Material vulnerabilities in gate valves under corrosive fluid exposure

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Corrosion Background and Objectives

Gate valves have been a critical component in fluid control systems for over a century, playing a vital role in various industries such as oil and gas, chemical processing, and water treatment. These valves are designed to regulate flow by using a flat or wedge-shaped gate that moves perpendicular to the flow path. However, the exposure of gate valves to corrosive fluids has long been a significant challenge, leading to material vulnerabilities that can compromise the integrity and performance of these crucial components.

The evolution of gate valve technology has been closely tied to advancements in metallurgy and materials science. Early gate valves were primarily constructed from cast iron or bronze, which offered limited resistance to corrosive environments. As industrial processes became more complex and demanding, the need for more resilient materials became apparent. This led to the development and adoption of stainless steel, high-nickel alloys, and other corrosion-resistant materials in gate valve construction.

Despite these improvements, the ongoing battle against corrosion in gate valves remains a pressing concern. The interaction between corrosive fluids and valve materials can lead to various forms of degradation, including general corrosion, pitting, stress corrosion cracking, and erosion-corrosion. These phenomena not only reduce the operational lifespan of gate valves but also pose significant safety and environmental risks in critical applications.

The primary objective of addressing material vulnerabilities in gate valves under corrosive fluid exposure is to enhance the longevity, reliability, and safety of fluid control systems. This involves a multifaceted approach that encompasses material selection, surface treatment technologies, and innovative design strategies. Researchers and engineers are focusing on developing advanced materials with superior corrosion resistance, such as duplex stainless steels and ceramic-metal composites.

Furthermore, there is a growing emphasis on understanding the specific corrosion mechanisms at play in different operational environments. This includes the study of electrochemical reactions, fluid dynamics, and the impact of temperature and pressure on material degradation. By gaining a deeper insight into these processes, it becomes possible to tailor material solutions and protective measures more effectively.

Another key objective is the development of predictive models and monitoring systems that can anticipate and detect corrosion-related issues before they lead to catastrophic failures. This proactive approach aims to revolutionize maintenance strategies, moving from reactive to preventive and ultimately predictive maintenance paradigms.

As industries continue to push the boundaries of operational conditions, with higher temperatures, pressures, and more aggressive chemical environments, the quest for corrosion-resistant gate valve materials becomes increasingly critical. The ultimate goal is to create gate valves that can withstand the harshest conditions while maintaining their functional integrity, thereby ensuring the safety, efficiency, and reliability of fluid control systems across various industrial applications.

The evolution of gate valve technology has been closely tied to advancements in metallurgy and materials science. Early gate valves were primarily constructed from cast iron or bronze, which offered limited resistance to corrosive environments. As industrial processes became more complex and demanding, the need for more resilient materials became apparent. This led to the development and adoption of stainless steel, high-nickel alloys, and other corrosion-resistant materials in gate valve construction.

Despite these improvements, the ongoing battle against corrosion in gate valves remains a pressing concern. The interaction between corrosive fluids and valve materials can lead to various forms of degradation, including general corrosion, pitting, stress corrosion cracking, and erosion-corrosion. These phenomena not only reduce the operational lifespan of gate valves but also pose significant safety and environmental risks in critical applications.

The primary objective of addressing material vulnerabilities in gate valves under corrosive fluid exposure is to enhance the longevity, reliability, and safety of fluid control systems. This involves a multifaceted approach that encompasses material selection, surface treatment technologies, and innovative design strategies. Researchers and engineers are focusing on developing advanced materials with superior corrosion resistance, such as duplex stainless steels and ceramic-metal composites.

Furthermore, there is a growing emphasis on understanding the specific corrosion mechanisms at play in different operational environments. This includes the study of electrochemical reactions, fluid dynamics, and the impact of temperature and pressure on material degradation. By gaining a deeper insight into these processes, it becomes possible to tailor material solutions and protective measures more effectively.

Another key objective is the development of predictive models and monitoring systems that can anticipate and detect corrosion-related issues before they lead to catastrophic failures. This proactive approach aims to revolutionize maintenance strategies, moving from reactive to preventive and ultimately predictive maintenance paradigms.

As industries continue to push the boundaries of operational conditions, with higher temperatures, pressures, and more aggressive chemical environments, the quest for corrosion-resistant gate valve materials becomes increasingly critical. The ultimate goal is to create gate valves that can withstand the harshest conditions while maintaining their functional integrity, thereby ensuring the safety, efficiency, and reliability of fluid control systems across various industrial applications.

Market Analysis for Corrosion-Resistant Gate Valves

The market for corrosion-resistant gate valves has been experiencing steady growth due to increasing demand across various industries, particularly in oil and gas, chemical processing, and water treatment sectors. This growth is primarily driven by the need for more durable and reliable valve solutions in harsh operating environments where corrosive fluids are prevalent.

In the oil and gas industry, the market for corrosion-resistant gate valves is particularly robust. As exploration and production activities expand into more challenging environments, such as deep-sea and high-pressure/high-temperature (HPHT) wells, the demand for valves that can withstand corrosive fluids and extreme conditions has surged. The chemical processing industry also contributes significantly to market growth, as manufacturers seek to improve process efficiency and reduce maintenance costs associated with valve failures due to corrosion.

The water treatment sector presents another substantial market opportunity for corrosion-resistant gate valves. With increasing global focus on water conservation and quality, there is a growing need for valves that can handle aggressive chemicals used in water purification processes. Municipal water systems and industrial wastewater treatment facilities are key consumers in this segment.

Geographically, North America and Europe currently dominate the market for corrosion-resistant gate valves, owing to their well-established industrial infrastructure and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in oil and gas exploration, and growing awareness of the importance of corrosion-resistant materials in industrial applications.

The market is characterized by intense competition among key players, including Emerson, Flowserve, IMI, and Velan. These companies are investing heavily in research and development to introduce innovative materials and coatings that enhance the corrosion resistance of gate valves. Additionally, there is a trend towards the development of smart valves with integrated sensors and monitoring capabilities, which allow for predictive maintenance and improved operational efficiency.

Despite the positive growth outlook, the market faces challenges such as high initial costs associated with corrosion-resistant materials and the need for specialized manufacturing processes. However, the long-term benefits of reduced maintenance costs and extended equipment lifespan are expected to outweigh these initial investments, driving continued market expansion.

In the oil and gas industry, the market for corrosion-resistant gate valves is particularly robust. As exploration and production activities expand into more challenging environments, such as deep-sea and high-pressure/high-temperature (HPHT) wells, the demand for valves that can withstand corrosive fluids and extreme conditions has surged. The chemical processing industry also contributes significantly to market growth, as manufacturers seek to improve process efficiency and reduce maintenance costs associated with valve failures due to corrosion.

The water treatment sector presents another substantial market opportunity for corrosion-resistant gate valves. With increasing global focus on water conservation and quality, there is a growing need for valves that can handle aggressive chemicals used in water purification processes. Municipal water systems and industrial wastewater treatment facilities are key consumers in this segment.

Geographically, North America and Europe currently dominate the market for corrosion-resistant gate valves, owing to their well-established industrial infrastructure and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in oil and gas exploration, and growing awareness of the importance of corrosion-resistant materials in industrial applications.

The market is characterized by intense competition among key players, including Emerson, Flowserve, IMI, and Velan. These companies are investing heavily in research and development to introduce innovative materials and coatings that enhance the corrosion resistance of gate valves. Additionally, there is a trend towards the development of smart valves with integrated sensors and monitoring capabilities, which allow for predictive maintenance and improved operational efficiency.

Despite the positive growth outlook, the market faces challenges such as high initial costs associated with corrosion-resistant materials and the need for specialized manufacturing processes. However, the long-term benefits of reduced maintenance costs and extended equipment lifespan are expected to outweigh these initial investments, driving continued market expansion.

Current Challenges in Gate Valve Material Selection

The selection of appropriate materials for gate valves exposed to corrosive fluids presents significant challenges in various industries, particularly in oil and gas, chemical processing, and water treatment sectors. The primary concern lies in the valve's ability to maintain its structural integrity and operational efficiency while resisting the degrading effects of aggressive media.

One of the foremost challenges is the diverse range of corrosive environments that gate valves may encounter. Different fluids, temperatures, and pressures can lead to various forms of corrosion, including general corrosion, pitting, stress corrosion cracking, and erosion-corrosion. This variability necessitates a comprehensive understanding of the specific operating conditions and the potential interactions between the valve materials and the process fluids.

Material selection must also consider the trade-offs between corrosion resistance, mechanical properties, and cost-effectiveness. While highly corrosion-resistant alloys like titanium or nickel-based superalloys offer excellent protection, their high cost and potential manufacturing complexities may render them impractical for widespread use. Conversely, more economical options like carbon steel may require frequent replacement or additional protective measures, potentially increasing long-term operational costs.

The challenge of balancing performance and economic considerations is further complicated by the need for materials that can withstand not only corrosive attack but also mechanical stresses and wear. Gate valves are subject to repeated opening and closing cycles, which can lead to material fatigue and wear, particularly at sealing surfaces. The selected material must therefore possess both corrosion resistance and adequate mechanical properties to ensure long-term reliability.

Another significant challenge is the potential for galvanic corrosion when dissimilar metals are used in valve construction. The combination of different materials, often necessary for optimizing performance of various valve components, can create galvanic couples that accelerate corrosion rates. Careful consideration of the electrochemical properties of materials in contact is crucial to mitigate this risk.

The industry also faces challenges related to emerging environmental regulations and sustainability concerns. There is a growing need for materials that not only resist corrosion but also comply with stringent environmental standards and support sustainable practices. This includes considerations for recyclability, reduced environmental impact during production, and the elimination of hazardous substances in material composition.

Lastly, the rapid pace of technological advancements and the development of new process fluids create an ongoing challenge in material selection. As industries evolve and new corrosive media are introduced, material scientists and engineers must continuously research and develop novel materials or coatings that can withstand these emerging challenges while meeting performance and regulatory requirements.

One of the foremost challenges is the diverse range of corrosive environments that gate valves may encounter. Different fluids, temperatures, and pressures can lead to various forms of corrosion, including general corrosion, pitting, stress corrosion cracking, and erosion-corrosion. This variability necessitates a comprehensive understanding of the specific operating conditions and the potential interactions between the valve materials and the process fluids.

Material selection must also consider the trade-offs between corrosion resistance, mechanical properties, and cost-effectiveness. While highly corrosion-resistant alloys like titanium or nickel-based superalloys offer excellent protection, their high cost and potential manufacturing complexities may render them impractical for widespread use. Conversely, more economical options like carbon steel may require frequent replacement or additional protective measures, potentially increasing long-term operational costs.

The challenge of balancing performance and economic considerations is further complicated by the need for materials that can withstand not only corrosive attack but also mechanical stresses and wear. Gate valves are subject to repeated opening and closing cycles, which can lead to material fatigue and wear, particularly at sealing surfaces. The selected material must therefore possess both corrosion resistance and adequate mechanical properties to ensure long-term reliability.

Another significant challenge is the potential for galvanic corrosion when dissimilar metals are used in valve construction. The combination of different materials, often necessary for optimizing performance of various valve components, can create galvanic couples that accelerate corrosion rates. Careful consideration of the electrochemical properties of materials in contact is crucial to mitigate this risk.

The industry also faces challenges related to emerging environmental regulations and sustainability concerns. There is a growing need for materials that not only resist corrosion but also comply with stringent environmental standards and support sustainable practices. This includes considerations for recyclability, reduced environmental impact during production, and the elimination of hazardous substances in material composition.

Lastly, the rapid pace of technological advancements and the development of new process fluids create an ongoing challenge in material selection. As industries evolve and new corrosive media are introduced, material scientists and engineers must continuously research and develop novel materials or coatings that can withstand these emerging challenges while meeting performance and regulatory requirements.

Existing Solutions for Corrosion Mitigation in Gate Valves

01 Corrosion resistance in gate valve materials

Gate valves are susceptible to corrosion, which can compromise their integrity and performance. Selecting materials with high corrosion resistance, such as stainless steel or specialized alloys, can mitigate this vulnerability. Proper material selection is crucial for extending the lifespan of gate valves in corrosive environments.- Corrosion resistance in gate valve materials: Gate valves are susceptible to corrosion, which can compromise their integrity and performance. Selecting corrosion-resistant materials such as stainless steel, nickel alloys, or specialized coatings can significantly enhance the valve's longevity and reliability in harsh environments. These materials provide a protective barrier against chemical attack and oxidation, reducing the risk of material degradation and potential failure.

- Thermal expansion and contraction issues: Gate valve materials can be vulnerable to thermal expansion and contraction, especially in applications with extreme temperature fluctuations. This can lead to seal failures, misalignment, or even cracking of valve components. Selecting materials with appropriate thermal expansion coefficients and designing valves with thermal stress relief features can mitigate these risks and improve overall valve performance and longevity.

- Wear resistance in high-cycle applications: Gate valves used in high-cycle applications are prone to wear, particularly at sealing surfaces and moving parts. Materials with poor wear resistance can lead to increased leakage, reduced efficiency, and more frequent maintenance. Incorporating wear-resistant materials such as stellite overlays, ceramic coatings, or hardened alloys in critical areas can significantly extend the valve's service life and maintain its performance over time.

- Material compatibility with process fluids: Gate valve materials must be compatible with the process fluids they control to prevent chemical reactions, degradation, or contamination. Incompatible materials can lead to accelerated corrosion, embrittlement, or even catastrophic failure. Careful selection of valve materials based on the specific chemical and physical properties of the process fluids is crucial for ensuring long-term reliability and safety of the valve system.

- Erosion resistance in high-velocity flow: Gate valves exposed to high-velocity flow or abrasive media are susceptible to erosion, which can lead to material loss, reduced sealing capability, and eventual failure. Materials with high erosion resistance, such as tungsten carbide or specialized alloys, can be used in critical areas to mitigate this vulnerability. Additionally, design features that minimize turbulence and distribute flow more evenly can help reduce localized erosion and extend valve life.

02 Wear and erosion in gate valve components

Gate valve components, particularly the gate and seat, are subject to wear and erosion due to frequent operation and exposure to abrasive fluids. This vulnerability can lead to leakage and reduced efficiency. Using hardened materials or applying wear-resistant coatings can help address this issue and improve the valve's longevity.Expand Specific Solutions03 Thermal expansion and contraction effects

Gate valves operating in environments with significant temperature fluctuations are vulnerable to thermal expansion and contraction. This can lead to material stress, deformation, and potential leakage. Designing valves with materials that have compatible thermal expansion coefficients and incorporating flexible sealing elements can help mitigate these issues.Expand Specific Solutions04 Material degradation due to chemical reactions

Certain fluids passing through gate valves may react with valve materials, causing degradation over time. This vulnerability can lead to material breakdown, compromising the valve's structural integrity. Careful consideration of material compatibility with the process fluid and potential chemical reactions is essential in valve design and material selection.Expand Specific Solutions05 Cybersecurity vulnerabilities in smart gate valves

As gate valves become increasingly integrated with digital control systems, they may be susceptible to cybersecurity threats. Vulnerabilities in the software or communication protocols could potentially allow unauthorized access or manipulation of valve operations. Implementing robust cybersecurity measures and regular software updates is crucial for protecting smart gate valves from these risks.Expand Specific Solutions

Key Players in Corrosion-Resistant Valve Manufacturing

The material vulnerabilities in gate valves under corrosive fluid exposure present a complex competitive landscape. The industry is in a mature stage, with established players like Flowserve Pte Ltd., Fisher Controls International LLC, and Cameron International Corp. dominating the market. The global valve market size is substantial, estimated to be in the billions of dollars, with a steady growth rate. Technologically, companies are focusing on developing advanced materials and coatings to enhance corrosion resistance. Firms such as Praxair S.T. Technology, Inc. and MKS, Inc. are investing in research and development to improve valve performance in harsh environments. The competition is intense, with companies like Fujikin, Inc. and Z & J Technologies GmbH offering specialized solutions for specific industries.

Flowserve Pte Ltd.

Technical Solution: Flowserve has developed advanced material solutions for gate valves exposed to corrosive fluids. Their approach includes the use of high-performance alloys such as duplex stainless steels and nickel-based alloys for critical components. They have implemented a proprietary coating technology that enhances the corrosion resistance of valve surfaces. Flowserve's gate valves incorporate innovative sealing systems designed to prevent leakage and maintain integrity under harsh conditions. The company has also developed advanced testing protocols to simulate long-term exposure to corrosive environments, allowing for more accurate prediction of valve performance and lifespan[1][3].

Strengths: Extensive experience in fluid control systems, global presence for diverse application insights. Weaknesses: Higher costs associated with advanced materials, potential over-engineering for less demanding applications.

Fisher Controls International LLC

Technical Solution: Fisher Controls has addressed material vulnerabilities in gate valves through a comprehensive approach. They have developed a range of specialized trim materials, including ceramic-based composites and advanced polymers, to withstand aggressive chemical environments. Their gate valves feature innovative design elements such as bellows seals and live-loaded packing systems to minimize exposure of vulnerable components. Fisher has also implemented advanced computational fluid dynamics (CFD) modeling to optimize flow paths and reduce localized corrosion. Additionally, they have introduced smart diagnostic capabilities in their valves to monitor corrosion rates and predict maintenance needs in real-time[2][5].

Strengths: Strong focus on digital integration and predictive maintenance, wide range of industry-specific solutions. Weaknesses: Complexity of smart systems may increase initial costs and require specialized training for operators.

Innovative Materials and Coatings for Corrosion Resistance

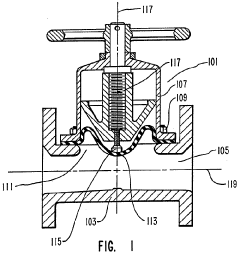

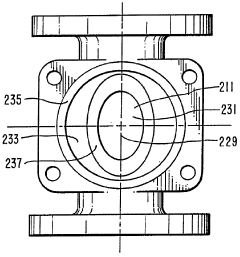

Valve having corrosion resistant polymeric coating

PatentWO2003036146A1

Innovation

- A valve with a corrosion-resistant polymeric coating, specifically poly-(p-xylylene), is applied to the interior surfaces exposed to corrosive fluids, with optional masking of surfaces subject to moving or frictional contact, and an optional coating on exterior surfaces.

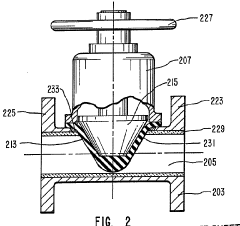

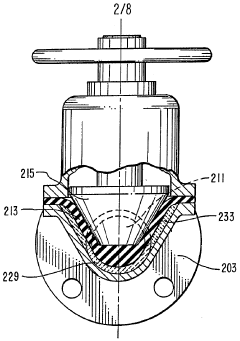

Valve body ceramic liners

PatentWO1991011647A1

Innovation

- A ceramic-lined valve with a non-ceramic valve body and a cylindrical ceramic liner, where the liner is bonded using a flexible, high-chemical-resistance adhesive, allowing for conventional machining and reducing mechanical and thermal stresses, and a conical ceramic insert to protect the bonnet opening from fluids.

Environmental Impact of Corrosion-Resistant Materials

The environmental impact of corrosion-resistant materials used in gate valves exposed to corrosive fluids is a critical consideration in various industries. These materials play a crucial role in mitigating the effects of corrosion, which can lead to equipment failure, leaks, and potential environmental hazards. The use of corrosion-resistant materials in gate valves significantly reduces the risk of material degradation and subsequent release of harmful substances into the environment.

One of the primary environmental benefits of using corrosion-resistant materials is the extended lifespan of gate valves. This longevity reduces the frequency of valve replacements, thereby minimizing waste generation and the need for raw material extraction. Materials such as stainless steel, titanium alloys, and high-performance polymers exhibit excellent resistance to corrosive fluids, ensuring the integrity of the valve system over extended periods.

The reduction in corrosion-related failures also translates to fewer incidents of fluid leakage. This is particularly important when dealing with hazardous or environmentally sensitive materials. By preventing uncontrolled releases, corrosion-resistant gate valves contribute to the protection of soil, water bodies, and surrounding ecosystems from contamination.

Furthermore, the use of advanced corrosion-resistant materials often allows for the design of more efficient valve systems. These improvements can lead to reduced energy consumption during operation, indirectly contributing to lower greenhouse gas emissions. Additionally, some corrosion-resistant materials, such as certain grades of stainless steel, are highly recyclable, promoting a circular economy approach and reducing the overall environmental footprint of valve manufacturing and disposal.

However, it is important to consider the environmental impact of producing these corrosion-resistant materials. Some alloys and specialized coatings may require energy-intensive manufacturing processes or the use of rare earth elements, which can have their own environmental implications. Balancing the long-term benefits of corrosion resistance against the initial environmental costs of material production is a key consideration in sustainable valve design.

In conclusion, while the use of corrosion-resistant materials in gate valves generally yields positive environmental outcomes through increased durability, reduced leakage risk, and improved operational efficiency, a holistic approach is necessary to fully assess their environmental impact. This includes considering the entire lifecycle of the materials, from production to disposal, to ensure that the environmental benefits outweigh any potential drawbacks associated with their manufacture and use.

One of the primary environmental benefits of using corrosion-resistant materials is the extended lifespan of gate valves. This longevity reduces the frequency of valve replacements, thereby minimizing waste generation and the need for raw material extraction. Materials such as stainless steel, titanium alloys, and high-performance polymers exhibit excellent resistance to corrosive fluids, ensuring the integrity of the valve system over extended periods.

The reduction in corrosion-related failures also translates to fewer incidents of fluid leakage. This is particularly important when dealing with hazardous or environmentally sensitive materials. By preventing uncontrolled releases, corrosion-resistant gate valves contribute to the protection of soil, water bodies, and surrounding ecosystems from contamination.

Furthermore, the use of advanced corrosion-resistant materials often allows for the design of more efficient valve systems. These improvements can lead to reduced energy consumption during operation, indirectly contributing to lower greenhouse gas emissions. Additionally, some corrosion-resistant materials, such as certain grades of stainless steel, are highly recyclable, promoting a circular economy approach and reducing the overall environmental footprint of valve manufacturing and disposal.

However, it is important to consider the environmental impact of producing these corrosion-resistant materials. Some alloys and specialized coatings may require energy-intensive manufacturing processes or the use of rare earth elements, which can have their own environmental implications. Balancing the long-term benefits of corrosion resistance against the initial environmental costs of material production is a key consideration in sustainable valve design.

In conclusion, while the use of corrosion-resistant materials in gate valves generally yields positive environmental outcomes through increased durability, reduced leakage risk, and improved operational efficiency, a holistic approach is necessary to fully assess their environmental impact. This includes considering the entire lifecycle of the materials, from production to disposal, to ensure that the environmental benefits outweigh any potential drawbacks associated with their manufacture and use.

Lifecycle Cost Analysis of Corrosion-Resistant Gate Valves

The lifecycle cost analysis of corrosion-resistant gate valves is a critical aspect of material selection and maintenance planning in industries dealing with corrosive fluids. This analysis encompasses the initial investment, operational costs, maintenance expenses, and potential replacement costs over the entire service life of the valve. Corrosion-resistant gate valves, while often more expensive upfront, can significantly reduce long-term costs associated with frequent replacements, production downtime, and potential safety hazards.

When conducting a lifecycle cost analysis, it is essential to consider the specific corrosive environment in which the valve will operate. Factors such as fluid composition, temperature, pressure, and flow rates all contribute to the corrosion rate and, consequently, the valve's lifespan. Materials commonly used for corrosion-resistant gate valves include stainless steel, duplex stainless steel, nickel alloys, and titanium, each offering different levels of corrosion resistance and cost implications.

The initial investment in corrosion-resistant gate valves is typically higher than standard carbon steel alternatives. However, this cost difference is often offset by the extended service life and reduced maintenance requirements. For instance, a stainless steel gate valve may cost 2-3 times more than a carbon steel valve but can last 5-10 times longer in corrosive environments. This longevity translates to fewer replacements over time, reducing both material costs and labor expenses associated with valve changeouts.

Operational costs are another crucial component of the lifecycle cost analysis. Corrosion-resistant gate valves generally maintain their performance characteristics over extended periods, ensuring consistent flow rates and minimal pressure drops. This stability can lead to energy savings in pumping systems and reduce the risk of product contamination, which is particularly important in industries such as pharmaceuticals and food processing.

Maintenance costs for corrosion-resistant gate valves are typically lower than those for standard valves in corrosive environments. The frequency of inspections, cleaning, and parts replacement is reduced, leading to lower labor costs and less production downtime. Additionally, the risk of unexpected failures is minimized, preventing costly emergency shutdowns and potential safety incidents.

When calculating the total lifecycle cost, it is crucial to factor in the potential for lost production due to valve failures or maintenance. In high-value production environments, even short periods of downtime can result in significant financial losses. Corrosion-resistant gate valves can substantially mitigate this risk, providing a more reliable and continuous operation.

When conducting a lifecycle cost analysis, it is essential to consider the specific corrosive environment in which the valve will operate. Factors such as fluid composition, temperature, pressure, and flow rates all contribute to the corrosion rate and, consequently, the valve's lifespan. Materials commonly used for corrosion-resistant gate valves include stainless steel, duplex stainless steel, nickel alloys, and titanium, each offering different levels of corrosion resistance and cost implications.

The initial investment in corrosion-resistant gate valves is typically higher than standard carbon steel alternatives. However, this cost difference is often offset by the extended service life and reduced maintenance requirements. For instance, a stainless steel gate valve may cost 2-3 times more than a carbon steel valve but can last 5-10 times longer in corrosive environments. This longevity translates to fewer replacements over time, reducing both material costs and labor expenses associated with valve changeouts.

Operational costs are another crucial component of the lifecycle cost analysis. Corrosion-resistant gate valves generally maintain their performance characteristics over extended periods, ensuring consistent flow rates and minimal pressure drops. This stability can lead to energy savings in pumping systems and reduce the risk of product contamination, which is particularly important in industries such as pharmaceuticals and food processing.

Maintenance costs for corrosion-resistant gate valves are typically lower than those for standard valves in corrosive environments. The frequency of inspections, cleaning, and parts replacement is reduced, leading to lower labor costs and less production downtime. Additionally, the risk of unexpected failures is minimized, preventing costly emergency shutdowns and potential safety incidents.

When calculating the total lifecycle cost, it is crucial to factor in the potential for lost production due to valve failures or maintenance. In high-value production environments, even short periods of downtime can result in significant financial losses. Corrosion-resistant gate valves can substantially mitigate this risk, providing a more reliable and continuous operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!