Energy usage optimization in electrically actuated gate valves

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Valve Energy Efficiency Background and Objectives

The optimization of energy usage in electrically actuated gate valves has become a critical focus in the industrial sector, driven by the increasing demand for energy efficiency and sustainability. Gate valves, widely used in various industries for flow control, have traditionally been energy-intensive components in fluid handling systems. The evolution of this technology has been marked by a gradual shift from manual operation to automated, electrically actuated systems, which has introduced new challenges and opportunities for energy optimization.

The primary objective of energy usage optimization in electrically actuated gate valves is to reduce power consumption while maintaining or improving operational performance. This goal aligns with broader industry trends towards energy conservation and reduced carbon footprints. The development of more efficient valve systems is not only environmentally beneficial but also economically advantageous, as it can lead to significant cost savings in large-scale industrial operations.

Historically, the focus on valve efficiency has intensified over the past few decades, coinciding with the global emphasis on energy conservation. Early electrically actuated valves were designed primarily for reliability and ease of operation, with less consideration given to energy efficiency. However, as energy costs have risen and environmental regulations have become more stringent, the industry has shifted its attention to developing valves that consume less power during operation and standby modes.

The technological evolution in this field has been characterized by improvements in actuator design, the integration of smart control systems, and the use of advanced materials. These advancements have collectively contributed to reducing friction, minimizing power requirements for valve movement, and optimizing overall system performance. The industry has also seen a trend towards the development of low-power electronics and more efficient motor technologies, which have further enhanced the energy efficiency of gate valve systems.

Current research and development efforts are focused on several key areas. These include the optimization of valve geometry to reduce flow resistance, the development of more efficient actuator mechanisms, and the integration of advanced sensors and control algorithms for precise operation. Additionally, there is growing interest in energy harvesting technologies that could potentially make valve systems self-powered or significantly reduce their reliance on external power sources.

The objectives of ongoing research in this field extend beyond mere energy reduction. They encompass the development of valves that are not only energy-efficient but also smart, self-diagnosing, and capable of predictive maintenance. This holistic approach aims to create valve systems that are not only environmentally friendly but also more reliable and cost-effective over their entire lifecycle.

The primary objective of energy usage optimization in electrically actuated gate valves is to reduce power consumption while maintaining or improving operational performance. This goal aligns with broader industry trends towards energy conservation and reduced carbon footprints. The development of more efficient valve systems is not only environmentally beneficial but also economically advantageous, as it can lead to significant cost savings in large-scale industrial operations.

Historically, the focus on valve efficiency has intensified over the past few decades, coinciding with the global emphasis on energy conservation. Early electrically actuated valves were designed primarily for reliability and ease of operation, with less consideration given to energy efficiency. However, as energy costs have risen and environmental regulations have become more stringent, the industry has shifted its attention to developing valves that consume less power during operation and standby modes.

The technological evolution in this field has been characterized by improvements in actuator design, the integration of smart control systems, and the use of advanced materials. These advancements have collectively contributed to reducing friction, minimizing power requirements for valve movement, and optimizing overall system performance. The industry has also seen a trend towards the development of low-power electronics and more efficient motor technologies, which have further enhanced the energy efficiency of gate valve systems.

Current research and development efforts are focused on several key areas. These include the optimization of valve geometry to reduce flow resistance, the development of more efficient actuator mechanisms, and the integration of advanced sensors and control algorithms for precise operation. Additionally, there is growing interest in energy harvesting technologies that could potentially make valve systems self-powered or significantly reduce their reliance on external power sources.

The objectives of ongoing research in this field extend beyond mere energy reduction. They encompass the development of valves that are not only energy-efficient but also smart, self-diagnosing, and capable of predictive maintenance. This holistic approach aims to create valve systems that are not only environmentally friendly but also more reliable and cost-effective over their entire lifecycle.

Market Demand for Energy-Efficient Valves

The market demand for energy-efficient valves has been steadily increasing in recent years, driven by several key factors. Industrial sectors, particularly oil and gas, chemical processing, and water treatment, are facing mounting pressure to reduce energy consumption and operational costs. This has led to a growing interest in electrically actuated gate valves that offer superior energy efficiency compared to traditional pneumatic or hydraulic systems.

Environmental regulations and sustainability initiatives have also played a significant role in shaping market demand. Governments worldwide are implementing stricter emissions standards and energy efficiency requirements, compelling industries to adopt more eco-friendly technologies. As a result, companies are actively seeking valve solutions that can help them meet these regulatory demands while simultaneously improving their environmental performance.

The rising cost of energy has further accelerated the demand for energy-efficient valves. With electricity prices continuing to climb in many regions, businesses are increasingly focused on minimizing energy consumption across their operations. Electrically actuated gate valves, when optimized for energy usage, can offer substantial long-term cost savings, making them an attractive investment for cost-conscious industries.

Another factor driving market demand is the growing trend towards automation and digitalization in industrial processes. Energy-efficient electrically actuated gate valves can be easily integrated into modern control systems, allowing for more precise operation and real-time monitoring. This compatibility with Industry 4.0 technologies has made them increasingly popular among forward-thinking companies looking to enhance their operational efficiency and competitiveness.

The oil and gas industry, in particular, has shown strong demand for energy-efficient valve solutions. As exploration and production activities expand into more challenging environments, the need for reliable and efficient valve systems has become paramount. Electrically actuated gate valves that optimize energy usage can significantly reduce operational costs in remote locations where power supply may be limited or expensive.

Water and wastewater treatment facilities have also emerged as a key market for energy-efficient valves. These facilities often operate continuously and require precise flow control, making energy optimization crucial for long-term sustainability. Municipalities and private operators are increasingly investing in advanced valve technologies to reduce their energy footprint and operational expenses.

The chemical processing industry is another sector driving demand for energy-efficient valve solutions. With its complex processes and stringent safety requirements, the industry values valves that can provide both energy savings and reliable performance. Electrically actuated gate valves with optimized energy usage can help chemical plants improve their overall efficiency while maintaining the necessary level of control and safety.

Environmental regulations and sustainability initiatives have also played a significant role in shaping market demand. Governments worldwide are implementing stricter emissions standards and energy efficiency requirements, compelling industries to adopt more eco-friendly technologies. As a result, companies are actively seeking valve solutions that can help them meet these regulatory demands while simultaneously improving their environmental performance.

The rising cost of energy has further accelerated the demand for energy-efficient valves. With electricity prices continuing to climb in many regions, businesses are increasingly focused on minimizing energy consumption across their operations. Electrically actuated gate valves, when optimized for energy usage, can offer substantial long-term cost savings, making them an attractive investment for cost-conscious industries.

Another factor driving market demand is the growing trend towards automation and digitalization in industrial processes. Energy-efficient electrically actuated gate valves can be easily integrated into modern control systems, allowing for more precise operation and real-time monitoring. This compatibility with Industry 4.0 technologies has made them increasingly popular among forward-thinking companies looking to enhance their operational efficiency and competitiveness.

The oil and gas industry, in particular, has shown strong demand for energy-efficient valve solutions. As exploration and production activities expand into more challenging environments, the need for reliable and efficient valve systems has become paramount. Electrically actuated gate valves that optimize energy usage can significantly reduce operational costs in remote locations where power supply may be limited or expensive.

Water and wastewater treatment facilities have also emerged as a key market for energy-efficient valves. These facilities often operate continuously and require precise flow control, making energy optimization crucial for long-term sustainability. Municipalities and private operators are increasingly investing in advanced valve technologies to reduce their energy footprint and operational expenses.

The chemical processing industry is another sector driving demand for energy-efficient valve solutions. With its complex processes and stringent safety requirements, the industry values valves that can provide both energy savings and reliable performance. Electrically actuated gate valves with optimized energy usage can help chemical plants improve their overall efficiency while maintaining the necessary level of control and safety.

Current Challenges in Valve Energy Optimization

The optimization of energy usage in electrically actuated gate valves faces several significant challenges in the current technological landscape. One of the primary obstacles is the inherent inefficiency in the conversion of electrical energy to mechanical motion. This conversion process often results in substantial energy losses, particularly during valve actuation and holding phases.

Another major challenge lies in the variability of operating conditions. Gate valves are frequently subjected to fluctuating pressures, temperatures, and flow rates, which can significantly impact their energy consumption. Designing a system that maintains optimal energy efficiency across this wide range of operating parameters remains a complex task for engineers and researchers.

The issue of standby power consumption also presents a considerable challenge. Many electrically actuated gate valves continue to draw power even when not in operation, contributing to unnecessary energy waste. This standby power, while seemingly minimal for a single valve, can accumulate to substantial amounts in large-scale industrial applications with numerous valves.

Furthermore, the integration of smart technologies and advanced control systems, while offering potential solutions, introduces its own set of challenges. These include increased system complexity, potential reliability issues, and the need for specialized maintenance and operational expertise. The balance between implementing sophisticated energy-saving technologies and maintaining system simplicity and robustness is a delicate one.

The sizing and selection of actuators for specific valve applications also present ongoing challenges. Oversized actuators, often chosen to ensure reliable operation under worst-case scenarios, can lead to significant energy inefficiencies during normal operations. Conversely, undersized actuators may struggle to provide adequate performance, potentially leading to increased energy consumption or operational failures.

Additionally, the thermal management of electrically actuated gate valves remains a persistent challenge. Heat generated during operation can affect the efficiency and lifespan of both the electrical components and the mechanical parts of the valve. Effective heat dissipation strategies are crucial but often difficult to implement, especially in compact or hazardous environments.

Lastly, the industry faces challenges in accurately measuring and monitoring energy consumption in real-time operational settings. Without precise data on energy usage patterns, it becomes difficult to identify opportunities for optimization and to quantify the effectiveness of implemented energy-saving measures. The development of cost-effective, reliable, and non-intrusive energy monitoring systems for gate valves is an ongoing area of research and development.

Another major challenge lies in the variability of operating conditions. Gate valves are frequently subjected to fluctuating pressures, temperatures, and flow rates, which can significantly impact their energy consumption. Designing a system that maintains optimal energy efficiency across this wide range of operating parameters remains a complex task for engineers and researchers.

The issue of standby power consumption also presents a considerable challenge. Many electrically actuated gate valves continue to draw power even when not in operation, contributing to unnecessary energy waste. This standby power, while seemingly minimal for a single valve, can accumulate to substantial amounts in large-scale industrial applications with numerous valves.

Furthermore, the integration of smart technologies and advanced control systems, while offering potential solutions, introduces its own set of challenges. These include increased system complexity, potential reliability issues, and the need for specialized maintenance and operational expertise. The balance between implementing sophisticated energy-saving technologies and maintaining system simplicity and robustness is a delicate one.

The sizing and selection of actuators for specific valve applications also present ongoing challenges. Oversized actuators, often chosen to ensure reliable operation under worst-case scenarios, can lead to significant energy inefficiencies during normal operations. Conversely, undersized actuators may struggle to provide adequate performance, potentially leading to increased energy consumption or operational failures.

Additionally, the thermal management of electrically actuated gate valves remains a persistent challenge. Heat generated during operation can affect the efficiency and lifespan of both the electrical components and the mechanical parts of the valve. Effective heat dissipation strategies are crucial but often difficult to implement, especially in compact or hazardous environments.

Lastly, the industry faces challenges in accurately measuring and monitoring energy consumption in real-time operational settings. Without precise data on energy usage patterns, it becomes difficult to identify opportunities for optimization and to quantify the effectiveness of implemented energy-saving measures. The development of cost-effective, reliable, and non-intrusive energy monitoring systems for gate valves is an ongoing area of research and development.

Existing Energy Optimization Solutions

01 Energy monitoring and optimization in valve systems

Electrically actuated gate valve systems can be equipped with energy monitoring and optimization features. These systems analyze energy consumption patterns, identify inefficiencies, and adjust valve operations to minimize energy usage. Advanced algorithms and machine learning techniques can be employed to predict energy needs and optimize valve actuation timing and duration.- Energy monitoring and optimization for valve systems: Implementing energy monitoring systems for electrically actuated gate valves to track and analyze energy consumption patterns. This allows for the identification of inefficiencies and optimization of valve operations to reduce overall energy usage. Advanced algorithms and machine learning techniques can be employed to predict energy consumption and suggest optimal operational parameters.

- Smart control systems for energy-efficient valve operation: Developing intelligent control systems that dynamically adjust valve operations based on real-time data and environmental conditions. These systems can incorporate sensors, IoT devices, and cloud-based analytics to optimize energy usage while maintaining required flow control. Adaptive control algorithms can learn from historical data to improve energy efficiency over time.

- Low-power actuator designs for gate valves: Creating innovative actuator designs that require less power to operate gate valves. This may include the use of advanced materials, improved mechanical designs, or novel actuation mechanisms. Low-friction components and energy-recuperation systems can be incorporated to minimize energy losses during valve operation.

- Energy harvesting and storage for valve systems: Integrating energy harvesting technologies into valve systems to capture and store energy from the surrounding environment or from the fluid flow itself. This stored energy can be used to power valve actuators or associated control systems, reducing reliance on external power sources and improving overall energy efficiency.

- Predictive maintenance for energy-efficient valve operation: Implementing predictive maintenance strategies using advanced sensors and data analytics to optimize the timing of valve maintenance and replacements. By ensuring valves are operating at peak efficiency and addressing potential issues before they lead to increased energy consumption, overall system energy usage can be reduced.

02 Low-power actuation mechanisms

Innovative designs for electrically actuated gate valves focus on reducing energy consumption through low-power actuation mechanisms. These may include energy-efficient motors, improved gear systems, or novel electromagnetic actuators that require less power to operate. Such designs aim to maintain valve performance while significantly reducing the overall energy footprint.Expand Specific Solutions03 Energy harvesting and storage solutions

Some electrically actuated gate valve systems incorporate energy harvesting technologies to supplement or replace traditional power sources. These may include solar panels, piezoelectric elements, or thermal energy harvesters. Additionally, advanced energy storage solutions like high-efficiency batteries or supercapacitors can be integrated to store excess energy for later use, further optimizing overall energy consumption.Expand Specific Solutions04 Smart control systems for energy efficiency

Intelligent control systems are implemented in electrically actuated gate valves to enhance energy efficiency. These systems use sensors, IoT connectivity, and advanced algorithms to monitor valve performance, environmental conditions, and system demands. By dynamically adjusting valve operations based on real-time data, these smart controls can significantly reduce unnecessary energy consumption while maintaining optimal performance.Expand Specific Solutions05 Energy-efficient materials and coatings

The use of advanced materials and coatings in electrically actuated gate valves can contribute to energy efficiency. Low-friction materials and specialized coatings can reduce the energy required for valve movement. Additionally, materials with improved thermal properties can help maintain optimal operating temperatures, reducing the need for energy-intensive heating or cooling systems in extreme environments.Expand Specific Solutions

Key Players in Electric Valve Industry

The energy usage optimization in electrically actuated gate valves market is in a growth phase, driven by increasing focus on energy efficiency across industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Ford Global Technologies, Saginomiya Seisakusho, and Peugeot SA leading innovation. Major automotive players such as Jaguar Land Rover, BMW, and Mercedes-Benz are also investing heavily in this technology, indicating its growing importance in the automotive sector. The involvement of diverse companies, from traditional valve manufacturers to automotive giants, suggests a maturing technology with wide-ranging applications and potential for further development.

Pfeiffer Vacuum Technology AG

Technical Solution: Pfeiffer Vacuum has developed a high-efficiency electric actuator system specifically designed for vacuum applications in gate valves. Their solution utilizes ultra-low friction bearings and advanced motor designs to minimize energy losses during valve operation[7]. The system incorporates a sophisticated power management module that optimizes energy distribution based on real-time pressure differentials and flow requirements[8]. Pfeiffer's actuators also feature an adaptive control algorithm that learns from operational patterns to further refine energy usage over time[9].

Strengths: Specialized for vacuum applications, ultra-low friction design, and adaptive learning capabilities. Weaknesses: Potentially limited applicability outside of vacuum systems and high-precision environments.

Toyota Motor Corp.

Technical Solution: Toyota has applied its hybrid vehicle technology expertise to develop an energy-efficient actuator system for gate valves. Their solution utilizes a compact electric motor coupled with a high-efficiency gear reduction system, drawing inspiration from their hybrid drivetrain designs[10]. The system incorporates regenerative braking principles, capturing energy during valve closure and storing it in ultra-capacitors for subsequent operations[11]. Toyota's actuator also features an eco-mode that optimizes energy usage during periods of low demand, further enhancing overall efficiency[12].

Strengths: Leverages proven hybrid vehicle technology, incorporates energy regeneration, and features multiple operating modes. Weaknesses: May be more suited to automotive and transportation applications, potentially limiting industrial adoption.

Core Innovations in Valve Energy Efficiency

Electromagnetically driven valve

PatentInactiveEP1789659A1

Innovation

- The design incorporates a rotary drive type electromagnetically driven valve that utilizes a combination of electromagnetic force and elastic force, with multiple magnetic circuits and coils to distribute force and reduce the mass of oscillating members, allowing for lower power consumption.

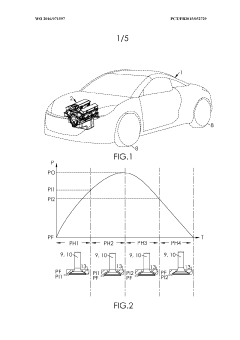

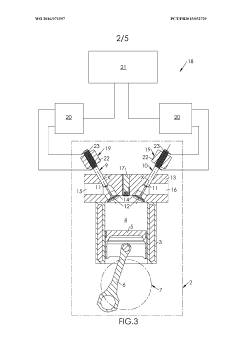

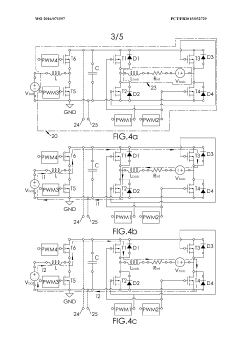

System for electromagnetic actuation of valves for an internal combustion engine

PatentWO2016071597A1

Innovation

- A valve actuation system that uses a control device with an active and passive configuration to manage acceleration and deceleration phases, where induced electrical energy from one valve is transmitted to another, eliminating the need for capacitors and optimizing energy consumption.

Environmental Impact of Valve Energy Consumption

The environmental impact of valve energy consumption is a critical consideration in the context of energy usage optimization for electrically actuated gate valves. As industrial processes become increasingly scrutinized for their environmental footprint, the energy efficiency of valve systems plays a significant role in overall sustainability efforts.

Electrically actuated gate valves, while essential for controlling fluid flow in various industries, can contribute substantially to energy consumption. The primary environmental concern stems from the electricity required to operate these valves, which often translates to increased carbon emissions when power is sourced from non-renewable energy sources. This is particularly relevant in industries with high valve usage, such as oil and gas, water treatment, and chemical processing.

The energy consumption of gate valves is not limited to their active operation but extends to standby power and maintenance requirements. Inefficient valve designs or poorly optimized control systems can lead to unnecessary energy waste, exacerbating their environmental impact. Moreover, the production and disposal of valve components, especially those with shorter lifespans due to inefficient operation, contribute to resource depletion and waste generation.

However, advancements in valve technology and control systems offer promising avenues for reducing environmental impact. Energy-efficient actuators, smart control algorithms, and improved valve designs can significantly decrease power consumption. For instance, the implementation of variable speed drives in valve actuators can optimize energy use based on demand, reducing overall consumption and associated emissions.

Furthermore, the integration of renewable energy sources to power valve systems can substantially mitigate their environmental footprint. Solar-powered actuators or wind energy systems for remote valve installations represent innovative approaches to sustainable valve operation. These solutions not only reduce direct emissions but also contribute to the broader transition towards cleaner energy infrastructure.

The lifecycle assessment of gate valves reveals opportunities for environmental improvement beyond operational energy use. Manufacturers are increasingly focusing on sustainable material selection, designing for longevity, and implementing circular economy principles in valve production and maintenance. This holistic approach addresses the environmental impact from raw material extraction through to end-of-life disposal or recycling.

In conclusion, while electrically actuated gate valves have historically contributed to industrial energy consumption and associated environmental impacts, ongoing technological advancements and sustainability initiatives are transforming the landscape. By prioritizing energy efficiency, embracing renewable power sources, and adopting lifecycle-oriented design principles, the valve industry is poised to significantly reduce its environmental footprint, aligning with global sustainability goals and regulatory requirements.

Electrically actuated gate valves, while essential for controlling fluid flow in various industries, can contribute substantially to energy consumption. The primary environmental concern stems from the electricity required to operate these valves, which often translates to increased carbon emissions when power is sourced from non-renewable energy sources. This is particularly relevant in industries with high valve usage, such as oil and gas, water treatment, and chemical processing.

The energy consumption of gate valves is not limited to their active operation but extends to standby power and maintenance requirements. Inefficient valve designs or poorly optimized control systems can lead to unnecessary energy waste, exacerbating their environmental impact. Moreover, the production and disposal of valve components, especially those with shorter lifespans due to inefficient operation, contribute to resource depletion and waste generation.

However, advancements in valve technology and control systems offer promising avenues for reducing environmental impact. Energy-efficient actuators, smart control algorithms, and improved valve designs can significantly decrease power consumption. For instance, the implementation of variable speed drives in valve actuators can optimize energy use based on demand, reducing overall consumption and associated emissions.

Furthermore, the integration of renewable energy sources to power valve systems can substantially mitigate their environmental footprint. Solar-powered actuators or wind energy systems for remote valve installations represent innovative approaches to sustainable valve operation. These solutions not only reduce direct emissions but also contribute to the broader transition towards cleaner energy infrastructure.

The lifecycle assessment of gate valves reveals opportunities for environmental improvement beyond operational energy use. Manufacturers are increasingly focusing on sustainable material selection, designing for longevity, and implementing circular economy principles in valve production and maintenance. This holistic approach addresses the environmental impact from raw material extraction through to end-of-life disposal or recycling.

In conclusion, while electrically actuated gate valves have historically contributed to industrial energy consumption and associated environmental impacts, ongoing technological advancements and sustainability initiatives are transforming the landscape. By prioritizing energy efficiency, embracing renewable power sources, and adopting lifecycle-oriented design principles, the valve industry is poised to significantly reduce its environmental footprint, aligning with global sustainability goals and regulatory requirements.

Regulatory Framework for Industrial Energy Efficiency

The regulatory framework for industrial energy efficiency plays a crucial role in shaping the landscape for energy usage optimization in electrically actuated gate valves. Governments worldwide have implemented various policies and regulations to promote energy efficiency in industrial processes, recognizing the significant impact of industrial energy consumption on overall energy demand and environmental sustainability.

In the United States, the Department of Energy (DOE) has established energy efficiency standards for industrial equipment, including electric motors used in gate valve actuators. These standards, outlined in the Energy Policy and Conservation Act (EPCA), set minimum efficiency levels for various types of electric motors, encouraging manufacturers to develop and implement more energy-efficient solutions.

The European Union has taken a comprehensive approach to industrial energy efficiency through its Energy Efficiency Directive (EED). This directive requires large enterprises to conduct regular energy audits and implement energy management systems. For electrically actuated gate valves, this translates into increased pressure on manufacturers and end-users to optimize energy consumption throughout the valve's lifecycle.

In China, the government has implemented the Energy Conservation Law, which sets energy efficiency targets for key industries and promotes the adoption of energy-saving technologies. This regulatory framework has spurred innovation in valve actuator design, with Chinese manufacturers focusing on developing more energy-efficient solutions to meet stringent requirements.

International standards, such as ISO 50001 for energy management systems, provide a global framework for organizations to improve energy performance. This standard encourages companies to integrate energy management into their overall efforts to improve quality and environmental management, directly impacting the design and operation of electrically actuated gate valves.

The regulatory landscape also includes incentives and support mechanisms for energy efficiency improvements. Many countries offer tax incentives, grants, and subsidies for companies investing in energy-efficient technologies. These financial incentives can significantly influence the adoption of optimized gate valve solutions in industrial applications.

Furthermore, energy labeling and certification programs have been established in various regions to provide transparency and promote energy-efficient products. While not specifically targeting gate valves, these programs create a market environment that values and rewards energy efficiency, indirectly influencing the development of more efficient valve actuators.

As the global focus on climate change intensifies, regulatory frameworks are evolving to include more stringent energy efficiency requirements. This trend is likely to drive further innovation in electrically actuated gate valve technology, pushing manufacturers to explore advanced control algorithms, improved motor designs, and smart energy management features to meet future regulatory standards.

In the United States, the Department of Energy (DOE) has established energy efficiency standards for industrial equipment, including electric motors used in gate valve actuators. These standards, outlined in the Energy Policy and Conservation Act (EPCA), set minimum efficiency levels for various types of electric motors, encouraging manufacturers to develop and implement more energy-efficient solutions.

The European Union has taken a comprehensive approach to industrial energy efficiency through its Energy Efficiency Directive (EED). This directive requires large enterprises to conduct regular energy audits and implement energy management systems. For electrically actuated gate valves, this translates into increased pressure on manufacturers and end-users to optimize energy consumption throughout the valve's lifecycle.

In China, the government has implemented the Energy Conservation Law, which sets energy efficiency targets for key industries and promotes the adoption of energy-saving technologies. This regulatory framework has spurred innovation in valve actuator design, with Chinese manufacturers focusing on developing more energy-efficient solutions to meet stringent requirements.

International standards, such as ISO 50001 for energy management systems, provide a global framework for organizations to improve energy performance. This standard encourages companies to integrate energy management into their overall efforts to improve quality and environmental management, directly impacting the design and operation of electrically actuated gate valves.

The regulatory landscape also includes incentives and support mechanisms for energy efficiency improvements. Many countries offer tax incentives, grants, and subsidies for companies investing in energy-efficient technologies. These financial incentives can significantly influence the adoption of optimized gate valve solutions in industrial applications.

Furthermore, energy labeling and certification programs have been established in various regions to provide transparency and promote energy-efficient products. While not specifically targeting gate valves, these programs create a market environment that values and rewards energy efficiency, indirectly influencing the development of more efficient valve actuators.

As the global focus on climate change intensifies, regulatory frameworks are evolving to include more stringent energy efficiency requirements. This trend is likely to drive further innovation in electrically actuated gate valve technology, pushing manufacturers to explore advanced control algorithms, improved motor designs, and smart energy management features to meet future regulatory standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!