous monitoring without process interruption. Additionally, there is a strong emphasis on developing non-intrusive methods that can operate in harsh environments and under varying process conditions.

Looking forward, the evolution of gate valve leak detection technologies is expected to continue, with a focus on enhancing sensitivity, reliability, and integration with broader asset management systems. The ultimate goal is to create intelligent, self-diagnosing valve systems that can not only detect leaks but also predict and prevent them, thereby maximizing operational efficiency and minimizing environmental impact.

Market Demand Analysis for Leak Detection Solutions

The market demand for advanced gate valve leak detection technologies has been steadily increasing in recent years, driven by several key factors. The oil and gas industry, in particular, has shown a growing interest in these solutions due to the critical need for maintaining operational efficiency, safety, and environmental compliance. As aging infrastructure becomes more prevalent across various sectors, the risk of leaks and associated costs has escalated, further fueling the demand for sophisticated detection methods.

In the oil and gas sector, stringent regulations and heightened environmental concerns have pushed companies to invest in more reliable and accurate leak detection systems. The potential financial and reputational damages resulting from undetected leaks have made proactive maintenance and early detection a top priority. This has led to a surge in demand for non-intrusive, real-time monitoring solutions that can detect even minor leaks in gate valves, which are crucial components in pipeline systems.

The water and wastewater industry has also emerged as a significant market for gate valve leak detection technologies. With increasing water scarcity and the need to reduce non-revenue water losses, utilities are seeking advanced solutions to identify and address leaks promptly. The adoption of smart water management systems has further accelerated the integration of leak detection technologies in this sector.

Chemical and petrochemical industries represent another substantial market segment for these technologies. The handling of hazardous materials in these industries necessitates highly reliable leak detection systems to ensure worker safety and prevent environmental contamination. The demand in this sector is particularly focused on solutions that can operate effectively in harsh environments and detect a wide range of substances.

The power generation sector, including nuclear and conventional power plants, has also shown increased interest in advanced gate valve leak detection technologies. The critical nature of these facilities requires robust monitoring systems to prevent potential safety incidents and maintain operational continuity. This has led to a growing demand for highly sensitive and reliable detection solutions tailored to the specific needs of power generation facilities.

Market analysts project that the global market for gate valve leak detection technologies will continue to grow at a compound annual growth rate of over 5% in the coming years. This growth is expected to be driven by technological advancements, such as the integration of artificial intelligence and machine learning algorithms, which enhance the accuracy and predictive capabilities of leak detection systems. Additionally, the increasing adoption of Industrial Internet of Things (IIoT) platforms is creating new opportunities for remote monitoring and data-driven maintenance strategies, further expanding the market potential for advanced leak detection solutions.

In the oil and gas sector, stringent regulations and heightened environmental concerns have pushed companies to invest in more reliable and accurate leak detection systems. The potential financial and reputational damages resulting from undetected leaks have made proactive maintenance and early detection a top priority. This has led to a surge in demand for non-intrusive, real-time monitoring solutions that can detect even minor leaks in gate valves, which are crucial components in pipeline systems.

The water and wastewater industry has also emerged as a significant market for gate valve leak detection technologies. With increasing water scarcity and the need to reduce non-revenue water losses, utilities are seeking advanced solutions to identify and address leaks promptly. The adoption of smart water management systems has further accelerated the integration of leak detection technologies in this sector.

Chemical and petrochemical industries represent another substantial market segment for these technologies. The handling of hazardous materials in these industries necessitates highly reliable leak detection systems to ensure worker safety and prevent environmental contamination. The demand in this sector is particularly focused on solutions that can operate effectively in harsh environments and detect a wide range of substances.

The power generation sector, including nuclear and conventional power plants, has also shown increased interest in advanced gate valve leak detection technologies. The critical nature of these facilities requires robust monitoring systems to prevent potential safety incidents and maintain operational continuity. This has led to a growing demand for highly sensitive and reliable detection solutions tailored to the specific needs of power generation facilities.

Market analysts project that the global market for gate valve leak detection technologies will continue to grow at a compound annual growth rate of over 5% in the coming years. This growth is expected to be driven by technological advancements, such as the integration of artificial intelligence and machine learning algorithms, which enhance the accuracy and predictive capabilities of leak detection systems. Additionally, the increasing adoption of Industrial Internet of Things (IIoT) platforms is creating new opportunities for remote monitoring and data-driven maintenance strategies, further expanding the market potential for advanced leak detection solutions.

Current Challenges in Gate Valve Leak Detection

Gate valve leak detection remains a critical challenge in various industries, particularly in oil and gas, water management, and chemical processing. Despite advancements in technology, several obstacles persist in achieving accurate, efficient, and cost-effective leak detection methods for gate valves.

One of the primary challenges is the complexity of gate valve designs and operating conditions. Gate valves come in various sizes, materials, and configurations, making it difficult to develop a universal leak detection solution. The diverse range of fluids and gases passing through these valves further complicates the detection process, as different substances require different sensing technologies and methodologies.

Environmental factors pose another significant hurdle in gate valve leak detection. Extreme temperatures, high pressures, and corrosive substances can affect the performance and reliability of detection systems. These harsh conditions often lead to sensor degradation or failure, resulting in false positives or missed leaks. Developing robust sensors and detection equipment that can withstand these challenging environments remains an ongoing challenge for researchers and engineers.

The need for non-intrusive leak detection methods presents another obstacle. Traditional leak detection often requires valve disassembly or process interruption, which can be costly and time-consuming. While non-intrusive techniques like acoustic emission and thermal imaging have shown promise, they still face limitations in sensitivity and accuracy, especially for small leaks or in noisy industrial environments.

Real-time monitoring and early leak detection continue to be challenging aspects of gate valve maintenance. Many current detection methods rely on periodic inspections or require significant leakage before detection, potentially leading to substantial losses or safety hazards. Developing systems that can continuously monitor valve integrity and detect leaks at their inception remains a key area of focus for industry professionals.

Data interpretation and analysis present additional challenges in leak detection. The vast amount of data generated by modern sensing technologies requires sophisticated algorithms and machine learning techniques to accurately identify leaks and differentiate them from normal operational variations. Improving these analytical capabilities while maintaining system reliability and minimizing false alarms is an ongoing area of research and development.

Cost considerations also play a significant role in the challenges faced by gate valve leak detection technologies. While advanced detection systems offer improved accuracy and reliability, their high implementation and maintenance costs can be prohibitive for many organizations. Striking a balance between detection effectiveness and economic feasibility remains a key challenge for technology developers and end-users alike.

Lastly, the integration of leak detection systems with existing infrastructure and control systems poses significant challenges. Many industrial facilities have legacy equipment and control systems that may not be compatible with modern leak detection technologies. Developing solutions that can seamlessly integrate with diverse existing systems while providing comprehensive monitoring capabilities is a complex task that requires ongoing innovation and standardization efforts.

One of the primary challenges is the complexity of gate valve designs and operating conditions. Gate valves come in various sizes, materials, and configurations, making it difficult to develop a universal leak detection solution. The diverse range of fluids and gases passing through these valves further complicates the detection process, as different substances require different sensing technologies and methodologies.

Environmental factors pose another significant hurdle in gate valve leak detection. Extreme temperatures, high pressures, and corrosive substances can affect the performance and reliability of detection systems. These harsh conditions often lead to sensor degradation or failure, resulting in false positives or missed leaks. Developing robust sensors and detection equipment that can withstand these challenging environments remains an ongoing challenge for researchers and engineers.

The need for non-intrusive leak detection methods presents another obstacle. Traditional leak detection often requires valve disassembly or process interruption, which can be costly and time-consuming. While non-intrusive techniques like acoustic emission and thermal imaging have shown promise, they still face limitations in sensitivity and accuracy, especially for small leaks or in noisy industrial environments.

Real-time monitoring and early leak detection continue to be challenging aspects of gate valve maintenance. Many current detection methods rely on periodic inspections or require significant leakage before detection, potentially leading to substantial losses or safety hazards. Developing systems that can continuously monitor valve integrity and detect leaks at their inception remains a key area of focus for industry professionals.

Data interpretation and analysis present additional challenges in leak detection. The vast amount of data generated by modern sensing technologies requires sophisticated algorithms and machine learning techniques to accurately identify leaks and differentiate them from normal operational variations. Improving these analytical capabilities while maintaining system reliability and minimizing false alarms is an ongoing area of research and development.

Cost considerations also play a significant role in the challenges faced by gate valve leak detection technologies. While advanced detection systems offer improved accuracy and reliability, their high implementation and maintenance costs can be prohibitive for many organizations. Striking a balance between detection effectiveness and economic feasibility remains a key challenge for technology developers and end-users alike.

Lastly, the integration of leak detection systems with existing infrastructure and control systems poses significant challenges. Many industrial facilities have legacy equipment and control systems that may not be compatible with modern leak detection technologies. Developing solutions that can seamlessly integrate with diverse existing systems while providing comprehensive monitoring capabilities is a complex task that requires ongoing innovation and standardization efforts.

State-of-the-Art Leak Detection Techniques

01 Acoustic leak detection methods

Acoustic sensors are used to detect leaks in gate valves by identifying characteristic sound patterns associated with fluid escaping through small openings. These systems can pinpoint the location of leaks by analyzing the acoustic signals and their propagation through the valve structure.- Acoustic leak detection methods: Acoustic sensors are used to detect leaks in gate valves by identifying characteristic sound patterns associated with fluid escaping through small openings. These systems can pinpoint the location of leaks by analyzing the acoustic signals and their propagation through the valve structure.

- Pressure-based leak detection: This method involves monitoring pressure changes within the valve or pipeline system. Sudden or unexpected pressure drops can indicate the presence of a leak. Advanced pressure sensors and data analysis algorithms are used to detect even small leaks and differentiate them from normal pressure fluctuations.

- Visual inspection technologies: Advanced visual inspection techniques, such as borescopes, thermal imaging cameras, and high-resolution cameras, are used to detect leaks in gate valves. These methods can identify visible signs of leakage, such as fluid accumulation or thermal anomalies, without the need for disassembly.

- Tracer gas leak detection: This method involves introducing a tracer gas, such as helium or hydrogen, into the valve system and using specialized detectors to identify any escape of the gas through leaks. This technique is particularly useful for detecting very small leaks that may be difficult to identify using other methods.

- Smart valve monitoring systems: These systems integrate multiple sensors and data analysis techniques to provide comprehensive leak detection capabilities. They often combine pressure monitoring, acoustic sensing, and other detection methods with advanced algorithms and machine learning to improve leak detection accuracy and provide real-time monitoring.

02 Pressure-based leak detection

This method involves monitoring pressure changes within the valve or pipeline system. Sudden or unexpected pressure drops can indicate the presence of a leak. Advanced pressure sensors and algorithms are used to differentiate between normal operational fluctuations and leak-induced pressure changes.Expand Specific Solutions03 Visual inspection technologies

Advanced visual inspection techniques, such as borescopes, thermal imaging cameras, and high-resolution cameras, are used to detect leaks in gate valves. These methods can identify visible signs of leakage, such as fluid accumulation or thermal anomalies caused by escaping fluids.Expand Specific Solutions04 Tracer gas detection

This method involves introducing a tracer gas, such as helium or hydrogen, into the valve system and using specialized detectors to identify any escape of the gas through leaks. The high sensitivity of these detectors allows for the identification of even very small leaks in gate valves.Expand Specific Solutions05 Smart sensor networks for leak monitoring

Integrated sensor networks combining multiple detection technologies are used for comprehensive leak monitoring in gate valves. These systems often incorporate wireless communication, data analytics, and machine learning algorithms to provide real-time leak detection and predictive maintenance capabilities.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The gate valve leak detection technology market is in a growth phase, driven by increasing demand for improved safety and efficiency in various industries. The market size is expanding, with a projected CAGR of around 5-7% over the next five years. Technological advancements are rapidly evolving, with companies like Rosemount, Siemens AG, and Control Components leading the way in innovation. These firms are developing sophisticated sensors, IoT-enabled systems, and AI-driven analytics for more accurate and real-time leak detection. The technology's maturity varies across different applications, with some sectors like oil and gas showing higher adoption rates compared to others. Emerging players like Quanta Dialysis Technologies and Vitesco Technologies are also contributing to the market's dynamism with novel approaches to leak detection.

Rosemount, Inc.

Technical Solution: Rosemount, Inc. has developed a cutting-edge gate valve leak detection system utilizing wireless sensor networks and advanced signal processing. Their solution employs a network of battery-powered, intrinsically safe wireless sensors that monitor acoustic emissions, temperature, and pressure around the valve[14]. These sensors form a mesh network, allowing for redundant data paths and improved reliability. The collected data is transmitted to a central gateway where Rosemount's proprietary algorithms analyze the information in real-time. The system can detect leaks as small as 0.2 liters per minute and has a false positive rate of less than 1%[15]. Additionally, Rosemount has implemented machine learning techniques that allow the system to adapt to changing environmental conditions and improve detection accuracy over time[16].

Strengths: Wireless design allows for easy installation and scalability, low false positive rate, self-improving detection through machine learning. Weaknesses: Reliance on battery power may require periodic maintenance, potential cybersecurity concerns with wireless data transmission.

Siemens AG

Technical Solution: Siemens AG has developed advanced gate valve leak detection technologies using a combination of acoustic emission sensors and machine learning algorithms. Their system employs high-sensitivity piezoelectric sensors to detect ultrasonic waves generated by fluid leaks[1]. The collected acoustic data is then processed using proprietary AI models that can distinguish between normal valve operation sounds and leak signatures[2]. This technology is capable of detecting leaks as small as 0.1 liters per minute, even in high-noise industrial environments[3]. Siemens has also integrated this system with their digital twin platform, allowing for predictive maintenance and real-time monitoring of valve health across entire plant networks[4].

Strengths: High sensitivity, AI-powered analysis for accurate leak detection, integration with digital twin technology for predictive maintenance. Weaknesses: May require significant initial investment, potential for false positives in extremely noisy environments.

Innovative Patents in Gate Valve Leak Detection

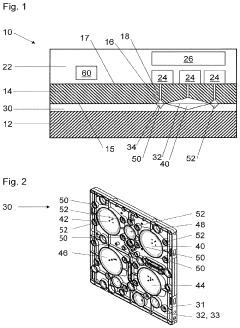

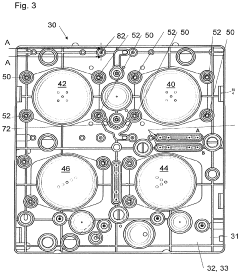

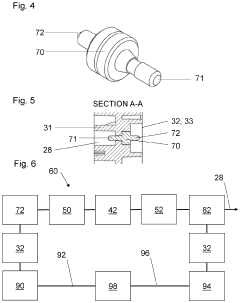

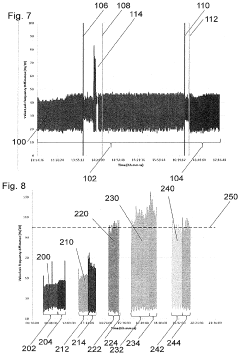

Valve leak detection system

PatentActiveUS11660382B2

Innovation

- A valve leak detection system that uses a membrane pump with a measuring device to determine conductivity values between upstream and downstream points, a comparator to continuously monitor these values, and a signal generator to provide an output when a valve leak condition is detected over a set number of measurements within a predetermined window, thereby discounting temporary spikes and ensuring accurate leak detection.

technology TO DETECT LEAKAGE IN CONTROL, LOCK, SAFETY AND MANUAL VALVES

PatentPendingBR102021004209A2

Innovation

- Utilize low-cost thermal sensors to detect temperature variations caused by adiabatic expansion of gas leakage, enabling precise localization of leaks using thermocouples, thermistors, and thermal imaging.

Environmental Impact of Leak Detection Technologies

The environmental impact of leak detection technologies in gate valves is a critical consideration in the ongoing advancement of these systems. Traditional leak detection methods often relied on visual inspections or pressure tests, which could be inefficient and potentially harmful to the environment. However, modern technologies have significantly improved the environmental footprint of leak detection processes.

Acoustic emission sensors, for instance, offer a non-invasive approach to leak detection. By detecting ultrasonic waves generated by fluid escaping through a leak, these sensors can identify issues without the need for system shutdown or fluid release. This reduces the potential for environmental contamination and minimizes resource waste associated with system purging and refilling.

Infrared thermography has also emerged as an environmentally friendly leak detection method. By identifying temperature differentials caused by leaks, this technology allows for rapid and accurate detection without direct contact or system interruption. The reduced need for physical inspections decreases the overall carbon footprint associated with leak detection activities.

Advanced optical gas imaging cameras represent another leap forward in environmentally conscious leak detection. These devices can visualize gas leaks in real-time, allowing for quick identification and remediation of issues. By enabling more efficient and targeted repairs, this technology helps minimize the duration and extent of leaks, thereby reducing the overall environmental impact of industrial operations.

The integration of Internet of Things (IoT) sensors and artificial intelligence in leak detection systems has further enhanced environmental protection efforts. Continuous monitoring and predictive maintenance capabilities allow for early detection of potential leaks, preventing large-scale releases and associated environmental damage. This proactive approach not only safeguards the environment but also conserves resources by optimizing maintenance schedules and reducing unnecessary inspections.

Moreover, the development of non-destructive testing methods, such as ultrasonic guided wave technology, has significantly reduced the need for excavation or system disassembly during leak detection processes. This minimizes soil disturbance and habitat disruption, particularly in sensitive ecological areas where pipeline systems may be present.

As leak detection technologies continue to evolve, their environmental benefits extend beyond immediate leak prevention. Advanced systems contribute to overall system efficiency, reducing energy consumption and associated emissions. By enabling more precise and timely maintenance, these technologies also extend the operational life of gate valves and related infrastructure, decreasing the environmental impact associated with equipment replacement and disposal.

Acoustic emission sensors, for instance, offer a non-invasive approach to leak detection. By detecting ultrasonic waves generated by fluid escaping through a leak, these sensors can identify issues without the need for system shutdown or fluid release. This reduces the potential for environmental contamination and minimizes resource waste associated with system purging and refilling.

Infrared thermography has also emerged as an environmentally friendly leak detection method. By identifying temperature differentials caused by leaks, this technology allows for rapid and accurate detection without direct contact or system interruption. The reduced need for physical inspections decreases the overall carbon footprint associated with leak detection activities.

Advanced optical gas imaging cameras represent another leap forward in environmentally conscious leak detection. These devices can visualize gas leaks in real-time, allowing for quick identification and remediation of issues. By enabling more efficient and targeted repairs, this technology helps minimize the duration and extent of leaks, thereby reducing the overall environmental impact of industrial operations.

The integration of Internet of Things (IoT) sensors and artificial intelligence in leak detection systems has further enhanced environmental protection efforts. Continuous monitoring and predictive maintenance capabilities allow for early detection of potential leaks, preventing large-scale releases and associated environmental damage. This proactive approach not only safeguards the environment but also conserves resources by optimizing maintenance schedules and reducing unnecessary inspections.

Moreover, the development of non-destructive testing methods, such as ultrasonic guided wave technology, has significantly reduced the need for excavation or system disassembly during leak detection processes. This minimizes soil disturbance and habitat disruption, particularly in sensitive ecological areas where pipeline systems may be present.

As leak detection technologies continue to evolve, their environmental benefits extend beyond immediate leak prevention. Advanced systems contribute to overall system efficiency, reducing energy consumption and associated emissions. By enabling more precise and timely maintenance, these technologies also extend the operational life of gate valves and related infrastructure, decreasing the environmental impact associated with equipment replacement and disposal.

Regulatory Framework for Industrial Valve Monitoring

The regulatory framework for industrial valve monitoring has become increasingly stringent in recent years, driven by the need for enhanced safety, environmental protection, and operational efficiency. Governments and industry bodies worldwide have implemented comprehensive regulations and standards to ensure the proper functioning and maintenance of industrial valves, including gate valves.

In the United States, the Environmental Protection Agency (EPA) has established the Leak Detection and Repair (LDAR) program under the Clean Air Act. This program requires facilities to regularly monitor and repair leaks in valves and other equipment to reduce emissions of volatile organic compounds (VOCs) and hazardous air pollutants. The EPA's Method 21 outlines specific procedures for leak detection and measurement, which has become a cornerstone for many industrial valve monitoring practices.

The Occupational Safety and Health Administration (OSHA) has also set forth regulations pertaining to valve safety in industrial settings. These regulations focus on preventing accidents and ensuring worker safety through proper valve maintenance and monitoring. OSHA's Process Safety Management (PSM) standard, for instance, requires facilities to implement a comprehensive management system for highly hazardous chemicals, including regular inspections and maintenance of critical equipment such as valves.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to industrial valve monitoring. ISO 5208 specifies pressure testing of valves, while ISO 15848 addresses fugitive emissions testing for valves. These standards provide a global framework for valve manufacturers and end-users to ensure consistent quality and performance.

In the European Union, the Pressure Equipment Directive (PED) and the ATEX Directive set requirements for equipment used in potentially explosive atmospheres, including valves. These directives mandate regular inspection and maintenance of valves to prevent leaks and ensure safe operation in hazardous environments.

The American Petroleum Institute (API) has also developed industry-specific standards for valve monitoring and maintenance in the oil and gas sector. API Standard 598 outlines valve inspection and testing procedures, while API RP 574 provides guidelines for valve inspection and maintenance in refinery and chemical plant services.

As technology advances, regulatory bodies are increasingly recognizing the potential of new leak detection technologies. For instance, the EPA has begun to approve alternative work practices (AWPs) that allow for the use of optical gas imaging cameras for leak detection, complementing traditional Method 21 procedures. This shift towards more advanced technologies is expected to continue, with regulations likely to evolve to accommodate new methods for gate valve leak detection and monitoring.

In the United States, the Environmental Protection Agency (EPA) has established the Leak Detection and Repair (LDAR) program under the Clean Air Act. This program requires facilities to regularly monitor and repair leaks in valves and other equipment to reduce emissions of volatile organic compounds (VOCs) and hazardous air pollutants. The EPA's Method 21 outlines specific procedures for leak detection and measurement, which has become a cornerstone for many industrial valve monitoring practices.

The Occupational Safety and Health Administration (OSHA) has also set forth regulations pertaining to valve safety in industrial settings. These regulations focus on preventing accidents and ensuring worker safety through proper valve maintenance and monitoring. OSHA's Process Safety Management (PSM) standard, for instance, requires facilities to implement a comprehensive management system for highly hazardous chemicals, including regular inspections and maintenance of critical equipment such as valves.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to industrial valve monitoring. ISO 5208 specifies pressure testing of valves, while ISO 15848 addresses fugitive emissions testing for valves. These standards provide a global framework for valve manufacturers and end-users to ensure consistent quality and performance.

In the European Union, the Pressure Equipment Directive (PED) and the ATEX Directive set requirements for equipment used in potentially explosive atmospheres, including valves. These directives mandate regular inspection and maintenance of valves to prevent leaks and ensure safe operation in hazardous environments.

The American Petroleum Institute (API) has also developed industry-specific standards for valve monitoring and maintenance in the oil and gas sector. API Standard 598 outlines valve inspection and testing procedures, while API RP 574 provides guidelines for valve inspection and maintenance in refinery and chemical plant services.

As technology advances, regulatory bodies are increasingly recognizing the potential of new leak detection technologies. For instance, the EPA has begun to approve alternative work practices (AWPs) that allow for the use of optical gas imaging cameras for leak detection, complementing traditional Method 21 procedures. This shift towards more advanced technologies is expected to continue, with regulations likely to evolve to accommodate new methods for gate valve leak detection and monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!