Investigating the effect of micro-environmental changes on gate valve performance

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution

Gate valves have undergone significant evolution since their inception, driven by the need for improved performance, reliability, and efficiency in various industrial applications. The earliest gate valves were simple in design, consisting of a wedge-shaped disc that moved perpendicular to the flow path to control fluid flow. These early designs were prone to leakage and had limited pressure and temperature capabilities.

As industrial processes became more complex and demanding, gate valve technology advanced to meet these challenges. The introduction of resilient-seated gate valves in the mid-20th century marked a significant improvement in sealing capabilities. These valves featured elastomeric seats that provided better sealing under low-pressure conditions and improved resistance to wear and corrosion.

The development of high-performance metal-seated gate valves followed, addressing the limitations of resilient-seated valves in high-temperature and high-pressure applications. These valves incorporated advanced metallurgy and precision manufacturing techniques to achieve tight shutoff and extended service life in harsh environments.

Parallel slide gate valves emerged as an innovation to overcome the wedging action of traditional gate valves, offering reduced operating torque and improved sealing in bi-directional flow applications. This design allowed for easier operation and maintenance, particularly in large-diameter pipelines.

The integration of actuators and control systems revolutionized gate valve operation, enabling remote and automated control. Pneumatic, hydraulic, and electric actuators improved the precision and speed of valve operation, while also enhancing safety in hazardous environments.

Recent advancements in gate valve technology have focused on addressing micro-environmental challenges. The development of specialized coatings and materials has improved resistance to corrosion, erosion, and chemical attack. Additionally, innovations in sealing technology, such as dual sealing systems and self-adjusting seats, have enhanced the valve's ability to maintain tight shutoff under varying pressure and temperature conditions.

The advent of smart valve technology has further transformed gate valve performance. Integrated sensors and diagnostic capabilities now allow for real-time monitoring of valve health, predictive maintenance, and optimization of valve operation based on specific process conditions. This evolution towards intelligent valve systems has significantly improved reliability and reduced downtime in critical applications.

As environmental concerns have gained prominence, gate valve design has also evolved to meet stringent emission standards. Low-emission packing systems and fugitive emission-certified designs have been developed to minimize leakage of hazardous substances, particularly in oil and gas applications.

As industrial processes became more complex and demanding, gate valve technology advanced to meet these challenges. The introduction of resilient-seated gate valves in the mid-20th century marked a significant improvement in sealing capabilities. These valves featured elastomeric seats that provided better sealing under low-pressure conditions and improved resistance to wear and corrosion.

The development of high-performance metal-seated gate valves followed, addressing the limitations of resilient-seated valves in high-temperature and high-pressure applications. These valves incorporated advanced metallurgy and precision manufacturing techniques to achieve tight shutoff and extended service life in harsh environments.

Parallel slide gate valves emerged as an innovation to overcome the wedging action of traditional gate valves, offering reduced operating torque and improved sealing in bi-directional flow applications. This design allowed for easier operation and maintenance, particularly in large-diameter pipelines.

The integration of actuators and control systems revolutionized gate valve operation, enabling remote and automated control. Pneumatic, hydraulic, and electric actuators improved the precision and speed of valve operation, while also enhancing safety in hazardous environments.

Recent advancements in gate valve technology have focused on addressing micro-environmental challenges. The development of specialized coatings and materials has improved resistance to corrosion, erosion, and chemical attack. Additionally, innovations in sealing technology, such as dual sealing systems and self-adjusting seats, have enhanced the valve's ability to maintain tight shutoff under varying pressure and temperature conditions.

The advent of smart valve technology has further transformed gate valve performance. Integrated sensors and diagnostic capabilities now allow for real-time monitoring of valve health, predictive maintenance, and optimization of valve operation based on specific process conditions. This evolution towards intelligent valve systems has significantly improved reliability and reduced downtime in critical applications.

As environmental concerns have gained prominence, gate valve design has also evolved to meet stringent emission standards. Low-emission packing systems and fugitive emission-certified designs have been developed to minimize leakage of hazardous substances, particularly in oil and gas applications.

Market Demand Analysis

The market demand for gate valves with enhanced performance in varying micro-environmental conditions has been steadily increasing across multiple industries. This growth is primarily driven by the need for more reliable and efficient fluid control systems in challenging operational environments. Industries such as oil and gas, chemical processing, water treatment, and power generation are particularly interested in gate valves that can maintain optimal performance despite fluctuations in temperature, pressure, and chemical composition of the surrounding environment.

In the oil and gas sector, the demand for high-performance gate valves is particularly strong due to the harsh conditions encountered in both upstream and downstream operations. Offshore platforms and subsea installations require valves that can withstand extreme pressure, temperature variations, and corrosive environments. The ability of gate valves to maintain their integrity and functionality under these conditions directly impacts the safety and efficiency of operations, making them a critical component in the industry's infrastructure.

The chemical processing industry also presents a significant market for advanced gate valves. As chemical manufacturers strive for greater process efficiency and safety, there is a growing need for valves that can handle a wide range of chemicals and maintain their performance under varying pH levels, temperatures, and pressures. The ability to resist corrosion and maintain tight sealing properties in diverse chemical environments is a key factor driving the demand for specialized gate valves in this sector.

Water treatment facilities represent another major market for gate valves that can adapt to micro-environmental changes. These facilities often deal with fluctuating water quality, temperature variations, and the presence of various contaminants. Gate valves that can maintain consistent performance and resist scaling or biofouling are essential for ensuring the reliability and efficiency of water treatment processes.

The power generation industry, particularly in thermal and nuclear power plants, requires gate valves that can operate reliably under high-temperature and high-pressure conditions. The ability of these valves to maintain their integrity and performance in the face of thermal cycling and potential radiation exposure is crucial for the safe and efficient operation of power generation facilities.

As industries continue to push the boundaries of operational efficiency and explore new frontiers, such as deep-sea oil extraction or advanced chemical processes, the demand for gate valves capable of adapting to extreme and rapidly changing micro-environments is expected to grow. This trend is further reinforced by the increasing focus on safety and environmental regulations, which require more robust and reliable fluid control systems.

The market is also seeing a shift towards smart gate valves equipped with sensors and monitoring capabilities. These advanced valves can provide real-time data on their performance and the surrounding micro-environment, allowing for predictive maintenance and optimized operation. This integration of digital technology with traditional valve design is opening up new market opportunities and driving innovation in the field.

In the oil and gas sector, the demand for high-performance gate valves is particularly strong due to the harsh conditions encountered in both upstream and downstream operations. Offshore platforms and subsea installations require valves that can withstand extreme pressure, temperature variations, and corrosive environments. The ability of gate valves to maintain their integrity and functionality under these conditions directly impacts the safety and efficiency of operations, making them a critical component in the industry's infrastructure.

The chemical processing industry also presents a significant market for advanced gate valves. As chemical manufacturers strive for greater process efficiency and safety, there is a growing need for valves that can handle a wide range of chemicals and maintain their performance under varying pH levels, temperatures, and pressures. The ability to resist corrosion and maintain tight sealing properties in diverse chemical environments is a key factor driving the demand for specialized gate valves in this sector.

Water treatment facilities represent another major market for gate valves that can adapt to micro-environmental changes. These facilities often deal with fluctuating water quality, temperature variations, and the presence of various contaminants. Gate valves that can maintain consistent performance and resist scaling or biofouling are essential for ensuring the reliability and efficiency of water treatment processes.

The power generation industry, particularly in thermal and nuclear power plants, requires gate valves that can operate reliably under high-temperature and high-pressure conditions. The ability of these valves to maintain their integrity and performance in the face of thermal cycling and potential radiation exposure is crucial for the safe and efficient operation of power generation facilities.

As industries continue to push the boundaries of operational efficiency and explore new frontiers, such as deep-sea oil extraction or advanced chemical processes, the demand for gate valves capable of adapting to extreme and rapidly changing micro-environments is expected to grow. This trend is further reinforced by the increasing focus on safety and environmental regulations, which require more robust and reliable fluid control systems.

The market is also seeing a shift towards smart gate valves equipped with sensors and monitoring capabilities. These advanced valves can provide real-time data on their performance and the surrounding micro-environment, allowing for predictive maintenance and optimized operation. This integration of digital technology with traditional valve design is opening up new market opportunities and driving innovation in the field.

Current Challenges

Gate valve performance is significantly influenced by micro-environmental changes, presenting several challenges in the current technological landscape. One of the primary issues is the lack of comprehensive understanding regarding the complex interactions between valve components and their immediate surroundings. This knowledge gap hinders the development of more resilient and adaptive valve designs.

Environmental factors such as temperature fluctuations, pressure variations, and chemical exposure can lead to material degradation and altered mechanical properties of valve components. These changes often result in reduced sealing efficiency, increased friction, and premature wear, ultimately compromising the valve's overall performance and lifespan. The industry currently struggles to accurately predict and mitigate these effects, especially in harsh or rapidly changing environments.

Another significant challenge lies in the limitations of existing sensing and monitoring technologies. While advancements have been made in condition monitoring systems, there is still a need for more sophisticated, real-time data collection methods that can detect subtle changes in the micro-environment and their immediate impact on valve performance. This lack of granular data hampers the development of predictive maintenance strategies and adaptive control systems.

The miniaturization of valve components, particularly in specialized industries like aerospace and microfluidics, introduces additional complexities. As valve sizes decrease, the influence of micro-environmental factors becomes more pronounced, making it increasingly difficult to maintain consistent performance across different operating conditions. Engineers face the challenge of designing valves that can maintain their integrity and functionality at these smaller scales while still being resilient to environmental fluctuations.

Corrosion and material compatibility issues continue to pose significant challenges, especially in industries dealing with aggressive fluids or gases. The interaction between valve materials and the micro-environment can lead to accelerated corrosion, material breakdown, or the formation of deposits that interfere with valve operation. Developing materials and coatings that can withstand these conditions while maintaining optimal performance remains an ongoing challenge for researchers and engineers.

Furthermore, the industry faces difficulties in standardizing testing and qualification procedures that accurately simulate the range of micro-environmental conditions a valve may encounter during its operational life. Current testing methods often fail to capture the full spectrum of environmental variables and their combined effects, leading to potential discrepancies between laboratory performance and real-world operation.

Lastly, the integration of smart technologies and IoT capabilities into valve systems, while promising, introduces new challenges related to data security, power management, and long-term reliability in varying environmental conditions. Ensuring these advanced systems can operate consistently and securely across diverse micro-environments adds another layer of complexity to valve design and maintenance strategies.

Environmental factors such as temperature fluctuations, pressure variations, and chemical exposure can lead to material degradation and altered mechanical properties of valve components. These changes often result in reduced sealing efficiency, increased friction, and premature wear, ultimately compromising the valve's overall performance and lifespan. The industry currently struggles to accurately predict and mitigate these effects, especially in harsh or rapidly changing environments.

Another significant challenge lies in the limitations of existing sensing and monitoring technologies. While advancements have been made in condition monitoring systems, there is still a need for more sophisticated, real-time data collection methods that can detect subtle changes in the micro-environment and their immediate impact on valve performance. This lack of granular data hampers the development of predictive maintenance strategies and adaptive control systems.

The miniaturization of valve components, particularly in specialized industries like aerospace and microfluidics, introduces additional complexities. As valve sizes decrease, the influence of micro-environmental factors becomes more pronounced, making it increasingly difficult to maintain consistent performance across different operating conditions. Engineers face the challenge of designing valves that can maintain their integrity and functionality at these smaller scales while still being resilient to environmental fluctuations.

Corrosion and material compatibility issues continue to pose significant challenges, especially in industries dealing with aggressive fluids or gases. The interaction between valve materials and the micro-environment can lead to accelerated corrosion, material breakdown, or the formation of deposits that interfere with valve operation. Developing materials and coatings that can withstand these conditions while maintaining optimal performance remains an ongoing challenge for researchers and engineers.

Furthermore, the industry faces difficulties in standardizing testing and qualification procedures that accurately simulate the range of micro-environmental conditions a valve may encounter during its operational life. Current testing methods often fail to capture the full spectrum of environmental variables and their combined effects, leading to potential discrepancies between laboratory performance and real-world operation.

Lastly, the integration of smart technologies and IoT capabilities into valve systems, while promising, introduces new challenges related to data security, power management, and long-term reliability in varying environmental conditions. Ensuring these advanced systems can operate consistently and securely across diverse micro-environments adds another layer of complexity to valve design and maintenance strategies.

Existing Solutions

01 Improved sealing performance

Gate valves with enhanced sealing mechanisms to prevent leakage and improve overall performance. This includes innovations in sealing materials, designs, and structures to ensure tight closure and minimize fluid loss.- Improved sealing performance: Gate valves with enhanced sealing mechanisms to prevent leakage and improve overall performance. This includes innovations in sealing materials, structures, and designs that ensure tight closure and minimize fluid loss.

- Optimized flow control: Advancements in gate valve designs that provide better control over fluid flow. This includes features such as improved gate shapes, flow channels, and actuation mechanisms that allow for more precise regulation of flow rates and pressure.

- Enhanced durability and reliability: Gate valves constructed with materials and designs that increase their lifespan and reliability under various operating conditions. This includes corrosion-resistant materials, reinforced structures, and wear-resistant components that withstand harsh environments and frequent use.

- Improved actuation and control systems: Integration of advanced actuation and control systems in gate valves to enhance their performance and ease of operation. This includes electronic controls, remote operation capabilities, and automated systems that improve response times and accuracy in valve operations.

- Maintenance and monitoring features: Incorporation of features that facilitate easier maintenance and real-time monitoring of gate valve performance. This includes designs that allow for quick disassembly, self-diagnostic capabilities, and sensors that provide data on valve condition and operation.

02 Optimized flow control

Advancements in gate valve designs to improve flow control capabilities. This involves modifications to the gate, seat, and body structures to enhance precision in regulating fluid flow and reduce pressure drop across the valve.Expand Specific Solutions03 Enhanced durability and reliability

Innovations focused on increasing the lifespan and reliability of gate valves. This includes the use of wear-resistant materials, improved manufacturing techniques, and design modifications to withstand harsh operating conditions and frequent cycling.Expand Specific Solutions04 Intelligent monitoring and control

Integration of smart technologies and sensors into gate valves for real-time monitoring and control. This enables remote operation, predictive maintenance, and improved performance through data-driven insights.Expand Specific Solutions05 Environmental and safety improvements

Developments in gate valve design to enhance environmental protection and operational safety. This includes features for fugitive emissions reduction, fire-safe designs, and improved emergency shutdown capabilities.Expand Specific Solutions

Key Industry Players

The investigation into micro-environmental effects on gate valve performance is at a mature stage, with significant market potential in various industries. The competitive landscape is characterized by a mix of established players and innovative newcomers. Companies like China Nuclear Wuhan Power Operation Technology Co. Ltd. and Halliburton Energy Services, Inc. are leveraging their industry expertise to develop advanced solutions. Meanwhile, research institutions such as MIT and Fraunhofer-Gesellschaft are driving technological advancements. The market is seeing increased collaboration between academia and industry, with firms like Caterpillar, Inc. and Robert Bosch GmbH investing in R&D to enhance valve performance in challenging micro-environments. This dynamic ecosystem is fostering rapid innovation and market growth.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed advanced gate valve systems with integrated sensors to monitor micro-environmental changes. Their technology utilizes real-time data analytics to assess valve performance under varying conditions. The system employs machine learning algorithms to predict potential issues and optimize valve operation based on environmental factors such as temperature, pressure, and fluid composition[1]. Halliburton's solution includes a network of smart sensors that continuously monitor key parameters, allowing for proactive maintenance and reduced downtime[2]. The company has also implemented corrosion-resistant materials and coatings to enhance valve longevity in harsh environments[3].

Strengths: Comprehensive real-time monitoring, predictive maintenance capabilities, and enhanced durability. Weaknesses: Potentially higher initial costs and complexity in implementation for existing systems.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed a comprehensive gate valve monitoring system for critical environments. Their technology incorporates multi-parameter sensors that continuously measure factors such as vibration, temperature, and fluid properties[10]. The system utilizes advanced signal processing techniques to filter out noise and detect subtle changes in valve performance. Mitsubishi's solution includes a digital twin model of each valve, allowing for real-time comparison between expected and actual performance[11]. This enables early detection of anomalies and more accurate prediction of maintenance needs. The company has also implemented adaptive control algorithms that optimize valve operation based on current environmental conditions and historical performance data[12].

Strengths: Comprehensive monitoring with digital twin technology, advanced signal processing, and adaptive control capabilities. Weaknesses: May require significant computational resources and expertise to fully implement and maintain.

Core Innovations

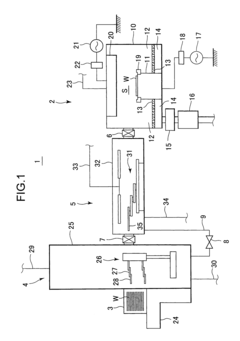

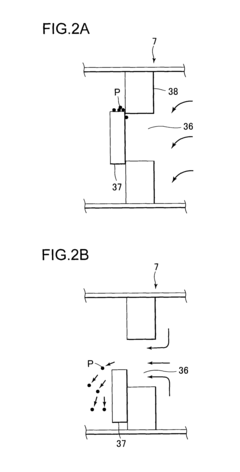

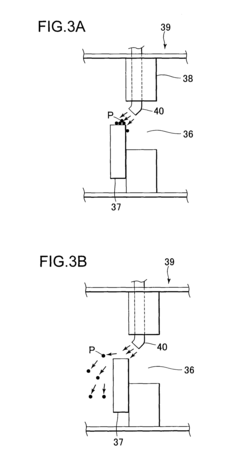

Gate valve cleaning method and substrate processing system

PatentInactiveUS8048235B2

Innovation

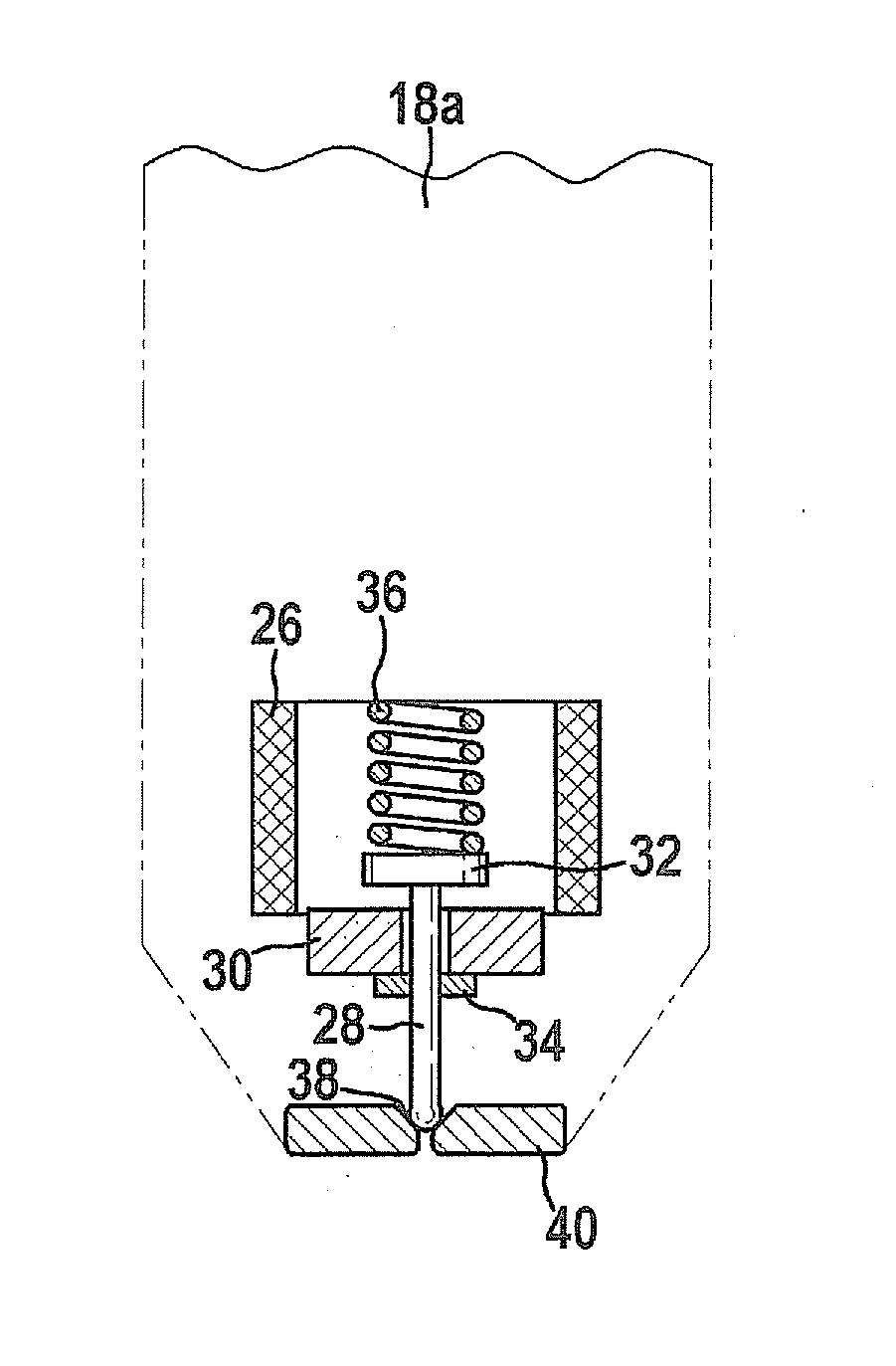

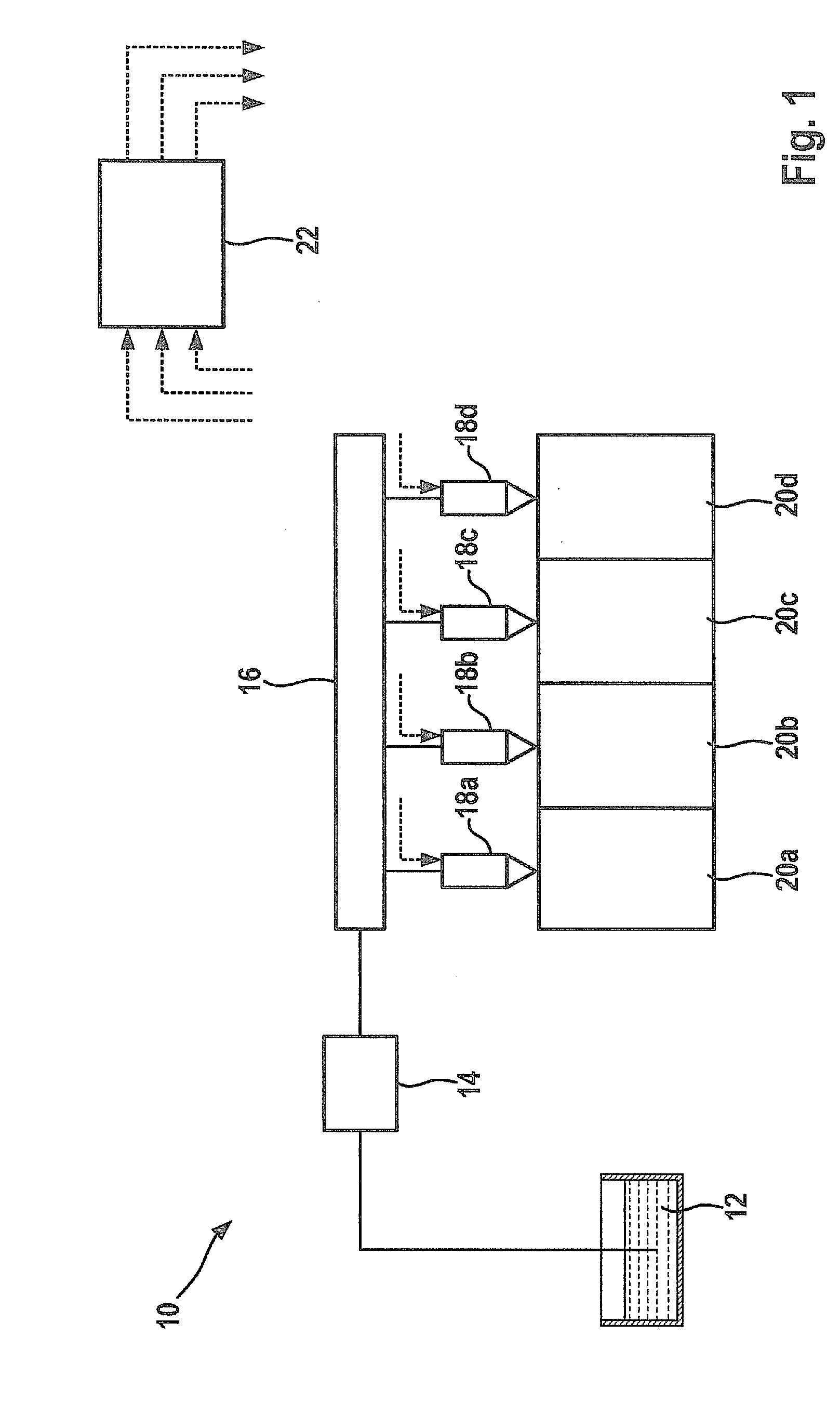

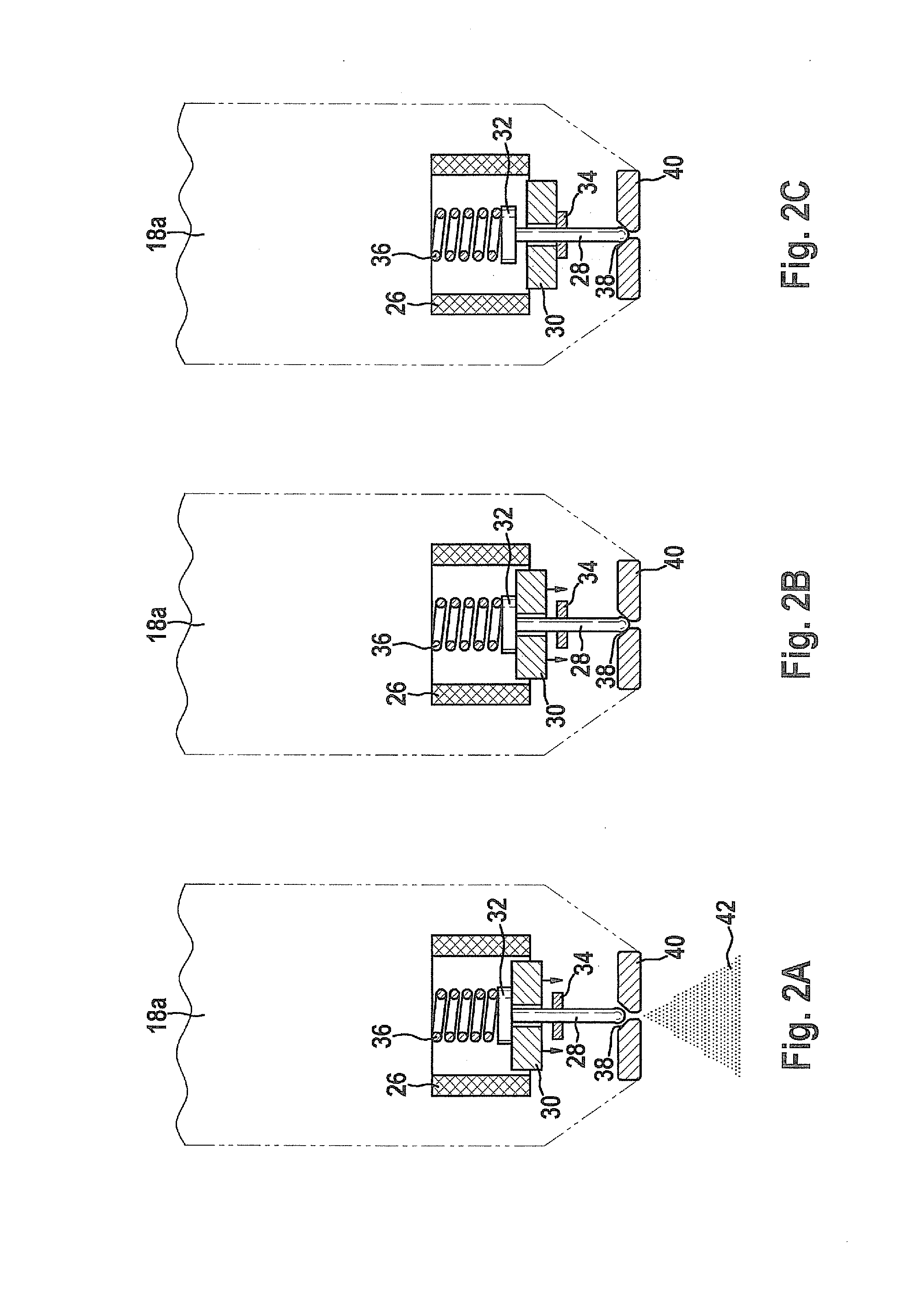

- A method that increases pressure in the internal pressure variable transfer chamber to scatter away foreign matter attached to the gate valve, allowing it to be discharged without manual cleaning, using a removal promoting substance such as high-temperature gas, vibration gas, or single-pole ion added gas to promote removal of particles from the valve element.

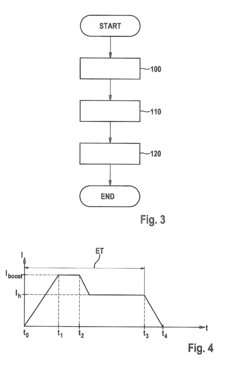

Method and control unit for operating a valve

PatentInactiveUS20120291757A1

Innovation

- A method that involves obtaining a reference variable to characterize the electromagnetic actuator's behavior, modifying the auxiliary variable based on this reference, and checking the modified auxiliary variable for predefinable characteristics, which enhances evaluation precision by simulating the signal portions generated by magnetic and electrical properties and movement of the magnetic circuit components.

Environmental Impact

The environmental impact of gate valve performance is a critical consideration in various industries, particularly in sectors such as oil and gas, water treatment, and chemical processing. Micro-environmental changes can significantly affect the functionality, reliability, and longevity of gate valves, which in turn can have broader implications for the surrounding ecosystem and operational efficiency.

One of the primary environmental factors influencing gate valve performance is temperature fluctuation. Extreme temperatures, both high and low, can cause thermal expansion or contraction of valve components, potentially leading to misalignment, leakage, or even complete failure. In harsh environments, such as offshore oil platforms or desert pipelines, these temperature variations can be particularly severe, necessitating robust valve designs and materials that can withstand such conditions.

Humidity and moisture levels also play a crucial role in gate valve performance. High humidity environments can accelerate corrosion processes, especially in valves made from susceptible materials. This corrosion can compromise the integrity of valve seals, stems, and body components, leading to reduced efficiency and increased maintenance requirements. In coastal or marine applications, the presence of salt spray further exacerbates these corrosion issues, demanding specialized coatings or corrosion-resistant alloys.

Pressure variations in the operating environment can significantly impact gate valve performance. Sudden pressure changes, common in industrial processes, can stress valve components and affect their sealing capabilities. Over time, these pressure fluctuations may lead to fatigue and premature wear of valve parts, potentially resulting in leaks or failures that could have environmental consequences, such as the release of hazardous materials.

Particulate matter and contaminants in the surrounding environment pose another challenge to gate valve performance. In dusty or polluted atmospheres, fine particles can accumulate on valve surfaces and penetrate internal mechanisms. This accumulation can interfere with smooth operation, cause increased friction, and potentially lead to jamming or incomplete closure. In severe cases, this can result in unintended emissions or leaks, posing environmental risks.

The presence of chemical agents in the micro-environment can also have profound effects on gate valve performance. Exposure to corrosive gases, acids, or other reactive substances can degrade valve materials, particularly elastomeric seals and non-metallic components. This degradation can compromise the valve's ability to maintain a tight seal, potentially leading to fugitive emissions and environmental contamination.

Understanding these environmental impacts is crucial for designing, selecting, and maintaining gate valves that can perform reliably under diverse conditions. Engineers and operators must consider these factors when specifying valve materials, coatings, and designs to ensure long-term performance and minimize environmental risks associated with valve failures or inefficiencies.

One of the primary environmental factors influencing gate valve performance is temperature fluctuation. Extreme temperatures, both high and low, can cause thermal expansion or contraction of valve components, potentially leading to misalignment, leakage, or even complete failure. In harsh environments, such as offshore oil platforms or desert pipelines, these temperature variations can be particularly severe, necessitating robust valve designs and materials that can withstand such conditions.

Humidity and moisture levels also play a crucial role in gate valve performance. High humidity environments can accelerate corrosion processes, especially in valves made from susceptible materials. This corrosion can compromise the integrity of valve seals, stems, and body components, leading to reduced efficiency and increased maintenance requirements. In coastal or marine applications, the presence of salt spray further exacerbates these corrosion issues, demanding specialized coatings or corrosion-resistant alloys.

Pressure variations in the operating environment can significantly impact gate valve performance. Sudden pressure changes, common in industrial processes, can stress valve components and affect their sealing capabilities. Over time, these pressure fluctuations may lead to fatigue and premature wear of valve parts, potentially resulting in leaks or failures that could have environmental consequences, such as the release of hazardous materials.

Particulate matter and contaminants in the surrounding environment pose another challenge to gate valve performance. In dusty or polluted atmospheres, fine particles can accumulate on valve surfaces and penetrate internal mechanisms. This accumulation can interfere with smooth operation, cause increased friction, and potentially lead to jamming or incomplete closure. In severe cases, this can result in unintended emissions or leaks, posing environmental risks.

The presence of chemical agents in the micro-environment can also have profound effects on gate valve performance. Exposure to corrosive gases, acids, or other reactive substances can degrade valve materials, particularly elastomeric seals and non-metallic components. This degradation can compromise the valve's ability to maintain a tight seal, potentially leading to fugitive emissions and environmental contamination.

Understanding these environmental impacts is crucial for designing, selecting, and maintaining gate valves that can perform reliably under diverse conditions. Engineers and operators must consider these factors when specifying valve materials, coatings, and designs to ensure long-term performance and minimize environmental risks associated with valve failures or inefficiencies.

Reliability Assessment

Reliability assessment is a critical aspect of investigating the effect of micro-environmental changes on gate valve performance. The reliability of gate valves is paramount in ensuring the safe and efficient operation of various industrial processes. Micro-environmental changes, such as temperature fluctuations, pressure variations, and chemical exposure, can significantly impact the performance and longevity of gate valves.

To conduct a comprehensive reliability assessment, it is essential to consider multiple factors that influence gate valve performance under varying micro-environmental conditions. One key aspect is the material selection for valve components. Different materials exhibit varying levels of resistance to corrosion, erosion, and thermal expansion, which directly affect the valve's reliability in diverse operating environments.

The sealing mechanism of gate valves is another crucial element in reliability assessment. Micro-environmental changes can lead to seal degradation, resulting in leakage and reduced performance. Evaluating the effectiveness of different sealing materials and designs under various environmental conditions is vital for predicting long-term reliability.

Mechanical stress analysis is an integral part of the reliability assessment process. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations can be employed to model the behavior of gate valves under different micro-environmental conditions. These tools help identify potential weak points and areas of high stress concentration, allowing for design optimizations to enhance reliability.

Accelerated life testing is a valuable technique for assessing gate valve reliability. By subjecting valves to extreme micro-environmental conditions, such as elevated temperatures or corrosive atmospheres, researchers can simulate long-term exposure and predict potential failure modes. This approach provides valuable data for estimating the mean time between failures (MTBF) and overall reliability metrics.

Statistical analysis of historical performance data is essential for a comprehensive reliability assessment. By analyzing failure rates, maintenance records, and operational data from gate valves exposed to various micro-environmental conditions, patterns and trends can be identified. This information aids in developing predictive models for valve reliability and optimizing maintenance schedules.

Reliability-centered maintenance (RCM) strategies can be implemented based on the findings of the reliability assessment. By focusing maintenance efforts on critical components and addressing specific vulnerabilities identified through the assessment, the overall reliability of gate valves can be significantly improved. This approach helps minimize downtime and reduces the risk of unexpected failures in industrial applications.

In conclusion, a thorough reliability assessment of gate valve performance under micro-environmental changes requires a multifaceted approach. By considering material properties, sealing mechanisms, mechanical stress analysis, accelerated life testing, statistical analysis, and implementing RCM strategies, engineers can gain valuable insights into valve behavior and optimize designs for enhanced reliability in diverse operating conditions.

To conduct a comprehensive reliability assessment, it is essential to consider multiple factors that influence gate valve performance under varying micro-environmental conditions. One key aspect is the material selection for valve components. Different materials exhibit varying levels of resistance to corrosion, erosion, and thermal expansion, which directly affect the valve's reliability in diverse operating environments.

The sealing mechanism of gate valves is another crucial element in reliability assessment. Micro-environmental changes can lead to seal degradation, resulting in leakage and reduced performance. Evaluating the effectiveness of different sealing materials and designs under various environmental conditions is vital for predicting long-term reliability.

Mechanical stress analysis is an integral part of the reliability assessment process. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations can be employed to model the behavior of gate valves under different micro-environmental conditions. These tools help identify potential weak points and areas of high stress concentration, allowing for design optimizations to enhance reliability.

Accelerated life testing is a valuable technique for assessing gate valve reliability. By subjecting valves to extreme micro-environmental conditions, such as elevated temperatures or corrosive atmospheres, researchers can simulate long-term exposure and predict potential failure modes. This approach provides valuable data for estimating the mean time between failures (MTBF) and overall reliability metrics.

Statistical analysis of historical performance data is essential for a comprehensive reliability assessment. By analyzing failure rates, maintenance records, and operational data from gate valves exposed to various micro-environmental conditions, patterns and trends can be identified. This information aids in developing predictive models for valve reliability and optimizing maintenance schedules.

Reliability-centered maintenance (RCM) strategies can be implemented based on the findings of the reliability assessment. By focusing maintenance efforts on critical components and addressing specific vulnerabilities identified through the assessment, the overall reliability of gate valves can be significantly improved. This approach helps minimize downtime and reduces the risk of unexpected failures in industrial applications.

In conclusion, a thorough reliability assessment of gate valve performance under micro-environmental changes requires a multifaceted approach. By considering material properties, sealing mechanisms, mechanical stress analysis, accelerated life testing, statistical analysis, and implementing RCM strategies, engineers can gain valuable insights into valve behavior and optimize designs for enhanced reliability in diverse operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!