Modifying gate valve operational protocols for high-density fluid movement

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Objectives

Gate valves have been a crucial component in fluid control systems for over a century, evolving significantly to meet the demands of various industries. The journey of gate valve technology began with simple designs primarily used in water distribution systems and has since progressed to sophisticated, high-performance valves capable of handling extreme pressures and temperatures in complex industrial processes.

The evolution of gate valves has been driven by the need for more efficient and reliable fluid control, particularly in high-density fluid applications. Early gate valves were limited in their ability to handle high-pressure and corrosive fluids, leading to frequent maintenance and replacement. As industries such as oil and gas, chemical processing, and power generation expanded, the demand for more robust and versatile gate valves grew exponentially.

A significant milestone in gate valve development was the introduction of wedge-type gate valves, which offered improved sealing capabilities and reduced wear. This innovation paved the way for further advancements, including the development of double-disc and parallel slide gate valves, each designed to address specific operational challenges in high-density fluid movement.

The advent of computer-aided design and advanced manufacturing techniques has revolutionized gate valve production, allowing for more precise tolerances and complex geometries. These technological advancements have resulted in gate valves with enhanced performance characteristics, including better flow control, reduced pressure drop, and increased resistance to erosion and corrosion.

In recent years, the focus has shifted towards developing smart gate valves equipped with sensors and actuators for remote operation and real-time monitoring. This integration of digital technology aims to improve operational efficiency, reduce downtime, and enhance safety in high-density fluid handling applications.

The primary objective in modifying gate valve operational protocols for high-density fluid movement is to optimize valve performance while ensuring safety and reliability. This involves addressing several key challenges, including minimizing fluid hammer effects, reducing wear on valve components, and improving the valve's response to rapid changes in flow conditions.

Another critical goal is to enhance the valve's ability to maintain a tight seal under high-pressure differentials, preventing leakage and ensuring the integrity of the fluid system. Additionally, there is a growing emphasis on developing operational protocols that can adapt to varying fluid densities and flow rates, allowing for greater flexibility in industrial processes.

As industries continue to push the boundaries of fluid handling capabilities, the evolution of gate valve technology and operational protocols remains an ongoing process. Future objectives include the development of more energy-efficient valve designs, the integration of advanced materials for improved durability, and the implementation of predictive maintenance strategies to further enhance reliability and reduce operational costs.

The evolution of gate valves has been driven by the need for more efficient and reliable fluid control, particularly in high-density fluid applications. Early gate valves were limited in their ability to handle high-pressure and corrosive fluids, leading to frequent maintenance and replacement. As industries such as oil and gas, chemical processing, and power generation expanded, the demand for more robust and versatile gate valves grew exponentially.

A significant milestone in gate valve development was the introduction of wedge-type gate valves, which offered improved sealing capabilities and reduced wear. This innovation paved the way for further advancements, including the development of double-disc and parallel slide gate valves, each designed to address specific operational challenges in high-density fluid movement.

The advent of computer-aided design and advanced manufacturing techniques has revolutionized gate valve production, allowing for more precise tolerances and complex geometries. These technological advancements have resulted in gate valves with enhanced performance characteristics, including better flow control, reduced pressure drop, and increased resistance to erosion and corrosion.

In recent years, the focus has shifted towards developing smart gate valves equipped with sensors and actuators for remote operation and real-time monitoring. This integration of digital technology aims to improve operational efficiency, reduce downtime, and enhance safety in high-density fluid handling applications.

The primary objective in modifying gate valve operational protocols for high-density fluid movement is to optimize valve performance while ensuring safety and reliability. This involves addressing several key challenges, including minimizing fluid hammer effects, reducing wear on valve components, and improving the valve's response to rapid changes in flow conditions.

Another critical goal is to enhance the valve's ability to maintain a tight seal under high-pressure differentials, preventing leakage and ensuring the integrity of the fluid system. Additionally, there is a growing emphasis on developing operational protocols that can adapt to varying fluid densities and flow rates, allowing for greater flexibility in industrial processes.

As industries continue to push the boundaries of fluid handling capabilities, the evolution of gate valve technology and operational protocols remains an ongoing process. Future objectives include the development of more energy-efficient valve designs, the integration of advanced materials for improved durability, and the implementation of predictive maintenance strategies to further enhance reliability and reduce operational costs.

High-Density Fluid Market Analysis

The high-density fluid market has experienced significant growth in recent years, driven by increasing demand across various industries, particularly in oil and gas, chemical processing, and mining sectors. This market segment is characterized by fluids with specific gravity greater than 1.0, which are crucial for applications requiring enhanced pressure control, well stability, and efficient material transport.

In the oil and gas industry, high-density fluids play a vital role in drilling operations, well completion, and enhanced oil recovery techniques. The market for these fluids has been expanding due to the exploration of deeper and more challenging reservoirs, where conventional fluids may not provide adequate performance. The chemical processing industry also relies heavily on high-density fluids for various applications, including separation processes, heat transfer, and reaction media.

The global high-density fluid market size was valued at several billion dollars in the past year, with projections indicating a compound annual growth rate (CAGR) in the mid-single digits over the next five years. This growth is attributed to the increasing complexity of industrial processes and the need for more efficient and environmentally friendly fluid solutions.

Regionally, North America and the Middle East dominate the high-density fluid market, primarily due to their extensive oil and gas operations. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand for high-density fluids, driven by industrialization and infrastructure development projects.

Key market drivers include technological advancements in fluid formulations, stringent environmental regulations promoting the use of eco-friendly high-density fluids, and the growing focus on operational efficiency in industrial processes. The development of synthetic-based high-density fluids has opened new avenues for market expansion, offering improved performance characteristics and reduced environmental impact compared to traditional oil-based fluids.

Challenges in the high-density fluid market include the volatility of raw material prices, which can significantly impact production costs and profit margins. Additionally, the industry faces pressure to develop more sustainable and biodegradable high-density fluid options to meet increasingly stringent environmental standards.

The market landscape is characterized by a mix of large multinational corporations and specialized regional players. Major companies in this space are investing heavily in research and development to create innovative high-density fluid solutions that offer superior performance while addressing environmental concerns. Collaborations between fluid manufacturers and end-users are becoming more common, fostering the development of customized solutions for specific industrial applications.

In the oil and gas industry, high-density fluids play a vital role in drilling operations, well completion, and enhanced oil recovery techniques. The market for these fluids has been expanding due to the exploration of deeper and more challenging reservoirs, where conventional fluids may not provide adequate performance. The chemical processing industry also relies heavily on high-density fluids for various applications, including separation processes, heat transfer, and reaction media.

The global high-density fluid market size was valued at several billion dollars in the past year, with projections indicating a compound annual growth rate (CAGR) in the mid-single digits over the next five years. This growth is attributed to the increasing complexity of industrial processes and the need for more efficient and environmentally friendly fluid solutions.

Regionally, North America and the Middle East dominate the high-density fluid market, primarily due to their extensive oil and gas operations. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in demand for high-density fluids, driven by industrialization and infrastructure development projects.

Key market drivers include technological advancements in fluid formulations, stringent environmental regulations promoting the use of eco-friendly high-density fluids, and the growing focus on operational efficiency in industrial processes. The development of synthetic-based high-density fluids has opened new avenues for market expansion, offering improved performance characteristics and reduced environmental impact compared to traditional oil-based fluids.

Challenges in the high-density fluid market include the volatility of raw material prices, which can significantly impact production costs and profit margins. Additionally, the industry faces pressure to develop more sustainable and biodegradable high-density fluid options to meet increasingly stringent environmental standards.

The market landscape is characterized by a mix of large multinational corporations and specialized regional players. Major companies in this space are investing heavily in research and development to create innovative high-density fluid solutions that offer superior performance while addressing environmental concerns. Collaborations between fluid manufacturers and end-users are becoming more common, fostering the development of customized solutions for specific industrial applications.

Gate Valve Challenges in High-Density Fluids

Gate valves play a crucial role in controlling the flow of high-density fluids in various industrial applications. However, their operation in such environments presents several significant challenges that must be addressed to ensure optimal performance and safety.

One of the primary challenges is the increased wear and tear on valve components due to the abrasive nature of high-density fluids. These fluids often contain suspended particles or have higher viscosities, which can accelerate erosion of valve seats, gates, and sealing surfaces. This accelerated wear can lead to reduced valve lifespan, increased maintenance requirements, and potential leakage issues.

The high pressure associated with dense fluid movement also poses a significant challenge for gate valve operation. The increased force exerted on the valve components can lead to deformation or damage, particularly during opening and closing operations. This pressure-induced stress can compromise the valve's integrity and its ability to maintain a tight seal, potentially resulting in fluid leakage or valve failure.

Corrosion resistance becomes a critical factor when dealing with high-density fluids, especially in industries such as chemical processing or oil and gas production. The aggressive nature of these fluids can rapidly degrade standard valve materials, necessitating the use of specialized alloys or coatings to protect valve components and extend their operational life.

The increased viscosity of high-density fluids presents challenges in valve actuation. Greater force is required to overcome the fluid resistance during valve opening and closing, which can strain actuators and lead to slower response times. This can be particularly problematic in applications requiring rapid flow control or emergency shutoff capabilities.

Thermal management is another significant concern when operating gate valves with high-density fluids. The friction generated during fluid movement can cause substantial heat buildup, potentially leading to thermal expansion of valve components. This expansion can affect valve clearances and sealing effectiveness, necessitating careful material selection and design considerations to maintain proper valve function across a range of operating temperatures.

Cavitation and flashing are phenomena that can occur in high-density fluid applications, particularly when there are significant pressure drops across the valve. These effects can cause severe damage to valve internals and downstream piping, requiring careful consideration of valve sizing, trim design, and operational protocols to mitigate their impact.

Lastly, the potential for fluid solidification or crystallization within the valve body poses a unique challenge in high-density fluid applications. This can lead to valve seizure or reduced flow capacity, necessitating the implementation of heating systems or specialized valve designs to prevent such occurrences and ensure reliable operation.

One of the primary challenges is the increased wear and tear on valve components due to the abrasive nature of high-density fluids. These fluids often contain suspended particles or have higher viscosities, which can accelerate erosion of valve seats, gates, and sealing surfaces. This accelerated wear can lead to reduced valve lifespan, increased maintenance requirements, and potential leakage issues.

The high pressure associated with dense fluid movement also poses a significant challenge for gate valve operation. The increased force exerted on the valve components can lead to deformation or damage, particularly during opening and closing operations. This pressure-induced stress can compromise the valve's integrity and its ability to maintain a tight seal, potentially resulting in fluid leakage or valve failure.

Corrosion resistance becomes a critical factor when dealing with high-density fluids, especially in industries such as chemical processing or oil and gas production. The aggressive nature of these fluids can rapidly degrade standard valve materials, necessitating the use of specialized alloys or coatings to protect valve components and extend their operational life.

The increased viscosity of high-density fluids presents challenges in valve actuation. Greater force is required to overcome the fluid resistance during valve opening and closing, which can strain actuators and lead to slower response times. This can be particularly problematic in applications requiring rapid flow control or emergency shutoff capabilities.

Thermal management is another significant concern when operating gate valves with high-density fluids. The friction generated during fluid movement can cause substantial heat buildup, potentially leading to thermal expansion of valve components. This expansion can affect valve clearances and sealing effectiveness, necessitating careful material selection and design considerations to maintain proper valve function across a range of operating temperatures.

Cavitation and flashing are phenomena that can occur in high-density fluid applications, particularly when there are significant pressure drops across the valve. These effects can cause severe damage to valve internals and downstream piping, requiring careful consideration of valve sizing, trim design, and operational protocols to mitigate their impact.

Lastly, the potential for fluid solidification or crystallization within the valve body poses a unique challenge in high-density fluid applications. This can lead to valve seizure or reduced flow capacity, necessitating the implementation of heating systems or specialized valve designs to prevent such occurrences and ensure reliable operation.

Current High-Density Fluid Protocols

01 Gate valve opening and closing mechanisms

Gate valves employ various mechanisms for opening and closing, including manual, hydraulic, and motorized systems. These mechanisms control the movement of the gate to regulate flow. Operational protocols often involve specific procedures for engaging and disengaging these mechanisms to ensure proper valve function and prevent damage.- Gate valve opening and closing mechanisms: Gate valves employ various mechanisms for opening and closing, including manual handwheels, pneumatic actuators, and electric motors. These mechanisms control the movement of the gate, which slides perpendicular to the flow path to regulate fluid flow. Proper design and operation of these mechanisms are crucial for efficient valve performance and longevity.

- Sealing and leak prevention in gate valves: Effective sealing is critical in gate valve operation to prevent leaks and ensure proper fluid control. This involves the use of specialized sealing materials, precise machining of valve components, and proper alignment of the gate with the valve body. Regular maintenance and inspection of sealing surfaces are essential for optimal performance.

- Gate valve automation and control systems: Modern gate valves often incorporate automation and advanced control systems for remote operation and monitoring. These systems may include sensors, actuators, and communication interfaces that allow for precise control of valve position, flow rate, and pressure. Integration with broader process control systems enables efficient management of complex fluid handling operations.

- Maintenance and troubleshooting protocols: Regular maintenance and effective troubleshooting are essential for ensuring the reliable operation of gate valves. This includes procedures for inspection, lubrication, parts replacement, and addressing common issues such as stem binding or seat wear. Proper documentation and adherence to maintenance schedules help prevent unexpected failures and extend valve life.

- Safety considerations in gate valve operation: Safety is paramount in gate valve operation, particularly in high-pressure or hazardous fluid applications. Operational protocols must address proper lockout/tagout procedures, pressure relief mechanisms, and emergency shutdown procedures. Training personnel in safe valve operation and ensuring compliance with industry standards are crucial aspects of gate valve safety protocols.

02 Safety protocols for gate valve operation

Safety is paramount in gate valve operations. Protocols typically include lockout/tagout procedures, pressure relief methods, and emergency shutdown procedures. These measures aim to protect personnel and equipment during valve manipulation, maintenance, or in case of system failures.Expand Specific Solutions03 Monitoring and control systems for gate valves

Advanced gate valve systems often incorporate monitoring and control technologies. These may include sensors for position, pressure, and flow rate, as well as remote operation capabilities. Such systems enhance operational efficiency and allow for real-time adjustments based on system conditions.Expand Specific Solutions04 Maintenance and inspection protocols

Regular maintenance and inspection are crucial for gate valve longevity and reliability. Protocols typically outline schedules for lubrication, seal replacement, and integrity checks. These procedures help identify potential issues early and ensure consistent valve performance over time.Expand Specific Solutions05 Environmental considerations in gate valve operations

Operational protocols for gate valves often address environmental concerns, particularly in industries dealing with hazardous materials. These may include procedures for preventing leaks, managing emissions, and proper disposal of valve-related waste. Such protocols aim to minimize environmental impact while maintaining operational efficiency.Expand Specific Solutions

Key Gate Valve Manufacturers

The market for modifying gate valve operational protocols for high-density fluid movement is in a growth phase, driven by increasing demand for efficient fluid handling in various industries. The market size is expanding, with significant potential in oil and gas, chemical processing, and water treatment sectors. Technologically, the field is advancing rapidly, with companies like Festo SE & Co. KG and Parker-Hannifin Corp. leading innovation in valve automation and control systems. Artemis Intelligent Power Ltd. and Emerson Process Management Regulator Technologies, Inc. are making strides in developing smart valve technologies, while Lam Research Corp. and Tokyo Electron Ltd. are applying their semiconductor expertise to enhance valve precision for high-density fluids. The competitive landscape is diverse, with both established players and emerging specialists contributing to technological advancements.

Festo SE & Co. KG

Technical Solution: Festo has developed innovative solutions for gate valve operation in high-density fluid applications, focusing on pneumatic and electropneumatic actuation systems. Their DFPD quarter turn actuator series offers precise control for gate valves, with options for explosion-proof designs suitable for hazardous environments[1]. Festo's valve positioners, such as the CMSX series, provide digital control interfaces and advanced diagnostics, allowing for real-time adjustment of valve positions based on fluid density and flow characteristics[3]. The company has also introduced smart valve monitoring systems that use IoT technology to predict maintenance needs and optimize valve performance for high-density fluids[5]. Festo's approach integrates automation and digitalization to enhance the efficiency and reliability of gate valve operations in challenging fluid environments.

Strengths: Strong focus on automation and digitalization, wide range of compatible systems, expertise in pneumatic technologies. Weaknesses: May require significant infrastructure changes for full implementation, potential complexity in retrofitting existing systems.

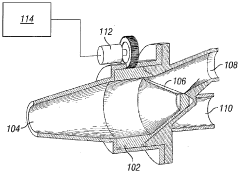

Cameron International Corp.

Technical Solution: Cameron International has innovated in gate valve technology for high-density fluid movement, particularly in subsea applications. Their DynaCENTRIK™ gate valve system incorporates a unique centralized stem design that reduces actuation forces and improves sealing performance under high-pressure conditions[2]. The company has also developed a hydraulic stepping actuator that allows for precise incremental control of valve position, crucial for managing high-density fluid flow[4]. Cameron's valves feature advanced materials such as super duplex stainless steel and specialized elastomers to resist erosion and corrosion in extreme environments[6]. Their valve control systems integrate with subsea control modules for remote operation and monitoring, enhancing safety and efficiency in deepwater operations[8].

Strengths: Specialized in subsea and high-pressure applications, advanced materials science, integrated control systems. Weaknesses: High cost of implementation, may be overengineered for less demanding applications.

Innovative Gate Valve Designs

Method and system for adjusting the flow rate of charge material in a charging process of a shaft furnace

PatentWO2010092132A1

Innovation

- A method and system that provide specific valve characteristics for each batch, allowing for real-time adjustment of flow rates by initializing and correcting valve settings based on actual discharge rates, thereby adapting to batch-specific properties such as material mixtures, granularity, and humidity.

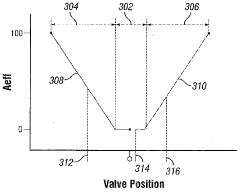

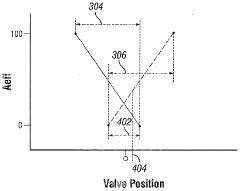

Three-way controllable valve

PatentWO2011123366A1

Innovation

- A conical valve body with shaped fluid openings and passageways that enhance flow controllability by providing a more linear effective flow area versus rotational position, allowing for increased flow capacity and improved control through a valve actuator and controller system.

Safety Standards for Fluid Control

Safety standards for fluid control in gate valve operations involving high-density fluids are critical to ensure the integrity of the system and the safety of personnel. These standards encompass a wide range of considerations, from material selection to operational procedures and maintenance protocols. For high-density fluid movement, the standards must address the increased pressure and potential for erosion or corrosion that these fluids can cause.

Material specifications for gate valves handling high-density fluids are more stringent, requiring corrosion-resistant alloys or specialized coatings to withstand the aggressive nature of the fluid. The standards typically mandate regular inspections and non-destructive testing to detect any signs of wear or material degradation. This includes ultrasonic thickness measurements and radiographic examinations to ensure the valve body and internal components maintain their structural integrity.

Operational protocols must be modified to account for the unique properties of high-density fluids. Standards often require slower opening and closing speeds to prevent water hammer effects, which can be more severe with denser fluids. Pressure relief systems must be designed with higher capacities and faster response times to manage potential overpressure scenarios. The standards also specify more frequent cycling of valves to prevent seizing and ensure smooth operation.

Leak detection and containment are paramount in safety standards for high-density fluid control. Advanced monitoring systems, including real-time pressure sensors and flow meters, are typically required to detect even minor leaks quickly. Secondary containment measures, such as double-walled piping and catch basins, are often mandated to prevent environmental contamination in case of a breach.

Personnel safety is a key focus of these standards, with enhanced personal protective equipment (PPE) requirements for operators working with high-density fluids. This may include chemical-resistant suits, specialized respirators, and additional training on the specific hazards associated with the fluid being handled. Emergency response procedures are more elaborate, with detailed protocols for spill containment and decontamination.

Maintenance schedules are typically more frequent and rigorous under these safety standards. They often require complete disassembly and inspection of gate valves at shorter intervals compared to those handling standard fluids. The standards may also specify the use of predictive maintenance techniques, such as vibration analysis and thermal imaging, to identify potential issues before they lead to failures.

Material specifications for gate valves handling high-density fluids are more stringent, requiring corrosion-resistant alloys or specialized coatings to withstand the aggressive nature of the fluid. The standards typically mandate regular inspections and non-destructive testing to detect any signs of wear or material degradation. This includes ultrasonic thickness measurements and radiographic examinations to ensure the valve body and internal components maintain their structural integrity.

Operational protocols must be modified to account for the unique properties of high-density fluids. Standards often require slower opening and closing speeds to prevent water hammer effects, which can be more severe with denser fluids. Pressure relief systems must be designed with higher capacities and faster response times to manage potential overpressure scenarios. The standards also specify more frequent cycling of valves to prevent seizing and ensure smooth operation.

Leak detection and containment are paramount in safety standards for high-density fluid control. Advanced monitoring systems, including real-time pressure sensors and flow meters, are typically required to detect even minor leaks quickly. Secondary containment measures, such as double-walled piping and catch basins, are often mandated to prevent environmental contamination in case of a breach.

Personnel safety is a key focus of these standards, with enhanced personal protective equipment (PPE) requirements for operators working with high-density fluids. This may include chemical-resistant suits, specialized respirators, and additional training on the specific hazards associated with the fluid being handled. Emergency response procedures are more elaborate, with detailed protocols for spill containment and decontamination.

Maintenance schedules are typically more frequent and rigorous under these safety standards. They often require complete disassembly and inspection of gate valves at shorter intervals compared to those handling standard fluids. The standards may also specify the use of predictive maintenance techniques, such as vibration analysis and thermal imaging, to identify potential issues before they lead to failures.

Environmental Impact Assessment

The modification of gate valve operational protocols for high-density fluid movement necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand and mitigate potential ecological consequences associated with the proposed changes in valve operation.

Firstly, the assessment must consider the impact on local water bodies. High-density fluid movement through modified gate valves may lead to increased turbidity in nearby streams or rivers. This could affect aquatic ecosystems by reducing light penetration, impacting photosynthetic organisms, and potentially altering the food chain. Additionally, changes in fluid dynamics may influence sediment transport patterns, potentially leading to erosion or deposition issues in downstream areas.

Air quality is another critical factor to evaluate. The modified protocols might result in increased emissions of volatile organic compounds (VOCs) or particulate matter during valve operations. This could have implications for local air quality standards and potentially affect human health in surrounding communities. Long-term monitoring of air quality parameters would be essential to assess the cumulative impact of these operational changes.

Soil contamination risks must also be carefully examined. High-density fluids, if leaked or spilled due to modified valve operations, could potentially contaminate soil and groundwater. The assessment should include a thorough analysis of soil characteristics, groundwater flow patterns, and potential contaminant migration pathways. Mitigation measures, such as improved containment systems or leak detection technologies, should be proposed to minimize these risks.

Noise pollution is another environmental concern that requires attention. Modified valve operations may lead to changes in noise levels, potentially affecting local wildlife and nearby residential areas. The assessment should include noise modeling studies to predict potential impacts and propose noise reduction strategies if necessary.

Furthermore, the environmental impact assessment must consider the broader ecological context. This includes evaluating potential effects on local flora and fauna, especially any endangered or protected species in the vicinity. Habitat fragmentation or disturbance due to increased operational activities should be carefully analyzed.

Lastly, the assessment should address the potential for cumulative environmental impacts. This involves considering the combined effects of the modified valve operations with other existing or planned industrial activities in the area. A holistic approach to environmental impact assessment will ensure a comprehensive understanding of the potential consequences and guide the development of effective mitigation strategies.

Firstly, the assessment must consider the impact on local water bodies. High-density fluid movement through modified gate valves may lead to increased turbidity in nearby streams or rivers. This could affect aquatic ecosystems by reducing light penetration, impacting photosynthetic organisms, and potentially altering the food chain. Additionally, changes in fluid dynamics may influence sediment transport patterns, potentially leading to erosion or deposition issues in downstream areas.

Air quality is another critical factor to evaluate. The modified protocols might result in increased emissions of volatile organic compounds (VOCs) or particulate matter during valve operations. This could have implications for local air quality standards and potentially affect human health in surrounding communities. Long-term monitoring of air quality parameters would be essential to assess the cumulative impact of these operational changes.

Soil contamination risks must also be carefully examined. High-density fluids, if leaked or spilled due to modified valve operations, could potentially contaminate soil and groundwater. The assessment should include a thorough analysis of soil characteristics, groundwater flow patterns, and potential contaminant migration pathways. Mitigation measures, such as improved containment systems or leak detection technologies, should be proposed to minimize these risks.

Noise pollution is another environmental concern that requires attention. Modified valve operations may lead to changes in noise levels, potentially affecting local wildlife and nearby residential areas. The assessment should include noise modeling studies to predict potential impacts and propose noise reduction strategies if necessary.

Furthermore, the environmental impact assessment must consider the broader ecological context. This includes evaluating potential effects on local flora and fauna, especially any endangered or protected species in the vicinity. Habitat fragmentation or disturbance due to increased operational activities should be carefully analyzed.

Lastly, the assessment should address the potential for cumulative environmental impacts. This involves considering the combined effects of the modified valve operations with other existing or planned industrial activities in the area. A holistic approach to environmental impact assessment will ensure a comprehensive understanding of the potential consequences and guide the development of effective mitigation strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!