Assessment of fluid dynamics changes with gate valve actuation responses

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluid Dynamics and Valve Actuation Background

Fluid dynamics and valve actuation are fundamental concepts in the field of mechanical engineering and process control. The study of fluid dynamics involves understanding how liquids and gases behave under various conditions, including pressure, temperature, and flow rates. This knowledge is crucial for designing and optimizing systems that involve fluid transport, such as pipelines, hydraulic systems, and industrial processes.

Gate valves, a common type of valve used in fluid control systems, play a critical role in regulating fluid flow. These valves operate by raising or lowering a gate or wedge-shaped disc perpendicular to the flow path. The actuation of gate valves, which refers to the process of opening or closing the valve, is a complex interplay between mechanical forces and fluid dynamics.

The relationship between fluid dynamics and gate valve actuation is multifaceted. As a gate valve opens or closes, it creates changes in the fluid flow characteristics, including velocity, pressure, and turbulence. These changes can have significant impacts on the overall system performance, efficiency, and safety. Understanding these interactions is crucial for designing effective control systems and predicting valve behavior under various operating conditions.

Historically, the development of fluid dynamics theory and valve technology has been closely intertwined. Early studies in fluid mechanics, dating back to the works of Daniel Bernoulli and Leonhard Euler in the 18th century, laid the foundation for understanding fluid behavior. As industrial processes became more complex, the need for precise fluid control led to advancements in valve design and actuation mechanisms.

In recent decades, computational fluid dynamics (CFD) has emerged as a powerful tool for analyzing and predicting fluid behavior in complex systems, including those involving valve actuation. CFD simulations allow engineers to model the intricate interactions between fluid flow and valve movement, providing insights that were previously difficult or impossible to obtain through physical experiments alone.

The assessment of fluid dynamics changes with gate valve actuation responses involves several key considerations. These include the valve's geometry, actuation speed, fluid properties, and system operating conditions. Researchers and engineers in this field aim to develop accurate models and methodologies for predicting how changes in valve position affect fluid flow characteristics and, conversely, how fluid forces impact valve performance.

Understanding these dynamics is crucial for optimizing valve design, improving control strategies, and enhancing overall system reliability. It also plays a vital role in addressing challenges such as cavitation, water hammer effects, and erosion, which can significantly impact the longevity and performance of fluid systems.

Gate valves, a common type of valve used in fluid control systems, play a critical role in regulating fluid flow. These valves operate by raising or lowering a gate or wedge-shaped disc perpendicular to the flow path. The actuation of gate valves, which refers to the process of opening or closing the valve, is a complex interplay between mechanical forces and fluid dynamics.

The relationship between fluid dynamics and gate valve actuation is multifaceted. As a gate valve opens or closes, it creates changes in the fluid flow characteristics, including velocity, pressure, and turbulence. These changes can have significant impacts on the overall system performance, efficiency, and safety. Understanding these interactions is crucial for designing effective control systems and predicting valve behavior under various operating conditions.

Historically, the development of fluid dynamics theory and valve technology has been closely intertwined. Early studies in fluid mechanics, dating back to the works of Daniel Bernoulli and Leonhard Euler in the 18th century, laid the foundation for understanding fluid behavior. As industrial processes became more complex, the need for precise fluid control led to advancements in valve design and actuation mechanisms.

In recent decades, computational fluid dynamics (CFD) has emerged as a powerful tool for analyzing and predicting fluid behavior in complex systems, including those involving valve actuation. CFD simulations allow engineers to model the intricate interactions between fluid flow and valve movement, providing insights that were previously difficult or impossible to obtain through physical experiments alone.

The assessment of fluid dynamics changes with gate valve actuation responses involves several key considerations. These include the valve's geometry, actuation speed, fluid properties, and system operating conditions. Researchers and engineers in this field aim to develop accurate models and methodologies for predicting how changes in valve position affect fluid flow characteristics and, conversely, how fluid forces impact valve performance.

Understanding these dynamics is crucial for optimizing valve design, improving control strategies, and enhancing overall system reliability. It also plays a vital role in addressing challenges such as cavitation, water hammer effects, and erosion, which can significantly impact the longevity and performance of fluid systems.

Market Demand Analysis

The market demand for gate valve actuation systems with improved fluid dynamics is experiencing significant growth across various industries. This surge is primarily driven by the increasing need for precise flow control, enhanced operational efficiency, and reduced energy consumption in critical applications such as oil and gas, water treatment, power generation, and chemical processing.

In the oil and gas sector, the demand for advanced gate valve actuation systems is particularly strong. As exploration and production activities expand into more challenging environments, including deep-water and ultra-deep-water operations, the need for reliable and responsive valve systems capable of handling high pressures and extreme temperatures has intensified. The industry's focus on safety and environmental protection further amplifies the demand for valves that can provide rapid and accurate shut-off capabilities in emergency situations.

The water treatment industry is another key driver of market demand for improved gate valve actuation systems. With growing concerns over water scarcity and the need for efficient water management, there is an increasing emphasis on minimizing leakage and optimizing flow control in distribution networks. Municipalities and water utilities are investing in smart water management systems that require advanced valve technologies capable of real-time monitoring and precise actuation.

In the power generation sector, the transition towards cleaner energy sources and the modernization of existing power plants have created a substantial market for gate valves with enhanced fluid dynamics. These valves play a crucial role in controlling steam flow in thermal power plants and managing coolant circulation in nuclear facilities. The demand for valves that can operate efficiently under varying load conditions and contribute to overall plant efficiency is on the rise.

The chemical processing industry is also a significant contributor to the market demand for advanced gate valve actuation systems. As chemical manufacturers strive for greater process control and product quality, there is a growing need for valves that can handle corrosive fluids, maintain tight shut-off, and provide precise flow regulation. The industry's focus on reducing downtime and improving maintenance schedules further drives the demand for valve systems with predictive maintenance capabilities and improved reliability.

Across all these industries, there is a common trend towards digitalization and automation, which is reshaping the market landscape for gate valve actuation systems. The integration of smart technologies, such as IoT sensors and advanced control algorithms, is becoming increasingly important. This shift is driving demand for valve systems that can seamlessly integrate with digital control systems, provide real-time performance data, and enable remote monitoring and operation.

In the oil and gas sector, the demand for advanced gate valve actuation systems is particularly strong. As exploration and production activities expand into more challenging environments, including deep-water and ultra-deep-water operations, the need for reliable and responsive valve systems capable of handling high pressures and extreme temperatures has intensified. The industry's focus on safety and environmental protection further amplifies the demand for valves that can provide rapid and accurate shut-off capabilities in emergency situations.

The water treatment industry is another key driver of market demand for improved gate valve actuation systems. With growing concerns over water scarcity and the need for efficient water management, there is an increasing emphasis on minimizing leakage and optimizing flow control in distribution networks. Municipalities and water utilities are investing in smart water management systems that require advanced valve technologies capable of real-time monitoring and precise actuation.

In the power generation sector, the transition towards cleaner energy sources and the modernization of existing power plants have created a substantial market for gate valves with enhanced fluid dynamics. These valves play a crucial role in controlling steam flow in thermal power plants and managing coolant circulation in nuclear facilities. The demand for valves that can operate efficiently under varying load conditions and contribute to overall plant efficiency is on the rise.

The chemical processing industry is also a significant contributor to the market demand for advanced gate valve actuation systems. As chemical manufacturers strive for greater process control and product quality, there is a growing need for valves that can handle corrosive fluids, maintain tight shut-off, and provide precise flow regulation. The industry's focus on reducing downtime and improving maintenance schedules further drives the demand for valve systems with predictive maintenance capabilities and improved reliability.

Across all these industries, there is a common trend towards digitalization and automation, which is reshaping the market landscape for gate valve actuation systems. The integration of smart technologies, such as IoT sensors and advanced control algorithms, is becoming increasingly important. This shift is driving demand for valve systems that can seamlessly integrate with digital control systems, provide real-time performance data, and enable remote monitoring and operation.

Current Challenges

The assessment of fluid dynamics changes with gate valve actuation responses faces several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of modeling and predicting fluid behavior during valve operation. The interaction between the moving valve components and the fluid flow creates intricate turbulence patterns and pressure fluctuations that are difficult to accurately simulate using conventional computational fluid dynamics (CFD) methods.

Another major challenge lies in the real-time monitoring and measurement of fluid dynamics during valve actuation. Traditional sensing technologies often struggle to capture high-speed flow changes and localized pressure variations without interfering with the flow itself. This limitation hinders the ability to validate theoretical models and improve the accuracy of predictive algorithms.

The diverse range of fluid properties and operating conditions across different industries further complicates the assessment process. Valves used in oil and gas, water treatment, and chemical processing industries encounter vastly different fluid viscosities, temperatures, and pressures. Developing a unified approach that can accommodate this wide spectrum of conditions remains a significant hurdle for researchers and engineers.

Material limitations also pose challenges in gate valve design and assessment. The need for materials that can withstand high pressures, extreme temperatures, and corrosive fluids while maintaining precise actuation capabilities restricts the design options available to engineers. This constraint often leads to compromises between performance and durability, impacting the overall efficiency of fluid control systems.

The integration of smart technologies and IoT capabilities into gate valve systems introduces new complexities in data management and interpretation. While these advancements offer the potential for improved monitoring and predictive maintenance, they also require sophisticated algorithms to process and analyze the vast amounts of data generated during valve operation.

Scaling laboratory findings to industrial applications presents another significant challenge. The behavior of fluids in controlled, small-scale experiments may not accurately represent the dynamics in large-scale industrial settings. This discrepancy often leads to unexpected performance issues when implementing new valve designs or control strategies in real-world applications.

Lastly, the industry faces a challenge in balancing the need for improved fluid dynamics assessment with cost-effectiveness and regulatory compliance. Developing advanced assessment tools and methodologies requires substantial investment, which must be justified by tangible improvements in valve performance, reliability, and safety. Additionally, any new assessment techniques or valve designs must adhere to stringent industry standards and regulations, further complicating the innovation process.

Another major challenge lies in the real-time monitoring and measurement of fluid dynamics during valve actuation. Traditional sensing technologies often struggle to capture high-speed flow changes and localized pressure variations without interfering with the flow itself. This limitation hinders the ability to validate theoretical models and improve the accuracy of predictive algorithms.

The diverse range of fluid properties and operating conditions across different industries further complicates the assessment process. Valves used in oil and gas, water treatment, and chemical processing industries encounter vastly different fluid viscosities, temperatures, and pressures. Developing a unified approach that can accommodate this wide spectrum of conditions remains a significant hurdle for researchers and engineers.

Material limitations also pose challenges in gate valve design and assessment. The need for materials that can withstand high pressures, extreme temperatures, and corrosive fluids while maintaining precise actuation capabilities restricts the design options available to engineers. This constraint often leads to compromises between performance and durability, impacting the overall efficiency of fluid control systems.

The integration of smart technologies and IoT capabilities into gate valve systems introduces new complexities in data management and interpretation. While these advancements offer the potential for improved monitoring and predictive maintenance, they also require sophisticated algorithms to process and analyze the vast amounts of data generated during valve operation.

Scaling laboratory findings to industrial applications presents another significant challenge. The behavior of fluids in controlled, small-scale experiments may not accurately represent the dynamics in large-scale industrial settings. This discrepancy often leads to unexpected performance issues when implementing new valve designs or control strategies in real-world applications.

Lastly, the industry faces a challenge in balancing the need for improved fluid dynamics assessment with cost-effectiveness and regulatory compliance. Developing advanced assessment tools and methodologies requires substantial investment, which must be justified by tangible improvements in valve performance, reliability, and safety. Additionally, any new assessment techniques or valve designs must adhere to stringent industry standards and regulations, further complicating the innovation process.

Existing Solutions

01 Flow control mechanisms in gate valves

Gate valves employ various flow control mechanisms to regulate fluid dynamics. These mechanisms include adjustable gate positions, specialized sealing surfaces, and flow path designs that minimize turbulence and pressure drops. Advanced gate valve designs incorporate features to optimize fluid flow characteristics and improve overall system efficiency.- Flow control mechanisms in gate valves: Gate valves employ various flow control mechanisms to regulate fluid dynamics. These mechanisms include adjustable gate positions, specialized sealing surfaces, and flow path designs that minimize turbulence and pressure drops. Advanced designs incorporate features to optimize flow characteristics and reduce wear on valve components.

- Pressure balancing and sealing techniques: Innovative pressure balancing and sealing techniques are utilized in gate valves to enhance fluid dynamics performance. These include pressure-assisted seals, balanced valve designs, and advanced sealing materials that adapt to varying pressure conditions. Such features help maintain consistent flow characteristics and improve valve reliability under diverse operating conditions.

- Fluid flow path optimization: Gate valve designs focus on optimizing the fluid flow path to reduce turbulence, minimize pressure losses, and improve overall efficiency. This involves streamlined gate geometries, carefully engineered valve body contours, and strategic placement of flow guides. Advanced computational fluid dynamics simulations are often employed to refine these designs.

- Actuation systems for precise flow control: Sophisticated actuation systems are integrated into gate valves to achieve precise flow control. These may include electric, hydraulic, or pneumatic actuators with advanced control algorithms. Such systems allow for fine-tuned adjustments of the gate position, enabling better management of fluid dynamics across a wide range of operating conditions.

- Materials and coatings for improved fluid dynamics: Advanced materials and surface coatings are employed in gate valve construction to enhance fluid dynamics performance. These include low-friction materials for gate surfaces, corrosion-resistant alloys for valve bodies, and specialized coatings that reduce fluid drag. Such material choices contribute to improved flow characteristics and extended valve lifespan.

02 Fluid dynamics modeling for gate valve design

Computational fluid dynamics (CFD) and advanced modeling techniques are used to analyze and optimize gate valve designs. These methods help engineers predict flow patterns, pressure distributions, and potential areas of turbulence or cavitation. By simulating fluid behavior, designers can refine valve geometries to enhance performance and reliability.Expand Specific Solutions03 Erosion and wear reduction in gate valves

Gate valve designs incorporate features to mitigate erosion and wear caused by fluid dynamics. This includes the use of erosion-resistant materials, optimized flow paths, and specialized coatings. Some designs also implement flow deflectors or sacrificial components to protect critical valve surfaces from high-velocity fluid impingement.Expand Specific Solutions04 Pressure balancing and force reduction

Advanced gate valve designs incorporate pressure balancing mechanisms to reduce operating forces and improve valve performance. These features help equalize pressure across the gate, minimizing the effects of fluid dynamics on valve operation. Pressure-balanced designs can lead to smoother actuation, reduced wear, and improved sealing capabilities.Expand Specific Solutions05 Cavitation prevention in gate valves

Gate valve designs address cavitation issues through careful consideration of fluid dynamics. This includes optimizing valve geometry, implementing multi-stage pressure reduction, and using specialized materials. Some designs incorporate features like anti-cavitation trims or flow straighteners to mitigate the risk of cavitation damage and improve overall valve performance.Expand Specific Solutions

Key Industry Players

The assessment of fluid dynamics changes with gate valve actuation responses is in a mature stage of development, with a substantial market size driven by industrial applications. The technology's maturity is evident from the involvement of established players like Caterpillar, Kubota, and Danfoss, who have integrated advanced valve systems into their product lines. Companies such as Swagelok and Seibu Electric & Machinery specialize in valve actuators and fluid system products, indicating a high level of technical sophistication. The competitive landscape is diverse, with both large conglomerates and specialized firms contributing to ongoing innovations in valve technology and fluid dynamics analysis.

The Swagelok Co.

Technical Solution: Swagelok has developed advanced computational fluid dynamics (CFD) models to assess fluid dynamics changes during gate valve actuation. Their approach combines high-fidelity 3D CFD simulations with reduced-order modeling techniques to capture transient flow behavior efficiently[1]. The company utilizes parallel computing and adaptive mesh refinement to resolve complex flow structures near the valve seat and gate. Swagelok's models account for multiphase flows, cavitation effects, and fluid-structure interactions to provide accurate predictions of pressure drops, flow forces, and potential erosion sites[2]. The company has also implemented machine learning algorithms to optimize valve geometries for improved flow characteristics across various operating conditions[3].

Strengths: Comprehensive modeling approach, industry-leading CFD expertise, integration of advanced numerical methods. Weaknesses: Computationally intensive, may require extensive validation for new valve designs or extreme operating conditions.

Danfoss A/S

Technical Solution: Danfoss has pioneered a holistic approach to assessing fluid dynamics changes in gate valve actuation, combining experimental testing with advanced simulation techniques. Their method incorporates high-speed imaging and particle image velocimetry (PIV) to visualize flow patterns during valve operation[4]. This data is then used to validate and refine their computational models, which include transient CFD simulations and one-dimensional system models. Danfoss has developed proprietary algorithms to predict cavitation inception and intensity, as well as to optimize valve trim designs for noise reduction and erosion mitigation[5]. The company's approach also considers the impact of fluid properties and operating conditions on valve performance, enabling more accurate sizing and selection of valves for specific applications[6].

Strengths: Integration of experimental and computational methods, focus on practical applications, extensive experience in various industries. Weaknesses: Potential limitations in modeling extreme operating conditions or highly specialized valve designs.

Core Innovations

Gate valve real time health monitoring systems

PatentActiveEP2938911A1

Innovation

- A system utilizing acoustic emission, vibration, and strain level sensors to monitor the condition of gate valves, providing real-time health data through passive and active sensing modes, allowing for continuous automated monitoring and reducing human intervention.

Methodology for analysis of valve dynamic closure performance

PatentInactiveUS20220058319A1

Innovation

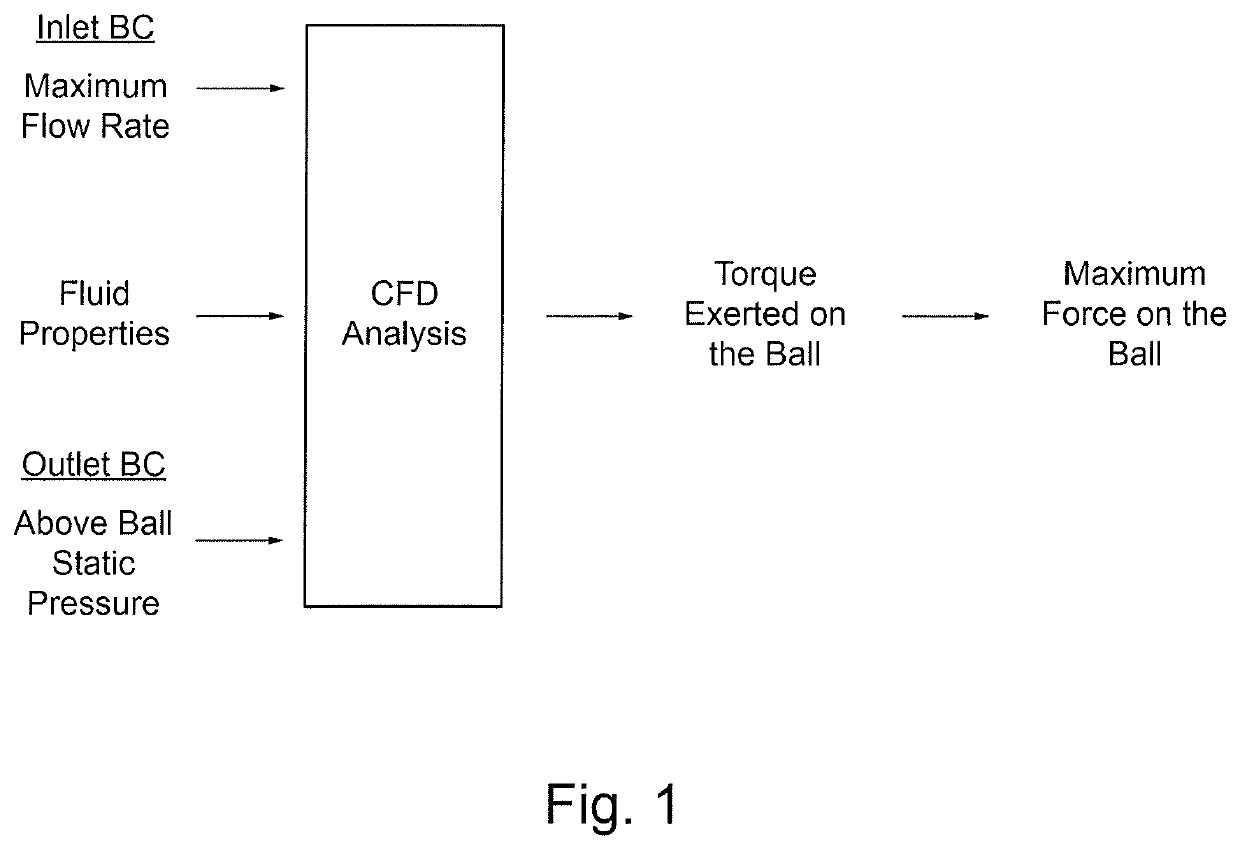

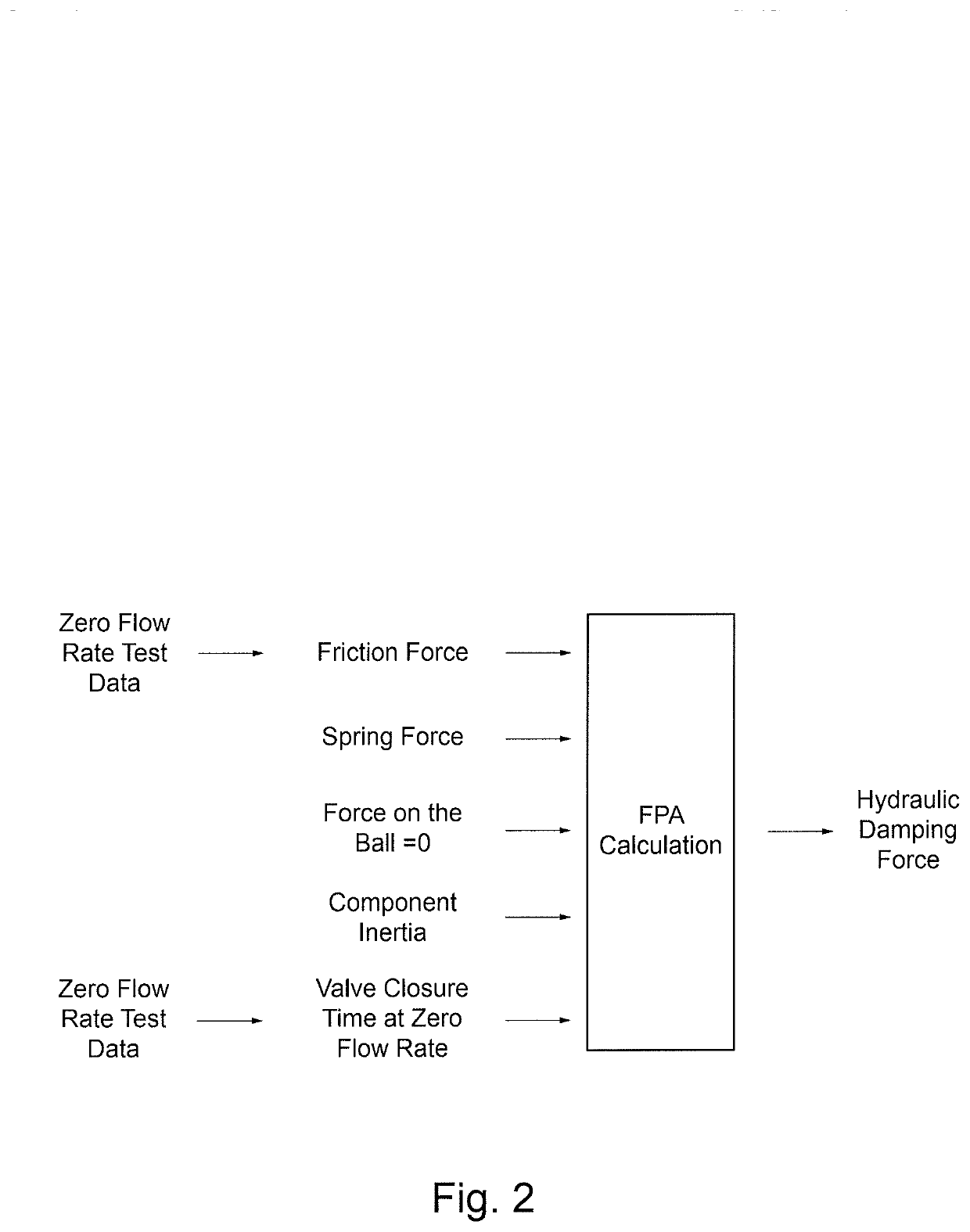

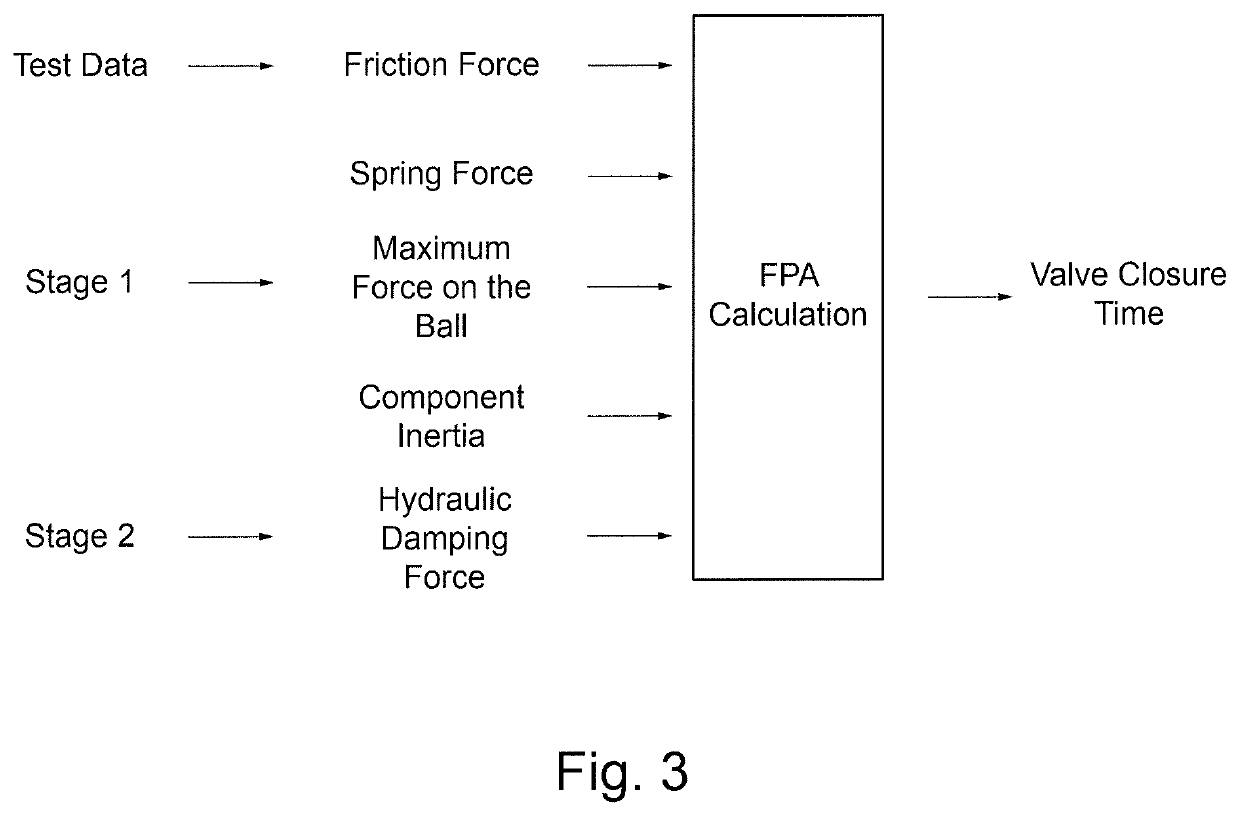

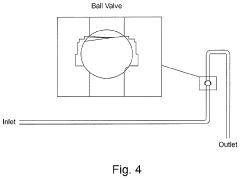

- Decoupling the CFD model from the FPA model allows a single CFD analysis to generate torque values usable in multiple FPA calculations, enabling quicker investigation of parameter variations and faster valve design modeling to assess functionality and compliance with performance standards.

Simulation and Modeling Techniques

Simulation and modeling techniques play a crucial role in assessing fluid dynamics changes with gate valve actuation responses. These methods provide valuable insights into the complex interactions between fluid flow and valve operation, enabling engineers to optimize valve design and performance.

Computational Fluid Dynamics (CFD) is a primary tool used in this field. CFD simulations allow for detailed analysis of fluid behavior within the valve system, including pressure distributions, velocity profiles, and turbulence patterns. Advanced CFD models can incorporate multiphase flows, compressibility effects, and heat transfer, providing a comprehensive understanding of the valve's operational characteristics.

Finite Element Analysis (FEA) is often employed in conjunction with CFD to evaluate the structural response of the valve components to fluid forces. This combined approach enables the assessment of fluid-structure interactions, which is critical for predicting valve performance under various operating conditions.

Transient analysis techniques are particularly important for studying gate valve actuation responses. These methods capture the time-dependent behavior of the fluid as the valve opens or closes, revealing phenomena such as pressure surges, cavitation, and flow instabilities. Transient simulations help in optimizing valve actuation speeds and identifying potential operational issues.

Machine learning algorithms are increasingly being integrated into simulation workflows. These techniques can enhance the accuracy of predictive models by learning from historical data and real-time sensor information. Neural networks and genetic algorithms, for instance, can be used to optimize valve control strategies based on simulated performance data.

Reduced-order modeling techniques are gaining traction in the field, offering a balance between computational efficiency and accuracy. These methods simplify complex fluid dynamics models while retaining essential physical characteristics, enabling rapid design iterations and real-time control applications.

Virtual prototyping and digital twin technologies leverage these simulation techniques to create comprehensive virtual representations of gate valve systems. These digital models can be used for design optimization, performance prediction, and condition monitoring throughout the valve's lifecycle.

Uncertainty quantification methods are being incorporated into simulation frameworks to account for variabilities in material properties, manufacturing tolerances, and operating conditions. These techniques provide probabilistic assessments of valve performance, enhancing the reliability of simulation results.

As computational capabilities continue to advance, the integration of high-fidelity simulations with real-time monitoring systems is becoming feasible. This convergence of simulation and operational data promises to revolutionize gate valve design and maintenance practices, leading to more efficient and reliable fluid control systems.

Computational Fluid Dynamics (CFD) is a primary tool used in this field. CFD simulations allow for detailed analysis of fluid behavior within the valve system, including pressure distributions, velocity profiles, and turbulence patterns. Advanced CFD models can incorporate multiphase flows, compressibility effects, and heat transfer, providing a comprehensive understanding of the valve's operational characteristics.

Finite Element Analysis (FEA) is often employed in conjunction with CFD to evaluate the structural response of the valve components to fluid forces. This combined approach enables the assessment of fluid-structure interactions, which is critical for predicting valve performance under various operating conditions.

Transient analysis techniques are particularly important for studying gate valve actuation responses. These methods capture the time-dependent behavior of the fluid as the valve opens or closes, revealing phenomena such as pressure surges, cavitation, and flow instabilities. Transient simulations help in optimizing valve actuation speeds and identifying potential operational issues.

Machine learning algorithms are increasingly being integrated into simulation workflows. These techniques can enhance the accuracy of predictive models by learning from historical data and real-time sensor information. Neural networks and genetic algorithms, for instance, can be used to optimize valve control strategies based on simulated performance data.

Reduced-order modeling techniques are gaining traction in the field, offering a balance between computational efficiency and accuracy. These methods simplify complex fluid dynamics models while retaining essential physical characteristics, enabling rapid design iterations and real-time control applications.

Virtual prototyping and digital twin technologies leverage these simulation techniques to create comprehensive virtual representations of gate valve systems. These digital models can be used for design optimization, performance prediction, and condition monitoring throughout the valve's lifecycle.

Uncertainty quantification methods are being incorporated into simulation frameworks to account for variabilities in material properties, manufacturing tolerances, and operating conditions. These techniques provide probabilistic assessments of valve performance, enhancing the reliability of simulation results.

As computational capabilities continue to advance, the integration of high-fidelity simulations with real-time monitoring systems is becoming feasible. This convergence of simulation and operational data promises to revolutionize gate valve design and maintenance practices, leading to more efficient and reliable fluid control systems.

Regulatory Compliance

Regulatory compliance plays a crucial role in the assessment of fluid dynamics changes with gate valve actuation responses. The operation and performance of gate valves in various industries are subject to stringent regulations and standards to ensure safety, reliability, and environmental protection.

In the oil and gas industry, regulatory bodies such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO) have established specific guidelines for gate valve design, testing, and operation. These standards, including API 6D and ISO 10434, outline requirements for valve construction, materials, and performance characteristics, which directly impact fluid dynamics and actuation responses.

The nuclear power industry imposes even more rigorous regulations on gate valve performance. The U.S. Nuclear Regulatory Commission (NRC) mandates strict compliance with standards such as ASME QME-1 and ASME OM Code, which govern the qualification and in-service testing of valves in nuclear power plants. These regulations emphasize the importance of accurate assessment of fluid dynamics changes during valve actuation to prevent potential safety hazards.

In the water and wastewater treatment sector, organizations like the American Water Works Association (AWWA) provide standards for gate valves used in water distribution systems. AWWA C509 and C515 specify requirements for resilient-seated gate valves, including performance criteria related to fluid dynamics and actuation responses.

Compliance with these regulations often necessitates comprehensive testing and documentation of gate valve performance under various operating conditions. This includes assessing factors such as pressure drop, flow coefficients, and actuation times across different fluid properties and flow rates. Advanced computational fluid dynamics (CFD) simulations and experimental studies are frequently employed to validate compliance with regulatory requirements.

Regulatory bodies also mandate regular inspection and maintenance programs to ensure ongoing compliance. These programs often involve periodic testing of gate valve actuation responses and fluid dynamics characteristics to detect any degradation in performance over time. Failure to maintain compliance can result in severe penalties, operational shutdowns, and potential safety risks.

As technology advances, regulatory frameworks continue to evolve, incorporating new insights into fluid dynamics and valve actuation. For instance, the increasing focus on energy efficiency has led to the development of regulations that consider the impact of valve design on overall system performance. This trend underscores the importance of ongoing research and development in gate valve technology to meet evolving regulatory standards.

In the oil and gas industry, regulatory bodies such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO) have established specific guidelines for gate valve design, testing, and operation. These standards, including API 6D and ISO 10434, outline requirements for valve construction, materials, and performance characteristics, which directly impact fluid dynamics and actuation responses.

The nuclear power industry imposes even more rigorous regulations on gate valve performance. The U.S. Nuclear Regulatory Commission (NRC) mandates strict compliance with standards such as ASME QME-1 and ASME OM Code, which govern the qualification and in-service testing of valves in nuclear power plants. These regulations emphasize the importance of accurate assessment of fluid dynamics changes during valve actuation to prevent potential safety hazards.

In the water and wastewater treatment sector, organizations like the American Water Works Association (AWWA) provide standards for gate valves used in water distribution systems. AWWA C509 and C515 specify requirements for resilient-seated gate valves, including performance criteria related to fluid dynamics and actuation responses.

Compliance with these regulations often necessitates comprehensive testing and documentation of gate valve performance under various operating conditions. This includes assessing factors such as pressure drop, flow coefficients, and actuation times across different fluid properties and flow rates. Advanced computational fluid dynamics (CFD) simulations and experimental studies are frequently employed to validate compliance with regulatory requirements.

Regulatory bodies also mandate regular inspection and maintenance programs to ensure ongoing compliance. These programs often involve periodic testing of gate valve actuation responses and fluid dynamics characteristics to detect any degradation in performance over time. Failure to maintain compliance can result in severe penalties, operational shutdowns, and potential safety risks.

As technology advances, regulatory frameworks continue to evolve, incorporating new insights into fluid dynamics and valve actuation. For instance, the increasing focus on energy efficiency has led to the development of regulations that consider the impact of valve design on overall system performance. This trend underscores the importance of ongoing research and development in gate valve technology to meet evolving regulatory standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!