Reliability engineering approaches for aging gate valves

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Aging Background and Objectives

Gate valves have been a critical component in various industrial applications for decades, playing a vital role in controlling fluid flow in pipelines and systems. As these valves age, their reliability becomes a growing concern for operators across multiple sectors, including oil and gas, water treatment, and power generation. The objective of this technical research is to comprehensively examine the reliability engineering approaches for aging gate valves, addressing the challenges associated with their long-term performance and maintenance.

The evolution of gate valve technology has seen significant advancements since its inception. Early designs focused primarily on basic functionality, while modern gate valves incorporate sophisticated materials and engineering principles to enhance durability and efficiency. This progression has been driven by the increasing demands of industrial processes, stricter regulatory requirements, and the need for improved safety and environmental protection.

Despite these advancements, the aging of gate valves remains a persistent issue. As valves reach the latter stages of their operational life, they become susceptible to various forms of degradation, including corrosion, erosion, and mechanical wear. These factors can lead to reduced performance, increased maintenance requirements, and, in severe cases, catastrophic failures that may result in significant economic losses and safety hazards.

The primary goal of reliability engineering in this context is to develop strategies that extend the operational life of gate valves while maintaining their performance and safety standards. This involves a multifaceted approach that encompasses predictive maintenance techniques, advanced monitoring systems, and innovative materials science. By implementing these strategies, industries aim to optimize the balance between operational efficiency and the cost of valve replacement or major overhauls.

Current trends in gate valve reliability engineering focus on the integration of smart technologies and data-driven decision-making processes. The advent of Industrial Internet of Things (IIoT) and advanced sensors has opened new avenues for real-time monitoring and predictive maintenance. These technologies enable operators to detect early signs of valve degradation, allowing for timely interventions that can significantly extend valve life and prevent unexpected failures.

Furthermore, the development of new materials and coatings has emerged as a key area of research in combating valve aging. Advanced alloys and surface treatments are being explored to enhance resistance to corrosion and erosion, particularly in harsh operating environments. These material innovations aim to address the root causes of valve degradation, potentially revolutionizing the longevity and reliability of gate valves in critical applications.

As we delve deeper into the reliability engineering approaches for aging gate valves, it is essential to consider the broader implications for industrial operations and safety standards. The outcomes of this research have the potential to significantly impact maintenance strategies, operational costs, and regulatory compliance across multiple industries. By addressing the challenges of valve aging, we aim to contribute to the development of more resilient and sustainable industrial systems.

The evolution of gate valve technology has seen significant advancements since its inception. Early designs focused primarily on basic functionality, while modern gate valves incorporate sophisticated materials and engineering principles to enhance durability and efficiency. This progression has been driven by the increasing demands of industrial processes, stricter regulatory requirements, and the need for improved safety and environmental protection.

Despite these advancements, the aging of gate valves remains a persistent issue. As valves reach the latter stages of their operational life, they become susceptible to various forms of degradation, including corrosion, erosion, and mechanical wear. These factors can lead to reduced performance, increased maintenance requirements, and, in severe cases, catastrophic failures that may result in significant economic losses and safety hazards.

The primary goal of reliability engineering in this context is to develop strategies that extend the operational life of gate valves while maintaining their performance and safety standards. This involves a multifaceted approach that encompasses predictive maintenance techniques, advanced monitoring systems, and innovative materials science. By implementing these strategies, industries aim to optimize the balance between operational efficiency and the cost of valve replacement or major overhauls.

Current trends in gate valve reliability engineering focus on the integration of smart technologies and data-driven decision-making processes. The advent of Industrial Internet of Things (IIoT) and advanced sensors has opened new avenues for real-time monitoring and predictive maintenance. These technologies enable operators to detect early signs of valve degradation, allowing for timely interventions that can significantly extend valve life and prevent unexpected failures.

Furthermore, the development of new materials and coatings has emerged as a key area of research in combating valve aging. Advanced alloys and surface treatments are being explored to enhance resistance to corrosion and erosion, particularly in harsh operating environments. These material innovations aim to address the root causes of valve degradation, potentially revolutionizing the longevity and reliability of gate valves in critical applications.

As we delve deeper into the reliability engineering approaches for aging gate valves, it is essential to consider the broader implications for industrial operations and safety standards. The outcomes of this research have the potential to significantly impact maintenance strategies, operational costs, and regulatory compliance across multiple industries. By addressing the challenges of valve aging, we aim to contribute to the development of more resilient and sustainable industrial systems.

Market Demand Analysis for Reliable Gate Valves

The market demand for reliable gate valves has been steadily increasing across various industries, driven by the critical need for enhanced safety, operational efficiency, and cost-effectiveness in fluid control systems. As industrial infrastructure continues to age, particularly in sectors such as oil and gas, water treatment, and power generation, the focus on maintaining and upgrading existing gate valve installations has intensified.

In the oil and gas industry, which represents a significant portion of the market, the demand for reliable gate valves is particularly strong. Aging pipelines and processing facilities require robust valves that can withstand harsh operating conditions and maintain integrity over extended periods. The industry's emphasis on preventing leaks and minimizing downtime has led to a growing interest in advanced reliability engineering approaches for gate valves.

The water and wastewater treatment sector also exhibits a substantial demand for reliable gate valves. As municipalities worldwide invest in upgrading their aging water infrastructure, the need for durable and low-maintenance valve solutions has become paramount. The market in this sector is driven by the increasing focus on water conservation, stringent environmental regulations, and the need to reduce operational costs associated with valve failures and maintenance.

Power generation facilities, including nuclear, thermal, and hydroelectric plants, constitute another major market segment for reliable gate valves. These facilities require valves that can operate consistently under extreme temperatures and pressures. The aging of many power plants worldwide has created a significant replacement and upgrade market for gate valves with enhanced reliability features.

The chemical and petrochemical industries also contribute significantly to the market demand for reliable gate valves. These sectors handle corrosive and hazardous materials, necessitating valves that can maintain their integrity and performance over time. The focus on process safety and environmental protection has led to increased investment in advanced valve technologies and reliability engineering approaches.

Market analysis indicates a growing trend towards predictive maintenance and condition monitoring solutions for gate valves. This shift is driven by the desire to optimize maintenance schedules, reduce unexpected failures, and extend the operational life of valve assets. As a result, there is an increasing demand for gate valves equipped with smart sensors and diagnostic capabilities that enable real-time monitoring and performance analysis.

The global market for reliable gate valves is expected to experience steady growth in the coming years, with a particular emphasis on solutions for aging infrastructure. Factors such as increasing industrialization in developing countries, stringent safety regulations, and the need for energy-efficient operations are likely to fuel this growth. Additionally, the market is seeing a rise in demand for customized valve solutions that address specific reliability challenges in different industrial applications.

In the oil and gas industry, which represents a significant portion of the market, the demand for reliable gate valves is particularly strong. Aging pipelines and processing facilities require robust valves that can withstand harsh operating conditions and maintain integrity over extended periods. The industry's emphasis on preventing leaks and minimizing downtime has led to a growing interest in advanced reliability engineering approaches for gate valves.

The water and wastewater treatment sector also exhibits a substantial demand for reliable gate valves. As municipalities worldwide invest in upgrading their aging water infrastructure, the need for durable and low-maintenance valve solutions has become paramount. The market in this sector is driven by the increasing focus on water conservation, stringent environmental regulations, and the need to reduce operational costs associated with valve failures and maintenance.

Power generation facilities, including nuclear, thermal, and hydroelectric plants, constitute another major market segment for reliable gate valves. These facilities require valves that can operate consistently under extreme temperatures and pressures. The aging of many power plants worldwide has created a significant replacement and upgrade market for gate valves with enhanced reliability features.

The chemical and petrochemical industries also contribute significantly to the market demand for reliable gate valves. These sectors handle corrosive and hazardous materials, necessitating valves that can maintain their integrity and performance over time. The focus on process safety and environmental protection has led to increased investment in advanced valve technologies and reliability engineering approaches.

Market analysis indicates a growing trend towards predictive maintenance and condition monitoring solutions for gate valves. This shift is driven by the desire to optimize maintenance schedules, reduce unexpected failures, and extend the operational life of valve assets. As a result, there is an increasing demand for gate valves equipped with smart sensors and diagnostic capabilities that enable real-time monitoring and performance analysis.

The global market for reliable gate valves is expected to experience steady growth in the coming years, with a particular emphasis on solutions for aging infrastructure. Factors such as increasing industrialization in developing countries, stringent safety regulations, and the need for energy-efficient operations are likely to fuel this growth. Additionally, the market is seeing a rise in demand for customized valve solutions that address specific reliability challenges in different industrial applications.

Current Challenges in Gate Valve Reliability

Gate valves are critical components in various industrial systems, and their reliability is paramount for ensuring operational efficiency and safety. However, as these valves age, they face numerous challenges that impact their performance and longevity. One of the primary issues is material degradation, which can lead to corrosion, erosion, and wear of valve components. This degradation is often exacerbated by harsh operating environments, including exposure to extreme temperatures, pressures, and corrosive substances.

Another significant challenge is the accumulation of deposits and scale within the valve, particularly in systems handling fluids with high mineral content or particulate matter. These deposits can impede valve movement, leading to increased operating torque and potential seizure. Additionally, the buildup can cause uneven wear on sealing surfaces, compromising the valve's ability to maintain a tight shut-off.

Mechanical stress is a persistent concern for aging gate valves. Repeated cycling, thermal expansion and contraction, and vibration can lead to fatigue and eventual failure of critical components such as stems, gates, and seats. This is particularly problematic in applications with frequent valve operations or those subject to thermal cycling.

Leakage is another major reliability issue that becomes more prevalent as gate valves age. Deterioration of sealing surfaces, packing, and gaskets can result in both internal and external leaks. Internal leakage reduces the valve's effectiveness in isolating flow, while external leakage poses environmental and safety risks, especially when handling hazardous fluids.

The challenge of obsolescence also affects the reliability of aging gate valves. As manufacturers discontinue older models, sourcing replacement parts becomes increasingly difficult. This can lead to extended downtime during maintenance or force operators to replace entire valve assemblies, incurring significant costs.

Monitoring and diagnostics present additional challenges for aging gate valves. Many older valves lack integrated sensors or diagnostic capabilities, making it difficult to assess their condition accurately without invasive inspections. This limitation can result in unexpected failures or unnecessary maintenance interventions.

Furthermore, the reliability of aging gate valves is impacted by changes in operational requirements over time. Valves that were initially designed for specific flow rates, pressures, or fluid compositions may struggle to meet new demands as processes evolve, leading to suboptimal performance or premature failure.

Addressing these challenges requires a comprehensive approach to reliability engineering that encompasses material science, predictive maintenance strategies, and innovative retrofit solutions. As industrial systems continue to age, developing effective methods to extend the service life and maintain the reliability of gate valves remains a critical focus for engineers and asset managers across various sectors.

Another significant challenge is the accumulation of deposits and scale within the valve, particularly in systems handling fluids with high mineral content or particulate matter. These deposits can impede valve movement, leading to increased operating torque and potential seizure. Additionally, the buildup can cause uneven wear on sealing surfaces, compromising the valve's ability to maintain a tight shut-off.

Mechanical stress is a persistent concern for aging gate valves. Repeated cycling, thermal expansion and contraction, and vibration can lead to fatigue and eventual failure of critical components such as stems, gates, and seats. This is particularly problematic in applications with frequent valve operations or those subject to thermal cycling.

Leakage is another major reliability issue that becomes more prevalent as gate valves age. Deterioration of sealing surfaces, packing, and gaskets can result in both internal and external leaks. Internal leakage reduces the valve's effectiveness in isolating flow, while external leakage poses environmental and safety risks, especially when handling hazardous fluids.

The challenge of obsolescence also affects the reliability of aging gate valves. As manufacturers discontinue older models, sourcing replacement parts becomes increasingly difficult. This can lead to extended downtime during maintenance or force operators to replace entire valve assemblies, incurring significant costs.

Monitoring and diagnostics present additional challenges for aging gate valves. Many older valves lack integrated sensors or diagnostic capabilities, making it difficult to assess their condition accurately without invasive inspections. This limitation can result in unexpected failures or unnecessary maintenance interventions.

Furthermore, the reliability of aging gate valves is impacted by changes in operational requirements over time. Valves that were initially designed for specific flow rates, pressures, or fluid compositions may struggle to meet new demands as processes evolve, leading to suboptimal performance or premature failure.

Addressing these challenges requires a comprehensive approach to reliability engineering that encompasses material science, predictive maintenance strategies, and innovative retrofit solutions. As industrial systems continue to age, developing effective methods to extend the service life and maintain the reliability of gate valves remains a critical focus for engineers and asset managers across various sectors.

Existing Reliability Solutions for Gate Valves

01 Improved sealing mechanisms

Gate valves with enhanced sealing mechanisms contribute to increased reliability. These improvements include advanced seal designs, materials, and configurations that prevent leakage and ensure consistent performance under various operating conditions. Such enhancements can significantly extend the valve's service life and reduce maintenance requirements.- Improved sealing mechanisms: Gate valves with enhanced sealing mechanisms contribute to increased reliability. These improvements include advanced seal designs, materials, and configurations that prevent leakage and ensure consistent performance under various operating conditions.

- Corrosion-resistant materials and coatings: The use of corrosion-resistant materials and protective coatings in gate valve construction significantly enhances their reliability. These materials and coatings protect critical components from degradation, extending the valve's lifespan and maintaining its performance in harsh environments.

- Advanced monitoring and diagnostic systems: Integration of monitoring and diagnostic systems in gate valves improves reliability by enabling real-time performance tracking and predictive maintenance. These systems can detect potential issues before they lead to failures, allowing for timely interventions and minimizing downtime.

- Optimized valve actuator designs: Improved actuator designs enhance gate valve reliability by ensuring precise and consistent valve operation. These designs focus on factors such as torque control, position feedback, and fail-safe mechanisms, contributing to overall system reliability.

- Enhanced testing and quality control procedures: Implementation of rigorous testing and quality control procedures during manufacturing and installation processes significantly improves gate valve reliability. These procedures include advanced leak detection methods, stress testing, and performance validation under simulated operating conditions.

02 Advanced materials and coatings

The use of advanced materials and coatings in gate valve construction improves their reliability. These materials offer superior resistance to corrosion, erosion, and wear, enhancing the valve's durability and performance in harsh environments. Specialized coatings can also reduce friction and improve the valve's operational efficiency.Expand Specific Solutions03 Intelligent monitoring and diagnostics

Integration of intelligent monitoring and diagnostic systems in gate valves enhances their reliability. These systems can provide real-time data on valve performance, predict potential failures, and facilitate preventive maintenance. This proactive approach helps minimize downtime and extends the valve's operational lifespan.Expand Specific Solutions04 Optimized valve design and flow characteristics

Improved gate valve designs focus on optimizing flow characteristics and reducing turbulence. These enhancements minimize wear on valve components, reduce the risk of cavitation, and improve overall performance. Such design optimizations contribute to increased reliability and extended service life of the valve.Expand Specific Solutions05 Enhanced actuation and control systems

Advanced actuation and control systems improve the reliability of gate valves. These systems provide more precise control over valve operation, reduce the risk of human error, and enable smoother opening and closing actions. Improved actuation mechanisms can also help prevent issues such as sticking or jamming, further enhancing valve reliability.Expand Specific Solutions

Key Players in Gate Valve Manufacturing

The reliability engineering approaches for aging gate valves are in a mature stage of development, with a well-established market and significant industry players. The global valve market size is projected to reach $85.6 billion by 2027, with gate valves being a crucial segment. Companies like State Grid Corp. of China, KSB SE & Co. KGaA, and Danfoss A/S are leading players in this field, demonstrating high technological maturity. These firms have extensive experience in developing and implementing reliability engineering solutions for aging infrastructure, including gate valves. The market is characterized by a mix of large multinational corporations and specialized valve manufacturers, all contributing to the continuous improvement of reliability engineering techniques for aging gate valves.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed a comprehensive reliability engineering approach for aging gate valves in power transmission and distribution systems. Their method combines advanced condition monitoring techniques with predictive maintenance strategies. They utilize IoT sensors to continuously monitor valve performance parameters such as pressure, temperature, and vibration[1]. This data is then analyzed using machine learning algorithms to predict potential failures and optimize maintenance schedules. The company has also implemented a digital twin system that creates virtual models of gate valves, allowing for real-time simulation and analysis of valve behavior under various operating conditions[2]. This approach enables proactive maintenance and extends the operational life of aging gate valves.

Strengths: Comprehensive approach combining IoT, machine learning, and digital twin technology. Weaknesses: High initial implementation cost and complexity in integrating with existing infrastructure.

NOV, Inc.

Technical Solution: NOV, Inc. has developed a reliability-centered maintenance (RCM) approach for aging gate valves in the oil and gas industry. Their method focuses on identifying critical failure modes and implementing targeted maintenance strategies. NOV utilizes advanced non-destructive testing techniques, including acoustic emission testing and ultrasonic thickness measurements, to assess valve integrity without disrupting operations[3]. They have also developed a proprietary software platform that integrates historical maintenance data, real-time sensor data, and industry standards to create customized maintenance plans for each valve. Additionally, NOV has introduced a novel coating technology that extends the lifespan of gate valves in corrosive environments, reducing the frequency of replacements and repairs[4].

Strengths: Industry-specific approach with advanced non-destructive testing and customized maintenance planning. Weaknesses: May be less applicable to other industries outside oil and gas.

Core Innovations in Gate Valve Reliability

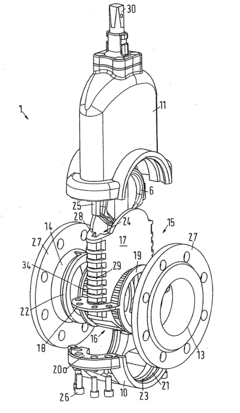

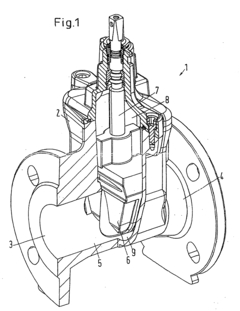

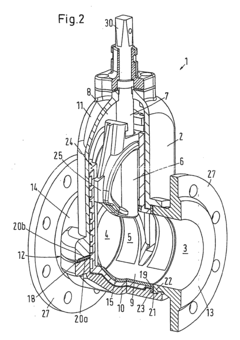

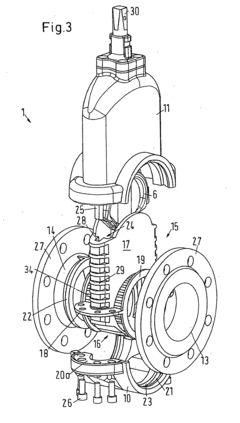

Gate valve

PatentInactiveUS20050098756A1

Innovation

- A gate valve design featuring a sealing insert with a rigid body connected to areas of reduced rigidity, allowing for complex shapes and improved accuracy, using a combination of polyoxy methylene (POM) and ethylene/propylene diene monomer (EPDM) materials, with clamping areas and a filling material to enhance retention and sealing, and incorporating holes for water circulation to prevent microorganism growth.

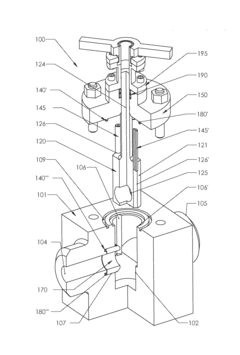

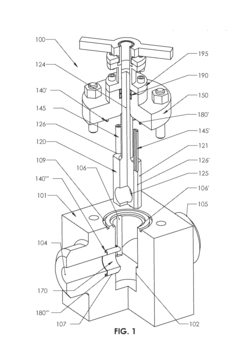

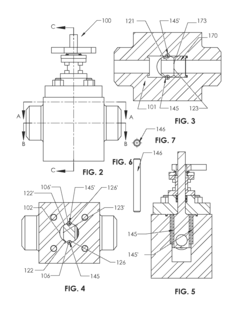

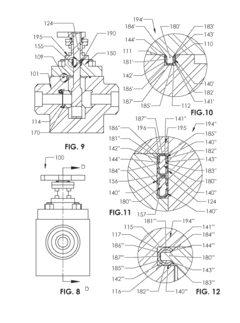

Trunnion control gate valve for severe service

PatentInactiveUS20160356399A1

Innovation

- A trunnion control gate valve with a novel gating mechanism using spring bars for misalignment compensation, a four-step throttling process, and a metal G ring seal assembly for high-temperature and high-pressure applications, along with a noise/cavitation reducer to stabilize flow and reduce noise.

Regulatory Framework for Industrial Valves

The regulatory framework for industrial valves plays a crucial role in ensuring the safety, reliability, and performance of gate valves in various industries. This framework encompasses a wide range of standards, codes, and regulations that govern the design, manufacture, installation, operation, and maintenance of industrial valves, including aging gate valves.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) develop and maintain standards that are widely adopted across industries. For instance, ISO 5208 specifies the pressure testing requirements for industrial valves, while IEC 60534 provides guidelines for the sizing and selection of control valves.

In the United States, the American Society of Mechanical Engineers (ASME) has developed a comprehensive set of standards for pressure vessels and piping systems, including valves. The ASME Boiler and Pressure Vessel Code (BPVC) and ASME B16 series of standards are particularly relevant for gate valves. These standards address issues such as material selection, design criteria, testing procedures, and quality assurance requirements.

The American Petroleum Institute (API) has also established industry-specific standards for valves used in oil and gas applications. API 600 and API 6D are widely recognized standards for gate valves in the petroleum and natural gas industries, covering aspects such as design, manufacturing, testing, and marking requirements.

In Europe, the Pressure Equipment Directive (PED) 2014/68/EU sets out the essential safety requirements for pressure equipment, including industrial valves. This directive is supported by harmonized European standards, such as EN 12516 for industrial valves and EN 19 for marking of metallic valves.

Regulatory bodies in various countries also play a significant role in enforcing these standards and regulations. For example, the U.S. Nuclear Regulatory Commission (NRC) oversees the use of valves in nuclear power plants, while the Occupational Safety and Health Administration (OSHA) regulates valve safety in industrial workplaces.

As gate valves age, the regulatory framework emphasizes the importance of ongoing inspection, maintenance, and testing programs. The American Society for Testing and Materials (ASTM) provides standards for non-destructive testing methods that can be applied to aging valves. Additionally, the National Association of Corrosion Engineers (NACE) offers guidelines for corrosion control and material selection, which are critical for maintaining the integrity of aging gate valves.

The regulatory landscape also addresses the challenges of obsolescence and the need for replacement or upgrade of aging valves. Standards such as those developed by the Manufacturers Standardization Society (MSS) provide guidance on valve repair and replacement procedures, ensuring that any modifications or upgrades meet current safety and performance requirements.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) develop and maintain standards that are widely adopted across industries. For instance, ISO 5208 specifies the pressure testing requirements for industrial valves, while IEC 60534 provides guidelines for the sizing and selection of control valves.

In the United States, the American Society of Mechanical Engineers (ASME) has developed a comprehensive set of standards for pressure vessels and piping systems, including valves. The ASME Boiler and Pressure Vessel Code (BPVC) and ASME B16 series of standards are particularly relevant for gate valves. These standards address issues such as material selection, design criteria, testing procedures, and quality assurance requirements.

The American Petroleum Institute (API) has also established industry-specific standards for valves used in oil and gas applications. API 600 and API 6D are widely recognized standards for gate valves in the petroleum and natural gas industries, covering aspects such as design, manufacturing, testing, and marking requirements.

In Europe, the Pressure Equipment Directive (PED) 2014/68/EU sets out the essential safety requirements for pressure equipment, including industrial valves. This directive is supported by harmonized European standards, such as EN 12516 for industrial valves and EN 19 for marking of metallic valves.

Regulatory bodies in various countries also play a significant role in enforcing these standards and regulations. For example, the U.S. Nuclear Regulatory Commission (NRC) oversees the use of valves in nuclear power plants, while the Occupational Safety and Health Administration (OSHA) regulates valve safety in industrial workplaces.

As gate valves age, the regulatory framework emphasizes the importance of ongoing inspection, maintenance, and testing programs. The American Society for Testing and Materials (ASTM) provides standards for non-destructive testing methods that can be applied to aging valves. Additionally, the National Association of Corrosion Engineers (NACE) offers guidelines for corrosion control and material selection, which are critical for maintaining the integrity of aging gate valves.

The regulatory landscape also addresses the challenges of obsolescence and the need for replacement or upgrade of aging valves. Standards such as those developed by the Manufacturers Standardization Society (MSS) provide guidance on valve repair and replacement procedures, ensuring that any modifications or upgrades meet current safety and performance requirements.

Economic Impact of Gate Valve Failures

The economic impact of gate valve failures in industrial settings can be substantial, affecting both operational efficiency and financial performance. Gate valves are critical components in various industries, including oil and gas, water treatment, and chemical processing. When these valves fail, the consequences can ripple through the entire production system, leading to significant economic losses.

Unplanned shutdowns due to gate valve failures are a primary source of economic impact. These shutdowns result in lost production time, which directly translates to reduced output and revenue. For instance, in the oil and gas industry, a single day of downtime can cost millions of dollars in lost production. Additionally, emergency repairs and replacements of failed gate valves often come at a premium, further increasing the financial burden on companies.

The cost of maintenance and repair for aging gate valves also contributes to the economic impact. As valves age, they require more frequent inspections, maintenance, and potential replacements. This increased maintenance schedule diverts resources from other critical areas and can lead to higher operational costs over time. Furthermore, the need for specialized technicians and equipment for valve maintenance adds to the overall expense.

Safety incidents resulting from gate valve failures can have severe economic repercussions. Leaks or ruptures can lead to environmental damage, necessitating costly clean-up operations and potential regulatory fines. In extreme cases, catastrophic failures may result in injuries or fatalities, leading to legal liabilities and damage to a company's reputation, which can have long-lasting financial implications.

The impact on product quality is another economic consideration. Malfunctioning gate valves can lead to inconsistent flow control, affecting the quality of the final product. This can result in increased waste, rework costs, and potential loss of customers due to quality issues. In industries with strict quality requirements, such as pharmaceuticals or food processing, the economic consequences of product quality problems can be particularly severe.

Supply chain disruptions caused by gate valve failures can extend the economic impact beyond the immediate facility. Delays in production or delivery can affect downstream customers, potentially leading to contractual penalties or loss of business relationships. This ripple effect can have far-reaching consequences across the entire supply chain, impacting multiple businesses and industries.

Investing in reliability engineering approaches for aging gate valves can mitigate these economic impacts. While there are upfront costs associated with implementing advanced monitoring systems, predictive maintenance strategies, and valve life extension programs, the long-term economic benefits often outweigh these initial investments. By reducing the frequency and severity of valve failures, companies can minimize downtime, improve operational efficiency, and avoid the substantial costs associated with unexpected failures.

Unplanned shutdowns due to gate valve failures are a primary source of economic impact. These shutdowns result in lost production time, which directly translates to reduced output and revenue. For instance, in the oil and gas industry, a single day of downtime can cost millions of dollars in lost production. Additionally, emergency repairs and replacements of failed gate valves often come at a premium, further increasing the financial burden on companies.

The cost of maintenance and repair for aging gate valves also contributes to the economic impact. As valves age, they require more frequent inspections, maintenance, and potential replacements. This increased maintenance schedule diverts resources from other critical areas and can lead to higher operational costs over time. Furthermore, the need for specialized technicians and equipment for valve maintenance adds to the overall expense.

Safety incidents resulting from gate valve failures can have severe economic repercussions. Leaks or ruptures can lead to environmental damage, necessitating costly clean-up operations and potential regulatory fines. In extreme cases, catastrophic failures may result in injuries or fatalities, leading to legal liabilities and damage to a company's reputation, which can have long-lasting financial implications.

The impact on product quality is another economic consideration. Malfunctioning gate valves can lead to inconsistent flow control, affecting the quality of the final product. This can result in increased waste, rework costs, and potential loss of customers due to quality issues. In industries with strict quality requirements, such as pharmaceuticals or food processing, the economic consequences of product quality problems can be particularly severe.

Supply chain disruptions caused by gate valve failures can extend the economic impact beyond the immediate facility. Delays in production or delivery can affect downstream customers, potentially leading to contractual penalties or loss of business relationships. This ripple effect can have far-reaching consequences across the entire supply chain, impacting multiple businesses and industries.

Investing in reliability engineering approaches for aging gate valves can mitigate these economic impacts. While there are upfront costs associated with implementing advanced monitoring systems, predictive maintenance strategies, and valve life extension programs, the long-term economic benefits often outweigh these initial investments. By reducing the frequency and severity of valve failures, companies can minimize downtime, improve operational efficiency, and avoid the substantial costs associated with unexpected failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!