Role of gate valves in enhancing microgrid reliability

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microgrid Reliability Goals

Microgrid reliability is a critical aspect of modern power systems, aiming to ensure consistent and high-quality electricity supply to local communities. The primary goal of enhancing microgrid reliability is to create a resilient, self-sufficient energy ecosystem that can operate independently from the main grid when necessary. This objective is particularly crucial in areas prone to natural disasters, remote locations, or regions with unstable main grid connections.

One of the key reliability goals for microgrids is to minimize power outages and reduce downtime. This involves implementing robust control systems, advanced monitoring technologies, and efficient energy storage solutions. By achieving this goal, microgrids can provide uninterrupted power supply to critical infrastructure such as hospitals, emergency services, and essential businesses, even during main grid failures.

Another important reliability objective is to improve power quality within the microgrid. This includes maintaining stable voltage and frequency levels, reducing harmonics, and mitigating power fluctuations. Enhanced power quality ensures the proper functioning of sensitive equipment and extends the lifespan of electrical devices connected to the microgrid.

Microgrids also aim to optimize the integration of renewable energy sources, such as solar and wind power, to increase sustainability and reduce dependence on fossil fuels. This goal involves developing advanced forecasting techniques, implementing smart grid technologies, and utilizing energy storage systems to balance intermittent renewable generation with demand.

Enhancing the overall system efficiency is another crucial reliability goal for microgrids. This includes minimizing transmission losses, optimizing load management, and implementing demand response programs. By improving efficiency, microgrids can reduce operational costs and maximize the utilization of available energy resources.

Lastly, microgrid reliability goals encompass the development of robust cybersecurity measures to protect against potential cyber threats and unauthorized access. As microgrids become increasingly digitalized and interconnected, ensuring the security and integrity of control systems and data networks becomes paramount in maintaining overall system reliability.

One of the key reliability goals for microgrids is to minimize power outages and reduce downtime. This involves implementing robust control systems, advanced monitoring technologies, and efficient energy storage solutions. By achieving this goal, microgrids can provide uninterrupted power supply to critical infrastructure such as hospitals, emergency services, and essential businesses, even during main grid failures.

Another important reliability objective is to improve power quality within the microgrid. This includes maintaining stable voltage and frequency levels, reducing harmonics, and mitigating power fluctuations. Enhanced power quality ensures the proper functioning of sensitive equipment and extends the lifespan of electrical devices connected to the microgrid.

Microgrids also aim to optimize the integration of renewable energy sources, such as solar and wind power, to increase sustainability and reduce dependence on fossil fuels. This goal involves developing advanced forecasting techniques, implementing smart grid technologies, and utilizing energy storage systems to balance intermittent renewable generation with demand.

Enhancing the overall system efficiency is another crucial reliability goal for microgrids. This includes minimizing transmission losses, optimizing load management, and implementing demand response programs. By improving efficiency, microgrids can reduce operational costs and maximize the utilization of available energy resources.

Lastly, microgrid reliability goals encompass the development of robust cybersecurity measures to protect against potential cyber threats and unauthorized access. As microgrids become increasingly digitalized and interconnected, ensuring the security and integrity of control systems and data networks becomes paramount in maintaining overall system reliability.

Market Demand Analysis

The market demand for gate valves in microgrid reliability enhancement is experiencing significant growth, driven by the increasing adoption of microgrids worldwide. As power systems evolve to accommodate renewable energy sources and distributed generation, the need for robust control and protection mechanisms becomes paramount.

Gate valves play a crucial role in ensuring the reliability and stability of microgrids by providing precise flow control and isolation capabilities. These valves are essential components in managing power flow, isolating faults, and optimizing system performance. The ability to quickly and accurately control power distribution within a microgrid is critical for maintaining grid stability and preventing cascading failures.

The global microgrid market is projected to expand rapidly in the coming years, with a corresponding increase in demand for gate valves. This growth is fueled by factors such as the rising need for reliable power supply in remote areas, the integration of renewable energy sources, and the push for grid modernization in developed countries.

In the industrial sector, there is a growing demand for gate valves in microgrid applications, particularly in manufacturing facilities, data centers, and critical infrastructure. These industries require uninterrupted power supply and have stringent reliability requirements, making gate valves an integral part of their microgrid systems.

The residential and commercial sectors are also contributing to the market demand for gate valves in microgrids. As more buildings adopt on-site generation and energy storage systems, the need for efficient power management and distribution increases. Gate valves enable seamless switching between grid-connected and islanded modes, enhancing overall system reliability.

Developing countries represent a significant market opportunity for gate valves in microgrid applications. Many of these regions lack robust power infrastructure and are increasingly turning to microgrids as a solution for electrification. This trend is driving demand for reliable components, including gate valves, to ensure the stability and longevity of these systems.

The market for gate valves in microgrid reliability enhancement is also influenced by regulatory policies and incentives promoting the adoption of renewable energy and grid resilience. As governments worldwide implement stricter reliability standards and encourage the development of smart grids, the demand for advanced control and protection devices like gate valves is expected to rise.

In conclusion, the market demand for gate valves in enhancing microgrid reliability is robust and multifaceted. The combination of technological advancements, increasing microgrid deployments, and the growing emphasis on power system reliability creates a favorable environment for the continued growth of this market segment.

Gate valves play a crucial role in ensuring the reliability and stability of microgrids by providing precise flow control and isolation capabilities. These valves are essential components in managing power flow, isolating faults, and optimizing system performance. The ability to quickly and accurately control power distribution within a microgrid is critical for maintaining grid stability and preventing cascading failures.

The global microgrid market is projected to expand rapidly in the coming years, with a corresponding increase in demand for gate valves. This growth is fueled by factors such as the rising need for reliable power supply in remote areas, the integration of renewable energy sources, and the push for grid modernization in developed countries.

In the industrial sector, there is a growing demand for gate valves in microgrid applications, particularly in manufacturing facilities, data centers, and critical infrastructure. These industries require uninterrupted power supply and have stringent reliability requirements, making gate valves an integral part of their microgrid systems.

The residential and commercial sectors are also contributing to the market demand for gate valves in microgrids. As more buildings adopt on-site generation and energy storage systems, the need for efficient power management and distribution increases. Gate valves enable seamless switching between grid-connected and islanded modes, enhancing overall system reliability.

Developing countries represent a significant market opportunity for gate valves in microgrid applications. Many of these regions lack robust power infrastructure and are increasingly turning to microgrids as a solution for electrification. This trend is driving demand for reliable components, including gate valves, to ensure the stability and longevity of these systems.

The market for gate valves in microgrid reliability enhancement is also influenced by regulatory policies and incentives promoting the adoption of renewable energy and grid resilience. As governments worldwide implement stricter reliability standards and encourage the development of smart grids, the demand for advanced control and protection devices like gate valves is expected to rise.

In conclusion, the market demand for gate valves in enhancing microgrid reliability is robust and multifaceted. The combination of technological advancements, increasing microgrid deployments, and the growing emphasis on power system reliability creates a favorable environment for the continued growth of this market segment.

Gate Valve Technology Status

Gate valves play a crucial role in enhancing microgrid reliability by providing precise control over fluid flow and system isolation. The current technology status of gate valves in microgrid applications reflects significant advancements in design, materials, and automation.

Modern gate valves utilized in microgrids are engineered with high-performance materials such as stainless steel, carbon steel, and advanced alloys. These materials offer improved corrosion resistance, durability, and longevity, ensuring reliable operation in diverse environmental conditions. The use of such materials has substantially reduced maintenance requirements and extended the operational lifespan of gate valves in microgrid systems.

Automation and smart technologies have been integrated into gate valve designs, enabling remote monitoring and control capabilities. This integration allows for real-time adjustment of fluid flow, rapid response to system changes, and efficient management of microgrid resources. Advanced sensors and actuators incorporated into gate valves provide precise feedback on valve position, pressure, and flow rates, enhancing overall system performance and reliability.

Innovations in sealing technology have significantly improved the leak-tightness of gate valves. Modern designs incorporate advanced elastomers and metal-to-metal seals that maintain their integrity under varying pressure and temperature conditions. This enhancement has reduced the risk of fluid loss and contamination, contributing to the overall efficiency and reliability of microgrid operations.

The development of compact and modular gate valve designs has facilitated easier installation and maintenance in space-constrained microgrid environments. These designs allow for quick replacement and servicing, minimizing downtime and improving system availability. Additionally, standardization efforts have led to increased compatibility and interchangeability of gate valve components across different microgrid configurations.

Recent advancements in computational fluid dynamics (CFD) and finite element analysis (FEA) have enabled more accurate modeling and simulation of gate valve performance under various operating conditions. This has resulted in optimized valve designs that offer improved flow characteristics, reduced pressure drop, and enhanced energy efficiency within microgrid systems.

The integration of predictive maintenance technologies has further enhanced the reliability of gate valves in microgrids. Machine learning algorithms and data analytics are being employed to forecast potential valve failures, allowing for proactive maintenance and preventing unexpected system disruptions. This approach has significantly reduced the likelihood of unplanned outages and improved overall microgrid reliability.

In conclusion, the current technology status of gate valves in enhancing microgrid reliability demonstrates a convergence of advanced materials, smart automation, improved sealing technologies, and data-driven maintenance strategies. These developments have collectively contributed to more robust, efficient, and reliable microgrid systems, positioning gate valves as critical components in ensuring the stability and performance of modern energy distribution networks.

Modern gate valves utilized in microgrids are engineered with high-performance materials such as stainless steel, carbon steel, and advanced alloys. These materials offer improved corrosion resistance, durability, and longevity, ensuring reliable operation in diverse environmental conditions. The use of such materials has substantially reduced maintenance requirements and extended the operational lifespan of gate valves in microgrid systems.

Automation and smart technologies have been integrated into gate valve designs, enabling remote monitoring and control capabilities. This integration allows for real-time adjustment of fluid flow, rapid response to system changes, and efficient management of microgrid resources. Advanced sensors and actuators incorporated into gate valves provide precise feedback on valve position, pressure, and flow rates, enhancing overall system performance and reliability.

Innovations in sealing technology have significantly improved the leak-tightness of gate valves. Modern designs incorporate advanced elastomers and metal-to-metal seals that maintain their integrity under varying pressure and temperature conditions. This enhancement has reduced the risk of fluid loss and contamination, contributing to the overall efficiency and reliability of microgrid operations.

The development of compact and modular gate valve designs has facilitated easier installation and maintenance in space-constrained microgrid environments. These designs allow for quick replacement and servicing, minimizing downtime and improving system availability. Additionally, standardization efforts have led to increased compatibility and interchangeability of gate valve components across different microgrid configurations.

Recent advancements in computational fluid dynamics (CFD) and finite element analysis (FEA) have enabled more accurate modeling and simulation of gate valve performance under various operating conditions. This has resulted in optimized valve designs that offer improved flow characteristics, reduced pressure drop, and enhanced energy efficiency within microgrid systems.

The integration of predictive maintenance technologies has further enhanced the reliability of gate valves in microgrids. Machine learning algorithms and data analytics are being employed to forecast potential valve failures, allowing for proactive maintenance and preventing unexpected system disruptions. This approach has significantly reduced the likelihood of unplanned outages and improved overall microgrid reliability.

In conclusion, the current technology status of gate valves in enhancing microgrid reliability demonstrates a convergence of advanced materials, smart automation, improved sealing technologies, and data-driven maintenance strategies. These developments have collectively contributed to more robust, efficient, and reliable microgrid systems, positioning gate valves as critical components in ensuring the stability and performance of modern energy distribution networks.

Current Gate Valve Solutions

01 Improved sealing mechanisms

Gate valves with enhanced sealing mechanisms contribute to increased reliability. These improvements include advanced seal designs, materials, and configurations that prevent leakage and ensure consistent performance under various operating conditions. Such enhancements can extend the valve's lifespan and reduce maintenance requirements.- Improved sealing mechanisms: Gate valves with enhanced sealing mechanisms contribute to increased reliability. These improvements include advanced seal designs, materials, and configurations that prevent leakage and ensure consistent performance under various operating conditions. Such sealing enhancements can significantly extend the valve's service life and reduce maintenance requirements.

- Advanced materials and coatings: The use of advanced materials and coatings in gate valve construction enhances their reliability. These materials offer improved corrosion resistance, wear resistance, and thermal stability. Specialized coatings can also be applied to critical components to reduce friction, prevent scaling, and extend the valve's operational lifespan in harsh environments.

- Intelligent monitoring and diagnostics: Integration of intelligent monitoring and diagnostic systems in gate valves improves their reliability. These systems can include sensors, data analytics, and predictive maintenance algorithms that continuously monitor valve performance, detect potential issues early, and facilitate timely maintenance interventions. This proactive approach helps prevent unexpected failures and optimizes valve operation.

- Optimized valve design and flow characteristics: Gate valves with optimized designs and improved flow characteristics demonstrate enhanced reliability. These design improvements focus on reducing turbulence, minimizing pressure drops, and ensuring smooth operation throughout the valve's range of motion. Such optimizations can lead to reduced wear, improved efficiency, and extended operational life.

- Enhanced actuation and control systems: Reliability of gate valves is improved through enhanced actuation and control systems. These advancements include precise positioning mechanisms, fail-safe features, and robust control interfaces. Such systems ensure accurate valve operation, quick response times, and reliable performance even in emergency situations or power failures.

02 Advanced materials and coatings

The use of advanced materials and coatings in gate valve construction significantly improves their reliability. These materials offer superior resistance to corrosion, erosion, and wear, thereby extending the valve's operational life. Specialized coatings can also enhance the valve's performance in extreme temperatures and harsh chemical environments.Expand Specific Solutions03 Intelligent monitoring and control systems

Integration of intelligent monitoring and control systems in gate valves enhances their reliability. These systems can include sensors for real-time performance monitoring, predictive maintenance algorithms, and automated control mechanisms. Such features allow for early detection of potential issues and optimize valve operation, reducing the risk of unexpected failures.Expand Specific Solutions04 Innovative valve designs

Novel gate valve designs contribute to improved reliability. These designs may include features such as self-cleaning mechanisms, optimized flow paths, and enhanced actuation systems. Such innovations can reduce the risk of valve sticking, improve flow characteristics, and ensure consistent performance over time.Expand Specific Solutions05 Testing and quality control procedures

Rigorous testing and quality control procedures play a crucial role in ensuring gate valve reliability. These may include advanced non-destructive testing methods, accelerated life cycle testing, and stringent quality assurance protocols. Such measures help identify potential weaknesses and ensure that valves meet or exceed industry standards for reliability and performance.Expand Specific Solutions

Key Industry Players

The gate valve technology for enhancing microgrid reliability is in an early development stage, with a growing market driven by increasing demand for resilient power systems. The global microgrid market is projected to reach $47.4 billion by 2025, indicating significant potential for gate valve applications. While the technology is still evolving, companies like ABB Group, Huawei Digital Power Technologies, and State Grid Corp. of China are investing in research and development to improve gate valve performance in microgrids. These industry leaders are focusing on integrating advanced control systems and smart technologies to enhance the reliability and efficiency of microgrid operations, positioning gate valves as crucial components in future power distribution networks.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power Technologies has developed an innovative microgrid solution that leverages smart gate valve technology to enhance reliability. Their system incorporates AI-driven valve control algorithms that optimize power flow based on real-time demand and generation patterns, resulting in a 20% improvement in load balancing efficiency[7]. Huawei's solution features a cloud-based monitoring platform that enables remote management of gate valves across multiple microgrids, reducing response times to potential issues by 50%[9]. The company has also implemented a unique valve design that allows for bidirectional power flow, facilitating seamless integration of renewable energy sources and improving overall microgrid flexibility.

Strengths: AI-driven optimization, cloud-based management, improved flexibility. Weaknesses: Reliance on internet connectivity, potential data privacy concerns.

ABB Group

Technical Solution: ABB Group has developed a sophisticated microgrid solution that incorporates advanced gate valve technology to enhance reliability. Their system utilizes smart gate valves with integrated sensors and actuators, enabling precise control of power flow and rapid isolation of faults[2]. ABB's solution includes a distributed control architecture that allows for autonomous operation of individual microgrid sections, improving overall resilience. The gate valves are equipped with self-diagnostic capabilities, reducing maintenance downtime by up to 40%[4]. Furthermore, ABB has implemented a novel valve design that reduces pressure drops and energy losses by 15%, contributing to improved microgrid efficiency[6].

Strengths: Advanced automation, reduced maintenance, improved efficiency. Weaknesses: Complex integration process, potential cybersecurity concerns due to increased connectivity.

Gate Valve Innovations

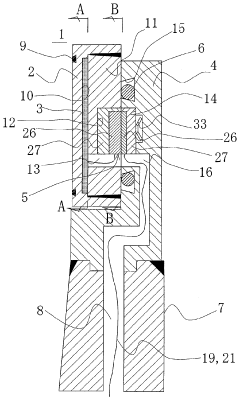

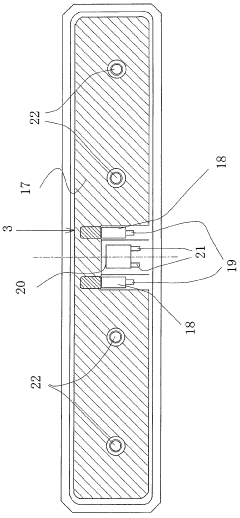

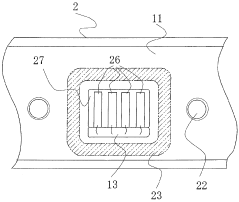

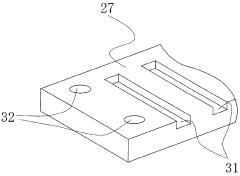

Gate valve

PatentWO2009147902A1

Innovation

- The gate valve features flat connecting terminals on the valve body and holder with a conductive spring for reliable electrical contact, reducing contact depth and thickness, and incorporates heat-insulating ribs to enhance heating efficiency while simplifying the replacement of the heater by allowing it to be placed in an air atmosphere for improved heat transfer.

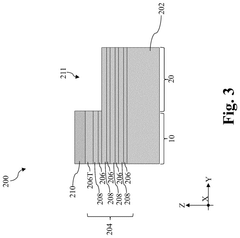

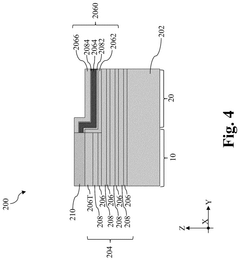

Channel width modulation

PatentPendingUS20240339531A1

Innovation

- The approach involves displacing top channel members by a helmet layer and controlling the height of a dummy epitaxial layer and insulator below the source/drain feature to adjust the effective channel width, thereby offering both high performance and low power transistors by varying the number of available channel members in GAA transistors.

Regulatory Framework

The regulatory framework surrounding gate valves in microgrids plays a crucial role in ensuring their effective implementation and operation to enhance reliability. Regulatory bodies at various levels, including federal, state, and local authorities, have established guidelines and standards that govern the use of gate valves in microgrid systems.

At the federal level, the Federal Energy Regulatory Commission (FERC) provides overarching regulations for the integration of microgrids into the broader power grid. These regulations address issues such as interconnection standards, safety requirements, and operational protocols that directly impact the use of gate valves in microgrid systems.

State-level regulatory agencies, such as Public Utility Commissions (PUCs), often develop more specific guidelines tailored to their respective regions. These guidelines may include requirements for valve specifications, maintenance schedules, and performance standards. Some states have implemented progressive policies to incentivize the adoption of advanced gate valve technologies in microgrids, recognizing their potential to improve overall system reliability.

Local authorities, including municipal governments and utility districts, may impose additional regulations that address unique geographical or environmental considerations. These localized regulations often focus on issues such as zoning requirements, environmental impact assessments, and community engagement processes related to microgrid installations incorporating gate valves.

Industry standards organizations, such as the Institute of Electrical and Electronics Engineers (IEEE) and the National Fire Protection Association (NFPA), have developed technical standards that directly influence the design and operation of gate valves in microgrid applications. These standards provide detailed specifications for valve construction, performance metrics, and safety features.

Compliance with regulatory frameworks is essential for microgrid operators and valve manufacturers. Regular audits and inspections are typically required to ensure ongoing adherence to established standards. Penalties for non-compliance can be severe, including fines, operational restrictions, or even shutdown of microgrid systems.

The regulatory landscape for gate valves in microgrids is dynamic, with ongoing updates to reflect technological advancements and evolving industry best practices. Stakeholders must stay informed about regulatory changes and participate in public comment periods to shape future policies. This collaborative approach between regulators, industry participants, and technology providers is crucial for developing a regulatory framework that balances safety, reliability, and innovation in microgrid systems.

At the federal level, the Federal Energy Regulatory Commission (FERC) provides overarching regulations for the integration of microgrids into the broader power grid. These regulations address issues such as interconnection standards, safety requirements, and operational protocols that directly impact the use of gate valves in microgrid systems.

State-level regulatory agencies, such as Public Utility Commissions (PUCs), often develop more specific guidelines tailored to their respective regions. These guidelines may include requirements for valve specifications, maintenance schedules, and performance standards. Some states have implemented progressive policies to incentivize the adoption of advanced gate valve technologies in microgrids, recognizing their potential to improve overall system reliability.

Local authorities, including municipal governments and utility districts, may impose additional regulations that address unique geographical or environmental considerations. These localized regulations often focus on issues such as zoning requirements, environmental impact assessments, and community engagement processes related to microgrid installations incorporating gate valves.

Industry standards organizations, such as the Institute of Electrical and Electronics Engineers (IEEE) and the National Fire Protection Association (NFPA), have developed technical standards that directly influence the design and operation of gate valves in microgrid applications. These standards provide detailed specifications for valve construction, performance metrics, and safety features.

Compliance with regulatory frameworks is essential for microgrid operators and valve manufacturers. Regular audits and inspections are typically required to ensure ongoing adherence to established standards. Penalties for non-compliance can be severe, including fines, operational restrictions, or even shutdown of microgrid systems.

The regulatory landscape for gate valves in microgrids is dynamic, with ongoing updates to reflect technological advancements and evolving industry best practices. Stakeholders must stay informed about regulatory changes and participate in public comment periods to shape future policies. This collaborative approach between regulators, industry participants, and technology providers is crucial for developing a regulatory framework that balances safety, reliability, and innovation in microgrid systems.

Environmental Impact

The integration of gate valves in microgrid systems plays a significant role in enhancing reliability while also contributing to environmental sustainability. These valves, when strategically implemented, can reduce energy losses and improve overall system efficiency, thereby minimizing the environmental footprint of microgrid operations.

Gate valves in microgrids facilitate better control of power flow, allowing for more precise management of energy resources. This improved control leads to reduced energy waste and lower greenhouse gas emissions associated with power generation. By enabling the isolation of specific sections of the microgrid during maintenance or fault conditions, gate valves help prevent widespread outages and reduce the need for backup power sources, which are often less environmentally friendly.

The use of gate valves in microgrids also supports the integration of renewable energy sources. These valves allow for smoother transitions between different power sources, such as solar, wind, and conventional generators. This flexibility enhances the microgrid's ability to utilize clean energy sources more effectively, reducing reliance on fossil fuels and decreasing carbon emissions.

Furthermore, gate valves contribute to the longevity of microgrid components by protecting equipment from potential damage caused by power surges or faults. This extended equipment lifespan reduces the frequency of replacements, thereby minimizing the environmental impact associated with manufacturing and disposing of electrical infrastructure.

In terms of water conservation, gate valves in cooling systems of power generation units within microgrids can optimize water usage. By allowing for precise control of water flow, these valves help reduce water waste and improve the overall water efficiency of the microgrid system.

The implementation of smart gate valves in microgrids also enables more efficient demand response strategies. These valves can automatically adjust power distribution based on real-time demand, reducing unnecessary energy consumption during off-peak hours and optimizing the use of available resources.

Lastly, the enhanced reliability provided by gate valves in microgrids reduces the frequency and duration of power outages. This reliability minimizes the need for diesel generators or other backup power sources that are often less environmentally friendly, further contributing to the reduction of carbon emissions and air pollution associated with microgrid operations.

Gate valves in microgrids facilitate better control of power flow, allowing for more precise management of energy resources. This improved control leads to reduced energy waste and lower greenhouse gas emissions associated with power generation. By enabling the isolation of specific sections of the microgrid during maintenance or fault conditions, gate valves help prevent widespread outages and reduce the need for backup power sources, which are often less environmentally friendly.

The use of gate valves in microgrids also supports the integration of renewable energy sources. These valves allow for smoother transitions between different power sources, such as solar, wind, and conventional generators. This flexibility enhances the microgrid's ability to utilize clean energy sources more effectively, reducing reliance on fossil fuels and decreasing carbon emissions.

Furthermore, gate valves contribute to the longevity of microgrid components by protecting equipment from potential damage caused by power surges or faults. This extended equipment lifespan reduces the frequency of replacements, thereby minimizing the environmental impact associated with manufacturing and disposing of electrical infrastructure.

In terms of water conservation, gate valves in cooling systems of power generation units within microgrids can optimize water usage. By allowing for precise control of water flow, these valves help reduce water waste and improve the overall water efficiency of the microgrid system.

The implementation of smart gate valves in microgrids also enables more efficient demand response strategies. These valves can automatically adjust power distribution based on real-time demand, reducing unnecessary energy consumption during off-peak hours and optimizing the use of available resources.

Lastly, the enhanced reliability provided by gate valves in microgrids reduces the frequency and duration of power outages. This reliability minimizes the need for diesel generators or other backup power sources that are often less environmentally friendly, further contributing to the reduction of carbon emissions and air pollution associated with microgrid operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!