Analysis of gate valve innovations in precision chemical dosing systems

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Objectives

Gate valves have played a crucial role in fluid control systems for over a century, evolving significantly to meet the demands of precision chemical dosing applications. The journey of gate valve technology began in the late 19th century with simple designs primarily used in water and steam systems. As industrial processes became more complex, the need for precise control in chemical handling emerged, driving innovations in gate valve design and functionality.

The evolution of gate valves in precision chemical dosing systems has been marked by several key milestones. In the mid-20th century, the introduction of corrosion-resistant materials such as stainless steel and specialized alloys allowed for the handling of aggressive chemicals. This was followed by the development of improved sealing technologies, including advanced elastomers and metal-to-metal seals, which significantly enhanced leak prevention and dosing accuracy.

The advent of computer-controlled systems in the late 20th century revolutionized gate valve operation in chemical dosing. Precision actuators and digital control interfaces enabled real-time adjustments and remote operation, vastly improving the accuracy and reliability of dosing processes. This technological leap also facilitated the integration of gate valves into broader automated control systems, allowing for more sophisticated chemical management in various industries.

Recent innovations have focused on miniaturization and enhanced precision. Micro-gate valves capable of handling minute quantities of chemicals with extreme accuracy have become essential in fields such as pharmaceutical manufacturing and microfluidics. Additionally, the incorporation of smart sensors and IoT connectivity has enabled predictive maintenance and real-time monitoring of valve performance, further optimizing chemical dosing operations.

The primary objectives driving gate valve innovations in precision chemical dosing systems are multifaceted. Foremost is the pursuit of unparalleled accuracy in chemical dispensing, aiming to achieve consistent and precise flow control down to the microliter level. Equally important is the goal of enhancing durability and reliability, particularly in harsh chemical environments, to ensure long-term performance and minimize downtime.

Another critical objective is the improvement of safety features, including fail-safe mechanisms and advanced leak detection systems, to protect both personnel and the environment from potential chemical hazards. Furthermore, there is a growing emphasis on developing eco-friendly valve designs that minimize waste and energy consumption, aligning with global sustainability initiatives.

Looking ahead, the future objectives for gate valve technology in precision chemical dosing systems include further integration with artificial intelligence for autonomous operation and self-optimization. There is also a push towards developing universal valve designs capable of handling a wide range of chemicals without the need for frequent replacements or modifications, potentially revolutionizing chemical processing industries.

The evolution of gate valves in precision chemical dosing systems has been marked by several key milestones. In the mid-20th century, the introduction of corrosion-resistant materials such as stainless steel and specialized alloys allowed for the handling of aggressive chemicals. This was followed by the development of improved sealing technologies, including advanced elastomers and metal-to-metal seals, which significantly enhanced leak prevention and dosing accuracy.

The advent of computer-controlled systems in the late 20th century revolutionized gate valve operation in chemical dosing. Precision actuators and digital control interfaces enabled real-time adjustments and remote operation, vastly improving the accuracy and reliability of dosing processes. This technological leap also facilitated the integration of gate valves into broader automated control systems, allowing for more sophisticated chemical management in various industries.

Recent innovations have focused on miniaturization and enhanced precision. Micro-gate valves capable of handling minute quantities of chemicals with extreme accuracy have become essential in fields such as pharmaceutical manufacturing and microfluidics. Additionally, the incorporation of smart sensors and IoT connectivity has enabled predictive maintenance and real-time monitoring of valve performance, further optimizing chemical dosing operations.

The primary objectives driving gate valve innovations in precision chemical dosing systems are multifaceted. Foremost is the pursuit of unparalleled accuracy in chemical dispensing, aiming to achieve consistent and precise flow control down to the microliter level. Equally important is the goal of enhancing durability and reliability, particularly in harsh chemical environments, to ensure long-term performance and minimize downtime.

Another critical objective is the improvement of safety features, including fail-safe mechanisms and advanced leak detection systems, to protect both personnel and the environment from potential chemical hazards. Furthermore, there is a growing emphasis on developing eco-friendly valve designs that minimize waste and energy consumption, aligning with global sustainability initiatives.

Looking ahead, the future objectives for gate valve technology in precision chemical dosing systems include further integration with artificial intelligence for autonomous operation and self-optimization. There is also a push towards developing universal valve designs capable of handling a wide range of chemicals without the need for frequent replacements or modifications, potentially revolutionizing chemical processing industries.

Chemical Dosing Market Analysis

The chemical dosing market has experienced significant growth in recent years, driven by increasing demand for precise and efficient chemical management across various industries. This market encompasses a wide range of applications, including water treatment, food and beverage production, pharmaceuticals, and industrial processes. The global chemical dosing market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors contributing to market growth is the rising emphasis on water and wastewater treatment, particularly in developing countries. Stringent environmental regulations and the need for sustainable water management practices have led to increased adoption of chemical dosing systems in municipal and industrial water treatment facilities. Additionally, the food and beverage industry's focus on quality control and product consistency has further boosted the demand for precision chemical dosing solutions.

The pharmaceutical sector represents another significant driver of market growth, as manufacturers seek to enhance production efficiency and maintain strict quality standards. Chemical dosing systems play a crucial role in ensuring accurate ingredient proportions and maintaining consistent product quality throughout the manufacturing process. The growing trend towards automation and digitalization in industrial processes has also contributed to the expansion of the chemical dosing market, as companies invest in advanced dosing technologies to improve operational efficiency and reduce human error.

In terms of regional dynamics, Asia-Pacific is emerging as a key growth market for chemical dosing systems, driven by rapid industrialization, urbanization, and increasing investments in water infrastructure. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and adopting more advanced dosing technologies. The Middle East and Africa region is also showing promising growth potential, particularly in the water treatment sector.

The competitive landscape of the chemical dosing market is characterized by the presence of both established players and innovative startups. Key market players are investing heavily in research and development to introduce new products and technologies, with a focus on improving accuracy, reliability, and energy efficiency. Mergers and acquisitions have become increasingly common as companies seek to expand their product portfolios and geographical presence.

Looking ahead, several trends are expected to shape the future of the chemical dosing market. These include the integration of Internet of Things (IoT) and artificial intelligence technologies to enable predictive maintenance and real-time monitoring of dosing systems, the development of more compact and modular dosing solutions for space-constrained applications, and the increasing adoption of eco-friendly and biodegradable chemicals in dosing processes. As industries continue to prioritize precision, efficiency, and sustainability, the chemical dosing market is poised for continued growth and innovation in the coming years.

One of the key factors contributing to market growth is the rising emphasis on water and wastewater treatment, particularly in developing countries. Stringent environmental regulations and the need for sustainable water management practices have led to increased adoption of chemical dosing systems in municipal and industrial water treatment facilities. Additionally, the food and beverage industry's focus on quality control and product consistency has further boosted the demand for precision chemical dosing solutions.

The pharmaceutical sector represents another significant driver of market growth, as manufacturers seek to enhance production efficiency and maintain strict quality standards. Chemical dosing systems play a crucial role in ensuring accurate ingredient proportions and maintaining consistent product quality throughout the manufacturing process. The growing trend towards automation and digitalization in industrial processes has also contributed to the expansion of the chemical dosing market, as companies invest in advanced dosing technologies to improve operational efficiency and reduce human error.

In terms of regional dynamics, Asia-Pacific is emerging as a key growth market for chemical dosing systems, driven by rapid industrialization, urbanization, and increasing investments in water infrastructure. North America and Europe continue to be significant markets, with a focus on upgrading existing infrastructure and adopting more advanced dosing technologies. The Middle East and Africa region is also showing promising growth potential, particularly in the water treatment sector.

The competitive landscape of the chemical dosing market is characterized by the presence of both established players and innovative startups. Key market players are investing heavily in research and development to introduce new products and technologies, with a focus on improving accuracy, reliability, and energy efficiency. Mergers and acquisitions have become increasingly common as companies seek to expand their product portfolios and geographical presence.

Looking ahead, several trends are expected to shape the future of the chemical dosing market. These include the integration of Internet of Things (IoT) and artificial intelligence technologies to enable predictive maintenance and real-time monitoring of dosing systems, the development of more compact and modular dosing solutions for space-constrained applications, and the increasing adoption of eco-friendly and biodegradable chemicals in dosing processes. As industries continue to prioritize precision, efficiency, and sustainability, the chemical dosing market is poised for continued growth and innovation in the coming years.

Current Gate Valve Challenges

Gate valves in precision chemical dosing systems face several significant challenges that hinder their optimal performance and reliability. One of the primary issues is the susceptibility to corrosion and chemical attack. The harsh chemical environment in which these valves operate can lead to material degradation, affecting the valve's sealing capabilities and overall lifespan. This challenge is particularly acute when dealing with highly reactive or corrosive chemicals, necessitating the use of specialized materials that may increase costs and complexity.

Another critical challenge is achieving and maintaining precise flow control. Traditional gate valve designs often struggle to provide the level of accuracy required for precision chemical dosing. The inherent design of gate valves, with their linear motion, can result in non-linear flow characteristics, making it difficult to achieve consistent and repeatable dosing across different operating conditions. This limitation can lead to inefficiencies in chemical processes and potentially compromise product quality in industries where precise chemical ratios are crucial.

Leakage prevention remains a persistent challenge for gate valves in these systems. The high-pressure environments and the need for frequent cycling can stress valve components, leading to wear and potential leak paths. Even minor leaks can have significant consequences in chemical dosing applications, ranging from process inefficiencies to safety hazards. The challenge is compounded by the need to balance tight sealing with ease of operation, as excessive sealing force can lead to increased wear and reduced valve life.

Maintenance and downtime issues also pose significant challenges. Gate valves in precision chemical dosing systems often require regular maintenance to ensure optimal performance. However, the complexity of these valves and the need for specialized skills can lead to extended downtime during maintenance or replacement. This downtime can be particularly problematic in continuous production environments where any interruption can result in substantial economic losses.

The challenge of scalability and adaptability is becoming increasingly important as industries demand more flexible and responsive chemical dosing systems. Gate valves must be able to handle a wide range of flow rates and chemical compositions while maintaining precision. However, traditional gate valve designs often struggle to provide this flexibility without compromising performance or requiring significant modifications.

Lastly, the integration of smart technologies and automation presents both opportunities and challenges. While these advancements can potentially address some of the aforementioned issues, they also introduce new complexities. The challenge lies in developing gate valves that can seamlessly integrate with digital control systems, provide real-time feedback, and adapt to changing process conditions without sacrificing reliability or increasing system vulnerability to cyber threats.

Another critical challenge is achieving and maintaining precise flow control. Traditional gate valve designs often struggle to provide the level of accuracy required for precision chemical dosing. The inherent design of gate valves, with their linear motion, can result in non-linear flow characteristics, making it difficult to achieve consistent and repeatable dosing across different operating conditions. This limitation can lead to inefficiencies in chemical processes and potentially compromise product quality in industries where precise chemical ratios are crucial.

Leakage prevention remains a persistent challenge for gate valves in these systems. The high-pressure environments and the need for frequent cycling can stress valve components, leading to wear and potential leak paths. Even minor leaks can have significant consequences in chemical dosing applications, ranging from process inefficiencies to safety hazards. The challenge is compounded by the need to balance tight sealing with ease of operation, as excessive sealing force can lead to increased wear and reduced valve life.

Maintenance and downtime issues also pose significant challenges. Gate valves in precision chemical dosing systems often require regular maintenance to ensure optimal performance. However, the complexity of these valves and the need for specialized skills can lead to extended downtime during maintenance or replacement. This downtime can be particularly problematic in continuous production environments where any interruption can result in substantial economic losses.

The challenge of scalability and adaptability is becoming increasingly important as industries demand more flexible and responsive chemical dosing systems. Gate valves must be able to handle a wide range of flow rates and chemical compositions while maintaining precision. However, traditional gate valve designs often struggle to provide this flexibility without compromising performance or requiring significant modifications.

Lastly, the integration of smart technologies and automation presents both opportunities and challenges. While these advancements can potentially address some of the aforementioned issues, they also introduce new complexities. The challenge lies in developing gate valves that can seamlessly integrate with digital control systems, provide real-time feedback, and adapt to changing process conditions without sacrificing reliability or increasing system vulnerability to cyber threats.

Existing Gate Valve Solutions

01 Precision control mechanisms for gate valves

Advanced control mechanisms are implemented in gate valves to enhance precision. These may include electronic sensors, actuators, and feedback systems that allow for more accurate positioning and control of the valve gate. Such mechanisms improve the overall performance and reliability of the valve in various applications.- Precision control mechanisms for gate valves: Advanced control mechanisms are implemented in gate valves to enhance precision. These may include electronic sensors, actuators, and feedback systems that allow for more accurate positioning and control of the valve opening. Such mechanisms improve the overall performance and reliability of gate valves in various applications.

- Innovative sealing technologies for gate valves: New sealing technologies are developed to improve the precision and leak-tightness of gate valves. These may include advanced materials, novel seal designs, or multi-layer sealing systems that can withstand high pressures and temperatures while maintaining tight tolerances.

- Precision manufacturing techniques for gate valve components: Advanced manufacturing techniques are employed to produce gate valve components with high precision. These may include CNC machining, 3D printing, or other cutting-edge fabrication methods that allow for tighter tolerances and improved surface finishes on critical parts.

- Integration of smart technologies in gate valves: Gate valves are being equipped with smart technologies to enhance their precision and functionality. This may include IoT connectivity, real-time monitoring systems, and predictive maintenance capabilities, allowing for more accurate control and improved operational efficiency.

- Precision flow control features in gate valves: Innovative design features are incorporated into gate valves to achieve more precise flow control. These may include specially shaped gates, multiple stages, or integrated flow measurement devices that allow for finer adjustments and more accurate regulation of fluid flow.

02 Improved sealing technologies for gate valves

Novel sealing technologies are developed to enhance the precision and effectiveness of gate valves. These may include advanced materials, innovative seal designs, and optimized sealing surfaces that minimize leakage and improve the valve's ability to maintain a tight seal under various operating conditions.Expand Specific Solutions03 Gate valve designs for high-precision applications

Specialized gate valve designs are created for high-precision applications. These designs may incorporate features such as precision-machined components, tight tolerances, and advanced materials to ensure accurate flow control and reliable operation in demanding environments.Expand Specific Solutions04 Integration of smart technologies in gate valves

Gate valves are enhanced with smart technologies to improve precision and functionality. This may include the integration of IoT sensors, real-time monitoring systems, and data analytics capabilities, allowing for predictive maintenance, remote operation, and optimized performance in various industrial settings.Expand Specific Solutions05 Precision manufacturing techniques for gate valve components

Advanced manufacturing techniques are employed to produce high-precision gate valve components. These may include CNC machining, 3D printing, and other cutting-edge fabrication methods that enable the production of complex geometries and tight tolerances, resulting in improved valve performance and reliability.Expand Specific Solutions

Key Players in Precision Dosing

The gate valve innovation landscape in precision chemical dosing systems is characterized by a mature market with steady growth. The global market size for precision dosing valves is estimated to be in the billions, driven by increasing demand in pharmaceutical, biotechnology, and chemical industries. Technologically, the field is advancing with innovations in materials, precision control, and integration of smart features. Companies like F. Hoffmann-La Roche Ltd., Nemera La Verpilliere SAS, and Gemu Valves, Inc. are at the forefront, developing high-precision valves with enhanced reliability and accuracy. The industry is seeing a shift towards miniaturization, improved sealing technologies, and the incorporation of IoT capabilities for real-time monitoring and control.

Gemu Valves, Inc.

Technical Solution: Gemu Valves has developed innovative gate valve solutions for precision chemical dosing systems. Their technology incorporates advanced sealing materials and precision-engineered valve bodies to ensure accurate and repeatable dosing. The company's gate valves feature a unique diaphragm design that allows for precise control of flow rates, even with highly corrosive or viscous chemicals[1]. Gemu's valves also integrate smart sensors and actuators for real-time monitoring and adjustment of dosing parameters, enhancing overall system efficiency and reliability[3]. The valves are designed with a modular architecture, allowing for easy maintenance and customization to specific application requirements[5].

Strengths: High precision control, compatibility with corrosive chemicals, and smart monitoring capabilities. Weaknesses: Potentially higher cost compared to traditional valves and may require specialized training for operation and maintenance.

Qisheng Valve Co., Ltd.

Technical Solution: Qisheng Valve Co. has introduced a series of gate valves specifically designed for precision chemical dosing systems. Their innovation lies in the use of advanced materials such as high-performance polymers and corrosion-resistant alloys to withstand aggressive chemicals[2]. The company has developed a proprietary sealing technology that minimizes leakage and ensures consistent dosing accuracy over extended periods[4]. Qisheng's gate valves incorporate a multi-stage flow control mechanism, allowing for fine-tuning of chemical flow rates across a wide range of operating conditions[6]. Additionally, the valves feature a compact design with reduced internal volume, minimizing dead space and improving system responsiveness[8].

Strengths: Excellent chemical resistance, high dosing accuracy, and compact design. Weaknesses: May have limitations in extremely high-pressure applications and could require more frequent maintenance in harsh environments.

Core Gate Valve Innovations

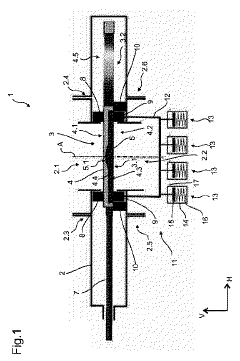

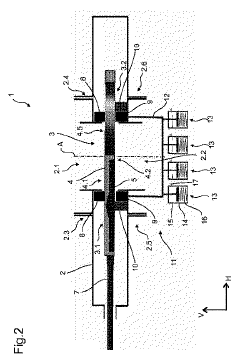

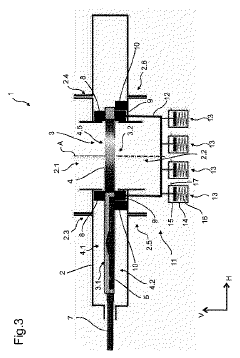

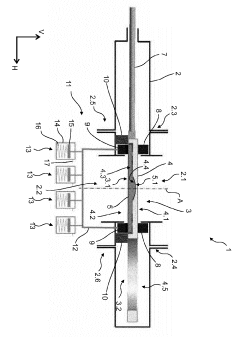

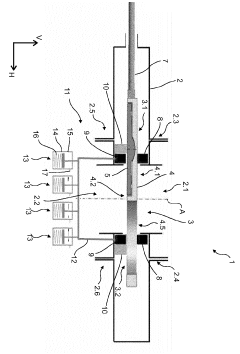

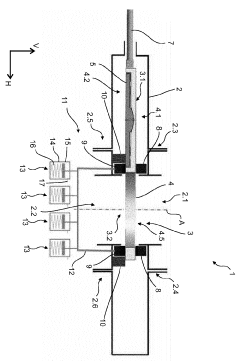

Gate valve for chemical plants

PatentInactiveJP2019533123A

Innovation

- A gate valve design featuring two independent sealing means, with a fixed upper sealing sheet and a movable lower sealing sheet, each supported by separate plates, which are thermally and structurally decoupled to minimize deformation and friction, using a pretensioned tightening device and actuator for controlled sealing engagement.

Gate valves for chemical plants

PatentInactiveKR1020190047109A

Innovation

- A gate valve design featuring two independent sealing plates, where one plate is protected from extreme temperatures and pressures, with a gap between them to minimize thermal deformation, and a clamping device that applies force only when needed, reducing friction and maintaining sealing integrity.

Material Compatibility Analysis

Material compatibility is a critical factor in the design and operation of precision chemical dosing systems, particularly concerning gate valve innovations. The selection of appropriate materials for valve components directly impacts system performance, longevity, and safety. In chemical dosing applications, valves are exposed to a wide range of corrosive and aggressive substances, necessitating careful consideration of material properties.

Stainless steel alloys, such as 316L and 904L, are commonly used in gate valve construction due to their excellent corrosion resistance and mechanical strength. These alloys offer superior performance in handling a broad spectrum of chemicals, including acids, bases, and oxidizing agents. However, for extremely corrosive environments, more specialized materials like Hastelloy, Monel, or titanium may be required to ensure long-term reliability and prevent premature valve failure.

Polymeric materials also play a significant role in gate valve design for chemical dosing systems. Fluoropolymers, such as PTFE (Polytetrafluoroethylene) and PVDF (Polyvinylidene fluoride), are widely used for valve seats, seals, and linings due to their exceptional chemical resistance and low friction properties. These materials provide excellent sealing capabilities and minimize the risk of chemical leakage, which is crucial for maintaining dosing accuracy and system safety.

Recent innovations in material science have led to the development of advanced composites and ceramic materials for gate valve applications. These materials offer unique combinations of properties, such as high wear resistance, low thermal expansion, and excellent chemical inertness. For instance, silicon carbide and alumina ceramics are increasingly being used for valve components in highly abrasive or corrosive environments, where traditional metallic materials may fail prematurely.

The compatibility of elastomeric materials used in valve seals and gaskets is another critical consideration. Fluoroelastomers, such as Viton, and perfluoroelastomers like Kalrez, offer superior chemical resistance and temperature stability compared to conventional rubber materials. These advanced elastomers maintain their sealing properties even when exposed to aggressive chemicals, ensuring long-term valve performance and minimizing maintenance requirements.

In the context of precision chemical dosing, the selection of valve materials must also account for factors such as thermal expansion, dimensional stability, and surface finish. These properties directly influence the valve's ability to maintain precise flow control and dosing accuracy over time. Additionally, considerations such as FDA compliance and biocompatibility may be necessary for applications in pharmaceutical or food processing industries.

Stainless steel alloys, such as 316L and 904L, are commonly used in gate valve construction due to their excellent corrosion resistance and mechanical strength. These alloys offer superior performance in handling a broad spectrum of chemicals, including acids, bases, and oxidizing agents. However, for extremely corrosive environments, more specialized materials like Hastelloy, Monel, or titanium may be required to ensure long-term reliability and prevent premature valve failure.

Polymeric materials also play a significant role in gate valve design for chemical dosing systems. Fluoropolymers, such as PTFE (Polytetrafluoroethylene) and PVDF (Polyvinylidene fluoride), are widely used for valve seats, seals, and linings due to their exceptional chemical resistance and low friction properties. These materials provide excellent sealing capabilities and minimize the risk of chemical leakage, which is crucial for maintaining dosing accuracy and system safety.

Recent innovations in material science have led to the development of advanced composites and ceramic materials for gate valve applications. These materials offer unique combinations of properties, such as high wear resistance, low thermal expansion, and excellent chemical inertness. For instance, silicon carbide and alumina ceramics are increasingly being used for valve components in highly abrasive or corrosive environments, where traditional metallic materials may fail prematurely.

The compatibility of elastomeric materials used in valve seals and gaskets is another critical consideration. Fluoroelastomers, such as Viton, and perfluoroelastomers like Kalrez, offer superior chemical resistance and temperature stability compared to conventional rubber materials. These advanced elastomers maintain their sealing properties even when exposed to aggressive chemicals, ensuring long-term valve performance and minimizing maintenance requirements.

In the context of precision chemical dosing, the selection of valve materials must also account for factors such as thermal expansion, dimensional stability, and surface finish. These properties directly influence the valve's ability to maintain precise flow control and dosing accuracy over time. Additionally, considerations such as FDA compliance and biocompatibility may be necessary for applications in pharmaceutical or food processing industries.

Safety and Regulatory Compliance

Safety and regulatory compliance are paramount considerations in the development and implementation of gate valve innovations for precision chemical dosing systems. These systems often handle hazardous substances, making it crucial to adhere to stringent safety standards and regulatory requirements.

In the context of chemical dosing, gate valves play a critical role in controlling the flow of potentially dangerous substances. As such, they must be designed and manufactured to withstand corrosive chemicals, high pressures, and extreme temperatures. Materials selection is a key factor, with manufacturers increasingly turning to advanced alloys and composite materials that offer superior resistance to chemical degradation and mechanical stress.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) have established comprehensive guidelines for the handling of hazardous chemicals. These regulations often mandate specific safety features for valves used in chemical dosing systems, including fail-safe mechanisms, leak detection systems, and redundant sealing technologies.

Innovations in gate valve design for chemical dosing systems have focused on enhancing safety features. For instance, double block and bleed (DBB) configurations have become increasingly common, providing an additional layer of protection against leaks. Smart valve technologies incorporating sensors and real-time monitoring capabilities allow for early detection of potential failures, reducing the risk of chemical spills or exposure.

Compliance with international standards such as ISO 15848 for fugitive emissions and API 6D for pipeline valves is essential for manufacturers. These standards set rigorous testing protocols and performance criteria for valves used in critical applications. As environmental regulations become more stringent, there is a growing emphasis on developing low-emission valve designs that minimize the release of volatile organic compounds (VOCs) and other harmful substances.

The integration of safety interlocks and automated emergency shutdown systems has become a standard feature in modern gate valve designs for chemical dosing applications. These systems can rapidly isolate chemical flows in the event of a detected anomaly, significantly reducing the risk of accidents and environmental contamination.

As the industry moves towards more sustainable practices, there is an increasing focus on developing valve technologies that not only meet safety and regulatory requirements but also contribute to overall process efficiency and environmental protection. This includes the development of energy-efficient actuators and valve designs that minimize waste and optimize chemical usage in dosing systems.

In the context of chemical dosing, gate valves play a critical role in controlling the flow of potentially dangerous substances. As such, they must be designed and manufactured to withstand corrosive chemicals, high pressures, and extreme temperatures. Materials selection is a key factor, with manufacturers increasingly turning to advanced alloys and composite materials that offer superior resistance to chemical degradation and mechanical stress.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) have established comprehensive guidelines for the handling of hazardous chemicals. These regulations often mandate specific safety features for valves used in chemical dosing systems, including fail-safe mechanisms, leak detection systems, and redundant sealing technologies.

Innovations in gate valve design for chemical dosing systems have focused on enhancing safety features. For instance, double block and bleed (DBB) configurations have become increasingly common, providing an additional layer of protection against leaks. Smart valve technologies incorporating sensors and real-time monitoring capabilities allow for early detection of potential failures, reducing the risk of chemical spills or exposure.

Compliance with international standards such as ISO 15848 for fugitive emissions and API 6D for pipeline valves is essential for manufacturers. These standards set rigorous testing protocols and performance criteria for valves used in critical applications. As environmental regulations become more stringent, there is a growing emphasis on developing low-emission valve designs that minimize the release of volatile organic compounds (VOCs) and other harmful substances.

The integration of safety interlocks and automated emergency shutdown systems has become a standard feature in modern gate valve designs for chemical dosing applications. These systems can rapidly isolate chemical flows in the event of a detected anomaly, significantly reducing the risk of accidents and environmental contamination.

As the industry moves towards more sustainable practices, there is an increasing focus on developing valve technologies that not only meet safety and regulatory requirements but also contribute to overall process efficiency and environmental protection. This includes the development of energy-efficient actuators and valve designs that minimize waste and optimize chemical usage in dosing systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!