Exploring bio-inspired designs in modern gate valve systems

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Inspired Valve Evolution

The evolution of bio-inspired valve designs in modern gate valve systems represents a fascinating convergence of nature's ingenuity and engineering innovation. This evolutionary process has been driven by the need for more efficient, reliable, and sustainable valve solutions across various industries. The journey began with observations of natural valve-like structures in living organisms, such as the human heart valves and the Venus flytrap's rapid closure mechanism.

Early attempts to mimic these biological systems in industrial valve designs were rudimentary, focusing primarily on basic structural similarities. However, as our understanding of biomechanics and materials science advanced, so did the sophistication of bio-inspired valve designs. The first significant breakthrough came with the development of flexible, leaf-like valve structures that could respond to fluid flow dynamics in a manner similar to natural valves.

As research progressed, engineers began to incorporate more complex biological principles into valve designs. For instance, the study of blood flow through heart valves led to the creation of gate valves with optimized flow patterns, reducing turbulence and improving overall efficiency. Similarly, the rapid response mechanisms observed in carnivorous plants inspired the development of quick-acting valve systems with minimal energy requirements.

The advent of advanced manufacturing techniques, particularly 3D printing and nanotechnology, has further accelerated the evolution of bio-inspired valve designs. These technologies have enabled the creation of intricate valve structures with micro-scale features that closely mimic their biological counterparts. For example, valve surfaces with biomimetic textures have been developed to reduce friction and wear, inspired by the low-friction properties of shark skin.

Recent years have seen a shift towards "smart" bio-inspired valves that can adapt to changing environmental conditions. Drawing inspiration from the sensory capabilities of plants and animals, these valves incorporate sensors and actuators that allow them to respond dynamically to variations in pressure, temperature, or fluid composition. This adaptive behavior not only enhances performance but also contributes to increased longevity and reduced maintenance requirements.

The latest frontier in bio-inspired valve evolution involves the integration of self-healing materials, mimicking the regenerative capabilities of living tissues. These innovative designs incorporate materials that can automatically repair minor damage, significantly extending the operational life of valve systems and reducing the need for manual interventions.

As we look to the future, the evolution of bio-inspired valve designs continues to push the boundaries of what is possible in fluid control systems. Researchers are now exploring the potential of biomolecular motors and cellular mechanisms to create valve systems that operate at the nanoscale, opening up new possibilities for applications in fields such as microfluidics and targeted drug delivery.

Early attempts to mimic these biological systems in industrial valve designs were rudimentary, focusing primarily on basic structural similarities. However, as our understanding of biomechanics and materials science advanced, so did the sophistication of bio-inspired valve designs. The first significant breakthrough came with the development of flexible, leaf-like valve structures that could respond to fluid flow dynamics in a manner similar to natural valves.

As research progressed, engineers began to incorporate more complex biological principles into valve designs. For instance, the study of blood flow through heart valves led to the creation of gate valves with optimized flow patterns, reducing turbulence and improving overall efficiency. Similarly, the rapid response mechanisms observed in carnivorous plants inspired the development of quick-acting valve systems with minimal energy requirements.

The advent of advanced manufacturing techniques, particularly 3D printing and nanotechnology, has further accelerated the evolution of bio-inspired valve designs. These technologies have enabled the creation of intricate valve structures with micro-scale features that closely mimic their biological counterparts. For example, valve surfaces with biomimetic textures have been developed to reduce friction and wear, inspired by the low-friction properties of shark skin.

Recent years have seen a shift towards "smart" bio-inspired valves that can adapt to changing environmental conditions. Drawing inspiration from the sensory capabilities of plants and animals, these valves incorporate sensors and actuators that allow them to respond dynamically to variations in pressure, temperature, or fluid composition. This adaptive behavior not only enhances performance but also contributes to increased longevity and reduced maintenance requirements.

The latest frontier in bio-inspired valve evolution involves the integration of self-healing materials, mimicking the regenerative capabilities of living tissues. These innovative designs incorporate materials that can automatically repair minor damage, significantly extending the operational life of valve systems and reducing the need for manual interventions.

As we look to the future, the evolution of bio-inspired valve designs continues to push the boundaries of what is possible in fluid control systems. Researchers are now exploring the potential of biomolecular motors and cellular mechanisms to create valve systems that operate at the nanoscale, opening up new possibilities for applications in fields such as microfluidics and targeted drug delivery.

Market Demand Analysis

The market demand for bio-inspired designs in modern gate valve systems has been steadily increasing in recent years. This trend is driven by the growing need for more efficient, reliable, and sustainable valve solutions across various industries. The global valve market, which includes gate valves, is projected to reach a substantial value in the coming years, with bio-inspired designs playing a significant role in this growth.

Industries such as oil and gas, water treatment, chemical processing, and power generation are particularly interested in bio-inspired gate valve systems. These sectors require valves that can withstand harsh operating conditions, minimize energy consumption, and reduce maintenance costs. Bio-inspired designs offer potential solutions to these challenges by mimicking natural structures and mechanisms that have evolved over millions of years.

One of the key drivers of market demand is the increasing focus on energy efficiency and sustainability. Bio-inspired gate valve designs often incorporate features that reduce friction, improve flow characteristics, and enhance sealing capabilities. These improvements can lead to significant energy savings in industrial processes, aligning with global efforts to reduce carbon emissions and operational costs.

The water management sector presents a particularly promising market for bio-inspired gate valve systems. With growing concerns over water scarcity and the need for efficient distribution systems, there is a rising demand for valves that can minimize leakage, reduce pressure drops, and operate reliably under varying conditions. Bio-inspired designs that emulate natural water flow systems or incorporate self-cleaning mechanisms are attracting considerable attention from water utilities and treatment facilities.

In the oil and gas industry, the demand for bio-inspired gate valves is driven by the need for improved performance in extreme environments. Valves inspired by organisms that thrive in high-pressure or corrosive conditions could offer enhanced durability and reliability, reducing downtime and maintenance costs in offshore and subsea applications.

The chemical processing industry is another significant market for bio-inspired gate valve systems. Here, the focus is on designs that can handle corrosive substances more effectively, prevent material buildup, and maintain consistent performance over extended periods. Bio-inspired surface textures and materials that resist fouling or facilitate self-cleaning are of particular interest to chemical manufacturers.

As industries continue to embrace digitalization and automation, there is a growing demand for smart valve solutions. Bio-inspired designs that incorporate sensing capabilities or adaptive behaviors could integrate seamlessly with Industrial Internet of Things (IIoT) systems, offering real-time monitoring and predictive maintenance features.

The market for bio-inspired gate valve systems is expected to see substantial growth in emerging economies, particularly in Asia-Pacific and the Middle East. Rapid industrialization and infrastructure development in these regions are driving the demand for advanced valve technologies that can meet stringent performance and efficiency requirements.

Industries such as oil and gas, water treatment, chemical processing, and power generation are particularly interested in bio-inspired gate valve systems. These sectors require valves that can withstand harsh operating conditions, minimize energy consumption, and reduce maintenance costs. Bio-inspired designs offer potential solutions to these challenges by mimicking natural structures and mechanisms that have evolved over millions of years.

One of the key drivers of market demand is the increasing focus on energy efficiency and sustainability. Bio-inspired gate valve designs often incorporate features that reduce friction, improve flow characteristics, and enhance sealing capabilities. These improvements can lead to significant energy savings in industrial processes, aligning with global efforts to reduce carbon emissions and operational costs.

The water management sector presents a particularly promising market for bio-inspired gate valve systems. With growing concerns over water scarcity and the need for efficient distribution systems, there is a rising demand for valves that can minimize leakage, reduce pressure drops, and operate reliably under varying conditions. Bio-inspired designs that emulate natural water flow systems or incorporate self-cleaning mechanisms are attracting considerable attention from water utilities and treatment facilities.

In the oil and gas industry, the demand for bio-inspired gate valves is driven by the need for improved performance in extreme environments. Valves inspired by organisms that thrive in high-pressure or corrosive conditions could offer enhanced durability and reliability, reducing downtime and maintenance costs in offshore and subsea applications.

The chemical processing industry is another significant market for bio-inspired gate valve systems. Here, the focus is on designs that can handle corrosive substances more effectively, prevent material buildup, and maintain consistent performance over extended periods. Bio-inspired surface textures and materials that resist fouling or facilitate self-cleaning are of particular interest to chemical manufacturers.

As industries continue to embrace digitalization and automation, there is a growing demand for smart valve solutions. Bio-inspired designs that incorporate sensing capabilities or adaptive behaviors could integrate seamlessly with Industrial Internet of Things (IIoT) systems, offering real-time monitoring and predictive maintenance features.

The market for bio-inspired gate valve systems is expected to see substantial growth in emerging economies, particularly in Asia-Pacific and the Middle East. Rapid industrialization and infrastructure development in these regions are driving the demand for advanced valve technologies that can meet stringent performance and efficiency requirements.

Current Challenges

Despite the significant advancements in gate valve systems, several challenges persist in the field of bio-inspired designs. One of the primary obstacles is the complexity of translating biological mechanisms into practical engineering solutions. Natural systems have evolved over millions of years, developing intricate structures and functions that are often difficult to replicate in artificial settings. This complexity poses a significant challenge in terms of design, materials selection, and manufacturing processes.

Another major hurdle is the scalability of bio-inspired designs. While nature provides excellent examples of efficient valve-like structures at microscopic levels, scaling these designs up to industrial applications often results in a loss of functionality or efficiency. This scaling issue is particularly pronounced in gate valve systems, where the demands of high-pressure, high-flow environments can be vastly different from the conditions in which biological valves operate.

Material limitations also present a substantial challenge. Biological systems often utilize materials with unique properties that are not easily replicated in synthetic materials. For instance, the flexibility, durability, and self-healing capabilities of certain biological valves are difficult to achieve with current engineering materials. This gap in material properties can limit the potential benefits of bio-inspired designs in gate valve systems.

Furthermore, the dynamic nature of biological systems poses a challenge in creating static engineering solutions. Many biological valves adapt and respond to changing environmental conditions, a feature that is difficult to incorporate into traditional gate valve designs. This lack of adaptability can result in suboptimal performance under varying operational conditions.

The integration of bio-inspired designs with existing industrial standards and practices is another significant challenge. Many industries have established norms and regulations for valve systems, which may not easily accommodate radical bio-inspired innovations. This resistance to change can slow down the adoption of potentially beneficial bio-inspired technologies.

Lastly, there is a knowledge gap between biologists and engineers. Effective bio-inspired design requires a deep understanding of both biological systems and engineering principles. However, interdisciplinary collaboration between these fields is often limited, hindering the development of truly innovative bio-inspired gate valve systems. Bridging this gap requires not only technical expertise but also effective communication and collaboration strategies across disciplines.

Another major hurdle is the scalability of bio-inspired designs. While nature provides excellent examples of efficient valve-like structures at microscopic levels, scaling these designs up to industrial applications often results in a loss of functionality or efficiency. This scaling issue is particularly pronounced in gate valve systems, where the demands of high-pressure, high-flow environments can be vastly different from the conditions in which biological valves operate.

Material limitations also present a substantial challenge. Biological systems often utilize materials with unique properties that are not easily replicated in synthetic materials. For instance, the flexibility, durability, and self-healing capabilities of certain biological valves are difficult to achieve with current engineering materials. This gap in material properties can limit the potential benefits of bio-inspired designs in gate valve systems.

Furthermore, the dynamic nature of biological systems poses a challenge in creating static engineering solutions. Many biological valves adapt and respond to changing environmental conditions, a feature that is difficult to incorporate into traditional gate valve designs. This lack of adaptability can result in suboptimal performance under varying operational conditions.

The integration of bio-inspired designs with existing industrial standards and practices is another significant challenge. Many industries have established norms and regulations for valve systems, which may not easily accommodate radical bio-inspired innovations. This resistance to change can slow down the adoption of potentially beneficial bio-inspired technologies.

Lastly, there is a knowledge gap between biologists and engineers. Effective bio-inspired design requires a deep understanding of both biological systems and engineering principles. However, interdisciplinary collaboration between these fields is often limited, hindering the development of truly innovative bio-inspired gate valve systems. Bridging this gap requires not only technical expertise but also effective communication and collaboration strategies across disciplines.

Existing Bio-Inspired Solutions

01 Gate valve design and structure

Gate valve systems incorporate various design elements to improve functionality and performance. These may include specific gate configurations, sealing mechanisms, and structural components that enhance durability and reliability. Advanced designs focus on optimizing flow control, reducing wear, and improving overall efficiency in different industrial applications.- Gate valve design and structure: Gate valve systems often feature innovative designs and structures to improve performance and reliability. These may include specialized sealing mechanisms, optimized flow paths, and robust construction materials to withstand high pressures and harsh environments. Advanced designs can enhance valve longevity, reduce maintenance requirements, and improve overall system efficiency.

- Actuation and control mechanisms: Various actuation and control mechanisms are employed in gate valve systems to facilitate precise operation. These can include electric, hydraulic, or pneumatic actuators, as well as manual override options. Advanced control systems may incorporate sensors and automation features for remote operation and monitoring, enhancing safety and operational efficiency in industrial applications.

- Sealing and leak prevention: Gate valve systems often incorporate advanced sealing technologies to prevent leaks and ensure proper isolation. This may include specialized seat designs, multiple sealing surfaces, and self-adjusting mechanisms to maintain seal integrity under varying pressure conditions. Materials selection plays a crucial role in achieving long-lasting and effective seals in different operating environments.

- Flow control and optimization: Gate valve systems are designed to provide efficient flow control and optimization in various applications. This can involve features such as streamlined gate designs, variable opening mechanisms, and flow-directing components. Advanced systems may incorporate computational fluid dynamics to optimize valve geometry for specific flow requirements and minimize pressure drops across the valve.

- Maintenance and serviceability: Improving maintenance and serviceability is a key focus in gate valve system design. This includes features such as easily accessible components, modular construction for quick replacement of wear parts, and in-line serviceability. Some designs incorporate self-cleaning mechanisms or special coatings to reduce buildup and extend maintenance intervals, thereby minimizing downtime and operational costs.

02 Actuation and control mechanisms

Gate valve systems employ diverse actuation and control mechanisms to facilitate precise operation. These may include manual, pneumatic, hydraulic, or electric actuators, as well as advanced control systems for remote operation. Such mechanisms ensure accurate valve positioning, smooth operation, and integration with broader control systems in industrial processes.Expand Specific Solutions03 Sealing and leak prevention

Effective sealing and leak prevention are crucial aspects of gate valve systems. Various sealing technologies and materials are employed to ensure tight shut-off and prevent fluid leakage. This may include specialized seat designs, advanced sealing materials, and pressure-balancing features to maintain seal integrity under different operating conditions.Expand Specific Solutions04 Maintenance and serviceability

Gate valve systems are designed with maintenance and serviceability in mind. Features may include easily accessible components, modular designs for quick replacement of parts, and self-cleaning mechanisms. These design considerations aim to reduce downtime, simplify maintenance procedures, and extend the operational life of the valve system.Expand Specific Solutions05 Specialized applications and adaptations

Gate valve systems are adapted for specialized applications in various industries. This includes designs for high-pressure or high-temperature environments, corrosive fluids, or specific flow control requirements. Specialized materials, coatings, and structural modifications are employed to meet the demands of these unique operating conditions and ensure reliable performance.Expand Specific Solutions

Key Industry Players

The bio-inspired design in modern gate valve systems is an emerging field at the intersection of biology and engineering, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for efficient and sustainable valve solutions across industries. The technology's maturity is still evolving, with key players like China Southern Power Grid Research Institute, Harbin Engineering University, and Edwards Lifesciences Corp. leading research efforts. Companies such as Control Components, Inc. and Worldwide Oilfield Machine, Inc. are exploring practical applications, while academic institutions like the University of Michigan and Fuzhou University contribute to fundamental research. This collaborative ecosystem of industry and academia is gradually advancing the technology towards commercial viability.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered bio-inspired gate valve designs based on the principles of fish gills and insect spiracles. Their innovative approach utilizes a series of microfluidic channels with flexible membranes that can rapidly open and close to regulate flow[2]. This design allows for precise control of fluid dynamics and can be scaled for various applications. The research team has also incorporated smart materials that respond to environmental stimuli, enabling autonomous valve operation in response to changes in temperature, pressure, or chemical composition[4].

Strengths: High precision control, scalability, and potential for autonomous operation. Weaknesses: Fabrication challenges at larger scales and potential for clogging in particulate-laden fluids.

Edwards Lifesciences Corp.

Technical Solution: Edwards Lifesciences has applied bio-inspired principles to their transcatheter heart valve systems, which can be relevant to industrial gate valve design. Their valves use bovine pericardial tissue mounted on a collapsible metal frame, mimicking natural heart valve function[5]. This design allows for minimally invasive deployment and excellent hemodynamics. The company has also developed synthetic leaflets that replicate the mechanical properties of natural tissue, potentially applicable to industrial valve systems requiring durability and flexibility[6].

Strengths: Proven biocompatibility, excellent flow characteristics, and minimally invasive deployment. Weaknesses: High cost and potential limitations in scaling to larger industrial applications.

Biomimetic Innovations

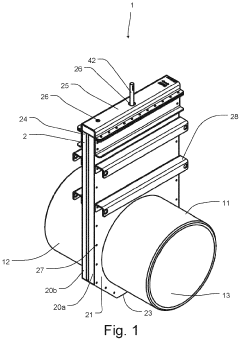

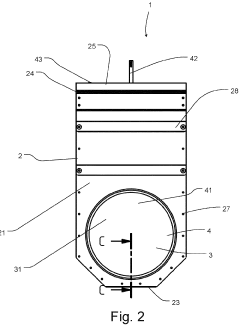

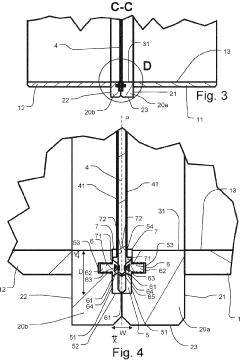

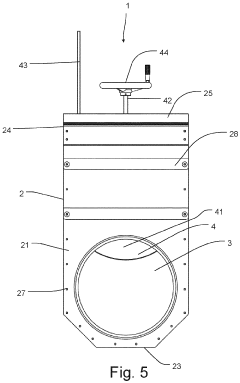

Gate valve

PatentInactiveEP1058797A1

Innovation

- The gate valve design features oval flow and blocking surfaces with transverse longitudinal axes, reducing overall height and flow losses, allowing for a shorter housing neck and increased pressure load capacity, and uses an offset oval flow cross-section to accommodate larger nominal sizes with 8-hole flanges, along with a clamping housing or flanges for easier assembly and reduced drag coefficient.

A gate valve

PatentActiveEP3954930A1

Innovation

- Incorporating a protrusion made of a more rigid material than the sealing members, positioned closer to the flow opening, which acts as a barrier to prevent deformation of the gate plate and retain the sealing members in place, reducing the force needed to open and close the valve.

Environmental Impact

The environmental impact of bio-inspired designs in modern gate valve systems is a crucial aspect to consider in the development and implementation of these innovative technologies. Bio-inspired designs often draw inspiration from nature's efficient and sustainable solutions, potentially offering significant environmental benefits compared to traditional gate valve systems.

One of the primary environmental advantages of bio-inspired gate valve designs is their potential for improved energy efficiency. By mimicking natural structures and mechanisms, these systems can achieve better flow control and reduced friction, leading to lower energy consumption during operation. This reduction in energy use translates to decreased greenhouse gas emissions and a smaller carbon footprint for industrial processes that rely on gate valves.

Bio-inspired gate valve systems may also contribute to resource conservation. Many natural systems exhibit remarkable durability and self-healing properties, which could be incorporated into valve designs. This approach could lead to longer-lasting components, reducing the need for frequent replacements and minimizing waste generation. Additionally, bio-inspired materials used in valve construction may be more environmentally friendly, potentially biodegradable or derived from renewable sources.

Water conservation is another area where bio-inspired gate valve systems can make a significant environmental impact. By drawing inspiration from natural water management systems, such as those found in plants or aquatic organisms, these valves could achieve more precise control over water flow. This improved efficiency could lead to reduced water waste in various applications, from industrial processes to municipal water distribution systems.

The potential for reduced chemical usage is an additional environmental benefit of bio-inspired gate valve designs. Natural systems often rely on physical rather than chemical mechanisms for functions such as self-cleaning or anti-fouling. By incorporating these principles into valve designs, it may be possible to decrease the reliance on harmful chemicals for maintenance and cleaning, thereby reducing the release of pollutants into the environment.

However, it is essential to consider the full lifecycle environmental impact of bio-inspired gate valve systems. While they may offer operational benefits, the manufacturing processes and materials used in their production must also be evaluated. Ensuring that these innovative designs do not introduce new environmental challenges during production or end-of-life disposal is crucial for their overall sustainability.

In conclusion, bio-inspired designs in modern gate valve systems hold significant promise for reducing environmental impact across various industries. Through improved energy efficiency, resource conservation, water management, and reduced chemical usage, these innovative systems could contribute to more sustainable industrial practices and infrastructure management. As research and development in this field progress, it will be crucial to conduct comprehensive environmental assessments to fully understand and optimize the ecological benefits of these bio-inspired technologies.

One of the primary environmental advantages of bio-inspired gate valve designs is their potential for improved energy efficiency. By mimicking natural structures and mechanisms, these systems can achieve better flow control and reduced friction, leading to lower energy consumption during operation. This reduction in energy use translates to decreased greenhouse gas emissions and a smaller carbon footprint for industrial processes that rely on gate valves.

Bio-inspired gate valve systems may also contribute to resource conservation. Many natural systems exhibit remarkable durability and self-healing properties, which could be incorporated into valve designs. This approach could lead to longer-lasting components, reducing the need for frequent replacements and minimizing waste generation. Additionally, bio-inspired materials used in valve construction may be more environmentally friendly, potentially biodegradable or derived from renewable sources.

Water conservation is another area where bio-inspired gate valve systems can make a significant environmental impact. By drawing inspiration from natural water management systems, such as those found in plants or aquatic organisms, these valves could achieve more precise control over water flow. This improved efficiency could lead to reduced water waste in various applications, from industrial processes to municipal water distribution systems.

The potential for reduced chemical usage is an additional environmental benefit of bio-inspired gate valve designs. Natural systems often rely on physical rather than chemical mechanisms for functions such as self-cleaning or anti-fouling. By incorporating these principles into valve designs, it may be possible to decrease the reliance on harmful chemicals for maintenance and cleaning, thereby reducing the release of pollutants into the environment.

However, it is essential to consider the full lifecycle environmental impact of bio-inspired gate valve systems. While they may offer operational benefits, the manufacturing processes and materials used in their production must also be evaluated. Ensuring that these innovative designs do not introduce new environmental challenges during production or end-of-life disposal is crucial for their overall sustainability.

In conclusion, bio-inspired designs in modern gate valve systems hold significant promise for reducing environmental impact across various industries. Through improved energy efficiency, resource conservation, water management, and reduced chemical usage, these innovative systems could contribute to more sustainable industrial practices and infrastructure management. As research and development in this field progress, it will be crucial to conduct comprehensive environmental assessments to fully understand and optimize the ecological benefits of these bio-inspired technologies.

Regulatory Considerations

The regulatory landscape for bio-inspired gate valve systems is complex and multifaceted, requiring careful consideration of various standards and guidelines. In the United States, the American Petroleum Institute (API) sets forth specifications for valves used in the oil and gas industry, including gate valves. API 6D and API 600 are particularly relevant, covering pipeline valves and steel gate valves, respectively. These standards may need to be adapted or expanded to accommodate novel bio-inspired designs.

The European Union's Pressure Equipment Directive (PED) 2014/68/EU governs the design and fabrication of pressure equipment, including valves. Bio-inspired gate valve systems must comply with these regulations, demonstrating safety and reliability through rigorous testing and documentation. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation may impact the materials used in bio-inspired valve designs, particularly if novel biomaterials are incorporated.

In the context of environmental regulations, bio-inspired gate valve systems may offer advantages in terms of energy efficiency and reduced environmental impact. The International Organization for Standardization (ISO) provides relevant standards, such as ISO 14001 for environmental management systems, which may be applicable to the manufacturing and implementation of these innovative valve designs.

Safety considerations are paramount in valve design and operation. The Occupational Safety and Health Administration (OSHA) in the United States and similar agencies worldwide set standards for workplace safety that must be adhered to in the development and deployment of bio-inspired gate valve systems. This includes considerations for safe operation, maintenance, and potential failure modes.

As bio-inspired designs often involve novel materials and structures, regulatory bodies may require additional testing and validation procedures. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, particularly Section VIII, provides guidelines for pressure vessels that may be applicable to certain aspects of bio-inspired valve design.

Intellectual property considerations are also crucial in the development of bio-inspired gate valve systems. Patent applications for these innovative designs must navigate existing patents in the valve industry while demonstrating the novelty and non-obviousness of bio-inspired features. Regulatory bodies such as the United States Patent and Trademark Office (USPTO) and the European Patent Office (EPO) will play a significant role in this process.

As the field of bio-inspired engineering continues to evolve, it is likely that new regulations and standards will emerge to address the unique characteristics of these designs. Industry stakeholders should actively engage with regulatory bodies to help shape these future guidelines, ensuring that they foster innovation while maintaining the highest standards of safety and performance.

The European Union's Pressure Equipment Directive (PED) 2014/68/EU governs the design and fabrication of pressure equipment, including valves. Bio-inspired gate valve systems must comply with these regulations, demonstrating safety and reliability through rigorous testing and documentation. Additionally, the EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation may impact the materials used in bio-inspired valve designs, particularly if novel biomaterials are incorporated.

In the context of environmental regulations, bio-inspired gate valve systems may offer advantages in terms of energy efficiency and reduced environmental impact. The International Organization for Standardization (ISO) provides relevant standards, such as ISO 14001 for environmental management systems, which may be applicable to the manufacturing and implementation of these innovative valve designs.

Safety considerations are paramount in valve design and operation. The Occupational Safety and Health Administration (OSHA) in the United States and similar agencies worldwide set standards for workplace safety that must be adhered to in the development and deployment of bio-inspired gate valve systems. This includes considerations for safe operation, maintenance, and potential failure modes.

As bio-inspired designs often involve novel materials and structures, regulatory bodies may require additional testing and validation procedures. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, particularly Section VIII, provides guidelines for pressure vessels that may be applicable to certain aspects of bio-inspired valve design.

Intellectual property considerations are also crucial in the development of bio-inspired gate valve systems. Patent applications for these innovative designs must navigate existing patents in the valve industry while demonstrating the novelty and non-obviousness of bio-inspired features. Regulatory bodies such as the United States Patent and Trademark Office (USPTO) and the European Patent Office (EPO) will play a significant role in this process.

As the field of bio-inspired engineering continues to evolve, it is likely that new regulations and standards will emerge to address the unique characteristics of these designs. Industry stakeholders should actively engage with regulatory bodies to help shape these future guidelines, ensuring that they foster innovation while maintaining the highest standards of safety and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!