Energy consumption analysis of gate valves in transient operation

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Energy Dynamics

Gate valves are critical components in fluid control systems, playing a vital role in regulating flow and pressure. The energy dynamics of gate valves during transient operations are complex and multifaceted, involving various physical phenomena and mechanical interactions. Understanding these dynamics is crucial for optimizing valve performance, reducing energy consumption, and enhancing overall system efficiency.

During transient operations, gate valves experience rapid changes in flow conditions, pressure differentials, and mechanical stresses. These dynamic events can significantly impact energy consumption and system stability. The primary energy transfer mechanisms in gate valves include fluid-structure interaction, friction between moving parts, and energy dissipation through turbulence and viscous effects.

The opening and closing of gate valves involve the conversion of mechanical energy into fluid energy and vice versa. As the valve gate moves, it displaces fluid, creating pressure waves that propagate through the system. These pressure waves can lead to energy losses and potential damage if not properly managed. Additionally, the sudden changes in flow velocity and direction during valve actuation result in complex flow patterns and vortex formation, further contributing to energy dissipation.

Friction plays a significant role in gate valve energy dynamics. The sliding contact between the valve gate and seat, as well as the interaction between the stem and packing, generates heat and resistance. This friction not only consumes energy but also affects the valve's response time and control precision. Minimizing friction through advanced materials and lubrication techniques is essential for improving energy efficiency and valve performance.

The geometry of the gate valve, including the shape of the gate, seat, and flow passages, greatly influences its energy characteristics. Optimized valve designs can reduce pressure drops, minimize turbulence, and improve flow coefficients, leading to lower energy consumption during both steady-state and transient operations. Computational fluid dynamics (CFD) simulations and experimental studies have been instrumental in understanding and refining these geometric factors.

Transient operations also induce dynamic loads on valve components, potentially leading to fatigue and wear. The repeated cycling of gate valves can result in material degradation and increased energy consumption over time. Advanced materials and surface treatments are being developed to enhance durability and maintain energy efficiency throughout the valve's lifecycle.

The control system governing valve actuation significantly impacts energy dynamics. Precise control algorithms that account for system dynamics can optimize valve movement, reducing overshoot and minimizing energy waste. Smart valve technologies incorporating sensors and real-time feedback mechanisms are emerging as powerful tools for energy-efficient valve operation in transient conditions.

During transient operations, gate valves experience rapid changes in flow conditions, pressure differentials, and mechanical stresses. These dynamic events can significantly impact energy consumption and system stability. The primary energy transfer mechanisms in gate valves include fluid-structure interaction, friction between moving parts, and energy dissipation through turbulence and viscous effects.

The opening and closing of gate valves involve the conversion of mechanical energy into fluid energy and vice versa. As the valve gate moves, it displaces fluid, creating pressure waves that propagate through the system. These pressure waves can lead to energy losses and potential damage if not properly managed. Additionally, the sudden changes in flow velocity and direction during valve actuation result in complex flow patterns and vortex formation, further contributing to energy dissipation.

Friction plays a significant role in gate valve energy dynamics. The sliding contact between the valve gate and seat, as well as the interaction between the stem and packing, generates heat and resistance. This friction not only consumes energy but also affects the valve's response time and control precision. Minimizing friction through advanced materials and lubrication techniques is essential for improving energy efficiency and valve performance.

The geometry of the gate valve, including the shape of the gate, seat, and flow passages, greatly influences its energy characteristics. Optimized valve designs can reduce pressure drops, minimize turbulence, and improve flow coefficients, leading to lower energy consumption during both steady-state and transient operations. Computational fluid dynamics (CFD) simulations and experimental studies have been instrumental in understanding and refining these geometric factors.

Transient operations also induce dynamic loads on valve components, potentially leading to fatigue and wear. The repeated cycling of gate valves can result in material degradation and increased energy consumption over time. Advanced materials and surface treatments are being developed to enhance durability and maintain energy efficiency throughout the valve's lifecycle.

The control system governing valve actuation significantly impacts energy dynamics. Precise control algorithms that account for system dynamics can optimize valve movement, reducing overshoot and minimizing energy waste. Smart valve technologies incorporating sensors and real-time feedback mechanisms are emerging as powerful tools for energy-efficient valve operation in transient conditions.

Market Demand Analysis

The market demand for energy consumption analysis of gate valves in transient operation has been steadily growing in recent years, driven by increasing focus on energy efficiency and sustainability across various industries. This demand is particularly pronounced in sectors such as oil and gas, water management, and process industries where gate valves play a crucial role in controlling fluid flow.

The global valve market, which includes gate valves, is projected to reach significant growth in the coming years. This growth is partly attributed to the rising need for energy-efficient solutions and the implementation of stringent regulations regarding energy consumption and emissions. As industries strive to optimize their operations and reduce energy costs, the demand for accurate energy consumption analysis of gate valves during transient operations has become more critical.

In the oil and gas sector, where gate valves are extensively used in pipelines and processing facilities, there is a strong emphasis on minimizing energy losses and improving overall system efficiency. The transient operation of gate valves, which occurs during opening and closing processes, can significantly impact energy consumption. As a result, companies in this sector are increasingly seeking advanced analysis tools and methodologies to understand and optimize valve performance during these critical phases.

The water management industry is another key driver of market demand for gate valve energy consumption analysis. With growing concerns about water scarcity and the need for efficient distribution systems, water utilities and municipalities are focusing on reducing energy waste in their networks. Gate valves are essential components in water distribution systems, and understanding their energy consumption during transient operations can lead to substantial energy savings and improved system reliability.

Process industries, including chemical, pharmaceutical, and food processing, are also contributing to the market demand. These industries often require precise control of fluid flow and are increasingly adopting energy-efficient practices. The ability to analyze and optimize gate valve performance during transient operations can lead to significant improvements in process efficiency and reduced energy costs.

The market demand is further fueled by the integration of smart technologies and the Industrial Internet of Things (IIoT) in valve systems. This trend is driving the development of advanced sensors and monitoring systems that can provide real-time data on valve performance, including energy consumption during transient operations. The ability to collect and analyze this data is becoming increasingly valuable for industries seeking to implement predictive maintenance strategies and optimize their operations.

As environmental regulations become more stringent worldwide, industries are under pressure to reduce their carbon footprint. This regulatory landscape is creating additional market demand for energy consumption analysis of gate valves, as companies seek to comply with emissions standards and demonstrate their commitment to sustainability.

The global valve market, which includes gate valves, is projected to reach significant growth in the coming years. This growth is partly attributed to the rising need for energy-efficient solutions and the implementation of stringent regulations regarding energy consumption and emissions. As industries strive to optimize their operations and reduce energy costs, the demand for accurate energy consumption analysis of gate valves during transient operations has become more critical.

In the oil and gas sector, where gate valves are extensively used in pipelines and processing facilities, there is a strong emphasis on minimizing energy losses and improving overall system efficiency. The transient operation of gate valves, which occurs during opening and closing processes, can significantly impact energy consumption. As a result, companies in this sector are increasingly seeking advanced analysis tools and methodologies to understand and optimize valve performance during these critical phases.

The water management industry is another key driver of market demand for gate valve energy consumption analysis. With growing concerns about water scarcity and the need for efficient distribution systems, water utilities and municipalities are focusing on reducing energy waste in their networks. Gate valves are essential components in water distribution systems, and understanding their energy consumption during transient operations can lead to substantial energy savings and improved system reliability.

Process industries, including chemical, pharmaceutical, and food processing, are also contributing to the market demand. These industries often require precise control of fluid flow and are increasingly adopting energy-efficient practices. The ability to analyze and optimize gate valve performance during transient operations can lead to significant improvements in process efficiency and reduced energy costs.

The market demand is further fueled by the integration of smart technologies and the Industrial Internet of Things (IIoT) in valve systems. This trend is driving the development of advanced sensors and monitoring systems that can provide real-time data on valve performance, including energy consumption during transient operations. The ability to collect and analyze this data is becoming increasingly valuable for industries seeking to implement predictive maintenance strategies and optimize their operations.

As environmental regulations become more stringent worldwide, industries are under pressure to reduce their carbon footprint. This regulatory landscape is creating additional market demand for energy consumption analysis of gate valves, as companies seek to comply with emissions standards and demonstrate their commitment to sustainability.

Technical Challenges

The analysis of energy consumption in gate valves during transient operation presents several significant technical challenges. One of the primary difficulties lies in accurately modeling the complex fluid dynamics within the valve during opening and closing processes. The transient nature of these operations introduces rapid changes in flow patterns, pressure distributions, and turbulence levels, making it challenging to capture all relevant phenomena in a single model.

Furthermore, the interaction between the fluid and the valve structure adds another layer of complexity. The forces exerted by the fluid on the valve components, such as the gate and seats, vary dynamically during transient operations. This fluid-structure interaction can lead to vibrations, deformations, and potential wear, all of which influence energy consumption but are difficult to quantify precisely.

Another technical hurdle is the accurate measurement and data acquisition during transient events. The rapid changes in flow conditions and valve positions require high-frequency sampling and sophisticated instrumentation. Ensuring the reliability and accuracy of these measurements under varying operational conditions poses a significant challenge.

The multiphysics nature of the problem also complicates the analysis. Energy consumption in gate valves during transient operation involves not only fluid dynamics but also thermodynamics, material science, and tribology. Integrating these diverse physical phenomena into a cohesive analytical framework requires advanced computational techniques and interdisciplinary expertise.

Moreover, the wide range of valve sizes, designs, and operational conditions in industrial applications makes it difficult to develop a universal model or analysis method. Each specific valve configuration may require tailored approaches, limiting the generalizability of research findings.

The time-dependent aspects of transient operations introduce additional complexities in energy consumption analysis. The duration of opening and closing cycles, acceleration and deceleration rates, and potential intermediate positions all influence energy consumption patterns. Capturing these temporal variations accurately in both experimental and computational studies is a significant technical challenge.

Lastly, the validation of analytical models and simulation results against real-world data presents its own set of difficulties. Conducting full-scale experiments under controlled conditions that replicate the diverse scenarios encountered in industrial settings is often impractical or prohibitively expensive. This gap between theoretical models and practical applications hinders the development of robust energy consumption prediction tools for gate valves in transient operation.

Furthermore, the interaction between the fluid and the valve structure adds another layer of complexity. The forces exerted by the fluid on the valve components, such as the gate and seats, vary dynamically during transient operations. This fluid-structure interaction can lead to vibrations, deformations, and potential wear, all of which influence energy consumption but are difficult to quantify precisely.

Another technical hurdle is the accurate measurement and data acquisition during transient events. The rapid changes in flow conditions and valve positions require high-frequency sampling and sophisticated instrumentation. Ensuring the reliability and accuracy of these measurements under varying operational conditions poses a significant challenge.

The multiphysics nature of the problem also complicates the analysis. Energy consumption in gate valves during transient operation involves not only fluid dynamics but also thermodynamics, material science, and tribology. Integrating these diverse physical phenomena into a cohesive analytical framework requires advanced computational techniques and interdisciplinary expertise.

Moreover, the wide range of valve sizes, designs, and operational conditions in industrial applications makes it difficult to develop a universal model or analysis method. Each specific valve configuration may require tailored approaches, limiting the generalizability of research findings.

The time-dependent aspects of transient operations introduce additional complexities in energy consumption analysis. The duration of opening and closing cycles, acceleration and deceleration rates, and potential intermediate positions all influence energy consumption patterns. Capturing these temporal variations accurately in both experimental and computational studies is a significant technical challenge.

Lastly, the validation of analytical models and simulation results against real-world data presents its own set of difficulties. Conducting full-scale experiments under controlled conditions that replicate the diverse scenarios encountered in industrial settings is often impractical or prohibitively expensive. This gap between theoretical models and practical applications hinders the development of robust energy consumption prediction tools for gate valves in transient operation.

Current Energy Solutions

01 Energy-efficient gate valve designs

Innovative gate valve designs focus on reducing energy consumption during operation. These designs may include improved sealing mechanisms, optimized flow paths, and lightweight materials to minimize the energy required for valve actuation and maintenance of proper sealing.- Energy-efficient gate valve designs: Innovative gate valve designs focus on reducing energy consumption during operation. These designs may include improved sealing mechanisms, optimized flow paths, and lightweight materials to minimize the energy required for valve actuation and maintenance of tight seals.

- Smart control systems for gate valves: Integration of smart control systems in gate valves enables precise regulation of flow and pressure, leading to optimized energy usage. These systems may incorporate sensors, actuators, and advanced algorithms to adjust valve positions based on real-time data and demand.

- Energy harvesting and storage in gate valve systems: Innovative gate valve systems incorporate energy harvesting technologies to capture and store energy from fluid flow or valve movement. This harvested energy can be used to power valve actuators, sensors, or other auxiliary equipment, reducing overall energy consumption.

- Low-friction materials and coatings for gate valves: The use of advanced materials and coatings with low friction properties in gate valve components reduces energy loss due to friction during valve operation. This results in smoother valve movement and lower energy requirements for actuation.

- Predictive maintenance and energy optimization: Implementation of predictive maintenance strategies and energy optimization algorithms for gate valve systems. These approaches use data analytics and machine learning to predict valve performance, schedule maintenance, and optimize valve operations for maximum energy efficiency.

02 Smart control systems for gate valves

Integration of smart control systems in gate valves to optimize energy usage. These systems may include sensors, actuators, and advanced algorithms to monitor valve performance, adjust operation parameters, and reduce unnecessary energy consumption during valve operation.Expand Specific Solutions03 Energy harvesting in gate valve systems

Incorporation of energy harvesting technologies in gate valve systems to capture and utilize energy from the fluid flow or surrounding environment. This approach aims to reduce reliance on external power sources and improve overall energy efficiency of the valve system.Expand Specific Solutions04 Low-friction materials and coatings

Use of advanced materials and coatings with low friction properties in gate valve components. These materials reduce energy loss due to friction during valve operation, resulting in improved energy efficiency and reduced wear on moving parts.Expand Specific Solutions05 Energy-efficient actuation mechanisms

Development of energy-efficient actuation mechanisms for gate valves, such as improved hydraulic or pneumatic systems, electric actuators with regenerative braking, or mechanical designs that minimize energy requirements for valve opening and closing operations.Expand Specific Solutions

Key Industry Players

The energy consumption analysis of gate valves in transient operation is an emerging field within the broader context of energy efficiency in industrial processes. This technology is in its early development stage, with growing interest due to increasing focus on sustainability and energy optimization. The market size is relatively small but expanding, driven by the need for more efficient valve operations in various industries. Companies like Kinetic Pressure Control Ltd. and Robert Bosch GmbH are at the forefront, developing innovative solutions. However, the technology's maturity is still evolving, with research institutions such as Xi'an Jiaotong University and Taiyuan University of Technology contributing significantly to advancing the field through academic studies and industry collaborations.

China Southern Power Grid Research Institute Co., Ltd.

Technical Solution: China Southern Power Grid Research Institute has developed an advanced energy consumption analysis system for gate valves in transient operation. Their approach utilizes real-time monitoring and machine learning algorithms to predict and optimize valve performance. The system employs sensors to collect data on pressure, flow rate, and valve position during transient states. This data is then processed using artificial neural networks to model energy consumption patterns[1]. The institute has also implemented a digital twin technology that simulates valve behavior under various operating conditions, allowing for predictive maintenance and energy optimization[3].

Strengths: Comprehensive real-time monitoring, advanced predictive modeling, and digital twin technology for optimization. Weaknesses: May require significant initial investment and complex integration with existing systems.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed a sophisticated energy management system for gate valves in transient operation. Their approach focuses on integrating smart grid technologies with valve control systems. The company utilizes advanced power electronics and adaptive control algorithms to minimize energy losses during valve transitions. They have implemented a distributed energy resource management system (DERMS) that optimizes valve operations across the entire grid network[2]. State Grid's solution also incorporates fault detection and isolation mechanisms to enhance system reliability and reduce energy waste during abnormal transient events[4].

Strengths: Large-scale integration capabilities, advanced grid management technologies, and robust fault detection systems. Weaknesses: May be overly complex for smaller operations and potentially high implementation costs.

Core Innovations

Circuit for controlling power transistors of an inverter arm

PatentActiveUS20240079971A1

Innovation

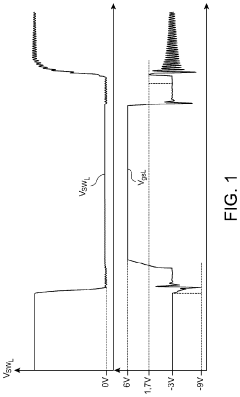

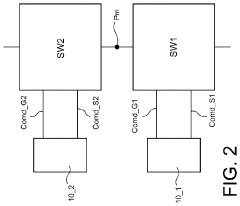

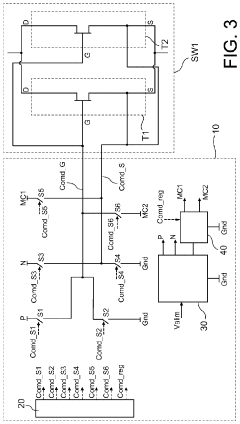

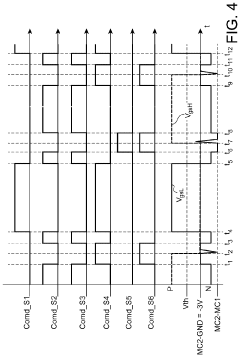

- A control circuit that adjusts the gate-source voltage of transistors in an inverter arm during activation and deactivation periods to mitigate transient overvoltages, using a scheme that reduces negative and positive excursions without requiring dedicated circuits for each transistor in parallel.

Regulatory Framework

The regulatory framework surrounding energy consumption analysis of gate valves in transient operation is complex and multifaceted, encompassing various international, national, and industry-specific standards and guidelines. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have developed standards that address energy efficiency and performance of industrial valves, including gate valves.

ISO 5208 and ISO 10434 are particularly relevant, as they provide specifications for industrial valves and their testing procedures, which indirectly impact energy consumption analysis. Additionally, the IEC 60534 series of standards focuses on industrial-process control valves, offering guidelines for sizing, performance evaluation, and testing that are applicable to gate valves in transient operation.

On a national level, regulatory bodies such as the U.S. Department of Energy (DOE) and the European Union's Energy Efficiency Directive (EED) have established frameworks for energy efficiency in industrial processes. These regulations often mandate energy audits and the implementation of energy management systems, which necessitate detailed analysis of energy consumption in various components, including gate valves.

Industry-specific standards also play a crucial role in shaping the regulatory landscape. For instance, the American Petroleum Institute (API) has developed standards like API 600 and API 6D, which specify requirements for steel gate valves used in pipeline transportation systems. These standards indirectly influence energy consumption analysis by setting performance criteria that valve manufacturers must meet.

The regulatory framework also extends to environmental protection and emissions reduction. Regulations such as the U.S. Environmental Protection Agency's (EPA) greenhouse gas reporting program and the European Union's Emissions Trading System (EU ETS) require industries to monitor and report their energy consumption and associated emissions. This has led to increased focus on energy efficiency in all aspects of industrial operations, including the performance of gate valves during transient operations.

Furthermore, emerging regulations around lifecycle assessment and circular economy principles are beginning to impact the valve industry. These regulations encourage manufacturers to consider the entire lifecycle energy consumption of their products, from production to disposal, which in turn influences the design and operation of gate valves to optimize energy efficiency throughout their lifespan.

ISO 5208 and ISO 10434 are particularly relevant, as they provide specifications for industrial valves and their testing procedures, which indirectly impact energy consumption analysis. Additionally, the IEC 60534 series of standards focuses on industrial-process control valves, offering guidelines for sizing, performance evaluation, and testing that are applicable to gate valves in transient operation.

On a national level, regulatory bodies such as the U.S. Department of Energy (DOE) and the European Union's Energy Efficiency Directive (EED) have established frameworks for energy efficiency in industrial processes. These regulations often mandate energy audits and the implementation of energy management systems, which necessitate detailed analysis of energy consumption in various components, including gate valves.

Industry-specific standards also play a crucial role in shaping the regulatory landscape. For instance, the American Petroleum Institute (API) has developed standards like API 600 and API 6D, which specify requirements for steel gate valves used in pipeline transportation systems. These standards indirectly influence energy consumption analysis by setting performance criteria that valve manufacturers must meet.

The regulatory framework also extends to environmental protection and emissions reduction. Regulations such as the U.S. Environmental Protection Agency's (EPA) greenhouse gas reporting program and the European Union's Emissions Trading System (EU ETS) require industries to monitor and report their energy consumption and associated emissions. This has led to increased focus on energy efficiency in all aspects of industrial operations, including the performance of gate valves during transient operations.

Furthermore, emerging regulations around lifecycle assessment and circular economy principles are beginning to impact the valve industry. These regulations encourage manufacturers to consider the entire lifecycle energy consumption of their products, from production to disposal, which in turn influences the design and operation of gate valves to optimize energy efficiency throughout their lifespan.

Environmental Impact

The environmental impact of gate valves in transient operation is a critical aspect to consider when analyzing their energy consumption. During transient operations, gate valves experience rapid changes in flow rates and pressures, which can lead to increased energy consumption and potential environmental consequences.

One of the primary environmental concerns associated with gate valve transient operations is the increased emissions of greenhouse gases. As valves undergo rapid opening and closing cycles, the energy required to operate them increases, often resulting in higher electricity consumption. This additional energy demand typically translates to increased carbon dioxide emissions from power plants, contributing to climate change and global warming.

Water hammer effects, commonly observed during valve transients, can also have significant environmental implications. The sudden pressure surges and flow reversals associated with water hammer can cause pipe damage, leaks, and even ruptures in extreme cases. These incidents not only waste water resources but can also lead to soil contamination and ecosystem disruption if the transported fluid is hazardous or chemically treated.

Noise pollution is another environmental factor to consider during gate valve transient operations. The rapid changes in flow and pressure can generate substantial noise levels, potentially affecting nearby wildlife and human populations. This acoustic disturbance may disrupt natural habitats and cause stress to local fauna, impacting biodiversity in the surrounding area.

The wear and tear on valve components during transient operations can lead to increased maintenance requirements and shorter equipment lifespans. This accelerated degradation results in more frequent replacements and repairs, contributing to increased resource consumption and waste generation. The production, transportation, and disposal of replacement parts all have associated environmental footprints that should be factored into the overall impact assessment.

Furthermore, the potential for fluid leakage during transient operations poses risks to soil and water quality. Sudden pressure changes can stress seals and gaskets, potentially leading to small leaks that may go unnoticed for extended periods. These leaks can contaminate surrounding soil and groundwater, particularly if the transported fluid contains harmful chemicals or pollutants.

To mitigate these environmental impacts, it is crucial to optimize valve design and control strategies for transient operations. Implementing advanced control algorithms and utilizing smart valve technologies can help reduce energy consumption and minimize the occurrence of water hammer effects. Additionally, regular maintenance and monitoring programs can help identify and address potential issues before they escalate into environmental hazards.

One of the primary environmental concerns associated with gate valve transient operations is the increased emissions of greenhouse gases. As valves undergo rapid opening and closing cycles, the energy required to operate them increases, often resulting in higher electricity consumption. This additional energy demand typically translates to increased carbon dioxide emissions from power plants, contributing to climate change and global warming.

Water hammer effects, commonly observed during valve transients, can also have significant environmental implications. The sudden pressure surges and flow reversals associated with water hammer can cause pipe damage, leaks, and even ruptures in extreme cases. These incidents not only waste water resources but can also lead to soil contamination and ecosystem disruption if the transported fluid is hazardous or chemically treated.

Noise pollution is another environmental factor to consider during gate valve transient operations. The rapid changes in flow and pressure can generate substantial noise levels, potentially affecting nearby wildlife and human populations. This acoustic disturbance may disrupt natural habitats and cause stress to local fauna, impacting biodiversity in the surrounding area.

The wear and tear on valve components during transient operations can lead to increased maintenance requirements and shorter equipment lifespans. This accelerated degradation results in more frequent replacements and repairs, contributing to increased resource consumption and waste generation. The production, transportation, and disposal of replacement parts all have associated environmental footprints that should be factored into the overall impact assessment.

Furthermore, the potential for fluid leakage during transient operations poses risks to soil and water quality. Sudden pressure changes can stress seals and gaskets, potentially leading to small leaks that may go unnoticed for extended periods. These leaks can contaminate surrounding soil and groundwater, particularly if the transported fluid contains harmful chemicals or pollutants.

To mitigate these environmental impacts, it is crucial to optimize valve design and control strategies for transient operations. Implementing advanced control algorithms and utilizing smart valve technologies can help reduce energy consumption and minimize the occurrence of water hammer effects. Additionally, regular maintenance and monitoring programs can help identify and address potential issues before they escalate into environmental hazards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!