Multi-material gate valve synthesis for enhanced adaptive capabilities

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multi-Material Gate Valve Evolution and Objectives

Multi-material gate valves have undergone significant evolution since their inception, driven by the increasing demand for enhanced adaptive capabilities in various industrial applications. The development of these valves can be traced back to the early 20th century when single-material valves were the norm. However, as industrial processes became more complex and demanding, the limitations of traditional valve designs became apparent, particularly in terms of their ability to withstand diverse operating conditions and handle multiple types of fluids.

The progression towards multi-material gate valves was fueled by advancements in materials science and manufacturing technologies. This evolution was marked by the introduction of composite materials and innovative fabrication techniques, which allowed for the integration of different materials within a single valve structure. The primary objective behind this technological shift was to create valves capable of adapting to varying operational environments while maintaining optimal performance and longevity.

One of the key milestones in this evolutionary journey was the development of bimetallic gate valves in the 1970s. These valves combined the strength of steel with the corrosion resistance of alloys like stainless steel or nickel-based materials. This breakthrough paved the way for more complex multi-material designs, incorporating ceramics, polymers, and advanced composites.

The current state-of-the-art in multi-material gate valve technology aims to achieve unprecedented levels of adaptability. Modern objectives include the development of valves that can dynamically adjust their material properties in response to changing fluid compositions, temperatures, and pressures. This involves the integration of smart materials, such as shape memory alloys and piezoelectric ceramics, which can alter their physical characteristics in real-time.

Another critical goal is the enhancement of valve lifespan and reliability through the strategic use of multiple materials. By combining wear-resistant coatings, self-lubricating components, and high-strength structural elements, researchers and engineers are working towards creating valves that require minimal maintenance and can operate efficiently in extreme conditions for extended periods.

The future trajectory of multi-material gate valve technology is focused on achieving even greater levels of functionality and efficiency. Objectives include the development of self-healing materials that can repair minor damage autonomously, as well as the incorporation of nanotechnology to create surfaces with advanced properties such as super-hydrophobicity or self-cleaning capabilities. Additionally, there is a growing emphasis on sustainability, with efforts directed towards using eco-friendly materials and designing valves that are easier to recycle at the end of their lifecycle.

The progression towards multi-material gate valves was fueled by advancements in materials science and manufacturing technologies. This evolution was marked by the introduction of composite materials and innovative fabrication techniques, which allowed for the integration of different materials within a single valve structure. The primary objective behind this technological shift was to create valves capable of adapting to varying operational environments while maintaining optimal performance and longevity.

One of the key milestones in this evolutionary journey was the development of bimetallic gate valves in the 1970s. These valves combined the strength of steel with the corrosion resistance of alloys like stainless steel or nickel-based materials. This breakthrough paved the way for more complex multi-material designs, incorporating ceramics, polymers, and advanced composites.

The current state-of-the-art in multi-material gate valve technology aims to achieve unprecedented levels of adaptability. Modern objectives include the development of valves that can dynamically adjust their material properties in response to changing fluid compositions, temperatures, and pressures. This involves the integration of smart materials, such as shape memory alloys and piezoelectric ceramics, which can alter their physical characteristics in real-time.

Another critical goal is the enhancement of valve lifespan and reliability through the strategic use of multiple materials. By combining wear-resistant coatings, self-lubricating components, and high-strength structural elements, researchers and engineers are working towards creating valves that require minimal maintenance and can operate efficiently in extreme conditions for extended periods.

The future trajectory of multi-material gate valve technology is focused on achieving even greater levels of functionality and efficiency. Objectives include the development of self-healing materials that can repair minor damage autonomously, as well as the incorporation of nanotechnology to create surfaces with advanced properties such as super-hydrophobicity or self-cleaning capabilities. Additionally, there is a growing emphasis on sustainability, with efforts directed towards using eco-friendly materials and designing valves that are easier to recycle at the end of their lifecycle.

Market Analysis for Adaptive Gate Valves

The market for adaptive gate valves is experiencing significant growth, driven by increasing demand for advanced flow control solutions across various industries. These innovative valves, capable of adjusting to changing operational conditions, are gaining traction in sectors such as oil and gas, water treatment, chemical processing, and power generation. The global market for smart valves, including adaptive gate valves, is projected to expand at a compound annual growth rate of over 6% through 2026.

Key factors fueling market growth include the need for improved efficiency, reduced maintenance costs, and enhanced process control in industrial applications. Adaptive gate valves offer superior performance compared to traditional valves, particularly in challenging environments where fluid properties or flow conditions may fluctuate. This adaptability translates to increased operational reliability and reduced downtime, making them an attractive option for industries seeking to optimize their processes.

The oil and gas sector represents a significant portion of the adaptive gate valve market, as these valves are crucial for managing the complex flow control requirements in upstream, midstream, and downstream operations. The industry's focus on maximizing production efficiency and minimizing environmental impact has led to increased adoption of advanced valve technologies. Water and wastewater treatment facilities are also emerging as key end-users, driven by the need for precise flow control in treatment processes and distribution systems.

Geographically, North America and Europe currently dominate the adaptive gate valve market, owing to their well-established industrial infrastructure and early adoption of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing investments in water infrastructure, and the expansion of the oil and gas sector in countries like China and India.

The market is characterized by intense competition among key players, including multinational corporations and specialized valve manufacturers. These companies are investing heavily in research and development to enhance the capabilities of adaptive gate valves, focusing on features such as improved materials, advanced sensors, and integration with digital control systems. The trend towards Industry 4.0 and the Industrial Internet of Things (IIoT) is also influencing product development, with manufacturers incorporating smart technologies to enable remote monitoring and predictive maintenance capabilities.

Despite the positive outlook, the market faces challenges such as high initial costs and the complexity of integrating advanced valve systems into existing infrastructure. However, the long-term benefits of improved efficiency and reduced operational costs are expected to outweigh these initial barriers, driving continued market expansion. As industries increasingly prioritize sustainability and operational excellence, the demand for adaptive gate valves is poised for sustained growth in the foreseeable future.

Key factors fueling market growth include the need for improved efficiency, reduced maintenance costs, and enhanced process control in industrial applications. Adaptive gate valves offer superior performance compared to traditional valves, particularly in challenging environments where fluid properties or flow conditions may fluctuate. This adaptability translates to increased operational reliability and reduced downtime, making them an attractive option for industries seeking to optimize their processes.

The oil and gas sector represents a significant portion of the adaptive gate valve market, as these valves are crucial for managing the complex flow control requirements in upstream, midstream, and downstream operations. The industry's focus on maximizing production efficiency and minimizing environmental impact has led to increased adoption of advanced valve technologies. Water and wastewater treatment facilities are also emerging as key end-users, driven by the need for precise flow control in treatment processes and distribution systems.

Geographically, North America and Europe currently dominate the adaptive gate valve market, owing to their well-established industrial infrastructure and early adoption of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization, increasing investments in water infrastructure, and the expansion of the oil and gas sector in countries like China and India.

The market is characterized by intense competition among key players, including multinational corporations and specialized valve manufacturers. These companies are investing heavily in research and development to enhance the capabilities of adaptive gate valves, focusing on features such as improved materials, advanced sensors, and integration with digital control systems. The trend towards Industry 4.0 and the Industrial Internet of Things (IIoT) is also influencing product development, with manufacturers incorporating smart technologies to enable remote monitoring and predictive maintenance capabilities.

Despite the positive outlook, the market faces challenges such as high initial costs and the complexity of integrating advanced valve systems into existing infrastructure. However, the long-term benefits of improved efficiency and reduced operational costs are expected to outweigh these initial barriers, driving continued market expansion. As industries increasingly prioritize sustainability and operational excellence, the demand for adaptive gate valves is poised for sustained growth in the foreseeable future.

Current Challenges in Multi-Material Synthesis

The synthesis of multi-material gate valves for enhanced adaptive capabilities faces several significant challenges in the current technological landscape. One of the primary obstacles is achieving seamless integration of diverse materials while maintaining structural integrity and performance. The interface between different materials often becomes a weak point, susceptible to stress concentrations and potential failure under operational conditions.

Material compatibility presents another major hurdle. Selecting materials that not only fulfill individual functional requirements but also exhibit chemical and physical compatibility with adjacent components is crucial. This challenge is further complicated by the need to consider factors such as thermal expansion coefficients, corrosion resistance, and mechanical properties across a wide range of operating conditions.

The manufacturing process itself poses considerable difficulties. Traditional manufacturing methods often struggle to effectively combine multiple materials in a single component, especially when dealing with complex geometries. Advanced manufacturing techniques like additive manufacturing show promise but are still limited in their ability to seamlessly integrate diverse materials with the precision and reliability required for high-performance gate valves.

Ensuring uniform performance across the entire valve structure is another significant challenge. Different materials may respond differently to operational stresses, temperature fluctuations, and chemical exposure, potentially leading to uneven wear, deformation, or degradation over time. This non-uniform behavior can compromise the valve's sealing capabilities and overall functionality.

The development of adaptive capabilities introduces additional complexities. Incorporating smart materials or sensors into the valve structure for real-time monitoring and response requires innovative design approaches and raises questions about long-term reliability and maintenance. The integration of these adaptive elements must not compromise the valve's primary functions or introduce new failure modes.

Cost-effectiveness remains a persistent challenge in multi-material synthesis. The use of advanced materials and manufacturing processes often leads to higher production costs, which must be balanced against the potential performance benefits. Scaling up production while maintaining quality and consistency across batches presents its own set of challenges, particularly for complex multi-material components.

Lastly, the regulatory landscape adds another layer of complexity. Ensuring that multi-material gate valves meet industry standards and safety regulations, which may not have kept pace with rapid technological advancements, can be challenging. This often requires extensive testing and validation processes, further adding to development time and costs.

Material compatibility presents another major hurdle. Selecting materials that not only fulfill individual functional requirements but also exhibit chemical and physical compatibility with adjacent components is crucial. This challenge is further complicated by the need to consider factors such as thermal expansion coefficients, corrosion resistance, and mechanical properties across a wide range of operating conditions.

The manufacturing process itself poses considerable difficulties. Traditional manufacturing methods often struggle to effectively combine multiple materials in a single component, especially when dealing with complex geometries. Advanced manufacturing techniques like additive manufacturing show promise but are still limited in their ability to seamlessly integrate diverse materials with the precision and reliability required for high-performance gate valves.

Ensuring uniform performance across the entire valve structure is another significant challenge. Different materials may respond differently to operational stresses, temperature fluctuations, and chemical exposure, potentially leading to uneven wear, deformation, or degradation over time. This non-uniform behavior can compromise the valve's sealing capabilities and overall functionality.

The development of adaptive capabilities introduces additional complexities. Incorporating smart materials or sensors into the valve structure for real-time monitoring and response requires innovative design approaches and raises questions about long-term reliability and maintenance. The integration of these adaptive elements must not compromise the valve's primary functions or introduce new failure modes.

Cost-effectiveness remains a persistent challenge in multi-material synthesis. The use of advanced materials and manufacturing processes often leads to higher production costs, which must be balanced against the potential performance benefits. Scaling up production while maintaining quality and consistency across batches presents its own set of challenges, particularly for complex multi-material components.

Lastly, the regulatory landscape adds another layer of complexity. Ensuring that multi-material gate valves meet industry standards and safety regulations, which may not have kept pace with rapid technological advancements, can be challenging. This often requires extensive testing and validation processes, further adding to development time and costs.

Existing Multi-Material Synthesis Techniques

01 Multi-material construction for improved performance

Gate valves incorporating multiple materials in their construction can offer enhanced performance characteristics. By utilizing different materials for various components, such as the valve body, gate, and seals, manufacturers can optimize strength, durability, and resistance to specific operating conditions. This multi-material approach allows for better adaptability to diverse fluid types and pressure ranges.- Multi-material construction for gate valves: Gate valves can be constructed using multiple materials to enhance their performance and adaptability. This approach allows for the combination of different materials with specific properties, such as corrosion resistance, wear resistance, and thermal stability, to optimize the valve's functionality in various operating conditions.

- Adaptive sealing mechanisms: Gate valves can incorporate adaptive sealing mechanisms that adjust to changes in pressure, temperature, or fluid composition. These mechanisms may include self-adjusting seals, floating seats, or dynamic sealing elements that maintain tight closure under varying conditions, improving the valve's reliability and longevity.

- Smart actuation systems: Integration of smart actuation systems in gate valves enables adaptive control and monitoring capabilities. These systems may include sensors, actuators, and control algorithms that allow the valve to respond to changing process conditions, optimize flow control, and provide real-time diagnostics for predictive maintenance.

- Modular design for customization: Gate valves with modular designs allow for easy customization and adaptation to specific application requirements. This approach enables the replacement or upgrade of individual components, such as seals, seats, or actuators, without replacing the entire valve, enhancing flexibility and reducing maintenance costs.

- Surface treatments and coatings: Advanced surface treatments and coatings can be applied to gate valve components to enhance their adaptive capabilities. These treatments may include anti-fouling coatings, wear-resistant layers, or self-lubricating surfaces that improve the valve's performance and longevity in challenging environments.

02 Adaptive sealing mechanisms

Advanced gate valves feature adaptive sealing mechanisms that can adjust to varying pressure conditions and fluid properties. These mechanisms may include self-adjusting seals, floating seats, or pressure-energized seals that respond to changes in operating parameters. Such adaptive capabilities ensure consistent sealing performance across a wide range of applications and extend the valve's operational lifespan.Expand Specific Solutions03 Smart control and monitoring systems

Integration of smart control and monitoring systems enhances the adaptive capabilities of gate valves. These systems may include sensors, actuators, and digital interfaces that allow for real-time adjustment of valve position, flow rate, and pressure control. Advanced algorithms can optimize valve performance based on changing process conditions, improving efficiency and reducing maintenance requirements.Expand Specific Solutions04 Modular design for customization and maintenance

Gate valves with modular designs offer increased adaptability through easy customization and maintenance. This approach allows for the replacement or upgrade of specific components without replacing the entire valve assembly. Modular designs can accommodate different materials, sizes, and functionalities, making it possible to adapt the valve to new requirements or process changes over time.Expand Specific Solutions05 Temperature and corrosion resistance adaptations

Gate valves designed for adaptive capabilities in extreme environments incorporate features to resist high temperatures and corrosive media. This may include specialized coatings, heat-resistant alloys, or composite materials that can withstand harsh conditions. Some designs also feature active cooling systems or sacrificial components that can be easily replaced, extending the valve's operational range and lifespan in challenging applications.Expand Specific Solutions

Key Industry Players and Competitors

The multi-material gate valve synthesis market is in its early growth stage, characterized by rapid technological advancements and increasing adoption across industries. The market size is expanding, driven by the demand for enhanced adaptive capabilities in various applications. While the technology is still evolving, several key players are making significant strides in its development. Companies like Taiwan Semiconductor Manufacturing Co., Ltd., Texas Instruments Incorporated, and Infineon Technologies AG are leveraging their expertise in semiconductor manufacturing to advance multi-material gate valve synthesis. Other major players such as GLOBALFOUNDRIES, Inc., Micron Technology, Inc., and Applied Materials, Inc. are also contributing to the technology's maturation through research and development efforts. As the technology progresses, we can expect increased competition and potential market consolidation.

Taiwan Semiconductor Manufacturing Co., Ltd.

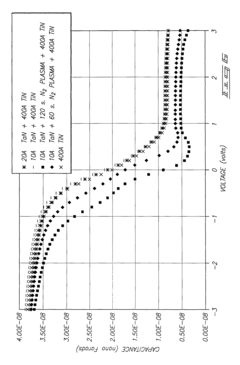

Technical Solution: TSMC has developed a cutting-edge multi-material gate valve synthesis technique to enhance adaptive capabilities in their advanced semiconductor manufacturing processes. Their approach utilizes a combination of atomic layer deposition (ALD) and selective etching techniques to create highly customizable gate structures with precise control over material composition and thickness[1]. TSMC's technology enables the integration of multiple work function metals and high-k dielectrics, allowing for optimized performance in both nMOS and pMOS devices on the same chip[2]. The company's solution incorporates advanced interface engineering and strain management techniques to minimize defects and enhance carrier mobility[3]. TSMC's multi-material gate valves have demonstrated excellent electrostatic control, reduced short-channel effects, and improved reliability in sub-5nm process nodes[4].

Strengths: Highly scalable solution suitable for high-volume manufacturing of advanced logic and memory devices. Weaknesses: May require significant investment in research and development to maintain technological leadership.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced multi-material gate valve synthesis techniques for enhanced adaptive capabilities in semiconductor manufacturing. Their approach utilizes atomic layer deposition (ALD) and physical vapor deposition (PVD) processes to create precisely controlled multi-layer gate structures[1]. This technology enables the fabrication of high-k metal gates with tunable work functions, allowing for optimized performance in both nMOS and pMOS devices[2]. The company's solution incorporates in-situ plasma treatment and interface engineering to minimize defects and improve reliability[3]. Applied Materials' multi-material gate valves demonstrate superior electrostatic control and reduced short-channel effects, contributing to improved device scalability and power efficiency in advanced logic nodes[4].

Strengths: Precise control over gate material composition and thickness, enabling fine-tuning of device characteristics. Weaknesses: Complex manufacturing process may increase production costs and cycle times.

Innovative Approaches in Material Integration

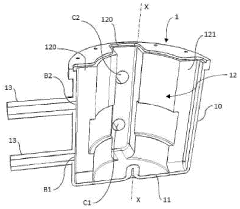

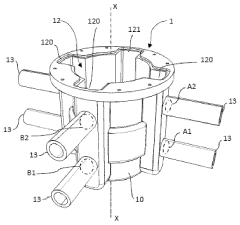

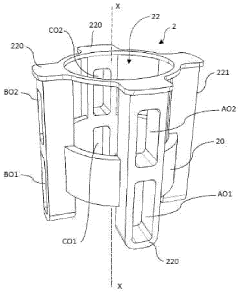

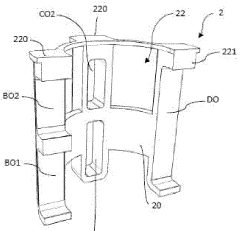

Multi-way valve

PatentWO2024115114A1

Innovation

- A multi-port valve design featuring three rotating members and a common channel that allows fluid communication between multiple stages, increasing the number of operating modes tenfold while maintaining a small footprint, and enabling the integration of multiple three-way or four-way valves for enhanced functionality.

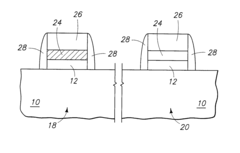

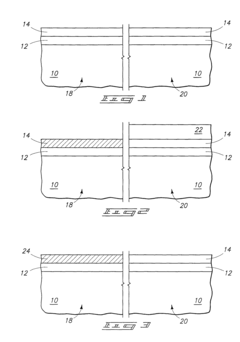

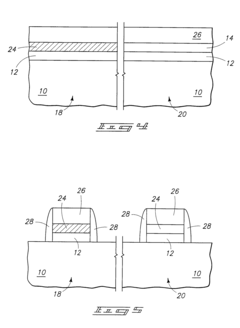

Transistor gate forming methods and integrated circuits

PatentActiveUS8089128B2

Innovation

- The method involves forming transistor gates with a lower metal layer and an upper metal layer, where the lower metal layer's work function is modified to differ between gates using plasma treatment, allowing for the same material to be used for both n-channel and p-channel gates with different work functions, simplifying the process by using materials like tantalum nitride and titanium nitride.

Environmental Impact Assessment

The environmental impact assessment of multi-material gate valve synthesis for enhanced adaptive capabilities is a crucial aspect of its development and implementation. This innovative technology, while promising significant advancements in valve performance and adaptability, also raises important environmental considerations.

The production process of multi-material gate valves involves the use of various materials, potentially including metals, polymers, and composites. This diversity in materials can lead to increased complexity in sourcing, manufacturing, and disposal processes. The extraction and processing of these materials may contribute to resource depletion and energy consumption, particularly if rare or specialized materials are required for enhanced adaptive capabilities.

During the manufacturing phase, the synthesis of multi-material components may require advanced techniques such as 3D printing, injection molding, or precision machining. These processes can be energy-intensive and may generate waste materials or emissions. However, the potential for improved efficiency and reduced material waste through additive manufacturing techniques could partially offset these impacts.

The operational phase of multi-material gate valves presents both challenges and opportunities from an environmental perspective. The enhanced adaptive capabilities may lead to improved performance and longevity, potentially reducing the frequency of replacements and associated waste. Additionally, the ability to adapt to varying conditions could result in more efficient fluid control systems, potentially reducing energy consumption in industrial applications.

End-of-life considerations for multi-material gate valves are particularly important. The combination of different materials in a single component can complicate recycling processes, potentially leading to increased waste if proper recycling methods are not developed. However, the modular nature of some multi-material designs may facilitate easier separation of components for recycling or reuse.

The environmental impact of these valves extends beyond their immediate lifecycle. Their enhanced adaptive capabilities may contribute to more efficient and reliable industrial processes, potentially reducing overall resource consumption and emissions in various applications. For instance, in the oil and gas industry, improved valve performance could lead to reduced leakage and more efficient extraction processes.

Water management systems could also benefit from these advanced valves, potentially leading to more efficient water distribution and treatment processes. This could indirectly contribute to water conservation efforts and reduce the environmental footprint of water management infrastructure.

In conclusion, while multi-material gate valve synthesis presents some environmental challenges, particularly in production and end-of-life phases, its potential for enhancing system efficiency and longevity may offer significant environmental benefits in the long term. Future research and development efforts should focus on minimizing the environmental impact of production processes and improving the recyclability of multi-material components to fully realize the environmental potential of this technology.

The production process of multi-material gate valves involves the use of various materials, potentially including metals, polymers, and composites. This diversity in materials can lead to increased complexity in sourcing, manufacturing, and disposal processes. The extraction and processing of these materials may contribute to resource depletion and energy consumption, particularly if rare or specialized materials are required for enhanced adaptive capabilities.

During the manufacturing phase, the synthesis of multi-material components may require advanced techniques such as 3D printing, injection molding, or precision machining. These processes can be energy-intensive and may generate waste materials or emissions. However, the potential for improved efficiency and reduced material waste through additive manufacturing techniques could partially offset these impacts.

The operational phase of multi-material gate valves presents both challenges and opportunities from an environmental perspective. The enhanced adaptive capabilities may lead to improved performance and longevity, potentially reducing the frequency of replacements and associated waste. Additionally, the ability to adapt to varying conditions could result in more efficient fluid control systems, potentially reducing energy consumption in industrial applications.

End-of-life considerations for multi-material gate valves are particularly important. The combination of different materials in a single component can complicate recycling processes, potentially leading to increased waste if proper recycling methods are not developed. However, the modular nature of some multi-material designs may facilitate easier separation of components for recycling or reuse.

The environmental impact of these valves extends beyond their immediate lifecycle. Their enhanced adaptive capabilities may contribute to more efficient and reliable industrial processes, potentially reducing overall resource consumption and emissions in various applications. For instance, in the oil and gas industry, improved valve performance could lead to reduced leakage and more efficient extraction processes.

Water management systems could also benefit from these advanced valves, potentially leading to more efficient water distribution and treatment processes. This could indirectly contribute to water conservation efforts and reduce the environmental footprint of water management infrastructure.

In conclusion, while multi-material gate valve synthesis presents some environmental challenges, particularly in production and end-of-life phases, its potential for enhancing system efficiency and longevity may offer significant environmental benefits in the long term. Future research and development efforts should focus on minimizing the environmental impact of production processes and improving the recyclability of multi-material components to fully realize the environmental potential of this technology.

Standardization and Quality Control Measures

Standardization and quality control measures are crucial for ensuring the consistent performance and reliability of multi-material gate valves with enhanced adaptive capabilities. These measures encompass a range of processes and protocols designed to maintain high standards throughout the manufacturing, testing, and implementation phases.

A comprehensive standardization framework for multi-material gate valves begins with the establishment of precise material specifications. This includes defining the exact composition, properties, and performance characteristics of each material used in the valve construction. Standardized testing procedures are developed to verify the integrity of individual materials as well as their compatibility when combined in the final product.

Quality control measures for multi-material gate valves involve rigorous inspection protocols at various stages of production. Non-destructive testing methods, such as ultrasonic and radiographic inspections, are employed to detect any internal defects or inconsistencies in the valve structure. Surface finish and dimensional accuracy are carefully monitored to ensure proper fit and function within the intended operating environment.

To address the unique challenges posed by multi-material construction, specialized quality control techniques are implemented. These may include advanced imaging technologies to assess the interface between different materials, as well as accelerated aging tests to evaluate long-term performance and material degradation under simulated operating conditions.

Standardized performance testing is a critical component of quality assurance for adaptive gate valves. This involves subjecting the valves to a range of operating scenarios, including extreme temperatures, pressures, and chemical environments, to verify their adaptive capabilities and overall functionality. Automated test rigs are often employed to ensure consistency and repeatability in performance evaluations.

Documentation and traceability play a vital role in maintaining quality standards. Each valve is assigned a unique identifier, allowing for the tracking of materials, manufacturing processes, and test results throughout its lifecycle. This comprehensive record-keeping facilitates continuous improvement efforts and enables swift identification and resolution of any issues that may arise during operation.

Certification programs and industry standards provide a framework for ensuring that multi-material gate valves meet or exceed established performance criteria. Manufacturers may seek certification from recognized bodies to demonstrate compliance with relevant standards, enhancing customer confidence and market acceptance of their products.

A comprehensive standardization framework for multi-material gate valves begins with the establishment of precise material specifications. This includes defining the exact composition, properties, and performance characteristics of each material used in the valve construction. Standardized testing procedures are developed to verify the integrity of individual materials as well as their compatibility when combined in the final product.

Quality control measures for multi-material gate valves involve rigorous inspection protocols at various stages of production. Non-destructive testing methods, such as ultrasonic and radiographic inspections, are employed to detect any internal defects or inconsistencies in the valve structure. Surface finish and dimensional accuracy are carefully monitored to ensure proper fit and function within the intended operating environment.

To address the unique challenges posed by multi-material construction, specialized quality control techniques are implemented. These may include advanced imaging technologies to assess the interface between different materials, as well as accelerated aging tests to evaluate long-term performance and material degradation under simulated operating conditions.

Standardized performance testing is a critical component of quality assurance for adaptive gate valves. This involves subjecting the valves to a range of operating scenarios, including extreme temperatures, pressures, and chemical environments, to verify their adaptive capabilities and overall functionality. Automated test rigs are often employed to ensure consistency and repeatability in performance evaluations.

Documentation and traceability play a vital role in maintaining quality standards. Each valve is assigned a unique identifier, allowing for the tracking of materials, manufacturing processes, and test results throughout its lifecycle. This comprehensive record-keeping facilitates continuous improvement efforts and enables swift identification and resolution of any issues that may arise during operation.

Certification programs and industry standards provide a framework for ensuring that multi-material gate valves meet or exceed established performance criteria. Manufacturers may seek certification from recognized bodies to demonstrate compliance with relevant standards, enhancing customer confidence and market acceptance of their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!