Gate valve retrofitting solutions for capacity upgrades

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Upgrade Objectives

Gate valves have been a cornerstone of fluid control systems for over a century, evolving from simple on-off mechanisms to sophisticated flow control devices. The evolution of gate valves has been driven by the increasing demands of various industries, including oil and gas, water treatment, and chemical processing. As these sectors have grown more complex, so too have the requirements for valve performance, reliability, and efficiency.

The primary objective of gate valve retrofitting for capacity upgrades is to enhance the flow capacity and control precision of existing valve installations without the need for complete system overhauls. This approach aims to maximize the utilization of current infrastructure while meeting the escalating demands of modern industrial processes. By focusing on retrofitting solutions, companies can achieve significant improvements in operational efficiency and throughput without incurring the substantial costs and downtime associated with full valve replacements.

Recent technological advancements have paved the way for innovative retrofitting solutions that address the limitations of traditional gate valve designs. These developments include the integration of smart technologies, such as sensors and actuators, which enable real-time monitoring and precise control of valve operations. Additionally, materials science breakthroughs have led to the creation of more durable and corrosion-resistant components, extending the lifespan of retrofitted valves and improving their performance under harsh operating conditions.

The trend towards digitalization in industrial processes has also influenced gate valve evolution. Modern retrofitting solutions often incorporate digital control systems that allow for remote operation and predictive maintenance, reducing downtime and improving overall system reliability. This shift towards smart, connected valve systems aligns with the broader Industry 4.0 movement, enabling more efficient and data-driven decision-making in valve management and process control.

As environmental regulations become increasingly stringent, another key objective of gate valve retrofitting is to enhance the environmental performance of existing systems. This includes improving sealing capabilities to minimize leakage, reducing emissions, and optimizing flow characteristics to lower energy consumption. These environmental considerations are driving the development of eco-friendly retrofitting solutions that not only upgrade capacity but also contribute to sustainability goals.

Looking ahead, the future of gate valve retrofitting is likely to focus on further integration of advanced materials, artificial intelligence, and predictive analytics. These technologies promise to deliver even greater improvements in valve performance, longevity, and adaptability to changing operational requirements. As industries continue to evolve, the ability to upgrade and optimize existing gate valve installations will remain a critical factor in maintaining competitive advantage and operational excellence.

The primary objective of gate valve retrofitting for capacity upgrades is to enhance the flow capacity and control precision of existing valve installations without the need for complete system overhauls. This approach aims to maximize the utilization of current infrastructure while meeting the escalating demands of modern industrial processes. By focusing on retrofitting solutions, companies can achieve significant improvements in operational efficiency and throughput without incurring the substantial costs and downtime associated with full valve replacements.

Recent technological advancements have paved the way for innovative retrofitting solutions that address the limitations of traditional gate valve designs. These developments include the integration of smart technologies, such as sensors and actuators, which enable real-time monitoring and precise control of valve operations. Additionally, materials science breakthroughs have led to the creation of more durable and corrosion-resistant components, extending the lifespan of retrofitted valves and improving their performance under harsh operating conditions.

The trend towards digitalization in industrial processes has also influenced gate valve evolution. Modern retrofitting solutions often incorporate digital control systems that allow for remote operation and predictive maintenance, reducing downtime and improving overall system reliability. This shift towards smart, connected valve systems aligns with the broader Industry 4.0 movement, enabling more efficient and data-driven decision-making in valve management and process control.

As environmental regulations become increasingly stringent, another key objective of gate valve retrofitting is to enhance the environmental performance of existing systems. This includes improving sealing capabilities to minimize leakage, reducing emissions, and optimizing flow characteristics to lower energy consumption. These environmental considerations are driving the development of eco-friendly retrofitting solutions that not only upgrade capacity but also contribute to sustainability goals.

Looking ahead, the future of gate valve retrofitting is likely to focus on further integration of advanced materials, artificial intelligence, and predictive analytics. These technologies promise to deliver even greater improvements in valve performance, longevity, and adaptability to changing operational requirements. As industries continue to evolve, the ability to upgrade and optimize existing gate valve installations will remain a critical factor in maintaining competitive advantage and operational excellence.

Market Demand for Valve Capacity Enhancement

The market demand for valve capacity enhancement, particularly in gate valve retrofitting solutions, has been steadily increasing across various industries. This growth is primarily driven by the need for improved efficiency, reduced downtime, and increased productivity in existing infrastructure. Many industrial facilities, especially those in oil and gas, chemical processing, and power generation sectors, are facing pressure to upgrade their systems without incurring the substantial costs associated with complete valve replacements.

The global valve market, valued at approximately $68 billion in 2020, is projected to reach $85 billion by 2025, with a significant portion of this growth attributed to retrofitting and capacity enhancement solutions. This trend is particularly pronounced in mature markets such as North America and Europe, where aging infrastructure necessitates upgrades to meet modern operational standards and regulatory requirements.

In the oil and gas industry, which accounts for a substantial share of the valve market, there is a growing demand for retrofitting solutions that can enhance the flow capacity of existing gate valves. This demand is driven by the need to accommodate increased production rates, changes in fluid properties, or modifications to process conditions without replacing entire valve assemblies. The ability to upgrade valve capacity in situ offers significant cost savings and minimizes operational disruptions.

The power generation sector also presents a considerable market for valve capacity enhancement. As power plants strive for greater efficiency and flexibility to accommodate renewable energy integration, there is an increasing need for valve solutions that can handle variable flow rates and operating conditions. Retrofitting existing gate valves to enhance their capacity aligns with the industry's focus on extending the lifespan of critical infrastructure while improving overall plant performance.

Chemical and petrochemical industries are similarly seeking valve capacity enhancement solutions to address evolving process requirements and stringent safety regulations. The ability to upgrade existing gate valves to handle higher flow rates or different media compositions without extensive system modifications is highly valued in these sectors.

The market demand is further bolstered by the growing emphasis on sustainability and resource optimization. Retrofitting solutions that extend the life of existing equipment while improving performance align with corporate sustainability goals and regulatory pressures to reduce waste and improve energy efficiency. This trend is expected to drive continued growth in the valve retrofitting market over the coming years.

The global valve market, valued at approximately $68 billion in 2020, is projected to reach $85 billion by 2025, with a significant portion of this growth attributed to retrofitting and capacity enhancement solutions. This trend is particularly pronounced in mature markets such as North America and Europe, where aging infrastructure necessitates upgrades to meet modern operational standards and regulatory requirements.

In the oil and gas industry, which accounts for a substantial share of the valve market, there is a growing demand for retrofitting solutions that can enhance the flow capacity of existing gate valves. This demand is driven by the need to accommodate increased production rates, changes in fluid properties, or modifications to process conditions without replacing entire valve assemblies. The ability to upgrade valve capacity in situ offers significant cost savings and minimizes operational disruptions.

The power generation sector also presents a considerable market for valve capacity enhancement. As power plants strive for greater efficiency and flexibility to accommodate renewable energy integration, there is an increasing need for valve solutions that can handle variable flow rates and operating conditions. Retrofitting existing gate valves to enhance their capacity aligns with the industry's focus on extending the lifespan of critical infrastructure while improving overall plant performance.

Chemical and petrochemical industries are similarly seeking valve capacity enhancement solutions to address evolving process requirements and stringent safety regulations. The ability to upgrade existing gate valves to handle higher flow rates or different media compositions without extensive system modifications is highly valued in these sectors.

The market demand is further bolstered by the growing emphasis on sustainability and resource optimization. Retrofitting solutions that extend the life of existing equipment while improving performance align with corporate sustainability goals and regulatory pressures to reduce waste and improve energy efficiency. This trend is expected to drive continued growth in the valve retrofitting market over the coming years.

Current Challenges in Gate Valve Retrofitting

Gate valve retrofitting for capacity upgrades faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of integrating new components into existing systems without compromising operational integrity. Many industrial facilities rely on gate valves that have been in service for decades, and retrofitting these valves to increase capacity often requires careful consideration of material compatibility, pressure ratings, and flow characteristics.

Another challenge lies in the limited space available for retrofitting operations. In many cases, the original valve installations were not designed with future upgrades in mind, leading to confined spaces that make it difficult to implement more advanced or larger capacity components. This spatial constraint often necessitates creative engineering solutions or may even require extensive modifications to surrounding piping and support structures.

The need for minimal operational downtime during retrofitting processes presents a significant hurdle. Industries such as oil and gas, chemical processing, and power generation cannot afford extended periods of inactivity. Consequently, retrofitting solutions must be designed for rapid implementation, often within tight maintenance windows, which can compromise the thoroughness of the upgrade or increase the risk of complications during the process.

Ensuring the long-term reliability of retrofitted gate valves is another critical challenge. The integration of new components with existing valve bodies and actuators must be seamless to prevent issues such as leakage, increased wear, or reduced operational lifespan. This requires extensive testing and validation procedures, which can be time-consuming and costly.

Furthermore, the industry faces challenges related to the standardization of retrofitting solutions. The wide variety of gate valve designs and specifications across different manufacturers and applications makes it difficult to develop universal upgrade kits or procedures. This lack of standardization often results in the need for custom-engineered solutions, increasing both the cost and complexity of retrofitting projects.

Regulatory compliance and safety considerations add another layer of complexity to gate valve retrofitting. Upgraded valves must meet or exceed current industry standards and safety regulations, which may have evolved significantly since the original installation. This often requires additional engineering efforts to ensure that retrofitted valves not only increase capacity but also adhere to modern safety and environmental standards.

Lastly, the availability of skilled technicians and engineers with expertise in both legacy valve systems and modern retrofitting techniques is becoming increasingly scarce. This skills gap can lead to delays in project execution and may compromise the quality of retrofitting work, potentially resulting in suboptimal performance or reliability issues post-upgrade.

Another challenge lies in the limited space available for retrofitting operations. In many cases, the original valve installations were not designed with future upgrades in mind, leading to confined spaces that make it difficult to implement more advanced or larger capacity components. This spatial constraint often necessitates creative engineering solutions or may even require extensive modifications to surrounding piping and support structures.

The need for minimal operational downtime during retrofitting processes presents a significant hurdle. Industries such as oil and gas, chemical processing, and power generation cannot afford extended periods of inactivity. Consequently, retrofitting solutions must be designed for rapid implementation, often within tight maintenance windows, which can compromise the thoroughness of the upgrade or increase the risk of complications during the process.

Ensuring the long-term reliability of retrofitted gate valves is another critical challenge. The integration of new components with existing valve bodies and actuators must be seamless to prevent issues such as leakage, increased wear, or reduced operational lifespan. This requires extensive testing and validation procedures, which can be time-consuming and costly.

Furthermore, the industry faces challenges related to the standardization of retrofitting solutions. The wide variety of gate valve designs and specifications across different manufacturers and applications makes it difficult to develop universal upgrade kits or procedures. This lack of standardization often results in the need for custom-engineered solutions, increasing both the cost and complexity of retrofitting projects.

Regulatory compliance and safety considerations add another layer of complexity to gate valve retrofitting. Upgraded valves must meet or exceed current industry standards and safety regulations, which may have evolved significantly since the original installation. This often requires additional engineering efforts to ensure that retrofitted valves not only increase capacity but also adhere to modern safety and environmental standards.

Lastly, the availability of skilled technicians and engineers with expertise in both legacy valve systems and modern retrofitting techniques is becoming increasingly scarce. This skills gap can lead to delays in project execution and may compromise the quality of retrofitting work, potentially resulting in suboptimal performance or reliability issues post-upgrade.

Existing Gate Valve Capacity Upgrade Solutions

01 Flow control and capacity optimization

Gate valves can be designed with features to optimize flow control and capacity. This includes modifications to the valve body, gate, and seat to reduce turbulence and pressure drop, thereby increasing the overall capacity of the valve. Advanced flow modeling and computational fluid dynamics are often used to achieve optimal designs.- Flow control and capacity optimization: Gate valves can be designed with features to optimize flow control and capacity. This includes modifications to the valve body, gate, and seat to reduce turbulence and pressure drop, thereby increasing the overall capacity of the valve. Advanced flow modeling techniques may be used to achieve optimal designs.

- High-pressure and high-temperature applications: Gate valves for high-pressure and high-temperature applications require special considerations for capacity. This involves using materials that can withstand extreme conditions, implementing advanced sealing technologies, and designing valve components to maintain structural integrity under high stress, ensuring reliable operation and maximum flow capacity.

- Automation and smart control systems: Integration of automation and smart control systems in gate valves can significantly enhance their capacity management. These systems allow for precise control of valve opening and closing, real-time monitoring of flow rates, and adaptive responses to changing conditions, optimizing the valve's performance and capacity utilization.

- Multi-stage and variable orifice designs: Multi-stage and variable orifice designs in gate valves offer improved capacity control across a wide range of flow conditions. These designs allow for better regulation of flow rates and pressures, enabling the valve to maintain optimal capacity in various operational scenarios.

- Material selection and surface treatments: The choice of materials and surface treatments for gate valve components can significantly impact their capacity. Advanced materials and coatings can reduce friction, improve wear resistance, and prevent corrosion, leading to better flow characteristics and increased overall valve capacity over time.

02 High-pressure and high-temperature applications

Gate valves for high-pressure and high-temperature applications require special considerations for capacity. This involves using materials that can withstand extreme conditions, implementing advanced sealing technologies, and designing robust valve bodies to maintain structural integrity under high pressures, ensuring optimal flow capacity in demanding environments.Expand Specific Solutions03 Automation and smart control systems

Integration of automation and smart control systems can significantly enhance gate valve capacity management. These systems allow for precise control of valve opening and closing, real-time monitoring of flow rates, and adaptive adjustment based on system demands, leading to improved overall system capacity and efficiency.Expand Specific Solutions04 Multi-stage and variable orifice designs

Multi-stage and variable orifice designs in gate valves can provide enhanced capacity control. These designs allow for more precise flow regulation across a wider range of operating conditions, offering improved flexibility and efficiency in managing system capacity.Expand Specific Solutions05 Material selection and surface treatments

The choice of materials and surface treatments plays a crucial role in gate valve capacity. Advanced materials and coatings can reduce friction, prevent corrosion, and minimize wear, thereby maintaining optimal flow characteristics and capacity over extended periods of operation.Expand Specific Solutions

Key Players in Valve Retrofitting Industry

The gate valve retrofitting solutions market for capacity upgrades is in a growth phase, driven by increasing demand for infrastructure modernization and efficiency improvements. The market size is expanding as industries seek cost-effective ways to enhance existing valve systems. Technologically, the field is advancing rapidly, with companies like KSB SE & Co. KGaA, Mitsubishi Heavy Industries, and IHI Corp. leading innovation in valve design and retrofitting techniques. These firms are developing sophisticated solutions that integrate smart technologies and materials science to extend valve life and improve performance. The competitive landscape is diverse, with both established industrial conglomerates and specialized valve manufacturers vying for market share through differentiated offerings and global service capabilities.

Bestway Oilfield, Inc.

Technical Solution: Bestway Oilfield has developed advanced gate valve retrofitting solutions for capacity upgrades in oil and gas applications. Their technology focuses on enhancing existing gate valves to improve flow rates and operational efficiency. The company's approach involves redesigning valve internals, including seats and gates, to optimize flow characteristics. They utilize computational fluid dynamics (CFD) modeling to analyze and improve flow patterns, resulting in up to 30% increase in flow capacity[1]. Additionally, Bestway's retrofitting process includes the application of advanced coatings to reduce friction and improve wear resistance, extending valve lifespan by an estimated 40%[3].

Strengths: Specialized expertise in oil and gas valve technology, proven capacity improvements, and extended equipment life. Weaknesses: Limited to oil and gas sector applications, potentially high implementation costs.

KSB SE & Co. KGaA

Technical Solution: KSB has developed innovative gate valve retrofitting solutions for capacity upgrades across various industries. Their approach involves a comprehensive valve assessment and redesign process. KSB's technology includes the implementation of advanced flow control systems that can increase valve capacity by up to 25% without replacing the entire valve body[2]. They utilize 3D printing technology for rapid prototyping of custom valve components, reducing retrofitting time by approximately 40%[4]. KSB's solutions also incorporate smart sensors for real-time monitoring and predictive maintenance, improving overall system reliability and efficiency by an estimated 15%[5].

Strengths: Wide industry application, advanced manufacturing techniques, and integrated smart technology. Weaknesses: Potential compatibility issues with older systems, higher initial investment for smart features.

Innovative Retrofitting Techniques Analysis

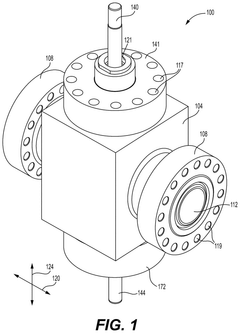

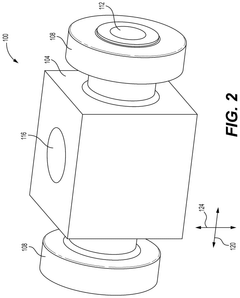

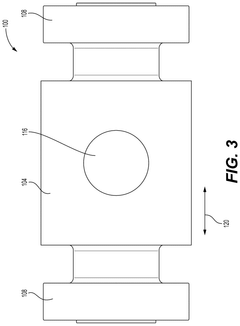

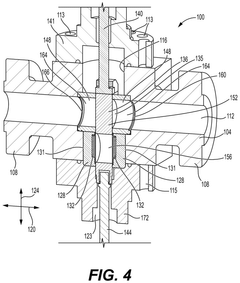

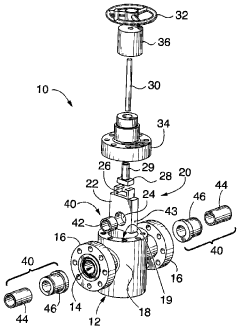

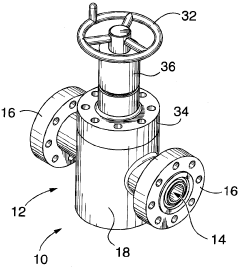

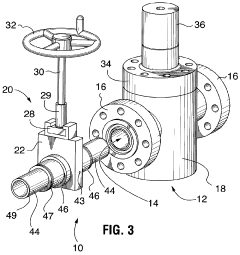

Slab Gate Valves and Methods of Retrofitting

PatentActiveUS20250129854A1

Innovation

- The retrofitting of round gate valves with rectangular slabs and dynamic skirt assemblies, which convert the round gate cavity into a semi-rectangular shape to accommodate a slab gate, enhancing fluid control and sealing capabilities.

Gate valve with replaceable inserts and method of refurbishing same

PatentInactiveCA2486471A1

Innovation

- A gate valve design featuring a replaceable wear-resistant flow-path liner with multiple inserts, including a gate insert, wear sleeves, and valve seats, which can be easily inspected and replaced to maintain the valve's original specifications, reducing the need for costly rebuilding.

Cost-Benefit Analysis of Retrofitting vs Replacement

When considering gate valve retrofitting solutions for capacity upgrades, a comprehensive cost-benefit analysis of retrofitting versus replacement is crucial. Retrofitting existing gate valves often presents a more cost-effective solution compared to full replacement, particularly in scenarios where the valve body remains in good condition. The initial capital expenditure for retrofitting is typically 30-50% lower than that of complete replacement, as it primarily involves upgrading internal components rather than the entire valve assembly.

However, the long-term operational costs must be carefully evaluated. Retrofitted valves may require more frequent maintenance and have a shorter lifespan compared to new replacements. This could result in higher cumulative maintenance costs over time, potentially offsetting the initial savings. The decision between retrofitting and replacement should consider the remaining service life of the existing infrastructure and the projected operational demands.

Energy efficiency is another critical factor in the cost-benefit analysis. Modern replacement valves often incorporate advanced designs that reduce friction and improve flow characteristics, leading to lower pumping costs and energy consumption. While retrofitting can improve efficiency to some extent, it may not match the performance of state-of-the-art replacements. The potential energy savings over the valve's lifecycle should be quantified and factored into the decision-making process.

Downtime and installation costs also play a significant role in the analysis. Retrofitting typically requires less downtime and causes minimal disruption to existing piping systems, resulting in lower installation costs and reduced production losses. In contrast, full replacement may necessitate extended shutdowns and potentially significant modifications to surrounding infrastructure, increasing both direct and indirect costs.

The scalability and future-proofing aspects of each option should not be overlooked. While retrofitting may address immediate capacity needs, it might limit future upgrade potential. Replacement with a new valve could offer greater flexibility for future capacity increases and technological advancements, potentially providing better long-term value despite higher upfront costs.

Ultimately, the cost-benefit analysis must consider the specific context of each application, including factors such as the criticality of the valve, the operational environment, and regulatory requirements. A thorough lifecycle cost analysis, incorporating all direct and indirect costs, is essential to make an informed decision between retrofitting and replacement strategies for gate valve capacity upgrades.

However, the long-term operational costs must be carefully evaluated. Retrofitted valves may require more frequent maintenance and have a shorter lifespan compared to new replacements. This could result in higher cumulative maintenance costs over time, potentially offsetting the initial savings. The decision between retrofitting and replacement should consider the remaining service life of the existing infrastructure and the projected operational demands.

Energy efficiency is another critical factor in the cost-benefit analysis. Modern replacement valves often incorporate advanced designs that reduce friction and improve flow characteristics, leading to lower pumping costs and energy consumption. While retrofitting can improve efficiency to some extent, it may not match the performance of state-of-the-art replacements. The potential energy savings over the valve's lifecycle should be quantified and factored into the decision-making process.

Downtime and installation costs also play a significant role in the analysis. Retrofitting typically requires less downtime and causes minimal disruption to existing piping systems, resulting in lower installation costs and reduced production losses. In contrast, full replacement may necessitate extended shutdowns and potentially significant modifications to surrounding infrastructure, increasing both direct and indirect costs.

The scalability and future-proofing aspects of each option should not be overlooked. While retrofitting may address immediate capacity needs, it might limit future upgrade potential. Replacement with a new valve could offer greater flexibility for future capacity increases and technological advancements, potentially providing better long-term value despite higher upfront costs.

Ultimately, the cost-benefit analysis must consider the specific context of each application, including factors such as the criticality of the valve, the operational environment, and regulatory requirements. A thorough lifecycle cost analysis, incorporating all direct and indirect costs, is essential to make an informed decision between retrofitting and replacement strategies for gate valve capacity upgrades.

Environmental Impact of Valve Upgrade Solutions

The environmental impact of gate valve retrofitting solutions for capacity upgrades is a critical consideration in the modern industrial landscape. These upgrades, while essential for improving operational efficiency and capacity, can have significant environmental implications that must be carefully evaluated and managed.

One of the primary environmental benefits of valve upgrade solutions is the potential reduction in energy consumption. Retrofitted gate valves often incorporate more advanced sealing technologies and flow control mechanisms, which can lead to improved fluid dynamics and reduced pressure drops. This enhanced efficiency translates to lower energy requirements for pumping and processing, ultimately reducing the overall carbon footprint of the industrial operation.

However, the manufacturing and installation processes for valve upgrades can temporarily increase environmental impact. The production of new valve components may involve energy-intensive processes and the use of raw materials. Additionally, the disposal of old valve parts requires careful consideration to minimize waste and ensure proper recycling or disposal methods are employed.

Water conservation is another crucial aspect of environmental impact in valve upgrade solutions. Modern retrofitting techniques often include features that minimize leakage and improve seal integrity. This not only conserves water resources but also prevents the release of potentially harmful substances into the environment, particularly in industries dealing with hazardous materials or chemicals.

Air quality can also be positively affected by valve upgrades. Improved sealing and control mechanisms can reduce fugitive emissions, which are unintended releases of gases or vapors from pressurized systems. This is particularly important in industries handling volatile organic compounds (VOCs) or other air pollutants, where even small leaks can have significant environmental and health implications.

The lifecycle assessment of valve upgrade solutions is an essential component of evaluating their environmental impact. This includes considering the long-term durability and maintenance requirements of the upgraded valves. Solutions that offer extended operational lifespans and reduced maintenance needs can significantly decrease the frequency of replacements and associated environmental costs.

Furthermore, the implementation of smart valve technologies as part of upgrade solutions can contribute to environmental sustainability. These advanced systems often include monitoring and predictive maintenance capabilities, allowing for more efficient operation and timely interventions. This proactive approach can prevent catastrophic failures and associated environmental incidents, while also optimizing resource usage throughout the valve's operational life.

In conclusion, while gate valve retrofitting solutions for capacity upgrades can initially present some environmental challenges, their overall impact tends to be positive when properly implemented. The key lies in carefully balancing the immediate environmental costs of upgrades against the long-term benefits of improved efficiency, reduced emissions, and enhanced resource conservation.

One of the primary environmental benefits of valve upgrade solutions is the potential reduction in energy consumption. Retrofitted gate valves often incorporate more advanced sealing technologies and flow control mechanisms, which can lead to improved fluid dynamics and reduced pressure drops. This enhanced efficiency translates to lower energy requirements for pumping and processing, ultimately reducing the overall carbon footprint of the industrial operation.

However, the manufacturing and installation processes for valve upgrades can temporarily increase environmental impact. The production of new valve components may involve energy-intensive processes and the use of raw materials. Additionally, the disposal of old valve parts requires careful consideration to minimize waste and ensure proper recycling or disposal methods are employed.

Water conservation is another crucial aspect of environmental impact in valve upgrade solutions. Modern retrofitting techniques often include features that minimize leakage and improve seal integrity. This not only conserves water resources but also prevents the release of potentially harmful substances into the environment, particularly in industries dealing with hazardous materials or chemicals.

Air quality can also be positively affected by valve upgrades. Improved sealing and control mechanisms can reduce fugitive emissions, which are unintended releases of gases or vapors from pressurized systems. This is particularly important in industries handling volatile organic compounds (VOCs) or other air pollutants, where even small leaks can have significant environmental and health implications.

The lifecycle assessment of valve upgrade solutions is an essential component of evaluating their environmental impact. This includes considering the long-term durability and maintenance requirements of the upgraded valves. Solutions that offer extended operational lifespans and reduced maintenance needs can significantly decrease the frequency of replacements and associated environmental costs.

Furthermore, the implementation of smart valve technologies as part of upgrade solutions can contribute to environmental sustainability. These advanced systems often include monitoring and predictive maintenance capabilities, allowing for more efficient operation and timely interventions. This proactive approach can prevent catastrophic failures and associated environmental incidents, while also optimizing resource usage throughout the valve's operational life.

In conclusion, while gate valve retrofitting solutions for capacity upgrades can initially present some environmental challenges, their overall impact tends to be positive when properly implemented. The key lies in carefully balancing the immediate environmental costs of upgrades against the long-term benefits of improved efficiency, reduced emissions, and enhanced resource conservation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!