Exploring automation impacts on gate valve lifecycle management

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automation in Valve Management: Background and Objectives

Gate valves have been a crucial component in various industries for decades, serving as essential flow control devices in pipelines and process systems. As industrial processes have evolved, so too has the need for more efficient and reliable valve management. The automation of gate valve lifecycle management represents a significant leap forward in this domain, promising to revolutionize how these critical components are monitored, maintained, and operated.

The background of automation in valve management can be traced back to the broader industrial automation movement that gained momentum in the late 20th century. As industries sought to improve efficiency, reduce human error, and enhance safety, the integration of automated systems into various processes became increasingly prevalent. In the context of valve management, early automation efforts focused primarily on remote operation and basic monitoring capabilities.

The objectives of exploring automation impacts on gate valve lifecycle management are multifaceted and align with the broader goals of Industry 4.0. Primarily, automation aims to optimize the performance and longevity of gate valves by implementing predictive maintenance strategies. By continuously monitoring valve conditions and performance metrics, automated systems can anticipate potential failures and schedule maintenance activities proactively, thereby reducing downtime and extending the operational life of these critical components.

Another key objective is to enhance operational efficiency. Automated valve management systems can enable real-time control and monitoring, allowing for rapid response to changing process conditions. This capability is particularly valuable in industries where precise flow control is crucial, such as oil and gas, chemical processing, and water treatment facilities.

Safety improvement is also a paramount objective of automation in valve management. By reducing the need for manual intervention in hazardous environments and providing early warning systems for potential valve failures, automated systems can significantly mitigate risks to personnel and equipment.

Furthermore, the integration of automation in gate valve lifecycle management seeks to improve data collection and analysis capabilities. By gathering comprehensive operational data over time, industries can gain valuable insights into valve performance trends, identify areas for improvement, and make more informed decisions regarding valve selection, maintenance schedules, and replacement strategies.

As we explore the impacts of automation on gate valve lifecycle management, it is essential to consider the technological advancements that enable these objectives. The rise of Internet of Things (IoT) devices, advanced sensors, and sophisticated data analytics platforms has paved the way for more comprehensive and intelligent automation solutions. These technologies, combined with machine learning algorithms, are driving the development of smart valve systems capable of self-diagnosis and adaptive performance optimization.

The background of automation in valve management can be traced back to the broader industrial automation movement that gained momentum in the late 20th century. As industries sought to improve efficiency, reduce human error, and enhance safety, the integration of automated systems into various processes became increasingly prevalent. In the context of valve management, early automation efforts focused primarily on remote operation and basic monitoring capabilities.

The objectives of exploring automation impacts on gate valve lifecycle management are multifaceted and align with the broader goals of Industry 4.0. Primarily, automation aims to optimize the performance and longevity of gate valves by implementing predictive maintenance strategies. By continuously monitoring valve conditions and performance metrics, automated systems can anticipate potential failures and schedule maintenance activities proactively, thereby reducing downtime and extending the operational life of these critical components.

Another key objective is to enhance operational efficiency. Automated valve management systems can enable real-time control and monitoring, allowing for rapid response to changing process conditions. This capability is particularly valuable in industries where precise flow control is crucial, such as oil and gas, chemical processing, and water treatment facilities.

Safety improvement is also a paramount objective of automation in valve management. By reducing the need for manual intervention in hazardous environments and providing early warning systems for potential valve failures, automated systems can significantly mitigate risks to personnel and equipment.

Furthermore, the integration of automation in gate valve lifecycle management seeks to improve data collection and analysis capabilities. By gathering comprehensive operational data over time, industries can gain valuable insights into valve performance trends, identify areas for improvement, and make more informed decisions regarding valve selection, maintenance schedules, and replacement strategies.

As we explore the impacts of automation on gate valve lifecycle management, it is essential to consider the technological advancements that enable these objectives. The rise of Internet of Things (IoT) devices, advanced sensors, and sophisticated data analytics platforms has paved the way for more comprehensive and intelligent automation solutions. These technologies, combined with machine learning algorithms, are driving the development of smart valve systems capable of self-diagnosis and adaptive performance optimization.

Market Demand for Automated Valve Solutions

The market demand for automated valve solutions has been steadily increasing in recent years, driven by the growing need for improved efficiency, reliability, and safety in various industries. Gate valves, as critical components in fluid control systems, are experiencing a significant shift towards automation, particularly in lifecycle management.

The oil and gas industry remains a primary driver for automated valve solutions, with a focus on enhancing operational efficiency and reducing downtime. As offshore and onshore operations become more complex, the need for remote monitoring and control of gate valves has become paramount. This demand is further amplified by the industry's push towards unmanned platforms and digital oilfields, where automated valve systems play a crucial role in maintaining production levels and ensuring safety.

In the water and wastewater treatment sector, there is a growing emphasis on smart water management systems. Municipalities and water utilities are increasingly adopting automated gate valves to optimize water distribution, reduce leakage, and improve overall system performance. The ability to remotely control and monitor valve operations has become essential in managing large-scale water networks efficiently.

The power generation industry, particularly in thermal and nuclear power plants, is another significant market for automated valve solutions. The demand is driven by the need for precise control of steam and water flow, as well as the imperative to enhance plant safety and reliability. Automated gate valves contribute to improved plant efficiency and reduced maintenance costs, which are critical factors in the highly competitive energy market.

Chemical and petrochemical industries are also showing increased interest in automated valve solutions. The need for precise control of process fluids, coupled with stringent safety requirements, has led to a higher adoption rate of automated gate valves. These industries value the ability to integrate valve operations into their broader process control systems, enabling more sophisticated and responsive production processes.

The mining sector is emerging as a potential growth area for automated valve solutions. As mining operations become more automated and remotely controlled, there is a growing demand for valve systems that can operate reliably in harsh environments and be managed from centralized control rooms.

Market analysts project that the global automated valve market will continue to grow at a compound annual growth rate of around 5-6% over the next five years. This growth is attributed to factors such as increasing industrial automation, the need for improved process efficiency, and stringent regulatory requirements across various industries.

The oil and gas industry remains a primary driver for automated valve solutions, with a focus on enhancing operational efficiency and reducing downtime. As offshore and onshore operations become more complex, the need for remote monitoring and control of gate valves has become paramount. This demand is further amplified by the industry's push towards unmanned platforms and digital oilfields, where automated valve systems play a crucial role in maintaining production levels and ensuring safety.

In the water and wastewater treatment sector, there is a growing emphasis on smart water management systems. Municipalities and water utilities are increasingly adopting automated gate valves to optimize water distribution, reduce leakage, and improve overall system performance. The ability to remotely control and monitor valve operations has become essential in managing large-scale water networks efficiently.

The power generation industry, particularly in thermal and nuclear power plants, is another significant market for automated valve solutions. The demand is driven by the need for precise control of steam and water flow, as well as the imperative to enhance plant safety and reliability. Automated gate valves contribute to improved plant efficiency and reduced maintenance costs, which are critical factors in the highly competitive energy market.

Chemical and petrochemical industries are also showing increased interest in automated valve solutions. The need for precise control of process fluids, coupled with stringent safety requirements, has led to a higher adoption rate of automated gate valves. These industries value the ability to integrate valve operations into their broader process control systems, enabling more sophisticated and responsive production processes.

The mining sector is emerging as a potential growth area for automated valve solutions. As mining operations become more automated and remotely controlled, there is a growing demand for valve systems that can operate reliably in harsh environments and be managed from centralized control rooms.

Market analysts project that the global automated valve market will continue to grow at a compound annual growth rate of around 5-6% over the next five years. This growth is attributed to factors such as increasing industrial automation, the need for improved process efficiency, and stringent regulatory requirements across various industries.

Current State and Challenges in Gate Valve Automation

Gate valve automation has made significant strides in recent years, revolutionizing the management and operation of these critical components in various industries. The current state of gate valve automation is characterized by a blend of advanced technologies and traditional mechanical systems, aiming to enhance efficiency, reliability, and safety in valve operations.

One of the primary advancements in gate valve automation is the integration of smart sensors and actuators. These devices enable real-time monitoring of valve position, pressure, and flow rates, providing operators with crucial data for informed decision-making. The implementation of Industrial Internet of Things (IIoT) technologies has further enhanced this capability, allowing for remote monitoring and control of gate valves across vast industrial networks.

Predictive maintenance has emerged as a key focus area in gate valve automation. Machine learning algorithms analyze historical data and current sensor readings to predict potential failures before they occur. This proactive approach significantly reduces downtime and maintenance costs, extending the overall lifecycle of gate valves.

Despite these advancements, the industry faces several challenges in fully realizing the potential of gate valve automation. One major hurdle is the integration of new technologies with legacy systems. Many industrial facilities still rely on older infrastructure, making it difficult to implement cutting-edge automation solutions without significant upgrades or replacements.

Cybersecurity remains a critical concern in the era of connected valve systems. As gate valves become increasingly networked, they become potential targets for cyber attacks. Ensuring the security and integrity of automated valve systems is paramount, requiring ongoing investment in robust cybersecurity measures.

Another challenge lies in the standardization of automation protocols across different manufacturers and industries. The lack of universal standards can lead to compatibility issues and increased complexity in system integration, hindering the widespread adoption of automated solutions.

The skills gap in the workforce presents an additional obstacle. As valve systems become more sophisticated, there is a growing need for technicians and engineers with expertise in both mechanical valve operations and advanced digital technologies. Bridging this knowledge gap requires significant investment in training and education programs.

Environmental concerns also pose challenges for gate valve automation. The industry is under pressure to develop more energy-efficient solutions and reduce the environmental impact of valve operations. This necessitates innovations in materials, designs, and control systems that can meet stringent environmental regulations while maintaining performance standards.

In conclusion, while gate valve automation has made remarkable progress, it continues to face a complex landscape of technological, operational, and regulatory challenges. Addressing these issues will be crucial for realizing the full potential of automation in gate valve lifecycle management and ensuring the continued evolution of this critical industrial technology.

One of the primary advancements in gate valve automation is the integration of smart sensors and actuators. These devices enable real-time monitoring of valve position, pressure, and flow rates, providing operators with crucial data for informed decision-making. The implementation of Industrial Internet of Things (IIoT) technologies has further enhanced this capability, allowing for remote monitoring and control of gate valves across vast industrial networks.

Predictive maintenance has emerged as a key focus area in gate valve automation. Machine learning algorithms analyze historical data and current sensor readings to predict potential failures before they occur. This proactive approach significantly reduces downtime and maintenance costs, extending the overall lifecycle of gate valves.

Despite these advancements, the industry faces several challenges in fully realizing the potential of gate valve automation. One major hurdle is the integration of new technologies with legacy systems. Many industrial facilities still rely on older infrastructure, making it difficult to implement cutting-edge automation solutions without significant upgrades or replacements.

Cybersecurity remains a critical concern in the era of connected valve systems. As gate valves become increasingly networked, they become potential targets for cyber attacks. Ensuring the security and integrity of automated valve systems is paramount, requiring ongoing investment in robust cybersecurity measures.

Another challenge lies in the standardization of automation protocols across different manufacturers and industries. The lack of universal standards can lead to compatibility issues and increased complexity in system integration, hindering the widespread adoption of automated solutions.

The skills gap in the workforce presents an additional obstacle. As valve systems become more sophisticated, there is a growing need for technicians and engineers with expertise in both mechanical valve operations and advanced digital technologies. Bridging this knowledge gap requires significant investment in training and education programs.

Environmental concerns also pose challenges for gate valve automation. The industry is under pressure to develop more energy-efficient solutions and reduce the environmental impact of valve operations. This necessitates innovations in materials, designs, and control systems that can meet stringent environmental regulations while maintaining performance standards.

In conclusion, while gate valve automation has made remarkable progress, it continues to face a complex landscape of technological, operational, and regulatory challenges. Addressing these issues will be crucial for realizing the full potential of automation in gate valve lifecycle management and ensuring the continued evolution of this critical industrial technology.

Existing Automated Lifecycle Management Solutions

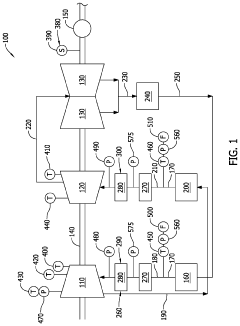

01 Lifecycle management systems for gate valves

Comprehensive systems for managing the entire lifecycle of gate valves, including design, manufacturing, installation, maintenance, and decommissioning. These systems integrate data collection, analysis, and decision-making processes to optimize valve performance, reduce downtime, and extend operational life.- Lifecycle management systems for gate valves: Comprehensive systems for managing the lifecycle of gate valves, including monitoring, maintenance scheduling, and performance optimization. These systems integrate data collection, analysis, and decision-making processes to enhance valve reliability and efficiency throughout their operational life.

- Predictive maintenance for gate valves: Utilizing advanced analytics and machine learning algorithms to predict potential failures or maintenance needs of gate valves. This approach enables proactive maintenance strategies, reducing downtime and extending the operational lifespan of the valves.

- Digital twin technology for gate valve management: Implementation of digital twin technology to create virtual representations of gate valves. This allows for real-time monitoring, simulation of various operational scenarios, and optimization of valve performance throughout its lifecycle.

- Asset management software for gate valves: Specialized software solutions designed for managing gate valve assets, including inventory tracking, maintenance history, performance data, and lifecycle cost analysis. These tools help in making informed decisions about valve replacement, upgrades, or decommissioning.

- IoT integration for gate valve monitoring: Incorporation of Internet of Things (IoT) devices and sensors for continuous monitoring of gate valve performance and condition. This enables real-time data collection, remote diagnostics, and automated alerts for potential issues, enhancing overall lifecycle management.

02 Predictive maintenance for gate valves

Advanced algorithms and data analytics techniques to predict potential failures or maintenance needs of gate valves. These systems utilize real-time monitoring, historical data, and machine learning to forecast valve performance, schedule maintenance activities, and prevent unexpected breakdowns.Expand Specific Solutions03 Digital twin technology for gate valve management

Implementation of digital twin technology to create virtual representations of physical gate valves. This approach enables real-time monitoring, simulation of various operating conditions, and optimization of valve performance throughout its lifecycle, enhancing decision-making and maintenance strategies.Expand Specific Solutions04 Asset management software for gate valves

Specialized software solutions designed for managing gate valve assets throughout their lifecycle. These platforms typically include features such as inventory management, maintenance scheduling, performance tracking, and reporting tools to streamline valve management processes and improve overall efficiency.Expand Specific Solutions05 Integration of IoT and sensors in gate valve lifecycle management

Incorporation of Internet of Things (IoT) devices and advanced sensors to continuously monitor gate valve performance and health. This approach enables real-time data collection, remote monitoring, and automated alerts, facilitating proactive maintenance and informed decision-making throughout the valve's lifecycle.Expand Specific Solutions

Key Players in Valve Automation Industry

The automation of gate valve lifecycle management is in a nascent stage, with the market poised for significant growth as industries seek to optimize operations and reduce downtime. The global market for valve automation is expanding, driven by increasing demand in oil & gas, water treatment, and power generation sectors. Technologically, the field is evolving rapidly, with companies like Schlumberger Technologies, Inc., Fisher Controls International LLC, and Festo SE & Co. KG leading innovation in smart valve systems and predictive maintenance solutions. These advancements are integrating IoT, AI, and data analytics to enhance valve performance, reliability, and longevity. However, the technology's maturity varies across different applications, with some sectors still in early adoption phases.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an advanced automation system for gate valve lifecycle management. Their solution integrates real-time monitoring, predictive maintenance, and remote operation capabilities. The system utilizes IoT sensors to continuously collect data on valve performance, including pressure, temperature, and flow rates[1]. This data is then analyzed using machine learning algorithms to predict potential failures and optimize maintenance schedules[2]. The automation system also includes a remote operation feature, allowing operators to control valves from a centralized location, reducing the need for on-site personnel and improving safety[3]. Additionally, Schlumberger has implemented digital twin technology to create virtual replicas of gate valves, enabling more accurate simulations and testing of different operational scenarios[4].

Strengths: Comprehensive solution integrating multiple technologies, predictive maintenance capabilities, improved safety through remote operation. Weaknesses: High initial implementation cost, potential cybersecurity risks associated with remote operation.

Festo SE & Co. KG

Technical Solution: Festo has developed an innovative automation solution for gate valve lifecycle management called "ValveXpert". This system leverages Festo's expertise in pneumatics and industrial automation to provide a comprehensive approach to valve management. ValveXpert utilizes smart sensors to monitor key valve performance parameters, including pressure, flow rate, and actuator position[1]. The data is processed using Festo's proprietary algorithms, which employ machine learning techniques to predict valve failures and optimize maintenance schedules[2]. The system features a modular design, allowing for easy integration with existing infrastructure and scalability as needs change[3]. ValveXpert also incorporates Festo's Motion Terminal technology, which uses piezo valves and software-based function changes to adapt valve behavior in real-time, improving efficiency and reducing wear[4]. Additionally, the system includes a mobile application that enables remote monitoring and control of valves, enhancing operational flexibility and safety[5].

Strengths: Leverages Festo's expertise in pneumatics, modular and scalable design, innovative Motion Terminal technology. Weaknesses: May be more focused on pneumatic systems, potentially limiting applicability in some industries, possible integration challenges with non-Festo components.

Innovative Approaches in Valve Automation

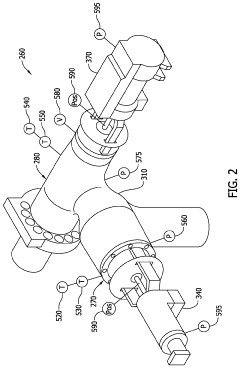

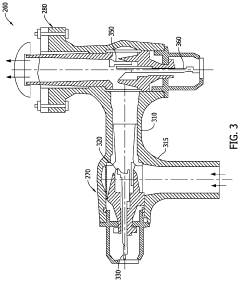

Gate valve assemblies and methods of use

PatentInactiveUS20130240052A1

Innovation

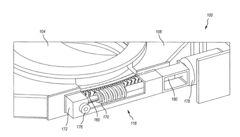

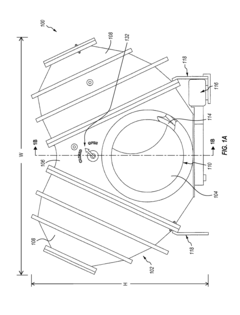

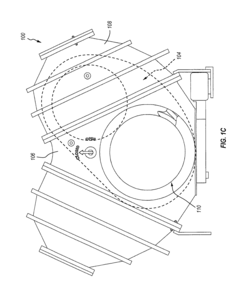

- A gate valve assembly with a worm gear system and an elliptical or kidney-like shaped gate that is rotatable between open and closed positions, featuring drive teeth for engagement with the worm gear, ensuring tight sealing, low maintenance, and efficient operation under severe conditions.

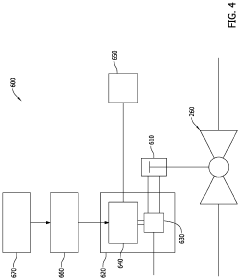

Method and system for a component lifetime counter

PatentActiveUS20200116024A1

Innovation

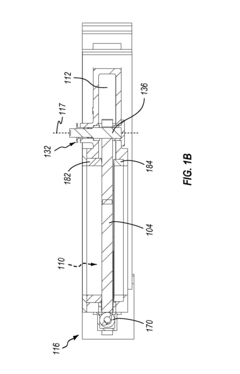

- The Online Valve Lifetime Counter (OVLIC) system, which includes sensors and a processor, monitors temperature and pressure parameters to determine creep and fatigue stresses, calculating the remaining life of valves by accumulating stress data over time and providing real-time or near-real-time evaluations of valve condition, enabling early warnings and informed maintenance planning.

Regulatory Framework for Industrial Valve Automation

The regulatory framework for industrial valve automation plays a crucial role in ensuring safety, reliability, and efficiency in various industries. As automation technologies continue to advance, regulatory bodies have been adapting their guidelines to address the unique challenges and opportunities presented by automated valve systems.

In the United States, the Occupational Safety and Health Administration (OSHA) has established standards for the safe operation of industrial valves, including those that are automated. These regulations cover aspects such as proper installation, maintenance, and inspection procedures. Additionally, the American Society of Mechanical Engineers (ASME) has developed specific codes and standards for automated valve systems, focusing on design, manufacturing, and testing requirements.

The European Union has implemented the Machinery Directive (2006/42/EC), which sets out essential health and safety requirements for machinery, including automated valve systems. This directive emphasizes risk assessment and mitigation strategies for automated equipment. Furthermore, the ATEX Directive (2014/34/EU) addresses the safety of equipment used in potentially explosive atmospheres, which is particularly relevant for automated valves in certain industrial settings.

In the oil and gas industry, which heavily relies on automated gate valves, the American Petroleum Institute (API) has developed standards such as API 6D and API 6FA. These standards provide guidelines for the design, testing, and qualification of automated valves used in pipeline transportation systems. Similarly, the International Electrotechnical Commission (IEC) has established standards for the functional safety of automated control systems, including those used in valve automation.

As the adoption of Industrial Internet of Things (IIoT) technologies increases in valve automation, regulatory bodies are also addressing cybersecurity concerns. The National Institute of Standards and Technology (NIST) in the United States has published guidelines for securing industrial control systems, which are applicable to automated valve networks. The International Society of Automation (ISA) has developed the ISA/IEC 62443 series of standards, providing a framework for securing industrial automation and control systems.

Environmental regulations also impact the automation of industrial valves. For instance, the U.S. Environmental Protection Agency (EPA) has implemented regulations under the Clean Air Act that require the use of automated valves and leak detection systems in certain industrial processes to minimize emissions. Similar environmental regulations exist in other countries, driving the adoption of automated valve technologies to improve environmental performance.

As automation technologies continue to evolve, regulatory frameworks are expected to adapt accordingly. This may include the development of new standards for emerging technologies such as artificial intelligence and machine learning in valve automation, as well as updates to existing regulations to address the changing landscape of industrial automation.

In the United States, the Occupational Safety and Health Administration (OSHA) has established standards for the safe operation of industrial valves, including those that are automated. These regulations cover aspects such as proper installation, maintenance, and inspection procedures. Additionally, the American Society of Mechanical Engineers (ASME) has developed specific codes and standards for automated valve systems, focusing on design, manufacturing, and testing requirements.

The European Union has implemented the Machinery Directive (2006/42/EC), which sets out essential health and safety requirements for machinery, including automated valve systems. This directive emphasizes risk assessment and mitigation strategies for automated equipment. Furthermore, the ATEX Directive (2014/34/EU) addresses the safety of equipment used in potentially explosive atmospheres, which is particularly relevant for automated valves in certain industrial settings.

In the oil and gas industry, which heavily relies on automated gate valves, the American Petroleum Institute (API) has developed standards such as API 6D and API 6FA. These standards provide guidelines for the design, testing, and qualification of automated valves used in pipeline transportation systems. Similarly, the International Electrotechnical Commission (IEC) has established standards for the functional safety of automated control systems, including those used in valve automation.

As the adoption of Industrial Internet of Things (IIoT) technologies increases in valve automation, regulatory bodies are also addressing cybersecurity concerns. The National Institute of Standards and Technology (NIST) in the United States has published guidelines for securing industrial control systems, which are applicable to automated valve networks. The International Society of Automation (ISA) has developed the ISA/IEC 62443 series of standards, providing a framework for securing industrial automation and control systems.

Environmental regulations also impact the automation of industrial valves. For instance, the U.S. Environmental Protection Agency (EPA) has implemented regulations under the Clean Air Act that require the use of automated valves and leak detection systems in certain industrial processes to minimize emissions. Similar environmental regulations exist in other countries, driving the adoption of automated valve technologies to improve environmental performance.

As automation technologies continue to evolve, regulatory frameworks are expected to adapt accordingly. This may include the development of new standards for emerging technologies such as artificial intelligence and machine learning in valve automation, as well as updates to existing regulations to address the changing landscape of industrial automation.

Environmental Impact of Automated Valve Systems

The implementation of automated valve systems in gate valve lifecycle management has significant environmental implications. These systems contribute to reduced energy consumption through optimized valve operations, minimizing unnecessary fluid flow and pressure losses. By precisely controlling valve positions, automated systems prevent overflows and leaks, thereby reducing waste and potential environmental contamination.

Automated valve systems also extend the operational lifespan of gate valves by ensuring proper usage and maintenance schedules. This longevity reduces the frequency of valve replacements, consequently decreasing the environmental impact associated with manufacturing and disposing of valve components. The improved efficiency and reduced downtime of automated systems lead to lower overall resource consumption in industrial processes.

Furthermore, automated valve systems enable more accurate monitoring and data collection, facilitating better environmental compliance and reporting. Real-time data on valve performance allows for quick identification and resolution of issues that could lead to environmental hazards. This proactive approach minimizes the risk of accidental releases or spills, protecting surrounding ecosystems.

The integration of automated valve systems with broader industrial control networks promotes energy-efficient operations across entire facilities. By coordinating valve actions with other process equipment, these systems optimize resource utilization and reduce overall environmental footprint. Additionally, the remote operation capabilities of automated systems reduce the need for on-site personnel, potentially decreasing transportation-related emissions.

However, the environmental impact of automated valve systems is not entirely positive. The production and disposal of electronic components and sensors used in these systems can contribute to electronic waste. Proper recycling and disposal protocols must be implemented to mitigate this concern. Additionally, the increased reliance on electricity for automated systems may have indirect environmental effects, depending on the source of power generation.

Despite these considerations, the net environmental impact of automated valve systems in gate valve lifecycle management is generally positive. The improved efficiency, reduced waste, and enhanced monitoring capabilities outweigh the potential drawbacks. As technology continues to advance, it is likely that the environmental benefits of these systems will further increase, contributing to more sustainable industrial practices.

Automated valve systems also extend the operational lifespan of gate valves by ensuring proper usage and maintenance schedules. This longevity reduces the frequency of valve replacements, consequently decreasing the environmental impact associated with manufacturing and disposing of valve components. The improved efficiency and reduced downtime of automated systems lead to lower overall resource consumption in industrial processes.

Furthermore, automated valve systems enable more accurate monitoring and data collection, facilitating better environmental compliance and reporting. Real-time data on valve performance allows for quick identification and resolution of issues that could lead to environmental hazards. This proactive approach minimizes the risk of accidental releases or spills, protecting surrounding ecosystems.

The integration of automated valve systems with broader industrial control networks promotes energy-efficient operations across entire facilities. By coordinating valve actions with other process equipment, these systems optimize resource utilization and reduce overall environmental footprint. Additionally, the remote operation capabilities of automated systems reduce the need for on-site personnel, potentially decreasing transportation-related emissions.

However, the environmental impact of automated valve systems is not entirely positive. The production and disposal of electronic components and sensors used in these systems can contribute to electronic waste. Proper recycling and disposal protocols must be implemented to mitigate this concern. Additionally, the increased reliance on electricity for automated systems may have indirect environmental effects, depending on the source of power generation.

Despite these considerations, the net environmental impact of automated valve systems in gate valve lifecycle management is generally positive. The improved efficiency, reduced waste, and enhanced monitoring capabilities outweigh the potential drawbacks. As technology continues to advance, it is likely that the environmental benefits of these systems will further increase, contributing to more sustainable industrial practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!