Design improvements of gate valves for minimal maintenance needs

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Objectives

Gate valves have been a crucial component in fluid control systems for over a century, evolving significantly since their inception. The primary objective of gate valve design has always been to provide reliable and efficient flow control in various industrial applications. However, as industries have advanced, the focus has shifted towards minimizing maintenance requirements, thereby reducing operational costs and improving overall system reliability.

The evolution of gate valves can be traced through several key stages. Initially, gate valves were simple mechanical devices with limited sealing capabilities and frequent maintenance needs. As manufacturing techniques improved, so did the precision and durability of gate valves. The introduction of new materials, such as high-grade stainless steels and advanced polymers, marked a significant milestone in gate valve development, enhancing their resistance to corrosion and wear.

In recent decades, the integration of automation and smart technologies has revolutionized gate valve design. The incorporation of electric and pneumatic actuators has improved operational efficiency and reduced the need for manual intervention. Furthermore, the advent of sensors and digital monitoring systems has enabled predictive maintenance strategies, allowing operators to anticipate and address potential issues before they escalate into major problems.

The current technological landscape presents both challenges and opportunities for gate valve design. The push towards Industry 4.0 and the Internet of Things (IoT) is driving the development of more intelligent and interconnected valve systems. These advancements aim to provide real-time monitoring, remote operation capabilities, and enhanced diagnostics, all contributing to the overarching goal of minimal maintenance.

Looking forward, the objectives for gate valve design improvements are multifaceted. Firstly, there is a strong emphasis on extending the operational lifespan of gate valves without compromising performance. This involves research into advanced materials that can withstand harsh environments and extreme operating conditions for longer periods without degradation.

Secondly, the focus is on developing self-diagnostic and self-healing mechanisms within gate valves. These innovations aim to detect wear and potential failures early, and in some cases, automatically initiate corrective actions, further reducing the need for manual maintenance interventions.

Lastly, there is a growing interest in modular designs that allow for easier component replacement and upgrades. This approach not only simplifies maintenance procedures but also extends the adaptability of gate valves to evolving industrial requirements, ensuring their relevance in future applications.

The evolution of gate valves can be traced through several key stages. Initially, gate valves were simple mechanical devices with limited sealing capabilities and frequent maintenance needs. As manufacturing techniques improved, so did the precision and durability of gate valves. The introduction of new materials, such as high-grade stainless steels and advanced polymers, marked a significant milestone in gate valve development, enhancing their resistance to corrosion and wear.

In recent decades, the integration of automation and smart technologies has revolutionized gate valve design. The incorporation of electric and pneumatic actuators has improved operational efficiency and reduced the need for manual intervention. Furthermore, the advent of sensors and digital monitoring systems has enabled predictive maintenance strategies, allowing operators to anticipate and address potential issues before they escalate into major problems.

The current technological landscape presents both challenges and opportunities for gate valve design. The push towards Industry 4.0 and the Internet of Things (IoT) is driving the development of more intelligent and interconnected valve systems. These advancements aim to provide real-time monitoring, remote operation capabilities, and enhanced diagnostics, all contributing to the overarching goal of minimal maintenance.

Looking forward, the objectives for gate valve design improvements are multifaceted. Firstly, there is a strong emphasis on extending the operational lifespan of gate valves without compromising performance. This involves research into advanced materials that can withstand harsh environments and extreme operating conditions for longer periods without degradation.

Secondly, the focus is on developing self-diagnostic and self-healing mechanisms within gate valves. These innovations aim to detect wear and potential failures early, and in some cases, automatically initiate corrective actions, further reducing the need for manual maintenance interventions.

Lastly, there is a growing interest in modular designs that allow for easier component replacement and upgrades. This approach not only simplifies maintenance procedures but also extends the adaptability of gate valves to evolving industrial requirements, ensuring their relevance in future applications.

Market Demand Analysis for Low-Maintenance Valves

The market demand for low-maintenance gate valves has been steadily increasing across various industries, driven by the need for improved operational efficiency and reduced downtime. Industries such as oil and gas, water treatment, power generation, and chemical processing are particularly interested in valve solutions that require minimal maintenance, as these sectors often operate in challenging environments where frequent maintenance can be costly and disruptive.

In the oil and gas industry, the demand for low-maintenance gate valves is particularly strong due to the harsh operating conditions and the critical nature of operations. Offshore platforms and remote pipeline installations require valves that can withstand corrosive environments and operate reliably for extended periods without intervention. The water treatment sector also shows significant interest in low-maintenance valves, as municipalities and water utilities seek to reduce maintenance costs and improve the reliability of their distribution systems.

The power generation industry, including both conventional and renewable energy sectors, is another key market for low-maintenance gate valves. Power plants require valves that can operate consistently under high temperatures and pressures, with minimal need for maintenance to ensure uninterrupted power supply. Similarly, the chemical processing industry values gate valves that can resist corrosion and maintain their integrity in the presence of aggressive chemicals, reducing the frequency of maintenance and replacement.

Market research indicates that end-users are willing to invest in higher-quality, low-maintenance gate valves despite potentially higher initial costs, recognizing the long-term benefits of reduced maintenance expenses and improved operational reliability. This trend is supported by the growing emphasis on total cost of ownership (TCO) in procurement decisions, where the lifecycle costs of equipment, including maintenance, are given greater consideration.

The demand for low-maintenance gate valves is also influenced by regulatory pressures and industry standards that emphasize safety and environmental protection. Stricter regulations on emissions and leakage prevention are driving the adoption of more reliable valve technologies that require less frequent maintenance and reduce the risk of fugitive emissions.

Emerging technologies such as smart valves and predictive maintenance systems are further shaping market demand. End-users are increasingly interested in gate valves equipped with sensors and diagnostic capabilities that can predict maintenance needs and optimize performance, aligning with the broader trend towards digitalization and Industry 4.0 practices.

As industries continue to focus on operational excellence and cost reduction, the market for low-maintenance gate valves is expected to grow. Manufacturers that can deliver innovative designs addressing the specific challenges of minimal maintenance while ensuring long-term reliability and performance are likely to gain a competitive edge in this evolving market landscape.

In the oil and gas industry, the demand for low-maintenance gate valves is particularly strong due to the harsh operating conditions and the critical nature of operations. Offshore platforms and remote pipeline installations require valves that can withstand corrosive environments and operate reliably for extended periods without intervention. The water treatment sector also shows significant interest in low-maintenance valves, as municipalities and water utilities seek to reduce maintenance costs and improve the reliability of their distribution systems.

The power generation industry, including both conventional and renewable energy sectors, is another key market for low-maintenance gate valves. Power plants require valves that can operate consistently under high temperatures and pressures, with minimal need for maintenance to ensure uninterrupted power supply. Similarly, the chemical processing industry values gate valves that can resist corrosion and maintain their integrity in the presence of aggressive chemicals, reducing the frequency of maintenance and replacement.

Market research indicates that end-users are willing to invest in higher-quality, low-maintenance gate valves despite potentially higher initial costs, recognizing the long-term benefits of reduced maintenance expenses and improved operational reliability. This trend is supported by the growing emphasis on total cost of ownership (TCO) in procurement decisions, where the lifecycle costs of equipment, including maintenance, are given greater consideration.

The demand for low-maintenance gate valves is also influenced by regulatory pressures and industry standards that emphasize safety and environmental protection. Stricter regulations on emissions and leakage prevention are driving the adoption of more reliable valve technologies that require less frequent maintenance and reduce the risk of fugitive emissions.

Emerging technologies such as smart valves and predictive maintenance systems are further shaping market demand. End-users are increasingly interested in gate valves equipped with sensors and diagnostic capabilities that can predict maintenance needs and optimize performance, aligning with the broader trend towards digitalization and Industry 4.0 practices.

As industries continue to focus on operational excellence and cost reduction, the market for low-maintenance gate valves is expected to grow. Manufacturers that can deliver innovative designs addressing the specific challenges of minimal maintenance while ensuring long-term reliability and performance are likely to gain a competitive edge in this evolving market landscape.

Current Challenges in Gate Valve Maintenance

Gate valves are critical components in various industrial applications, but they face several maintenance challenges that impact their performance and longevity. One of the primary issues is wear and tear on sealing surfaces. Over time, the repeated opening and closing of the gate can lead to erosion and damage to the sealing faces, resulting in leakage and reduced efficiency. This problem is particularly acute in high-pressure or high-temperature environments, where the stress on the valve components is intensified.

Corrosion is another significant challenge in gate valve maintenance. Depending on the operating environment and the materials used in valve construction, corrosion can severely compromise the integrity of valve components. This not only affects the valve's performance but also increases the frequency of maintenance interventions and replacement needs. Corrosion-resistant materials and coatings have been developed, but their application often involves trade-offs in terms of cost and mechanical properties.

Stem packing deterioration is a persistent issue that leads to leakage around the valve stem. The packing material, typically made of compressed graphite or PTFE, can degrade over time due to pressure, temperature fluctuations, and chemical exposure. This degradation can result in stem leakage, which not only poses safety risks but also reduces the valve's operational efficiency. Regular repacking is often required, which increases maintenance downtime and costs.

Lubrication management presents another challenge in gate valve maintenance. Proper lubrication is essential for smooth operation and prevention of wear, especially in the stem and gate assembly. However, maintaining optimal lubrication can be difficult, particularly in valves that are infrequently operated or exposed to extreme temperatures. Over-lubrication can lead to contamination of the process fluid, while under-lubrication can cause increased friction and accelerated wear.

Debris accumulation within the valve body is a common problem that affects valve performance and increases maintenance requirements. Particulate matter from the process fluid can settle in the valve cavity, interfering with the gate's movement and potentially causing scoring of the sealing surfaces. This issue is particularly prevalent in applications involving slurries or fluids with high solid content. Regular flushing and cleaning procedures are often necessary, adding to the maintenance burden.

The complexity of gate valve designs can also pose challenges for maintenance. Many gate valves have numerous components, making disassembly, inspection, and reassembly time-consuming and labor-intensive. This complexity not only increases the duration of maintenance activities but also raises the risk of errors during reassembly, potentially leading to performance issues or premature failure.

Corrosion is another significant challenge in gate valve maintenance. Depending on the operating environment and the materials used in valve construction, corrosion can severely compromise the integrity of valve components. This not only affects the valve's performance but also increases the frequency of maintenance interventions and replacement needs. Corrosion-resistant materials and coatings have been developed, but their application often involves trade-offs in terms of cost and mechanical properties.

Stem packing deterioration is a persistent issue that leads to leakage around the valve stem. The packing material, typically made of compressed graphite or PTFE, can degrade over time due to pressure, temperature fluctuations, and chemical exposure. This degradation can result in stem leakage, which not only poses safety risks but also reduces the valve's operational efficiency. Regular repacking is often required, which increases maintenance downtime and costs.

Lubrication management presents another challenge in gate valve maintenance. Proper lubrication is essential for smooth operation and prevention of wear, especially in the stem and gate assembly. However, maintaining optimal lubrication can be difficult, particularly in valves that are infrequently operated or exposed to extreme temperatures. Over-lubrication can lead to contamination of the process fluid, while under-lubrication can cause increased friction and accelerated wear.

Debris accumulation within the valve body is a common problem that affects valve performance and increases maintenance requirements. Particulate matter from the process fluid can settle in the valve cavity, interfering with the gate's movement and potentially causing scoring of the sealing surfaces. This issue is particularly prevalent in applications involving slurries or fluids with high solid content. Regular flushing and cleaning procedures are often necessary, adding to the maintenance burden.

The complexity of gate valve designs can also pose challenges for maintenance. Many gate valves have numerous components, making disassembly, inspection, and reassembly time-consuming and labor-intensive. This complexity not only increases the duration of maintenance activities but also raises the risk of errors during reassembly, potentially leading to performance issues or premature failure.

Existing Low-Maintenance Gate Valve Solutions

01 Regular inspection and cleaning

Gate valves require periodic inspection and cleaning to maintain optimal performance. This includes checking for wear, corrosion, and debris accumulation. Regular cleaning helps prevent blockages and ensures smooth operation of the valve components.- Regular inspection and cleaning: Gate valves require periodic inspection and cleaning to maintain optimal performance. This includes checking for wear, corrosion, and debris accumulation. Regular cleaning helps prevent blockages and ensures smooth operation of the valve components.

- Lubrication of moving parts: Proper lubrication of gate valve components is essential for smooth operation and longevity. This involves applying suitable lubricants to moving parts such as stems, gates, and seals to reduce friction and prevent wear.

- Seal replacement and repair: Gate valve seals may deteriorate over time, leading to leaks. Regular inspection and timely replacement or repair of damaged seals is crucial for maintaining valve integrity and preventing fluid loss.

- Corrosion prevention and treatment: Gate valves exposed to corrosive environments require special attention. This includes applying protective coatings, using corrosion-resistant materials, and implementing cathodic protection systems to prevent or mitigate corrosion damage.

- Automation and monitoring systems: Implementation of automated monitoring and control systems can enhance gate valve maintenance. These systems can provide real-time data on valve performance, predict maintenance needs, and facilitate remote operation and diagnostics.

02 Lubrication of moving parts

Proper lubrication of gate valve components is essential for smooth operation and longevity. This involves applying suitable lubricants to moving parts such as stems, gates, and seals to reduce friction and prevent wear.Expand Specific Solutions03 Seal replacement and repair

Gate valve seals may deteriorate over time, leading to leaks. Regular inspection and timely replacement of worn or damaged seals is crucial for maintaining valve integrity and preventing fluid loss.Expand Specific Solutions04 Corrosion prevention and treatment

Gate valves exposed to corrosive environments require special attention. This includes applying protective coatings, using corrosion-resistant materials, and implementing cathodic protection systems to prevent or mitigate corrosion damage.Expand Specific Solutions05 Automation and monitoring systems

Implementation of automated monitoring and control systems can enhance gate valve maintenance. These systems can provide real-time data on valve performance, predict maintenance needs, and allow for remote operation and diagnostics.Expand Specific Solutions

Key Players in Valve Manufacturing Industry

The gate valve design improvement market is in a mature phase, with established players focusing on incremental innovations to enhance efficiency and reduce maintenance needs. The global industrial valve market, which includes gate valves, is projected to reach $85 billion by 2025. Technologically, companies like KSB SE & Co. KGaA and BELIMO Holding AG are leading advancements in valve automation and smart control systems. Safoco, Inc. and L.B. Bentley Ltd. specialize in high-performance valves for specific industries, while larger conglomerates such as Kohler Co. and Panasonic Holdings Corp. integrate valve technologies into broader product lines. The competitive landscape is characterized by a mix of specialized valve manufacturers and diversified industrial giants, with innovation efforts centered on materials science, IoT integration, and predictive maintenance capabilities.

KSB SE & Co. KGaA

Technical Solution: KSB has developed innovative gate valve designs focusing on minimal maintenance needs. Their ECOLINE GT 150-600 series incorporates a flexible wedge design that ensures tight sealing and reduces wear [1]. The valve body features optimized flow paths to minimize turbulence and erosion. KSB's proprietary coating technology, such as NORI®COAT, enhances corrosion and wear resistance, extending the valve's service life [2]. Additionally, KSB has implemented a modular design approach, allowing for easy replacement of wear parts without removing the entire valve from the pipeline [3].

Strengths: Advanced sealing technology, corrosion-resistant coatings, and modular design for easy maintenance. Weaknesses: Potentially higher initial cost compared to traditional designs.

Kohler Co.

Technical Solution: Kohler has developed innovative gate valve designs for residential and commercial plumbing applications with a focus on longevity and minimal maintenance. Their valves feature a ceramic disc technology that provides superior wear resistance compared to traditional rubber seals [6]. Kohler has also implemented a self-cleaning design that helps prevent mineral buildup and reduces the need for periodic cleaning. The company's gate valves incorporate a low-torque operation mechanism that minimizes wear on internal components and ensures smooth operation over time [7]. Additionally, Kohler has developed a corrosion-resistant alloy for valve bodies that significantly extends the product's lifespan in harsh water conditions.

Strengths: Ceramic disc technology, self-cleaning design, and corrosion-resistant materials. Weaknesses: Primarily focused on plumbing applications, may have limited suitability for industrial processes.

Innovative Materials and Coatings for Valve Longevity

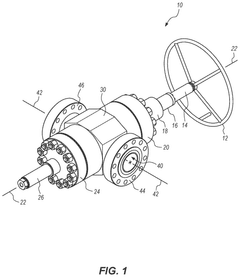

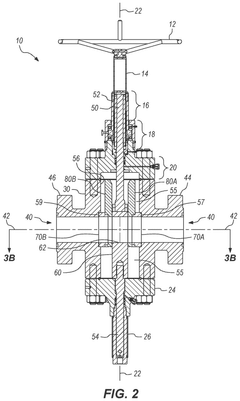

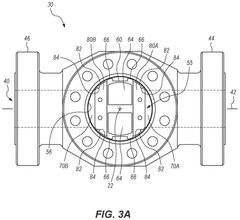

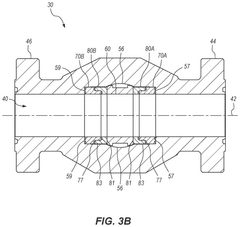

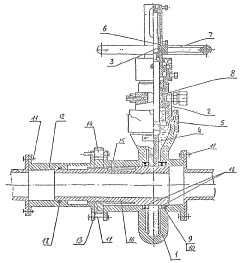

Extended seat for a gate valve

PatentPendingUS20250257807A1

Innovation

- A gate valve design featuring interchangeable first and second seats with flat sides and body bushings, allowing for a smooth transition between open and closed positions, and utilizing seal rings and elastomeric cords to maintain a tight seal without requiring grease, ensuring fluid isolation and reducing maintenance needs.

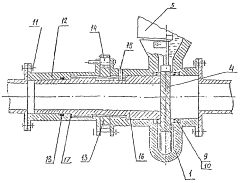

Valve provided with a safety device

PatentWO2008080197A2

Innovation

- The valve design incorporates an elongated housing flange with an adapter and a rod that moves via a screw and gear mechanism, allowing the working elements to be isolated from the medium's pressure, enabling maintenance without shutting off the flow by using sealing elements and a special protrusion to guide the rod's movement.

Environmental Impact of Valve Maintenance Reduction

The reduction of maintenance needs for gate valves has significant environmental implications. By minimizing the frequency and extent of maintenance activities, the environmental footprint associated with valve upkeep can be substantially reduced. This impact is multifaceted, encompassing various aspects of environmental conservation and sustainability.

One of the primary environmental benefits of reduced valve maintenance is the decrease in resource consumption. Traditional maintenance practices often require the replacement of parts, lubricants, and other materials. By extending the operational life of valve components through improved design, the demand for raw materials and manufactured replacement parts is diminished. This reduction in material consumption translates to lower energy requirements for production and transportation, thereby decreasing associated carbon emissions.

Furthermore, minimizing maintenance needs leads to a reduction in waste generation. Fewer replaced parts and less frequent maintenance interventions result in a decreased volume of discarded materials, including metal components, seals, and packaging. This reduction in waste contributes to the alleviation of landfill pressures and the conservation of valuable resources.

The environmental impact extends to the realm of chemical usage as well. Many maintenance procedures involve the application of lubricants, solvents, and cleaning agents. By reducing the frequency of these activities, the release of potentially harmful chemicals into the environment is curtailed. This not only minimizes soil and water contamination risks but also reduces the exposure of maintenance personnel to hazardous substances.

Energy conservation is another significant aspect of the environmental impact. Maintenance operations often require the shutdown of systems, leading to energy-intensive restart procedures. By reducing the frequency of these shutdowns, energy consumption is optimized, contributing to overall energy efficiency and reduced greenhouse gas emissions.

The transportation sector also benefits from reduced maintenance needs. Fewer maintenance interventions translate to decreased vehicle movements for service personnel and equipment, leading to lower fuel consumption and reduced emissions from transportation activities.

Moreover, the improved reliability resulting from enhanced valve designs contributes to the overall efficiency of industrial processes. This increased efficiency can lead to optimized resource utilization and reduced waste generation across entire systems, amplifying the environmental benefits beyond the immediate scope of valve maintenance.

In conclusion, the environmental impact of reducing valve maintenance needs is far-reaching, encompassing resource conservation, waste reduction, chemical usage minimization, energy efficiency, and broader systemic improvements. These benefits align with global sustainability goals and contribute to the overall reduction of industrial environmental footprints.

One of the primary environmental benefits of reduced valve maintenance is the decrease in resource consumption. Traditional maintenance practices often require the replacement of parts, lubricants, and other materials. By extending the operational life of valve components through improved design, the demand for raw materials and manufactured replacement parts is diminished. This reduction in material consumption translates to lower energy requirements for production and transportation, thereby decreasing associated carbon emissions.

Furthermore, minimizing maintenance needs leads to a reduction in waste generation. Fewer replaced parts and less frequent maintenance interventions result in a decreased volume of discarded materials, including metal components, seals, and packaging. This reduction in waste contributes to the alleviation of landfill pressures and the conservation of valuable resources.

The environmental impact extends to the realm of chemical usage as well. Many maintenance procedures involve the application of lubricants, solvents, and cleaning agents. By reducing the frequency of these activities, the release of potentially harmful chemicals into the environment is curtailed. This not only minimizes soil and water contamination risks but also reduces the exposure of maintenance personnel to hazardous substances.

Energy conservation is another significant aspect of the environmental impact. Maintenance operations often require the shutdown of systems, leading to energy-intensive restart procedures. By reducing the frequency of these shutdowns, energy consumption is optimized, contributing to overall energy efficiency and reduced greenhouse gas emissions.

The transportation sector also benefits from reduced maintenance needs. Fewer maintenance interventions translate to decreased vehicle movements for service personnel and equipment, leading to lower fuel consumption and reduced emissions from transportation activities.

Moreover, the improved reliability resulting from enhanced valve designs contributes to the overall efficiency of industrial processes. This increased efficiency can lead to optimized resource utilization and reduced waste generation across entire systems, amplifying the environmental benefits beyond the immediate scope of valve maintenance.

In conclusion, the environmental impact of reducing valve maintenance needs is far-reaching, encompassing resource conservation, waste reduction, chemical usage minimization, energy efficiency, and broader systemic improvements. These benefits align with global sustainability goals and contribute to the overall reduction of industrial environmental footprints.

Cost-Benefit Analysis of Low-Maintenance Gate Valves

The cost-benefit analysis of low-maintenance gate valves reveals significant advantages for industrial applications. Initial investment in these advanced valves may be higher, but the long-term savings in maintenance costs and operational efficiency justify the expenditure. Low-maintenance gate valves typically feature improved sealing mechanisms, corrosion-resistant materials, and enhanced actuation systems, all contributing to extended service life and reduced downtime.

One of the primary benefits is the reduction in labor costs associated with routine maintenance. Traditional gate valves often require frequent inspections, lubrication, and parts replacement. In contrast, low-maintenance variants can operate for extended periods without intervention, significantly reducing the man-hours dedicated to valve upkeep. This reduction in maintenance frequency also minimizes the risk of human error during servicing, which can lead to costly failures or safety incidents.

The improved reliability of low-maintenance gate valves translates to increased process uptime. In industries where continuous operation is critical, such as oil and gas, power generation, or chemical processing, even short periods of downtime can result in substantial financial losses. By reducing the likelihood of unexpected failures and the need for planned maintenance shutdowns, these valves contribute to improved overall plant efficiency and productivity.

Environmental benefits also factor into the cost-benefit equation. Low-maintenance gate valves often incorporate advanced sealing technologies that minimize leakage, reducing product loss and environmental impact. This not only saves on material costs but also helps companies avoid potential fines and cleanup expenses associated with leaks or spills.

From a lifecycle cost perspective, low-maintenance gate valves offer superior value. While the initial purchase price may be 20-30% higher than standard models, the total cost of ownership over the valve's lifespan is often significantly lower. This is due to reduced maintenance expenses, fewer replacement parts, and less frequent valve replacements. Studies have shown that maintenance costs can account for up to 70% of a valve's total lifecycle cost, making the low-maintenance option increasingly attractive.

The adoption of low-maintenance gate valves also aligns with the broader industry trend towards predictive maintenance and Industry 4.0 principles. Many of these valves can be equipped with sensors and monitoring systems, enabling real-time performance tracking and predictive maintenance scheduling. This data-driven approach further optimizes maintenance activities, reducing costs and improving asset management strategies.

In conclusion, the cost-benefit analysis strongly favors the implementation of low-maintenance gate valves in most industrial settings. The combination of reduced operational costs, improved reliability, and environmental benefits presents a compelling case for their adoption, particularly in critical applications where valve performance directly impacts overall system efficiency and profitability.

One of the primary benefits is the reduction in labor costs associated with routine maintenance. Traditional gate valves often require frequent inspections, lubrication, and parts replacement. In contrast, low-maintenance variants can operate for extended periods without intervention, significantly reducing the man-hours dedicated to valve upkeep. This reduction in maintenance frequency also minimizes the risk of human error during servicing, which can lead to costly failures or safety incidents.

The improved reliability of low-maintenance gate valves translates to increased process uptime. In industries where continuous operation is critical, such as oil and gas, power generation, or chemical processing, even short periods of downtime can result in substantial financial losses. By reducing the likelihood of unexpected failures and the need for planned maintenance shutdowns, these valves contribute to improved overall plant efficiency and productivity.

Environmental benefits also factor into the cost-benefit equation. Low-maintenance gate valves often incorporate advanced sealing technologies that minimize leakage, reducing product loss and environmental impact. This not only saves on material costs but also helps companies avoid potential fines and cleanup expenses associated with leaks or spills.

From a lifecycle cost perspective, low-maintenance gate valves offer superior value. While the initial purchase price may be 20-30% higher than standard models, the total cost of ownership over the valve's lifespan is often significantly lower. This is due to reduced maintenance expenses, fewer replacement parts, and less frequent valve replacements. Studies have shown that maintenance costs can account for up to 70% of a valve's total lifecycle cost, making the low-maintenance option increasingly attractive.

The adoption of low-maintenance gate valves also aligns with the broader industry trend towards predictive maintenance and Industry 4.0 principles. Many of these valves can be equipped with sensors and monitoring systems, enabling real-time performance tracking and predictive maintenance scheduling. This data-driven approach further optimizes maintenance activities, reducing costs and improving asset management strategies.

In conclusion, the cost-benefit analysis strongly favors the implementation of low-maintenance gate valves in most industrial settings. The combination of reduced operational costs, improved reliability, and environmental benefits presents a compelling case for their adoption, particularly in critical applications where valve performance directly impacts overall system efficiency and profitability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!