Exploring the role of smart gate valves in circular economies

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Valve Evolution

The evolution of smart gate valves represents a significant technological advancement in the field of fluid control systems. Initially, traditional gate valves were manually operated, requiring physical intervention for adjustments. The first step towards automation came with the introduction of actuators, which allowed for remote operation of valves.

As industrial processes became more complex, the need for precise control and monitoring of fluid flow increased. This led to the development of smart gate valves, which incorporated sensors and digital control systems. These valves could not only be operated remotely but also provided real-time data on flow rates, pressure, and valve position.

The integration of Internet of Things (IoT) technology marked a pivotal moment in smart valve evolution. IoT-enabled valves could now communicate with central control systems, allowing for predictive maintenance and optimized performance. This connectivity also facilitated the implementation of machine learning algorithms, enabling valves to adapt to changing conditions autonomously.

Recent advancements have focused on enhancing the sustainability and efficiency of smart gate valves. The incorporation of energy-efficient actuators and the use of eco-friendly materials in valve construction have reduced the environmental impact of these devices. Additionally, the development of self-diagnostic capabilities has further improved reliability and reduced maintenance requirements.

In the context of circular economies, smart gate valves have evolved to play a crucial role in resource conservation and waste reduction. Modern smart valves are designed with modularity in mind, allowing for easy repair and component replacement, thus extending their lifecycle. Some manufacturers have also implemented take-back programs, where old valves are refurbished or recycled, contributing to the circular economy model.

The latest generation of smart gate valves incorporates advanced materials science, with the use of self-healing coatings and corrosion-resistant alloys. These innovations have significantly extended the operational lifespan of valves, reducing the need for frequent replacements and aligning with circular economy principles.

Looking towards the future, the evolution of smart gate valves is likely to continue in the direction of increased intelligence and sustainability. Developments in artificial intelligence may lead to valves that can predict and prevent failures before they occur, while advancements in materials science could result in fully biodegradable valve components, further supporting circular economy goals.

As industrial processes became more complex, the need for precise control and monitoring of fluid flow increased. This led to the development of smart gate valves, which incorporated sensors and digital control systems. These valves could not only be operated remotely but also provided real-time data on flow rates, pressure, and valve position.

The integration of Internet of Things (IoT) technology marked a pivotal moment in smart valve evolution. IoT-enabled valves could now communicate with central control systems, allowing for predictive maintenance and optimized performance. This connectivity also facilitated the implementation of machine learning algorithms, enabling valves to adapt to changing conditions autonomously.

Recent advancements have focused on enhancing the sustainability and efficiency of smart gate valves. The incorporation of energy-efficient actuators and the use of eco-friendly materials in valve construction have reduced the environmental impact of these devices. Additionally, the development of self-diagnostic capabilities has further improved reliability and reduced maintenance requirements.

In the context of circular economies, smart gate valves have evolved to play a crucial role in resource conservation and waste reduction. Modern smart valves are designed with modularity in mind, allowing for easy repair and component replacement, thus extending their lifecycle. Some manufacturers have also implemented take-back programs, where old valves are refurbished or recycled, contributing to the circular economy model.

The latest generation of smart gate valves incorporates advanced materials science, with the use of self-healing coatings and corrosion-resistant alloys. These innovations have significantly extended the operational lifespan of valves, reducing the need for frequent replacements and aligning with circular economy principles.

Looking towards the future, the evolution of smart gate valves is likely to continue in the direction of increased intelligence and sustainability. Developments in artificial intelligence may lead to valves that can predict and prevent failures before they occur, while advancements in materials science could result in fully biodegradable valve components, further supporting circular economy goals.

Circular Economy Demand

The circular economy concept has gained significant traction in recent years, driving demand for technologies that support resource efficiency, waste reduction, and sustainable practices. Smart gate valves have emerged as a crucial component in this paradigm shift, offering enhanced control, monitoring, and optimization capabilities in various industrial processes.

The market demand for smart gate valves in circular economies is primarily driven by the need for improved resource management and waste reduction. Industries such as water treatment, chemical processing, and manufacturing are increasingly adopting these advanced valves to minimize material losses, optimize energy consumption, and extend the lifespan of equipment. This demand is further amplified by stringent environmental regulations and corporate sustainability goals, which push companies to invest in technologies that support circular economy principles.

In the water sector, smart gate valves play a vital role in leak detection and prevention, contributing to water conservation efforts. Municipalities and water utilities are investing in these technologies to reduce non-revenue water losses and improve overall system efficiency. The ability of smart gate valves to provide real-time data on flow rates, pressure, and valve position enables proactive maintenance and rapid response to potential issues, aligning with circular economy objectives of resource preservation and waste minimization.

The manufacturing industry is another key driver of demand for smart gate valves in circular economies. These valves enable precise control of material flows, reducing waste and improving product quality. By integrating with industrial Internet of Things (IIoT) platforms, smart gate valves contribute to the optimization of production processes, supporting the circular economy goal of maximizing resource utilization and minimizing waste generation.

The chemical processing sector is also experiencing increased demand for smart gate valves as part of its circular economy initiatives. These valves enable more efficient handling of chemicals, reducing the risk of spills and leaks that can lead to environmental contamination. The ability to monitor and control chemical flows with high precision supports the industry's efforts to implement closed-loop systems and recover valuable materials from waste streams.

As circular economy principles become more widely adopted, the demand for smart gate valves is expected to grow across various industries. The integration of these valves with advanced analytics and artificial intelligence systems will further enhance their role in supporting circular economy objectives. This trend is likely to drive innovation in valve design, sensor technologies, and data management systems, creating new opportunities for manufacturers and technology providers in the smart valve market.

The market demand for smart gate valves in circular economies is primarily driven by the need for improved resource management and waste reduction. Industries such as water treatment, chemical processing, and manufacturing are increasingly adopting these advanced valves to minimize material losses, optimize energy consumption, and extend the lifespan of equipment. This demand is further amplified by stringent environmental regulations and corporate sustainability goals, which push companies to invest in technologies that support circular economy principles.

In the water sector, smart gate valves play a vital role in leak detection and prevention, contributing to water conservation efforts. Municipalities and water utilities are investing in these technologies to reduce non-revenue water losses and improve overall system efficiency. The ability of smart gate valves to provide real-time data on flow rates, pressure, and valve position enables proactive maintenance and rapid response to potential issues, aligning with circular economy objectives of resource preservation and waste minimization.

The manufacturing industry is another key driver of demand for smart gate valves in circular economies. These valves enable precise control of material flows, reducing waste and improving product quality. By integrating with industrial Internet of Things (IIoT) platforms, smart gate valves contribute to the optimization of production processes, supporting the circular economy goal of maximizing resource utilization and minimizing waste generation.

The chemical processing sector is also experiencing increased demand for smart gate valves as part of its circular economy initiatives. These valves enable more efficient handling of chemicals, reducing the risk of spills and leaks that can lead to environmental contamination. The ability to monitor and control chemical flows with high precision supports the industry's efforts to implement closed-loop systems and recover valuable materials from waste streams.

As circular economy principles become more widely adopted, the demand for smart gate valves is expected to grow across various industries. The integration of these valves with advanced analytics and artificial intelligence systems will further enhance their role in supporting circular economy objectives. This trend is likely to drive innovation in valve design, sensor technologies, and data management systems, creating new opportunities for manufacturers and technology providers in the smart valve market.

Technical Challenges

The integration of smart gate valves in circular economies presents several technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the development of robust and reliable sensors capable of accurately monitoring various parameters in real-time. These sensors must withstand harsh industrial environments while maintaining precision in measuring factors such as flow rates, pressure, temperature, and fluid composition.

Another significant challenge lies in the design of advanced control systems that can effectively process and interpret the data collected by these sensors. These systems must be capable of making rapid, intelligent decisions to optimize valve operations in response to changing conditions. The complexity of integrating multiple valves across diverse industrial processes adds another layer of difficulty to this challenge.

Data security and communication protocols pose additional hurdles. As smart gate valves become increasingly connected within industrial networks, ensuring the integrity and confidentiality of data transmission becomes crucial. Developing secure, standardized communication protocols that allow seamless integration with existing industrial control systems is a complex task that requires careful consideration.

The durability and longevity of smart gate valves in circular economy applications present another technical challenge. These valves must be designed to withstand frequent cycling, corrosive environments, and varying operational conditions while maintaining their smart capabilities over extended periods. This necessitates the development of advanced materials and manufacturing techniques that can ensure both the mechanical reliability of the valve and the integrity of its electronic components.

Energy efficiency and power management represent further areas of technical difficulty. Smart gate valves often require a constant power supply to operate their sensors and control systems. Developing energy-efficient solutions, potentially incorporating energy harvesting technologies or low-power electronics, is essential for reducing the overall energy footprint of these systems in line with circular economy principles.

Maintenance and diagnostics pose unique challenges in the context of smart gate valves. While these valves offer the potential for predictive maintenance, developing accurate algorithms to forecast failures and optimize maintenance schedules remains a complex task. Additionally, ensuring that maintenance procedures can be carried out without compromising the valve's smart capabilities or the integrity of the circular economy system is a significant consideration.

Lastly, the challenge of scalability and interoperability cannot be overlooked. As circular economy initiatives expand, smart gate valves must be capable of seamlessly integrating with a wide range of existing and future systems. Developing standardized interfaces and protocols that allow for easy scaling and compatibility across different manufacturers and industries is a complex but necessary endeavor to realize the full potential of smart gate valves in circular economies.

Another significant challenge lies in the design of advanced control systems that can effectively process and interpret the data collected by these sensors. These systems must be capable of making rapid, intelligent decisions to optimize valve operations in response to changing conditions. The complexity of integrating multiple valves across diverse industrial processes adds another layer of difficulty to this challenge.

Data security and communication protocols pose additional hurdles. As smart gate valves become increasingly connected within industrial networks, ensuring the integrity and confidentiality of data transmission becomes crucial. Developing secure, standardized communication protocols that allow seamless integration with existing industrial control systems is a complex task that requires careful consideration.

The durability and longevity of smart gate valves in circular economy applications present another technical challenge. These valves must be designed to withstand frequent cycling, corrosive environments, and varying operational conditions while maintaining their smart capabilities over extended periods. This necessitates the development of advanced materials and manufacturing techniques that can ensure both the mechanical reliability of the valve and the integrity of its electronic components.

Energy efficiency and power management represent further areas of technical difficulty. Smart gate valves often require a constant power supply to operate their sensors and control systems. Developing energy-efficient solutions, potentially incorporating energy harvesting technologies or low-power electronics, is essential for reducing the overall energy footprint of these systems in line with circular economy principles.

Maintenance and diagnostics pose unique challenges in the context of smart gate valves. While these valves offer the potential for predictive maintenance, developing accurate algorithms to forecast failures and optimize maintenance schedules remains a complex task. Additionally, ensuring that maintenance procedures can be carried out without compromising the valve's smart capabilities or the integrity of the circular economy system is a significant consideration.

Lastly, the challenge of scalability and interoperability cannot be overlooked. As circular economy initiatives expand, smart gate valves must be capable of seamlessly integrating with a wide range of existing and future systems. Developing standardized interfaces and protocols that allow for easy scaling and compatibility across different manufacturers and industries is a complex but necessary endeavor to realize the full potential of smart gate valves in circular economies.

Current Smart Solutions

01 Smart control systems for gate valves

Advanced control systems are integrated into gate valves to enable remote operation, monitoring, and automation. These smart systems can include sensors, actuators, and communication interfaces that allow for real-time data collection and analysis, improving valve performance and efficiency.- Smart control systems for gate valves: Advanced control systems are integrated into gate valves to enable remote operation, monitoring, and automation. These smart systems can include sensors, actuators, and communication interfaces that allow for real-time data collection and analysis, improving valve performance and efficiency.

- Wireless communication in smart gate valves: Smart gate valves incorporate wireless communication technologies to facilitate remote control and data transmission. This enables operators to monitor and adjust valve settings from a distance, enhancing operational flexibility and reducing the need for on-site interventions.

- Intelligent flow control and optimization: Smart gate valves utilize advanced algorithms and machine learning techniques to optimize flow control. These systems can automatically adjust valve positions based on real-time data, pressure differentials, and flow rates, ensuring optimal performance and energy efficiency in various industrial applications.

- Predictive maintenance and diagnostics: Smart gate valves incorporate sensors and diagnostic tools to monitor valve health and predict potential failures. This predictive maintenance approach allows for timely interventions, reducing downtime and extending the lifespan of the valve components.

- Integration with industrial IoT systems: Smart gate valves are designed to seamlessly integrate with Industrial Internet of Things (IIoT) platforms. This integration enables comprehensive data collection, analysis, and visualization across entire industrial processes, facilitating improved decision-making and operational efficiency.

02 Wireless communication in smart gate valves

Smart gate valves incorporate wireless communication technologies to facilitate remote control and data transmission. This enables operators to monitor and adjust valve settings from a distance, enhancing operational flexibility and reducing the need for on-site interventions.Expand Specific Solutions03 Intelligent flow control and optimization

Smart gate valves utilize advanced algorithms and machine learning techniques to optimize flow control. These systems can automatically adjust valve positions based on real-time data, pressure differentials, and system demands, resulting in improved efficiency and reduced energy consumption.Expand Specific Solutions04 Predictive maintenance and diagnostics

Smart gate valves incorporate sensors and diagnostic tools to monitor valve health and performance. These systems can predict potential failures, schedule maintenance activities, and provide early warnings, thereby reducing downtime and improving overall system reliability.Expand Specific Solutions05 Integration with industrial IoT platforms

Smart gate valves are designed to seamlessly integrate with Industrial Internet of Things (IIoT) platforms. This integration allows for comprehensive data collection, analysis, and visualization across entire industrial processes, enabling better decision-making and process optimization.Expand Specific Solutions

Industry Leaders

The market for smart gate valves in circular economies is in its early growth stage, with increasing adoption driven by sustainability initiatives and resource efficiency goals. The global market size is projected to expand significantly in the coming years, fueled by advancements in IoT and automation technologies. While the technology is maturing, there's still room for innovation and improvement. Key players like Cameron International Corp., ITT Engineered Valves LLC, and Festo SE & Co. KG are leading the development of smart valve solutions, leveraging their expertise in industrial automation and control systems. Emerging companies such as Harbin Haguo Valve Co. Ltd. and Sedelon Valve Co.,Ltd are also contributing to the competitive landscape, focusing on niche applications and regional markets.

Cameron International Corp.

Technical Solution: Cameron International Corp. has developed smart gate valves that integrate advanced sensors and actuators with digital control systems. Their solution incorporates real-time monitoring capabilities to detect leaks, pressure anomalies, and flow irregularities. The valves can automatically adjust their position based on system conditions, optimizing flow control and reducing waste. Cameron's smart valves also feature predictive maintenance algorithms that analyze operational data to forecast potential failures, enabling proactive servicing and minimizing downtime[1][3]. This technology contributes to circular economies by extending equipment lifespan, reducing resource consumption, and improving overall system efficiency.

Strengths: Advanced sensor integration, predictive maintenance capabilities, and automated flow optimization. Weaknesses: Potentially higher initial costs and complexity compared to traditional valves.

FMC Tech Ltd.

Technical Solution: FMC Tech Ltd. has developed smart gate valves that focus on subsea applications, contributing to circular economies in offshore operations. Their solution incorporates high-pressure, high-temperature (HPHT) resistant materials and designs to withstand extreme underwater conditions. FMC's smart valves feature electro-hydraulic actuation systems that provide precise control and rapid response times. The valves are equipped with multiple redundant sensors for pressure, temperature, and flow monitoring, ensuring reliable operation in critical subsea environments[9]. FMC has also implemented a condition-based monitoring system that uses acoustic emissions and vibration analysis to detect early signs of wear or potential failures. This predictive maintenance approach extends valve lifespan and reduces the need for frequent interventions, aligning with circular economy principles by minimizing resource use and operational disruptions[10].

Strengths: Specialized for subsea applications, HPHT-resistant design, and advanced condition-based monitoring. Weaknesses: High costs associated with subsea technology and limited use in non-marine environments.

Key Valve Innovations

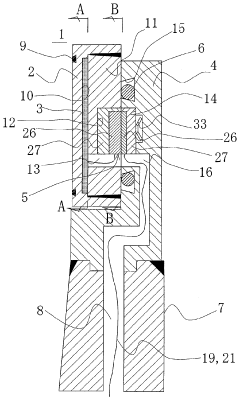

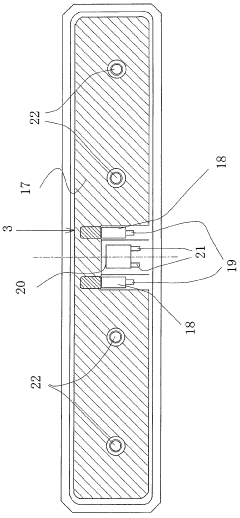

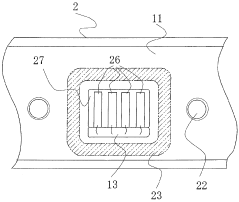

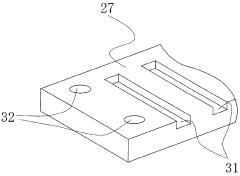

Gate valve

PatentWO2009147902A1

Innovation

- The gate valve features flat connecting terminals on the valve body and holder with a conductive spring for reliable electrical contact, reducing contact depth and thickness, and incorporates heat-insulating ribs to enhance heating efficiency while simplifying the replacement of the heater by allowing it to be placed in an air atmosphere for improved heat transfer.

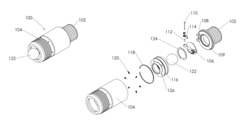

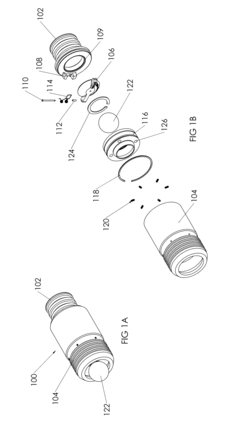

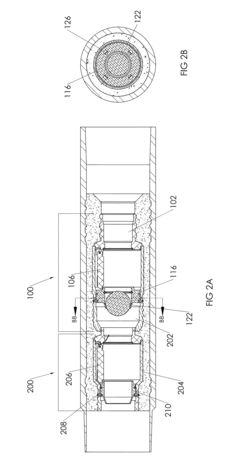

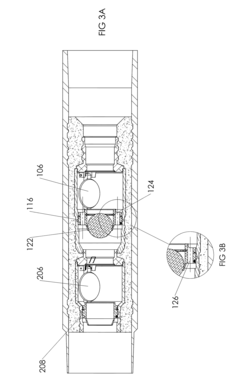

Convertible valve with retained conversion element

PatentInactiveUS20150377372A1

Innovation

- A valve design featuring a seat and conversion element that moves in response to fluid pressure, using shear devices and bi-directional fluid flow passages to transition from open to closed positions, ensuring reliable conversion from bi-directional to unidirectional flow, with optional secondary valve gates for enhanced control.

Sustainability Impact

Smart gate valves play a crucial role in advancing circular economies by enhancing resource efficiency and minimizing waste in various industrial processes. These intelligent devices contribute significantly to sustainability efforts by optimizing water and energy usage, reducing material losses, and extending the lifespan of infrastructure systems.

In the context of water management, smart gate valves enable precise control of water flow, preventing leaks and reducing water waste. By integrating sensors and real-time monitoring capabilities, these valves can detect anomalies and adjust flow rates automatically, ensuring optimal water distribution and conservation. This not only preserves a vital resource but also reduces the energy required for water treatment and distribution.

In industrial applications, smart gate valves contribute to circular economy principles by improving process efficiency and reducing material waste. Through advanced control algorithms and predictive maintenance capabilities, these valves minimize downtime, optimize production cycles, and prevent product loss. This results in more efficient use of raw materials and energy, aligning with the circular economy's goal of maximizing resource utilization.

The implementation of smart gate valves in waste management systems further enhances sustainability efforts. These valves can be used to control the flow of waste materials, enabling more effective sorting and recycling processes. By optimizing waste stream management, smart gate valves contribute to increased material recovery rates and reduced landfill usage, supporting the transition towards a more circular economy.

Moreover, smart gate valves play a vital role in extending the lifespan of infrastructure systems. Through continuous monitoring and predictive maintenance, these valves help prevent catastrophic failures and reduce the need for premature replacements. This not only conserves resources but also minimizes the environmental impact associated with manufacturing and installing new infrastructure components.

The data collected by smart gate valves also contributes to sustainability efforts by providing valuable insights for system optimization. This information can be used to identify inefficiencies, develop more sustainable operational strategies, and inform future infrastructure planning. By leveraging this data, organizations can make more informed decisions that align with circular economy principles and long-term sustainability goals.

In conclusion, smart gate valves serve as a key enabler for circular economies by enhancing resource efficiency, minimizing waste, and promoting sustainable practices across various industries. Their impact on sustainability extends beyond immediate operational improvements, contributing to long-term environmental conservation and the development of more resilient, circular systems.

In the context of water management, smart gate valves enable precise control of water flow, preventing leaks and reducing water waste. By integrating sensors and real-time monitoring capabilities, these valves can detect anomalies and adjust flow rates automatically, ensuring optimal water distribution and conservation. This not only preserves a vital resource but also reduces the energy required for water treatment and distribution.

In industrial applications, smart gate valves contribute to circular economy principles by improving process efficiency and reducing material waste. Through advanced control algorithms and predictive maintenance capabilities, these valves minimize downtime, optimize production cycles, and prevent product loss. This results in more efficient use of raw materials and energy, aligning with the circular economy's goal of maximizing resource utilization.

The implementation of smart gate valves in waste management systems further enhances sustainability efforts. These valves can be used to control the flow of waste materials, enabling more effective sorting and recycling processes. By optimizing waste stream management, smart gate valves contribute to increased material recovery rates and reduced landfill usage, supporting the transition towards a more circular economy.

Moreover, smart gate valves play a vital role in extending the lifespan of infrastructure systems. Through continuous monitoring and predictive maintenance, these valves help prevent catastrophic failures and reduce the need for premature replacements. This not only conserves resources but also minimizes the environmental impact associated with manufacturing and installing new infrastructure components.

The data collected by smart gate valves also contributes to sustainability efforts by providing valuable insights for system optimization. This information can be used to identify inefficiencies, develop more sustainable operational strategies, and inform future infrastructure planning. By leveraging this data, organizations can make more informed decisions that align with circular economy principles and long-term sustainability goals.

In conclusion, smart gate valves serve as a key enabler for circular economies by enhancing resource efficiency, minimizing waste, and promoting sustainable practices across various industries. Their impact on sustainability extends beyond immediate operational improvements, contributing to long-term environmental conservation and the development of more resilient, circular systems.

Regulatory Framework

The regulatory framework surrounding smart gate valves in circular economies is evolving to address the unique challenges and opportunities presented by this technology. As governments and industries recognize the potential of smart valves to enhance resource efficiency and reduce waste, new regulations are being developed to ensure their safe and effective implementation.

One key aspect of the regulatory landscape is the establishment of standards for smart valve performance and reliability. Organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) are working to develop guidelines that define minimum requirements for smart valve functionality, data security, and interoperability. These standards aim to create a common language for manufacturers, operators, and regulators, facilitating the adoption of smart valve technology across various industries.

Environmental regulations are also playing a significant role in shaping the use of smart gate valves in circular economies. Many countries are implementing stricter regulations on resource consumption and waste generation, which indirectly promote the adoption of smart valve technologies. For instance, the European Union's Circular Economy Action Plan includes measures that encourage the use of smart technologies to optimize resource use and minimize environmental impact.

Data privacy and security regulations are another critical component of the regulatory framework. As smart valves collect and transmit large amounts of operational data, regulations such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the United States are being applied to ensure the protection of sensitive information. These regulations require manufacturers and operators to implement robust data protection measures and obtain necessary consents for data collection and processing.

The regulatory landscape also includes incentives and support mechanisms to encourage the adoption of smart valve technologies in circular economy initiatives. Many governments are offering tax incentives, grants, and subsidies to businesses that invest in smart technologies that contribute to resource efficiency and waste reduction. These financial incentives are designed to offset the initial costs of implementing smart valve systems and accelerate their integration into existing infrastructure.

As the technology continues to evolve, regulators are adopting a more flexible and adaptive approach to governance. This includes the use of regulatory sandboxes, which allow companies to test innovative smart valve applications in controlled environments with reduced regulatory burden. Such initiatives aim to strike a balance between fostering innovation and ensuring public safety and environmental protection.

One key aspect of the regulatory landscape is the establishment of standards for smart valve performance and reliability. Organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) are working to develop guidelines that define minimum requirements for smart valve functionality, data security, and interoperability. These standards aim to create a common language for manufacturers, operators, and regulators, facilitating the adoption of smart valve technology across various industries.

Environmental regulations are also playing a significant role in shaping the use of smart gate valves in circular economies. Many countries are implementing stricter regulations on resource consumption and waste generation, which indirectly promote the adoption of smart valve technologies. For instance, the European Union's Circular Economy Action Plan includes measures that encourage the use of smart technologies to optimize resource use and minimize environmental impact.

Data privacy and security regulations are another critical component of the regulatory framework. As smart valves collect and transmit large amounts of operational data, regulations such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the United States are being applied to ensure the protection of sensitive information. These regulations require manufacturers and operators to implement robust data protection measures and obtain necessary consents for data collection and processing.

The regulatory landscape also includes incentives and support mechanisms to encourage the adoption of smart valve technologies in circular economy initiatives. Many governments are offering tax incentives, grants, and subsidies to businesses that invest in smart technologies that contribute to resource efficiency and waste reduction. These financial incentives are designed to offset the initial costs of implementing smart valve systems and accelerate their integration into existing infrastructure.

As the technology continues to evolve, regulators are adopting a more flexible and adaptive approach to governance. This includes the use of regulatory sandboxes, which allow companies to test innovative smart valve applications in controlled environments with reduced regulatory burden. Such initiatives aim to strike a balance between fostering innovation and ensuring public safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!