Exploring temperature gradient effects on gate valve operation precision

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Temperature Gradient Effects on Gate Valves

Temperature gradients play a crucial role in the operation and precision of gate valves, significantly impacting their performance across various industrial applications. These gradients arise from differences in temperature between the valve body, gate, and surrounding environment, leading to thermal expansion and contraction of valve components. Such thermal effects can result in changes to the valve's internal clearances, potentially affecting its sealing capabilities and overall operational accuracy.

The influence of temperature gradients on gate valve operation precision is particularly pronounced in industries dealing with extreme temperature variations, such as oil and gas, chemical processing, and power generation. In these sectors, valves may be subjected to rapid temperature fluctuations or sustained exposure to high or low temperatures, exacerbating the challenges posed by thermal gradients.

One of the primary concerns associated with temperature gradients is the potential for thermal binding or thermal expansion locking. This phenomenon occurs when different parts of the valve expand or contract at varying rates due to temperature differences, leading to increased friction or even seizure of the gate within the valve body. Such issues can compromise the valve's ability to open or close smoothly, reducing its operational precision and potentially causing system failures.

Moreover, temperature gradients can induce thermal stress within the valve components, potentially leading to material fatigue, deformation, or even fracture over time. This is especially critical in high-pressure applications where the structural integrity of the valve is paramount for safe and efficient operation.

The effects of temperature gradients on gate valve precision are not limited to mechanical aspects alone. Thermal variations can also impact the properties of sealing materials, affecting their elasticity, hardness, and overall sealing effectiveness. This can result in increased leakage rates and reduced valve performance, particularly in applications requiring tight shut-off capabilities.

To address these challenges, engineers and researchers have been exploring various strategies to mitigate the impact of temperature gradients on gate valve operation precision. These efforts include the development of advanced materials with improved thermal properties, innovative valve designs that accommodate thermal expansion, and the implementation of sophisticated thermal management systems.

Furthermore, the integration of smart technologies and sensors for real-time monitoring of temperature distributions within gate valves has emerged as a promising approach. This enables predictive maintenance strategies and allows for dynamic adjustments to valve operation parameters based on current thermal conditions, thereby enhancing overall precision and reliability.

The influence of temperature gradients on gate valve operation precision is particularly pronounced in industries dealing with extreme temperature variations, such as oil and gas, chemical processing, and power generation. In these sectors, valves may be subjected to rapid temperature fluctuations or sustained exposure to high or low temperatures, exacerbating the challenges posed by thermal gradients.

One of the primary concerns associated with temperature gradients is the potential for thermal binding or thermal expansion locking. This phenomenon occurs when different parts of the valve expand or contract at varying rates due to temperature differences, leading to increased friction or even seizure of the gate within the valve body. Such issues can compromise the valve's ability to open or close smoothly, reducing its operational precision and potentially causing system failures.

Moreover, temperature gradients can induce thermal stress within the valve components, potentially leading to material fatigue, deformation, or even fracture over time. This is especially critical in high-pressure applications where the structural integrity of the valve is paramount for safe and efficient operation.

The effects of temperature gradients on gate valve precision are not limited to mechanical aspects alone. Thermal variations can also impact the properties of sealing materials, affecting their elasticity, hardness, and overall sealing effectiveness. This can result in increased leakage rates and reduced valve performance, particularly in applications requiring tight shut-off capabilities.

To address these challenges, engineers and researchers have been exploring various strategies to mitigate the impact of temperature gradients on gate valve operation precision. These efforts include the development of advanced materials with improved thermal properties, innovative valve designs that accommodate thermal expansion, and the implementation of sophisticated thermal management systems.

Furthermore, the integration of smart technologies and sensors for real-time monitoring of temperature distributions within gate valves has emerged as a promising approach. This enables predictive maintenance strategies and allows for dynamic adjustments to valve operation parameters based on current thermal conditions, thereby enhancing overall precision and reliability.

Market Demand for Precision Valve Control

The market demand for precision valve control has been steadily increasing across various industries, driven by the need for enhanced operational efficiency, safety, and regulatory compliance. In the oil and gas sector, where gate valves are extensively used, the demand for precise control is particularly high due to the critical nature of operations and the potential environmental and economic impacts of valve failures.

Temperature gradients significantly affect gate valve operation precision, making it a key focus area for improvement. As industrial processes become more complex and automated, the ability to maintain consistent valve performance across varying temperature conditions has become crucial. This demand is further amplified by the expansion of operations in extreme environments, such as deep-sea drilling and arctic exploration, where temperature fluctuations are more pronounced.

The petrochemical industry, another major user of gate valves, requires exceptionally precise flow control to maintain product quality and process efficiency. Temperature-induced changes in valve operation can lead to off-spec products, increased waste, and potential safety hazards. Consequently, there is a growing market for gate valves that can maintain operational precision despite temperature gradients.

In the power generation sector, particularly in nuclear and thermal power plants, the demand for precision valve control is driven by safety considerations and the need for optimal energy efficiency. Temperature variations can affect the sealing properties of gate valves, potentially leading to leaks or inefficient steam management. This has created a market for advanced valve technologies that can adapt to temperature changes while maintaining precise control.

The water and wastewater treatment industry is also experiencing increased demand for precision valve control. As water scarcity becomes a global concern, efficient water management is paramount. Gate valves that can maintain precise flow control regardless of temperature fluctuations are essential for optimizing water distribution systems and reducing water loss.

Market research indicates that the global industrial valve market, which includes gate valves, is expected to grow significantly in the coming years. This growth is partly attributed to the increasing demand for smart valves with advanced control capabilities, including those that can compensate for temperature gradient effects.

The aerospace and defense sectors represent emerging markets for precision valve control technologies. In these applications, gate valves must operate with extreme precision under widely varying temperature conditions, from the cold of high altitudes to the heat generated during high-speed flight or rocket launches.

As industries continue to prioritize operational excellence and sustainability, the market demand for gate valves with enhanced precision control capabilities is likely to intensify. This trend is driving innovation in valve design, materials science, and control systems, creating opportunities for companies that can develop solutions to mitigate the effects of temperature gradients on valve operation precision.

Temperature gradients significantly affect gate valve operation precision, making it a key focus area for improvement. As industrial processes become more complex and automated, the ability to maintain consistent valve performance across varying temperature conditions has become crucial. This demand is further amplified by the expansion of operations in extreme environments, such as deep-sea drilling and arctic exploration, where temperature fluctuations are more pronounced.

The petrochemical industry, another major user of gate valves, requires exceptionally precise flow control to maintain product quality and process efficiency. Temperature-induced changes in valve operation can lead to off-spec products, increased waste, and potential safety hazards. Consequently, there is a growing market for gate valves that can maintain operational precision despite temperature gradients.

In the power generation sector, particularly in nuclear and thermal power plants, the demand for precision valve control is driven by safety considerations and the need for optimal energy efficiency. Temperature variations can affect the sealing properties of gate valves, potentially leading to leaks or inefficient steam management. This has created a market for advanced valve technologies that can adapt to temperature changes while maintaining precise control.

The water and wastewater treatment industry is also experiencing increased demand for precision valve control. As water scarcity becomes a global concern, efficient water management is paramount. Gate valves that can maintain precise flow control regardless of temperature fluctuations are essential for optimizing water distribution systems and reducing water loss.

Market research indicates that the global industrial valve market, which includes gate valves, is expected to grow significantly in the coming years. This growth is partly attributed to the increasing demand for smart valves with advanced control capabilities, including those that can compensate for temperature gradient effects.

The aerospace and defense sectors represent emerging markets for precision valve control technologies. In these applications, gate valves must operate with extreme precision under widely varying temperature conditions, from the cold of high altitudes to the heat generated during high-speed flight or rocket launches.

As industries continue to prioritize operational excellence and sustainability, the market demand for gate valves with enhanced precision control capabilities is likely to intensify. This trend is driving innovation in valve design, materials science, and control systems, creating opportunities for companies that can develop solutions to mitigate the effects of temperature gradients on valve operation precision.

Current Challenges in Thermal Management

Temperature gradients pose significant challenges in the thermal management of gate valve operations, particularly in maintaining precision and reliability. The primary issue stems from the uneven distribution of heat across the valve components, leading to thermal expansion and contraction that can affect the valve's performance and longevity.

One of the most pressing challenges is the thermal stress induced by temperature differentials between the valve body and the gate. This stress can cause warping, misalignment, or even cracking of components, compromising the valve's sealing ability and overall functionality. The problem is exacerbated in high-temperature applications, where the temperature gradients are more pronounced and the materials are pushed closer to their operational limits.

Another critical challenge is the impact of thermal gradients on the valve's actuator system. Temperature fluctuations can affect the viscosity of hydraulic fluids or the performance of electric motors, leading to inconsistent actuation speeds or force. This variability can result in imprecise valve positioning, which is particularly problematic in applications requiring fine control over flow rates or pressure.

The thermal expansion of different materials used in valve construction presents an additional layer of complexity. Components made from materials with varying coefficients of thermal expansion may respond differently to temperature changes, potentially causing gaps, leaks, or binding between moving parts. This differential expansion can lead to increased wear, reduced operational life, and potential safety hazards in critical systems.

Furthermore, the cyclical nature of temperature changes in many industrial processes introduces fatigue considerations. Repeated thermal cycling can lead to the degradation of seals, gaskets, and other soft components, necessitating more frequent maintenance and replacement. This not only increases operational costs but also introduces potential points of failure that could compromise system integrity.

The challenge of heat dissipation in compact valve designs is also a significant concern. As industrial processes demand more compact and efficient equipment, the ability to effectively manage heat within confined spaces becomes increasingly difficult. Inadequate heat dissipation can lead to localized hot spots, accelerating wear and potentially causing premature failure of critical components.

Addressing these thermal management challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and sophisticated modeling and simulation tools. The development of new materials with improved thermal properties, such as enhanced thermal conductivity or reduced thermal expansion, is crucial. Similarly, the integration of active cooling systems or smart thermal management solutions may be necessary to maintain precise temperature control in extreme operating conditions.

One of the most pressing challenges is the thermal stress induced by temperature differentials between the valve body and the gate. This stress can cause warping, misalignment, or even cracking of components, compromising the valve's sealing ability and overall functionality. The problem is exacerbated in high-temperature applications, where the temperature gradients are more pronounced and the materials are pushed closer to their operational limits.

Another critical challenge is the impact of thermal gradients on the valve's actuator system. Temperature fluctuations can affect the viscosity of hydraulic fluids or the performance of electric motors, leading to inconsistent actuation speeds or force. This variability can result in imprecise valve positioning, which is particularly problematic in applications requiring fine control over flow rates or pressure.

The thermal expansion of different materials used in valve construction presents an additional layer of complexity. Components made from materials with varying coefficients of thermal expansion may respond differently to temperature changes, potentially causing gaps, leaks, or binding between moving parts. This differential expansion can lead to increased wear, reduced operational life, and potential safety hazards in critical systems.

Furthermore, the cyclical nature of temperature changes in many industrial processes introduces fatigue considerations. Repeated thermal cycling can lead to the degradation of seals, gaskets, and other soft components, necessitating more frequent maintenance and replacement. This not only increases operational costs but also introduces potential points of failure that could compromise system integrity.

The challenge of heat dissipation in compact valve designs is also a significant concern. As industrial processes demand more compact and efficient equipment, the ability to effectively manage heat within confined spaces becomes increasingly difficult. Inadequate heat dissipation can lead to localized hot spots, accelerating wear and potentially causing premature failure of critical components.

Addressing these thermal management challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and sophisticated modeling and simulation tools. The development of new materials with improved thermal properties, such as enhanced thermal conductivity or reduced thermal expansion, is crucial. Similarly, the integration of active cooling systems or smart thermal management solutions may be necessary to maintain precise temperature control in extreme operating conditions.

Existing Thermal Compensation Solutions

01 Precision control mechanisms

Gate valves can be equipped with advanced control mechanisms to enhance operation precision. These may include electronic positioning systems, servo motors, or hydraulic actuators that allow for precise adjustment of the gate position. Such mechanisms can provide accurate flow control and reduce the risk of operational errors.- Precision control mechanisms: Gate valves can be equipped with advanced control mechanisms to improve operation precision. These may include electronic positioning systems, servo motors, or hydraulic actuators that allow for precise adjustment of the gate position. Such mechanisms enable fine-tuning of flow rates and pressure control, enhancing overall valve performance and reliability.

- Improved sealing technologies: Enhanced sealing technologies contribute to better operation precision in gate valves. This includes the use of advanced materials for seals, such as high-performance polymers or metal-to-metal seals, as well as innovative sealing designs that minimize leakage and improve shut-off capabilities. These improvements result in more accurate flow control and increased valve longevity.

- Intelligent monitoring and feedback systems: Integration of smart sensors and feedback systems in gate valves allows for real-time monitoring of valve position, pressure, and flow rates. This data can be used to make automatic adjustments or alert operators to potential issues, ensuring more precise and responsive valve operation. Such systems may include digital displays, remote monitoring capabilities, or integration with broader control systems.

- Optimized valve geometry and flow path design: Improvements in valve geometry and flow path design can significantly enhance operation precision. This includes streamlined gate designs, optimized seat configurations, and carefully engineered flow channels that reduce turbulence and pressure drop. These design optimizations result in smoother operation, more accurate flow control, and reduced wear on valve components.

- Advanced manufacturing and material technologies: The use of advanced manufacturing techniques, such as precision CNC machining or 3D printing, allows for tighter tolerances and more complex geometries in gate valve components. Additionally, the application of advanced materials, including high-strength alloys or composites, can improve valve durability and performance under various operating conditions, contributing to enhanced precision and reliability.

02 Improved sealing technologies

Enhanced sealing technologies can significantly improve the operation precision of gate valves. This may involve the use of advanced materials for seals, such as high-performance polymers or metal-to-metal seals, as well as innovative sealing designs that minimize leakage and ensure consistent performance across various operating conditions.Expand Specific Solutions03 Intelligent monitoring and feedback systems

Integration of smart sensors and feedback systems can greatly enhance the operation precision of gate valves. These systems can provide real-time data on valve position, flow rates, and pressure, allowing for continuous monitoring and adjustment. This enables more accurate control and early detection of potential issues that may affect precision.Expand Specific Solutions04 Optimized valve design for precision

Innovative gate valve designs focusing on precision can significantly improve operational accuracy. This may include optimized gate geometries, guide systems to ensure smooth and precise movement, and balanced pressure designs that minimize the effects of fluid forces on valve operation. Such designs can enhance the overall precision and reliability of the valve.Expand Specific Solutions05 Advanced manufacturing techniques

Utilizing advanced manufacturing techniques can lead to improved operation precision in gate valves. This may involve high-precision machining, 3D printing of complex components, or the use of advanced materials with superior mechanical properties. These techniques can result in tighter tolerances, better surface finishes, and more consistent performance in valve operation.Expand Specific Solutions

Key Players in Valve Manufacturing

The exploration of temperature gradient effects on gate valve operation precision is currently in a developing stage, with the market showing moderate growth potential. The technology's maturity varies across different sectors, with companies like Toyota Motor Corp. and Robert Bosch GmbH leading in automotive applications. In the industrial sector, firms such as Valqua Ltd. and SAMSON AG are making significant strides. The aerospace industry sees contributions from companies like Mitsubishi Heavy Industries, Ltd. As the technology evolves, cross-sector collaborations between these players are likely to accelerate advancements, potentially expanding the market size and improving precision in valve operations across various temperature ranges.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated approach to address temperature gradient effects on gate valve operation precision, leveraging their expertise in automotive and industrial technologies. Their solution incorporates advanced materials with carefully engineered thermal properties to minimize distortion and maintain dimensional stability across temperature gradients[1]. Bosch has also implemented a network of micro-sensors throughout the valve assembly, providing real-time temperature mapping and enabling predictive thermal management[3]. This data feeds into their proprietary control algorithms, which dynamically adjust valve parameters to compensate for thermal effects. Additionally, Bosch has developed an active cooling system that selectively targets critical components, ensuring consistent performance even in extreme temperature environments[5]. Their approach also includes machine learning algorithms that continuously optimize valve operation based on historical performance data and current thermal conditions.

Strengths: Extensive experience in precision engineering, advanced sensor technologies, and sophisticated control systems. Weaknesses: Potential for higher complexity and cost due to the integration of multiple advanced technologies.

SAMSON AG

Technical Solution: SAMSON AG has pioneered a novel approach to mitigating temperature gradient effects on gate valve operation precision. Their solution incorporates advanced materials with low thermal expansion coefficients and high thermal conductivity to minimize distortion and ensure uniform heat distribution[2]. They have also developed a proprietary cooling system that actively regulates the temperature around critical valve components, maintaining consistent performance across a wide range of operating conditions[4]. Furthermore, SAMSON's valves feature adaptive control algorithms that compensate for temperature-induced changes in fluid properties, ensuring precise flow control even under varying thermal conditions[5].

Strengths: Innovative cooling systems, adaptive control algorithms, and extensive experience in industrial valve applications. Weaknesses: May require more complex installation and maintenance procedures due to advanced cooling and control systems.

Innovations in Temperature-Resistant Materials

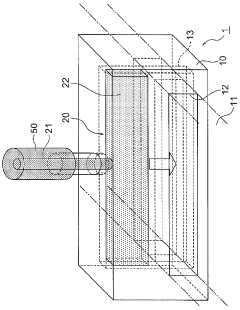

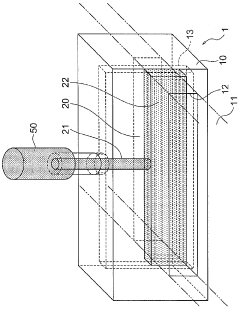

Temperature-controlled purge gate valve for chemical vapor deposition chamber

PatentActiveUS20130327266A1

Innovation

- A method and system for controlling the temperature of the gate valve in a CVD reactor using purge gas streams and heating/cooling elements to maintain the valve at temperatures that prevent condensation and reaction of corrosive gases while avoiding thermal damage to sealing materials, combined with a low thermal mass reactor and external GaCl3 source for efficient precursor delivery.

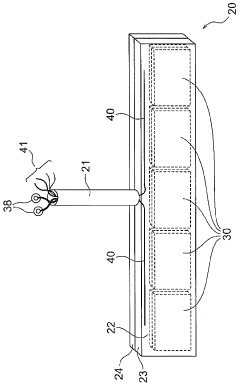

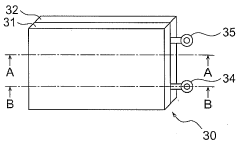

Gate valve

PatentWO2009101884A1

Innovation

- A gate valve design featuring a valve plate with multiple heat generating modules and a base material composed of two plate-like members, allowing for independent control of temperature distribution and gradient settings, along with a wiring section for power supply and a temperature sensor for precise control, enabling uniform heating and reducing the risk of equipment shutdown.

Regulatory Standards for Valve Performance

Regulatory standards for valve performance play a crucial role in ensuring the safety, reliability, and efficiency of gate valve operations across various industries. These standards are established by regulatory bodies and industry organizations to provide guidelines for the design, manufacturing, testing, and maintenance of valves, including those subject to temperature gradient effects.

The American Petroleum Institute (API) has developed several standards specifically addressing valve performance, such as API 6D for pipeline valves and API 600 for steel gate valves. These standards outline requirements for design, materials, testing, and marking of valves used in petroleum and natural gas industries. They also provide specifications for temperature ratings and pressure-temperature limits, which are essential considerations when exploring temperature gradient effects on gate valve operation precision.

The American Society of Mechanical Engineers (ASME) has also contributed significantly to valve performance standards. ASME B16.34 covers valves in various materials and pressure classes, specifying requirements for pressure-temperature ratings, dimensions, tolerances, and testing. This standard is particularly relevant when considering the impact of temperature gradients on valve operation, as it addresses the performance of valves under different temperature conditions.

In Europe, the EN 12266 standard series focuses on industrial valves, providing test procedures and acceptance criteria for various valve types, including gate valves. These standards cover both shell testing and seat leakage testing, which are critical aspects of valve performance affected by temperature gradients.

The International Organization for Standardization (ISO) has developed ISO 5208, which specifies pressure test requirements for industrial valves. This standard is particularly important when evaluating the effects of temperature gradients on valve operation precision, as it addresses the performance of valves under different pressure and temperature conditions.

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) also impose specific requirements on valve performance in certain applications. These regulations often focus on preventing leaks and ensuring worker safety, which can be significantly impacted by temperature gradient effects on valve operation.

Industry-specific standards, such as those developed by the American Water Works Association (AWWA) for water and wastewater systems, provide additional guidelines for valve performance in specific applications. These standards often include considerations for temperature effects on valve operation and maintenance.

Compliance with these regulatory standards is essential for manufacturers, operators, and maintenance personnel working with gate valves. As research into temperature gradient effects on gate valve operation precision continues, it is likely that these standards will evolve to incorporate new findings and best practices, ensuring continued improvement in valve performance and safety across industries.

The American Petroleum Institute (API) has developed several standards specifically addressing valve performance, such as API 6D for pipeline valves and API 600 for steel gate valves. These standards outline requirements for design, materials, testing, and marking of valves used in petroleum and natural gas industries. They also provide specifications for temperature ratings and pressure-temperature limits, which are essential considerations when exploring temperature gradient effects on gate valve operation precision.

The American Society of Mechanical Engineers (ASME) has also contributed significantly to valve performance standards. ASME B16.34 covers valves in various materials and pressure classes, specifying requirements for pressure-temperature ratings, dimensions, tolerances, and testing. This standard is particularly relevant when considering the impact of temperature gradients on valve operation, as it addresses the performance of valves under different temperature conditions.

In Europe, the EN 12266 standard series focuses on industrial valves, providing test procedures and acceptance criteria for various valve types, including gate valves. These standards cover both shell testing and seat leakage testing, which are critical aspects of valve performance affected by temperature gradients.

The International Organization for Standardization (ISO) has developed ISO 5208, which specifies pressure test requirements for industrial valves. This standard is particularly important when evaluating the effects of temperature gradients on valve operation precision, as it addresses the performance of valves under different pressure and temperature conditions.

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) also impose specific requirements on valve performance in certain applications. These regulations often focus on preventing leaks and ensuring worker safety, which can be significantly impacted by temperature gradient effects on valve operation.

Industry-specific standards, such as those developed by the American Water Works Association (AWWA) for water and wastewater systems, provide additional guidelines for valve performance in specific applications. These standards often include considerations for temperature effects on valve operation and maintenance.

Compliance with these regulatory standards is essential for manufacturers, operators, and maintenance personnel working with gate valves. As research into temperature gradient effects on gate valve operation precision continues, it is likely that these standards will evolve to incorporate new findings and best practices, ensuring continued improvement in valve performance and safety across industries.

Environmental Impact of Valve Operations

The environmental impact of valve operations, particularly in the context of temperature gradient effects on gate valve operation precision, is a critical consideration in industrial processes. Temperature fluctuations can significantly influence the performance and integrity of valve systems, leading to potential environmental consequences.

Thermal expansion and contraction of valve components due to temperature gradients can affect sealing capabilities, potentially resulting in leaks. These leaks may release harmful substances into the environment, contaminating soil, water, or air. In industries handling hazardous materials, even minor leaks can have severe ecological implications, necessitating stringent monitoring and control measures.

Energy consumption is another environmental concern related to valve operations under varying temperature conditions. Maintaining precise control over valve positions in the presence of temperature gradients often requires additional energy input, contributing to increased carbon footprints. This is particularly relevant in industries with high-temperature processes, where energy-intensive heating or cooling systems are employed to manage valve performance.

The choice of materials used in valve construction also plays a crucial role in environmental impact. Temperature-resistant materials may have higher embodied energy or involve more resource-intensive manufacturing processes. Balancing the need for temperature resilience with environmental sustainability presents an ongoing challenge for valve designers and manufacturers.

Maintenance and replacement cycles of valves subjected to temperature gradients can indirectly affect the environment. More frequent maintenance or replacement due to thermal stress may lead to increased waste generation and resource consumption. This underscores the importance of developing durable, temperature-resistant valve designs to minimize lifecycle environmental impacts.

Water usage in cooling systems for temperature management around critical valves is another environmental consideration. In water-scarce regions, this can strain local water resources and potentially impact aquatic ecosystems. Implementing closed-loop cooling systems or exploring alternative cooling methods can help mitigate these effects.

The precision of valve operation under temperature gradients also influences process efficiency. Imprecise control can lead to suboptimal process conditions, resulting in increased waste generation, higher energy consumption, and reduced product quality. Enhancing valve precision through advanced materials and control systems can contribute to more environmentally friendly industrial operations.

In conclusion, the environmental impact of valve operations in the context of temperature gradients extends beyond immediate operational concerns. It encompasses issues of resource consumption, waste generation, energy efficiency, and potential environmental contamination. Addressing these challenges requires a holistic approach, integrating advanced materials science, precision engineering, and sustainable design principles to minimize the ecological footprint of industrial valve systems.

Thermal expansion and contraction of valve components due to temperature gradients can affect sealing capabilities, potentially resulting in leaks. These leaks may release harmful substances into the environment, contaminating soil, water, or air. In industries handling hazardous materials, even minor leaks can have severe ecological implications, necessitating stringent monitoring and control measures.

Energy consumption is another environmental concern related to valve operations under varying temperature conditions. Maintaining precise control over valve positions in the presence of temperature gradients often requires additional energy input, contributing to increased carbon footprints. This is particularly relevant in industries with high-temperature processes, where energy-intensive heating or cooling systems are employed to manage valve performance.

The choice of materials used in valve construction also plays a crucial role in environmental impact. Temperature-resistant materials may have higher embodied energy or involve more resource-intensive manufacturing processes. Balancing the need for temperature resilience with environmental sustainability presents an ongoing challenge for valve designers and manufacturers.

Maintenance and replacement cycles of valves subjected to temperature gradients can indirectly affect the environment. More frequent maintenance or replacement due to thermal stress may lead to increased waste generation and resource consumption. This underscores the importance of developing durable, temperature-resistant valve designs to minimize lifecycle environmental impacts.

Water usage in cooling systems for temperature management around critical valves is another environmental consideration. In water-scarce regions, this can strain local water resources and potentially impact aquatic ecosystems. Implementing closed-loop cooling systems or exploring alternative cooling methods can help mitigate these effects.

The precision of valve operation under temperature gradients also influences process efficiency. Imprecise control can lead to suboptimal process conditions, resulting in increased waste generation, higher energy consumption, and reduced product quality. Enhancing valve precision through advanced materials and control systems can contribute to more environmentally friendly industrial operations.

In conclusion, the environmental impact of valve operations in the context of temperature gradients extends beyond immediate operational concerns. It encompasses issues of resource consumption, waste generation, energy efficiency, and potential environmental contamination. Addressing these challenges requires a holistic approach, integrating advanced materials science, precision engineering, and sustainable design principles to minimize the ecological footprint of industrial valve systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!