Development of hybrid systems for multi-functional gate valve operations

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Valve Systems: Background and Objectives

Hybrid valve systems have emerged as a revolutionary technology in the field of fluid control, combining the advantages of traditional mechanical valves with advanced electronic control systems. The development of these systems for multi-functional gate valve operations represents a significant leap forward in valve technology, addressing the growing demands for more efficient, precise, and versatile fluid control solutions across various industries.

The evolution of valve technology has been driven by the need for improved performance, reliability, and adaptability in increasingly complex industrial processes. Traditional gate valves, while effective for basic on-off control, have limitations in terms of precision, speed, and multi-functionality. The concept of hybrid systems aims to overcome these limitations by integrating electronic sensors, actuators, and control algorithms with mechanical valve components.

The primary objective of developing hybrid systems for multi-functional gate valve operations is to create a new generation of valves that can perform multiple tasks simultaneously, adapt to changing process conditions, and provide real-time feedback and control. This technology seeks to enhance operational efficiency, reduce maintenance requirements, and improve overall system performance in applications ranging from oil and gas production to water treatment and chemical processing.

One of the key drivers behind this technological advancement is the increasing complexity of industrial processes, which require more sophisticated fluid control solutions. Hybrid valve systems aim to meet these demands by offering features such as variable flow control, pressure regulation, and intelligent diagnostics within a single valve assembly. This integration of multiple functions not only simplifies system design but also reduces the overall footprint and cost of fluid control systems.

The development of hybrid systems for multi-functional gate valve operations also aligns with the broader trend of industrial digitalization and the Internet of Things (IoT). By incorporating smart sensors and communication capabilities, these valves can become integral components of connected industrial ecosystems, enabling remote monitoring, predictive maintenance, and data-driven optimization of processes.

Furthermore, the push towards more sustainable and energy-efficient industrial operations has influenced the development of hybrid valve systems. These advanced valves have the potential to significantly reduce energy consumption and fluid waste by providing more precise control and eliminating the need for multiple separate valve units.

As we delve deeper into the background of hybrid valve systems, it is important to recognize the interdisciplinary nature of this technology. The development of these systems requires expertise in mechanical engineering, electronics, control systems, and materials science. This convergence of disciplines presents both challenges and opportunities for innovation, driving researchers and engineers to explore novel approaches to valve design and operation.

The evolution of valve technology has been driven by the need for improved performance, reliability, and adaptability in increasingly complex industrial processes. Traditional gate valves, while effective for basic on-off control, have limitations in terms of precision, speed, and multi-functionality. The concept of hybrid systems aims to overcome these limitations by integrating electronic sensors, actuators, and control algorithms with mechanical valve components.

The primary objective of developing hybrid systems for multi-functional gate valve operations is to create a new generation of valves that can perform multiple tasks simultaneously, adapt to changing process conditions, and provide real-time feedback and control. This technology seeks to enhance operational efficiency, reduce maintenance requirements, and improve overall system performance in applications ranging from oil and gas production to water treatment and chemical processing.

One of the key drivers behind this technological advancement is the increasing complexity of industrial processes, which require more sophisticated fluid control solutions. Hybrid valve systems aim to meet these demands by offering features such as variable flow control, pressure regulation, and intelligent diagnostics within a single valve assembly. This integration of multiple functions not only simplifies system design but also reduces the overall footprint and cost of fluid control systems.

The development of hybrid systems for multi-functional gate valve operations also aligns with the broader trend of industrial digitalization and the Internet of Things (IoT). By incorporating smart sensors and communication capabilities, these valves can become integral components of connected industrial ecosystems, enabling remote monitoring, predictive maintenance, and data-driven optimization of processes.

Furthermore, the push towards more sustainable and energy-efficient industrial operations has influenced the development of hybrid valve systems. These advanced valves have the potential to significantly reduce energy consumption and fluid waste by providing more precise control and eliminating the need for multiple separate valve units.

As we delve deeper into the background of hybrid valve systems, it is important to recognize the interdisciplinary nature of this technology. The development of these systems requires expertise in mechanical engineering, electronics, control systems, and materials science. This convergence of disciplines presents both challenges and opportunities for innovation, driving researchers and engineers to explore novel approaches to valve design and operation.

Market Analysis for Multi-Functional Gate Valves

The market for multi-functional gate valves has experienced significant growth in recent years, driven by increasing demand for efficient and versatile flow control solutions across various industries. These advanced valves, which combine multiple functionalities in a single unit, have gained traction due to their ability to streamline operations, reduce maintenance costs, and improve overall system performance.

In the oil and gas sector, multi-functional gate valves have become particularly popular for their ability to handle high-pressure and high-temperature applications while providing precise flow control. The offshore drilling segment has shown strong adoption rates, as these valves offer enhanced safety features and reduced downtime during critical operations. Similarly, the petrochemical industry has embraced multi-functional gate valves for their corrosion resistance and ability to handle diverse fluid compositions.

The power generation sector, especially in thermal and nuclear power plants, has also contributed to market growth. Multi-functional gate valves play a crucial role in managing steam flow and ensuring plant efficiency. As countries worldwide invest in upgrading their energy infrastructure, the demand for these advanced valves is expected to rise further.

Water and wastewater treatment facilities represent another significant market segment for multi-functional gate valves. The need for precise control over water distribution and treatment processes has led to increased adoption of these valves in municipal and industrial applications. Their ability to integrate multiple functions, such as flow regulation, isolation, and backflow prevention, makes them particularly attractive for complex water management systems.

Geographically, North America and Europe have been leading markets for multi-functional gate valves, primarily due to their well-established industrial sectors and stringent regulatory standards. However, the Asia-Pacific region is emerging as a key growth area, driven by rapid industrialization, infrastructure development, and increasing investments in oil and gas exploration activities.

The market landscape is characterized by a mix of established players and innovative startups. Major valve manufacturers have been expanding their product portfolios to include multi-functional gate valves, while specialized companies are focusing on developing cutting-edge solutions tailored to specific industry needs. This competitive environment has led to continuous product improvements and technological advancements in areas such as materials science, automation, and smart valve technologies.

Looking ahead, the market for multi-functional gate valves is poised for continued growth. Factors such as increasing focus on energy efficiency, growing demand for process automation, and the need for reliable flow control solutions in harsh environments are expected to drive market expansion. Additionally, the integration of IoT and AI technologies in valve systems presents new opportunities for predictive maintenance and remote monitoring, further enhancing the appeal of multi-functional gate valves across various industries.

In the oil and gas sector, multi-functional gate valves have become particularly popular for their ability to handle high-pressure and high-temperature applications while providing precise flow control. The offshore drilling segment has shown strong adoption rates, as these valves offer enhanced safety features and reduced downtime during critical operations. Similarly, the petrochemical industry has embraced multi-functional gate valves for their corrosion resistance and ability to handle diverse fluid compositions.

The power generation sector, especially in thermal and nuclear power plants, has also contributed to market growth. Multi-functional gate valves play a crucial role in managing steam flow and ensuring plant efficiency. As countries worldwide invest in upgrading their energy infrastructure, the demand for these advanced valves is expected to rise further.

Water and wastewater treatment facilities represent another significant market segment for multi-functional gate valves. The need for precise control over water distribution and treatment processes has led to increased adoption of these valves in municipal and industrial applications. Their ability to integrate multiple functions, such as flow regulation, isolation, and backflow prevention, makes them particularly attractive for complex water management systems.

Geographically, North America and Europe have been leading markets for multi-functional gate valves, primarily due to their well-established industrial sectors and stringent regulatory standards. However, the Asia-Pacific region is emerging as a key growth area, driven by rapid industrialization, infrastructure development, and increasing investments in oil and gas exploration activities.

The market landscape is characterized by a mix of established players and innovative startups. Major valve manufacturers have been expanding their product portfolios to include multi-functional gate valves, while specialized companies are focusing on developing cutting-edge solutions tailored to specific industry needs. This competitive environment has led to continuous product improvements and technological advancements in areas such as materials science, automation, and smart valve technologies.

Looking ahead, the market for multi-functional gate valves is poised for continued growth. Factors such as increasing focus on energy efficiency, growing demand for process automation, and the need for reliable flow control solutions in harsh environments are expected to drive market expansion. Additionally, the integration of IoT and AI technologies in valve systems presents new opportunities for predictive maintenance and remote monitoring, further enhancing the appeal of multi-functional gate valves across various industries.

Technical Challenges in Hybrid Valve Development

The development of hybrid systems for multi-functional gate valve operations presents several significant technical challenges. One of the primary obstacles is the integration of diverse control mechanisms within a single valve system. This integration requires sophisticated engineering to ensure seamless operation between mechanical, electrical, and potentially hydraulic components. The complexity increases when designing systems capable of handling various fluid types, pressures, and flow rates.

Material selection poses another critical challenge. Hybrid valve systems must withstand a wide range of operational conditions, including extreme temperatures, corrosive environments, and high-pressure differentials. Engineers must carefully balance durability, weight, and cost-effectiveness when choosing materials for valve components. Advanced composites and alloys are often necessary, but their implementation can introduce manufacturing complexities and increase production costs.

Sealing technology remains a persistent challenge in hybrid valve development. The need for reliable seals that can maintain integrity across multiple operational modes and diverse environmental conditions is paramount. Innovations in seal materials and designs are required to prevent leakage and ensure long-term performance, particularly in applications where even minor leaks can have significant consequences.

The miniaturization of control systems presents another hurdle. As industries demand more compact and efficient valve solutions, engineers must develop ways to incorporate advanced control mechanisms into smaller form factors. This miniaturization often involves the use of microelectromechanical systems (MEMS) and advanced sensor technologies, which can be challenging to integrate and protect within the harsh operating environments typical of valve applications.

Power management and energy efficiency are also key concerns in hybrid valve development. Many advanced valve systems require continuous power for monitoring and control functions. Designing low-power electronics and exploring energy harvesting technologies to support long-term, autonomous operation are areas of ongoing research and development.

Lastly, the challenge of standardization and interoperability cannot be overlooked. As hybrid valve systems become more complex, ensuring compatibility with existing infrastructure and control systems becomes increasingly difficult. Developing standardized interfaces and communication protocols that can accommodate a wide range of operational requirements while maintaining backward compatibility is a significant technical challenge facing the industry.

Material selection poses another critical challenge. Hybrid valve systems must withstand a wide range of operational conditions, including extreme temperatures, corrosive environments, and high-pressure differentials. Engineers must carefully balance durability, weight, and cost-effectiveness when choosing materials for valve components. Advanced composites and alloys are often necessary, but their implementation can introduce manufacturing complexities and increase production costs.

Sealing technology remains a persistent challenge in hybrid valve development. The need for reliable seals that can maintain integrity across multiple operational modes and diverse environmental conditions is paramount. Innovations in seal materials and designs are required to prevent leakage and ensure long-term performance, particularly in applications where even minor leaks can have significant consequences.

The miniaturization of control systems presents another hurdle. As industries demand more compact and efficient valve solutions, engineers must develop ways to incorporate advanced control mechanisms into smaller form factors. This miniaturization often involves the use of microelectromechanical systems (MEMS) and advanced sensor technologies, which can be challenging to integrate and protect within the harsh operating environments typical of valve applications.

Power management and energy efficiency are also key concerns in hybrid valve development. Many advanced valve systems require continuous power for monitoring and control functions. Designing low-power electronics and exploring energy harvesting technologies to support long-term, autonomous operation are areas of ongoing research and development.

Lastly, the challenge of standardization and interoperability cannot be overlooked. As hybrid valve systems become more complex, ensuring compatibility with existing infrastructure and control systems becomes increasingly difficult. Developing standardized interfaces and communication protocols that can accommodate a wide range of operational requirements while maintaining backward compatibility is a significant technical challenge facing the industry.

Current Hybrid Valve System Solutions

01 Hybrid actuation systems for gate valves

Hybrid systems combining multiple actuation methods for gate valve operations, such as electric and hydraulic or pneumatic and manual, to provide enhanced functionality and reliability. These systems offer redundancy, improved control, and adaptability to various operating conditions.- Hybrid actuation systems for gate valves: Hybrid systems combining multiple actuation methods for gate valve operations, such as electric and hydraulic or pneumatic and manual, to provide redundancy and improved functionality. These systems offer flexibility in operation, increased reliability, and the ability to switch between different power sources as needed.

- Intelligent control systems for gate valves: Integration of smart control systems and sensors for automated and remote operation of gate valves. These systems can monitor valve status, adjust operations based on real-time data, and provide predictive maintenance capabilities, enhancing overall efficiency and reducing downtime.

- Multi-functional gate valve designs: Gate valve designs incorporating multiple functions within a single unit, such as integrated flow control, pressure regulation, or safety shut-off mechanisms. These multi-functional designs optimize space, reduce complexity, and improve overall system performance in various industrial applications.

- Energy-efficient gate valve systems: Development of energy-efficient gate valve systems that minimize power consumption during operation. These systems may utilize regenerative braking, energy recovery mechanisms, or low-power standby modes to reduce overall energy usage while maintaining optimal performance.

- Modular and adaptable gate valve systems: Modular gate valve systems designed for easy customization and adaptation to various operational requirements. These systems allow for quick replacement of components, easy upgrades, and seamless integration with different control interfaces, enhancing flexibility and reducing maintenance time.

02 Intelligent control systems for gate valves

Integration of smart control systems and sensors for automated and remote operation of gate valves. These systems incorporate advanced algorithms, real-time monitoring, and data analysis to optimize valve performance, predict maintenance needs, and enhance overall system efficiency.Expand Specific Solutions03 Multi-functional gate valve designs

Innovative gate valve designs that incorporate multiple functions within a single unit, such as integrated flow control, pressure regulation, or safety features. These designs aim to reduce complexity, improve space efficiency, and enhance overall system performance.Expand Specific Solutions04 Energy-efficient gate valve operations

Development of energy-saving technologies and methods for gate valve operations, including low-power actuators, energy recovery systems, and optimized control strategies. These innovations aim to reduce power consumption and environmental impact while maintaining reliable valve performance.Expand Specific Solutions05 Modular and adaptable gate valve systems

Design of modular gate valve systems that can be easily customized, upgraded, or reconfigured for different applications and operating conditions. These systems offer flexibility in installation, maintenance, and future expansions, improving overall system versatility and cost-effectiveness.Expand Specific Solutions

Key Players in Hybrid Valve Industry

The development of hybrid systems for multi-functional gate valve operations is in a nascent stage, with the market showing significant growth potential. The technology is still evolving, with various players at different levels of maturity. Companies like Siemens AG and Bürkert Werke GmbH & Co. KG are leveraging their expertise in automation and control systems to advance this field. Emerging players such as Yuhuan Huifeng Valve Co., Ltd. and Giacomini SpA are focusing on specialized valve solutions. The market is characterized by a mix of established industrial giants and niche valve manufacturers, indicating a competitive landscape with opportunities for innovation and market expansion.

Siemens AG

Technical Solution: Siemens AG has pioneered hybrid systems for multi-functional gate valve operations in industrial applications. Their approach combines pneumatic actuation with electric control systems, offering a balance between power and precision. Siemens' hybrid gate valves incorporate advanced diagnostics and predictive maintenance capabilities, utilizing IoT and AI technologies to monitor valve health and performance in real-time[2]. The system employs a modular design, allowing for easy customization and upgrades to meet specific industry requirements. Siemens has also developed energy-efficient actuators that recover and store energy from valve operations, significantly reducing power consumption in large-scale installations[4]. Their hybrid valves feature adaptive control algorithms that optimize performance based on changing process conditions, ensuring consistent operation across various industrial environments.

Strengths: Advanced diagnostics, energy efficiency, adaptability to different industries. Weaknesses: Potential over-reliance on digital systems, cybersecurity concerns.

Hitachi Construction Machinery Co., Ltd.

Technical Solution: Hitachi Construction Machinery has developed hybrid systems for multi-functional gate valve operations specifically tailored for heavy machinery and construction equipment. Their approach combines hydraulic power with electric control systems, optimized for harsh operating environments. Hitachi's hybrid gate valves incorporate a regenerative energy system that captures and reuses energy from valve closures, significantly improving overall energy efficiency[7]. The company has implemented advanced sealing technologies to ensure reliable operation in dusty and high-vibration conditions common in construction sites. Hitachi's hybrid valves also feature a smart control system that adapts to different load conditions, optimizing performance and reducing wear on components. The valves are designed with a compact form factor, allowing for easy integration into existing machinery with minimal modifications.

Strengths: Robust design for harsh environments, energy regeneration capabilities, compact size. Weaknesses: Potentially higher cost compared to traditional hydraulic systems, may require specialized training for operators.

Core Innovations in Multi-Functional Valves

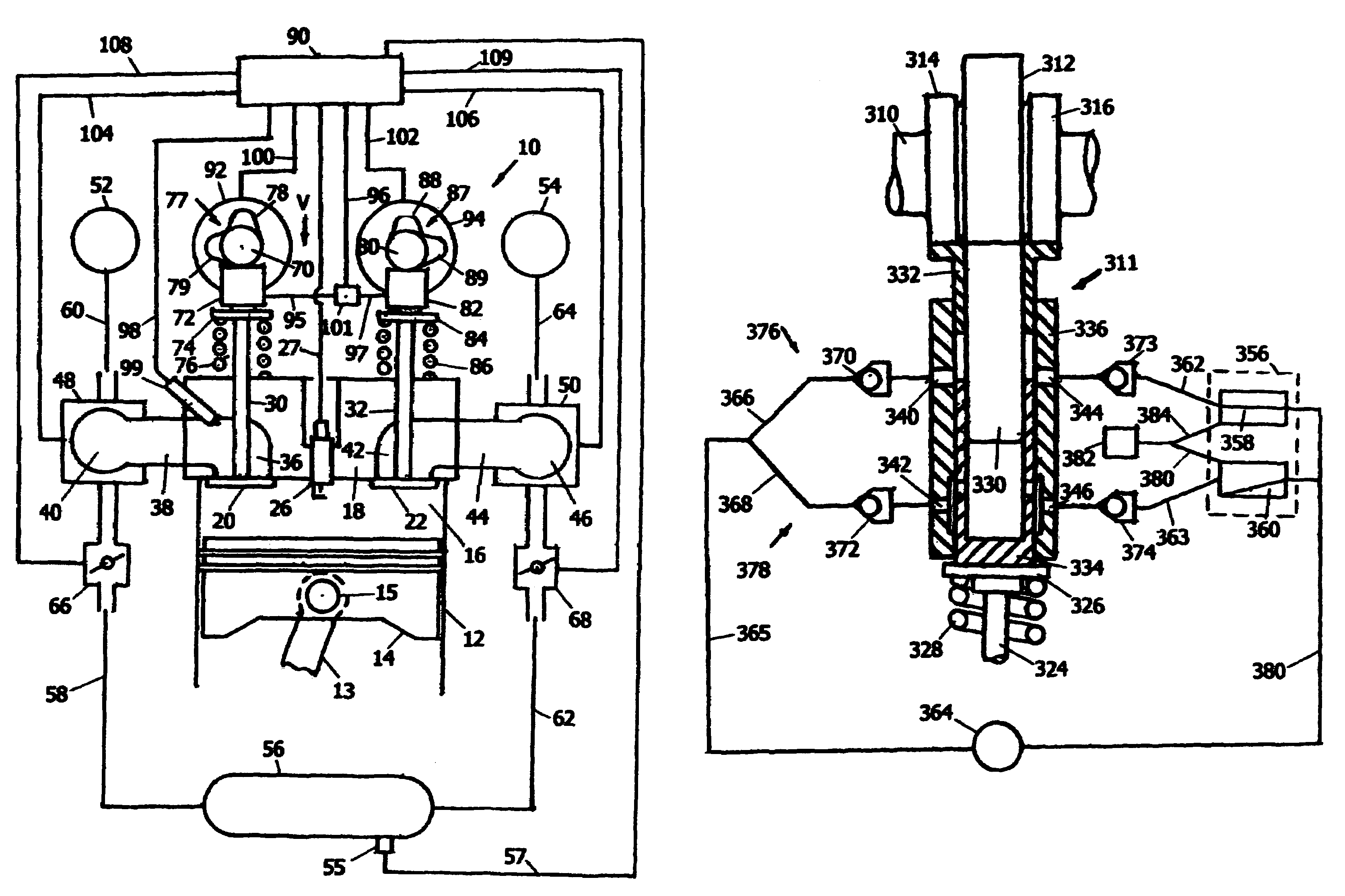

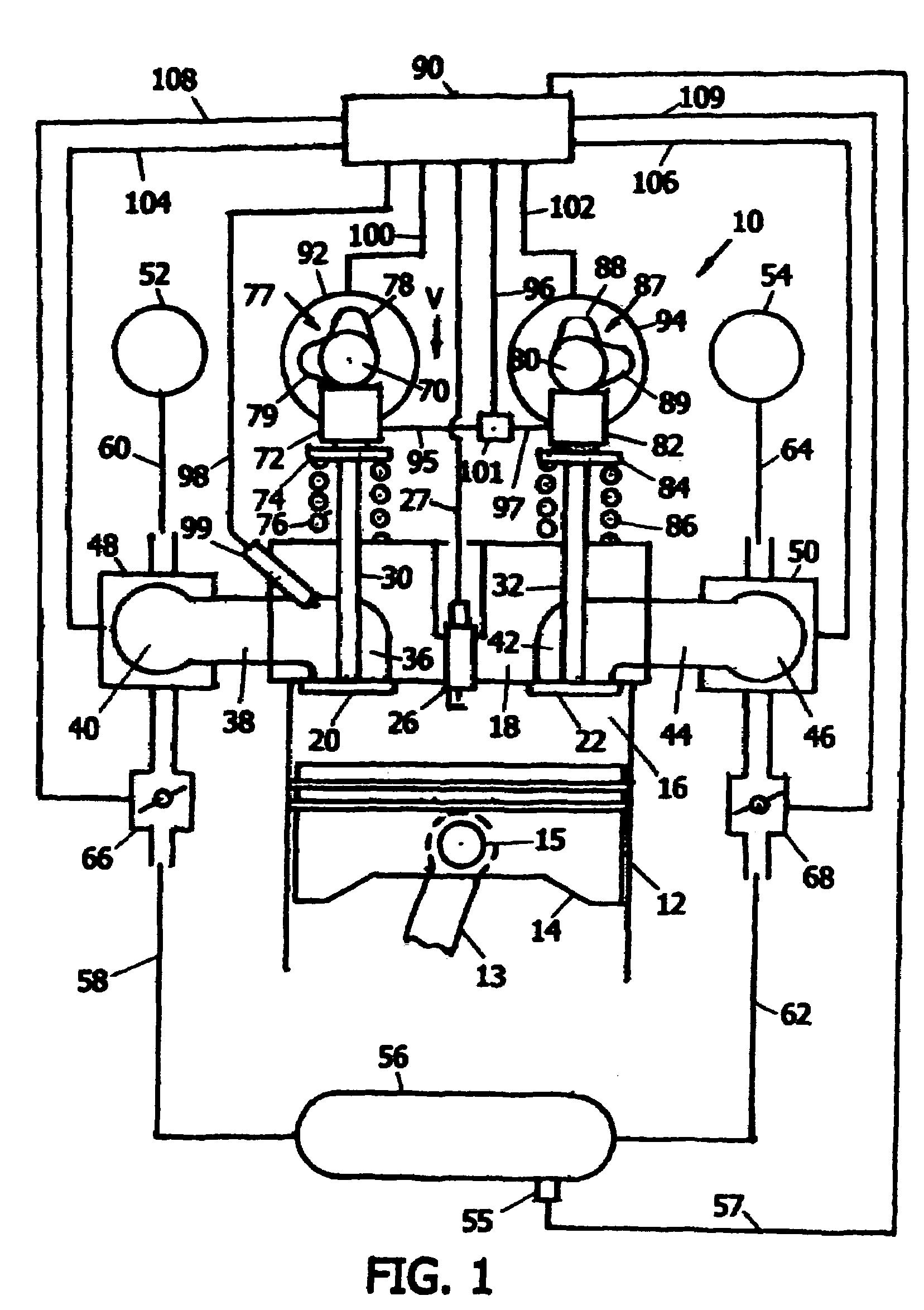

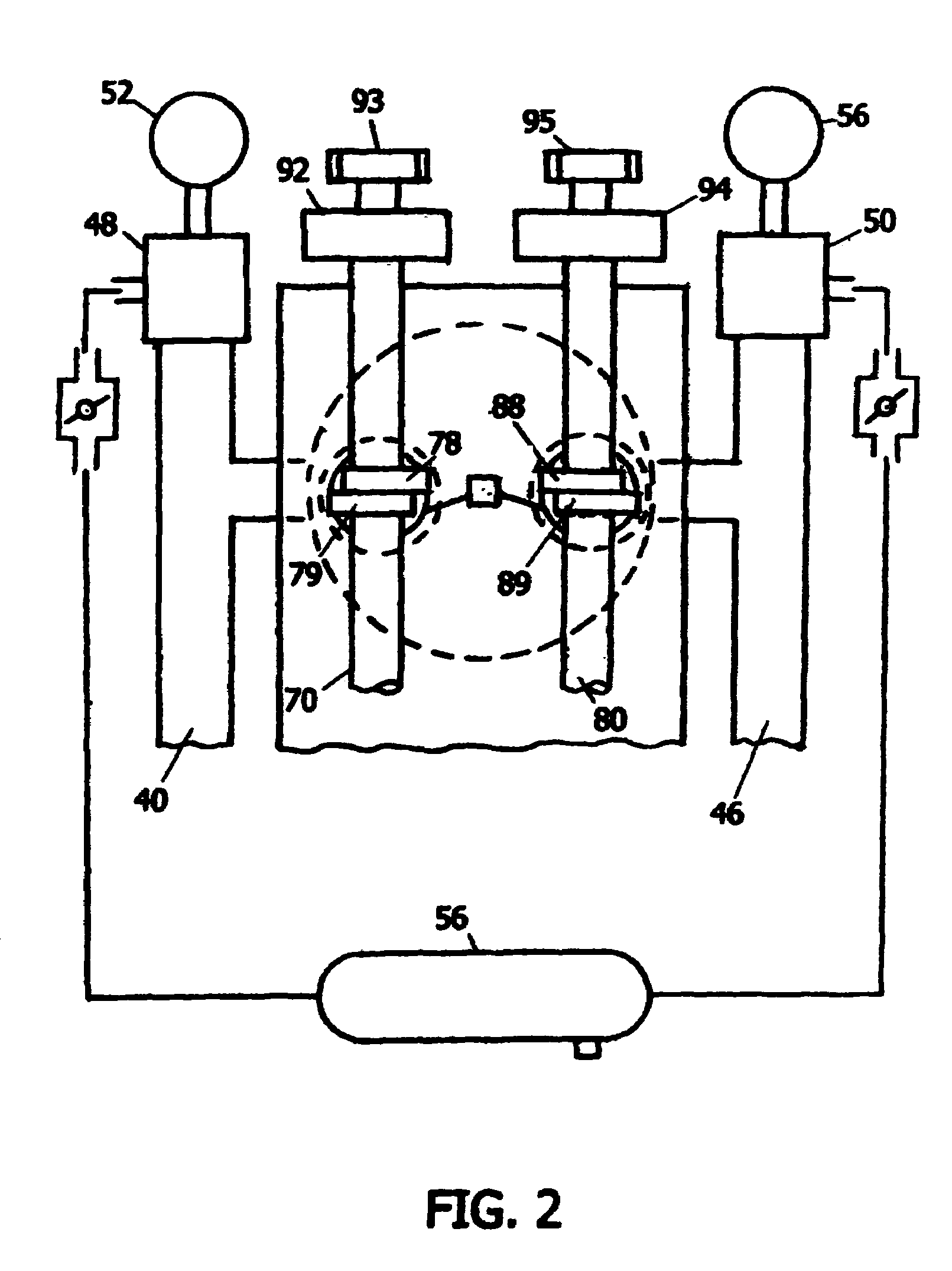

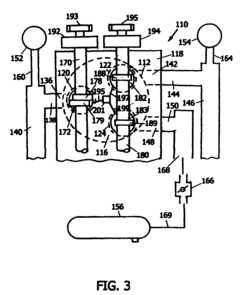

Operating an air-hybrid vehicle with camshaft-driven engine valves

PatentInactiveUS7464675B1

Innovation

- The use of camshafts and conventional camshaft phase shifters to operate and control engine valves, eliminating the need for high-pressure hydraulic systems and reducing the number of solenoid valves, thereby simplifying the system and improving reliability, efficiency, and ease of conversion from conventional engines.

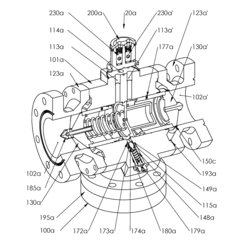

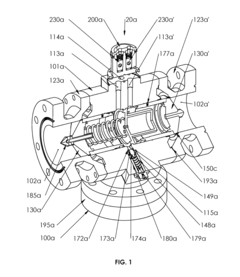

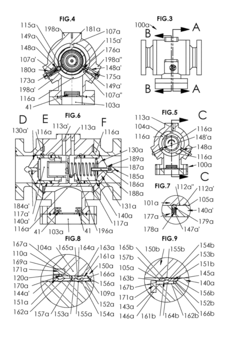

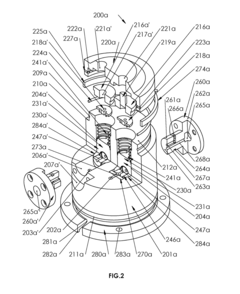

Hybrid high integrity pressure protection systems and valves

PatentActiveUS20170220053A1

Innovation

- A hybrid pressure protection system with redundant plug assemblies and pilots, utilizing metal B-ring assemblies for high-integrity sealing, and an anti-cavitation trim to reduce erosion and cavitation, along with a volume substitute box for temperature stabilization, enabling efficient blocking and releasing of overpressure fluids without external actuators.

Safety Standards for Hybrid Valve Systems

Safety standards for hybrid valve systems in the development of multi-functional gate valve operations are crucial to ensure the safe and reliable performance of these complex systems. These standards encompass a wide range of considerations, from design and manufacturing to installation, operation, and maintenance.

The primary focus of safety standards for hybrid valve systems is to mitigate potential risks associated with the integration of multiple functionalities within a single valve unit. This includes addressing potential failure modes, ensuring proper isolation of different operational modes, and maintaining system integrity under various operating conditions.

One key aspect of these safety standards is the requirement for redundancy in critical components and control systems. This redundancy helps to prevent single-point failures that could compromise the overall safety of the valve system. Additionally, standards often mandate the implementation of fail-safe mechanisms, ensuring that the valve defaults to a safe position in the event of a system malfunction or power loss.

Material selection and compatibility are also crucial considerations in safety standards for hybrid valve systems. The materials used must be able to withstand the diverse operating conditions and media that the valve may encounter, including extreme temperatures, pressures, and potentially corrosive substances. Standards typically specify minimum requirements for material properties and testing procedures to verify their suitability.

Pressure and temperature ratings are another critical area addressed by safety standards. Hybrid valve systems must be designed and tested to withstand the maximum anticipated operating conditions with an appropriate safety margin. This often involves rigorous testing procedures, including hydrostatic and pneumatic tests, as well as cyclic fatigue testing to ensure long-term reliability.

Sealing and leakage prevention are paramount in safety standards for hybrid valve systems. Standards typically define acceptable leakage rates and specify testing methods to verify seal integrity. This is particularly important in applications where even minor leaks could pose significant safety or environmental risks.

Control system safety is a key focus area, given the complex nature of hybrid valve systems. Standards often require the implementation of safety-rated control systems, including redundant sensors, fail-safe logic, and robust communication protocols. These systems must be designed to detect and respond to abnormal conditions quickly and reliably.

Maintenance and inspection requirements are also outlined in safety standards, ensuring that hybrid valve systems remain safe and reliable throughout their operational life. This includes guidelines for regular inspections, preventive maintenance, and testing procedures to verify ongoing compliance with safety standards.

Human factors and operator safety are addressed through requirements for clear and intuitive controls, proper labeling, and comprehensive documentation. Standards may also specify training requirements for personnel involved in the operation and maintenance of hybrid valve systems.

Overall, safety standards for hybrid valve systems in multi-functional gate valve operations aim to create a comprehensive framework that addresses all aspects of system safety, from design and manufacturing to long-term operation and maintenance. These standards continue to evolve as technology advances, ensuring that safety remains paramount in the development and deployment of increasingly complex valve systems.

The primary focus of safety standards for hybrid valve systems is to mitigate potential risks associated with the integration of multiple functionalities within a single valve unit. This includes addressing potential failure modes, ensuring proper isolation of different operational modes, and maintaining system integrity under various operating conditions.

One key aspect of these safety standards is the requirement for redundancy in critical components and control systems. This redundancy helps to prevent single-point failures that could compromise the overall safety of the valve system. Additionally, standards often mandate the implementation of fail-safe mechanisms, ensuring that the valve defaults to a safe position in the event of a system malfunction or power loss.

Material selection and compatibility are also crucial considerations in safety standards for hybrid valve systems. The materials used must be able to withstand the diverse operating conditions and media that the valve may encounter, including extreme temperatures, pressures, and potentially corrosive substances. Standards typically specify minimum requirements for material properties and testing procedures to verify their suitability.

Pressure and temperature ratings are another critical area addressed by safety standards. Hybrid valve systems must be designed and tested to withstand the maximum anticipated operating conditions with an appropriate safety margin. This often involves rigorous testing procedures, including hydrostatic and pneumatic tests, as well as cyclic fatigue testing to ensure long-term reliability.

Sealing and leakage prevention are paramount in safety standards for hybrid valve systems. Standards typically define acceptable leakage rates and specify testing methods to verify seal integrity. This is particularly important in applications where even minor leaks could pose significant safety or environmental risks.

Control system safety is a key focus area, given the complex nature of hybrid valve systems. Standards often require the implementation of safety-rated control systems, including redundant sensors, fail-safe logic, and robust communication protocols. These systems must be designed to detect and respond to abnormal conditions quickly and reliably.

Maintenance and inspection requirements are also outlined in safety standards, ensuring that hybrid valve systems remain safe and reliable throughout their operational life. This includes guidelines for regular inspections, preventive maintenance, and testing procedures to verify ongoing compliance with safety standards.

Human factors and operator safety are addressed through requirements for clear and intuitive controls, proper labeling, and comprehensive documentation. Standards may also specify training requirements for personnel involved in the operation and maintenance of hybrid valve systems.

Overall, safety standards for hybrid valve systems in multi-functional gate valve operations aim to create a comprehensive framework that addresses all aspects of system safety, from design and manufacturing to long-term operation and maintenance. These standards continue to evolve as technology advances, ensuring that safety remains paramount in the development and deployment of increasingly complex valve systems.

Environmental Impact of Hybrid Valve Technologies

The environmental impact of hybrid valve technologies in multi-functional gate valve operations is a critical consideration in the development and implementation of these systems. These hybrid systems, which combine traditional mechanical components with advanced electronic controls and sensors, offer potential benefits in terms of efficiency and performance. However, they also present unique environmental challenges that must be carefully evaluated.

One of the primary environmental advantages of hybrid valve technologies is their potential for improved energy efficiency. By incorporating electronic controls and sensors, these systems can optimize valve operations, reducing unnecessary energy consumption. This can lead to a significant decrease in the overall carbon footprint of industrial processes that rely on gate valves, particularly in sectors such as oil and gas, water treatment, and chemical processing.

Furthermore, hybrid valve systems often enable more precise control over fluid flow, which can result in reduced waste and improved resource utilization. This precision can minimize the risk of leaks or spills, thereby decreasing the potential for environmental contamination. In industries where hazardous materials are handled, this enhanced control can be particularly beneficial in preventing accidental releases and protecting surrounding ecosystems.

However, the introduction of electronic components in hybrid valve systems also raises concerns about electronic waste (e-waste) generation. As these systems become more prevalent, there is a need to address the end-of-life disposal of electronic components, which may contain hazardous materials. Proper recycling and disposal protocols must be developed and implemented to mitigate the environmental impact of these components.

Another environmental consideration is the potential for increased electromagnetic emissions from hybrid valve systems. While generally low-level, these emissions may have implications for sensitive environments or wildlife. Comprehensive studies are needed to assess the long-term effects of these emissions on local ecosystems, particularly in areas with high concentrations of industrial equipment.

The manufacturing process of hybrid valve technologies also warrants environmental scrutiny. The production of electronic components often involves the use of rare earth elements and other materials with significant environmental footprints. Balancing the environmental costs of production against the operational benefits of these systems is crucial in determining their overall environmental impact.

In terms of maintenance and longevity, hybrid valve systems may offer advantages over traditional mechanical valves. Their ability to self-diagnose and report potential issues can lead to more timely maintenance, potentially extending the operational life of the equipment. This could reduce the frequency of replacements and, consequently, the environmental impact associated with manufacturing and disposing of valve components.

As the adoption of hybrid valve technologies continues to grow, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental implications. These assessments should consider factors such as raw material extraction, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life disposal. Only through such holistic evaluations can the true environmental impact of these technologies be accurately determined and effectively managed.

One of the primary environmental advantages of hybrid valve technologies is their potential for improved energy efficiency. By incorporating electronic controls and sensors, these systems can optimize valve operations, reducing unnecessary energy consumption. This can lead to a significant decrease in the overall carbon footprint of industrial processes that rely on gate valves, particularly in sectors such as oil and gas, water treatment, and chemical processing.

Furthermore, hybrid valve systems often enable more precise control over fluid flow, which can result in reduced waste and improved resource utilization. This precision can minimize the risk of leaks or spills, thereby decreasing the potential for environmental contamination. In industries where hazardous materials are handled, this enhanced control can be particularly beneficial in preventing accidental releases and protecting surrounding ecosystems.

However, the introduction of electronic components in hybrid valve systems also raises concerns about electronic waste (e-waste) generation. As these systems become more prevalent, there is a need to address the end-of-life disposal of electronic components, which may contain hazardous materials. Proper recycling and disposal protocols must be developed and implemented to mitigate the environmental impact of these components.

Another environmental consideration is the potential for increased electromagnetic emissions from hybrid valve systems. While generally low-level, these emissions may have implications for sensitive environments or wildlife. Comprehensive studies are needed to assess the long-term effects of these emissions on local ecosystems, particularly in areas with high concentrations of industrial equipment.

The manufacturing process of hybrid valve technologies also warrants environmental scrutiny. The production of electronic components often involves the use of rare earth elements and other materials with significant environmental footprints. Balancing the environmental costs of production against the operational benefits of these systems is crucial in determining their overall environmental impact.

In terms of maintenance and longevity, hybrid valve systems may offer advantages over traditional mechanical valves. Their ability to self-diagnose and report potential issues can lead to more timely maintenance, potentially extending the operational life of the equipment. This could reduce the frequency of replacements and, consequently, the environmental impact associated with manufacturing and disposing of valve components.

As the adoption of hybrid valve technologies continues to grow, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental implications. These assessments should consider factors such as raw material extraction, manufacturing processes, operational efficiency, maintenance requirements, and end-of-life disposal. Only through such holistic evaluations can the true environmental impact of these technologies be accurately determined and effectively managed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!