Performance validation of smart gate valves in adaptive industrial controls

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Valve Evolution

The evolution of smart gate valves in adaptive industrial controls represents a significant advancement in process automation and control systems. This technological progression has been driven by the increasing demand for more efficient, reliable, and intelligent industrial operations.

In the early stages of valve technology, manual operation was the norm, requiring constant human intervention for adjustments and maintenance. The introduction of pneumatic and hydraulic actuators marked the first step towards automation, allowing for remote operation and basic control capabilities.

The advent of electric actuators in the mid-20th century brought about a new era of precision and reliability in valve control. These actuators offered improved accuracy and the ability to integrate with emerging electronic control systems, laying the groundwork for more sophisticated automation.

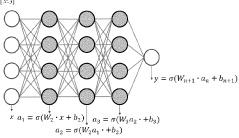

The true smart valve revolution began with the integration of microprocessors and digital technologies in the late 20th century. This integration allowed for real-time monitoring, data collection, and advanced control algorithms. Smart valves could now communicate with central control systems, providing valuable insights into process conditions and valve performance.

As industrial control systems became more complex, the need for adaptive and self-optimizing valves grew. The development of advanced sensors and diagnostic capabilities enabled smart valves to perform self-diagnostics, predict maintenance needs, and adapt to changing process conditions autonomously.

Recent advancements in artificial intelligence and machine learning have further enhanced the capabilities of smart gate valves. These technologies enable predictive maintenance, optimized flow control, and adaptive responses to complex process variables. The integration of Industrial Internet of Things (IIoT) platforms has also facilitated seamless connectivity and data exchange between smart valves and other industrial assets.

The latest generation of smart gate valves incorporates advanced materials and design techniques to improve durability and performance under extreme conditions. Features such as self-cleaning mechanisms, enhanced sealing technologies, and corrosion-resistant materials have extended the lifespan and reliability of these critical components.

Looking ahead, the evolution of smart gate valves is expected to continue with a focus on increased autonomy, improved energy efficiency, and enhanced cybersecurity measures. The integration of edge computing capabilities and advanced analytics will likely lead to even more intelligent and responsive valve systems, capable of making complex decisions in real-time without relying on centralized control systems.

In the early stages of valve technology, manual operation was the norm, requiring constant human intervention for adjustments and maintenance. The introduction of pneumatic and hydraulic actuators marked the first step towards automation, allowing for remote operation and basic control capabilities.

The advent of electric actuators in the mid-20th century brought about a new era of precision and reliability in valve control. These actuators offered improved accuracy and the ability to integrate with emerging electronic control systems, laying the groundwork for more sophisticated automation.

The true smart valve revolution began with the integration of microprocessors and digital technologies in the late 20th century. This integration allowed for real-time monitoring, data collection, and advanced control algorithms. Smart valves could now communicate with central control systems, providing valuable insights into process conditions and valve performance.

As industrial control systems became more complex, the need for adaptive and self-optimizing valves grew. The development of advanced sensors and diagnostic capabilities enabled smart valves to perform self-diagnostics, predict maintenance needs, and adapt to changing process conditions autonomously.

Recent advancements in artificial intelligence and machine learning have further enhanced the capabilities of smart gate valves. These technologies enable predictive maintenance, optimized flow control, and adaptive responses to complex process variables. The integration of Industrial Internet of Things (IIoT) platforms has also facilitated seamless connectivity and data exchange between smart valves and other industrial assets.

The latest generation of smart gate valves incorporates advanced materials and design techniques to improve durability and performance under extreme conditions. Features such as self-cleaning mechanisms, enhanced sealing technologies, and corrosion-resistant materials have extended the lifespan and reliability of these critical components.

Looking ahead, the evolution of smart gate valves is expected to continue with a focus on increased autonomy, improved energy efficiency, and enhanced cybersecurity measures. The integration of edge computing capabilities and advanced analytics will likely lead to even more intelligent and responsive valve systems, capable of making complex decisions in real-time without relying on centralized control systems.

Industrial Control Needs

The industrial control sector is experiencing a significant shift towards smart and adaptive systems, driven by the increasing demand for efficiency, reliability, and flexibility in manufacturing processes. Smart gate valves represent a critical component in this evolution, offering precise flow control and real-time monitoring capabilities that are essential for optimizing industrial operations. The performance validation of these valves in adaptive industrial controls is crucial for ensuring their effectiveness and reliability in diverse industrial applications.

Industrial control systems face numerous challenges that smart gate valves aim to address. One of the primary needs is the ability to respond rapidly to changing process conditions. Traditional valve systems often lack the agility to adjust quickly, leading to inefficiencies and potential safety risks. Smart gate valves, with their advanced sensors and actuators, can provide instantaneous feedback and adjustment, meeting the industry's need for responsive control mechanisms.

Another critical requirement in industrial control is the ability to integrate seamlessly with existing automation systems. As industries move towards Industry 4.0 and the Industrial Internet of Things (IIoT), there is a growing need for valves that can communicate effectively with other components of the control system. Smart gate valves, equipped with digital interfaces and communication protocols, fulfill this requirement by enabling real-time data exchange and remote monitoring capabilities.

Energy efficiency is also a paramount concern in industrial processes. The industrial sector consumes a significant portion of global energy resources, and there is a pressing need to optimize energy usage. Smart gate valves contribute to this goal by providing precise control over fluid flow, reducing waste, and minimizing energy consumption associated with pumping and processing.

Predictive maintenance is another area where smart gate valves address a critical industrial control need. Unplanned downtime due to equipment failure can result in substantial financial losses and production delays. By continuously monitoring valve performance and health, smart gate valves enable proactive maintenance strategies, reducing the risk of unexpected failures and optimizing maintenance schedules.

Furthermore, the industrial sector requires solutions that can operate reliably in harsh environments. Smart gate valves must demonstrate robustness and durability to withstand extreme temperatures, pressures, and corrosive substances commonly encountered in industrial settings. The performance validation of these valves must, therefore, include rigorous testing under various environmental conditions to ensure their long-term reliability and effectiveness.

Industrial control systems face numerous challenges that smart gate valves aim to address. One of the primary needs is the ability to respond rapidly to changing process conditions. Traditional valve systems often lack the agility to adjust quickly, leading to inefficiencies and potential safety risks. Smart gate valves, with their advanced sensors and actuators, can provide instantaneous feedback and adjustment, meeting the industry's need for responsive control mechanisms.

Another critical requirement in industrial control is the ability to integrate seamlessly with existing automation systems. As industries move towards Industry 4.0 and the Industrial Internet of Things (IIoT), there is a growing need for valves that can communicate effectively with other components of the control system. Smart gate valves, equipped with digital interfaces and communication protocols, fulfill this requirement by enabling real-time data exchange and remote monitoring capabilities.

Energy efficiency is also a paramount concern in industrial processes. The industrial sector consumes a significant portion of global energy resources, and there is a pressing need to optimize energy usage. Smart gate valves contribute to this goal by providing precise control over fluid flow, reducing waste, and minimizing energy consumption associated with pumping and processing.

Predictive maintenance is another area where smart gate valves address a critical industrial control need. Unplanned downtime due to equipment failure can result in substantial financial losses and production delays. By continuously monitoring valve performance and health, smart gate valves enable proactive maintenance strategies, reducing the risk of unexpected failures and optimizing maintenance schedules.

Furthermore, the industrial sector requires solutions that can operate reliably in harsh environments. Smart gate valves must demonstrate robustness and durability to withstand extreme temperatures, pressures, and corrosive substances commonly encountered in industrial settings. The performance validation of these valves must, therefore, include rigorous testing under various environmental conditions to ensure their long-term reliability and effectiveness.

Valve Tech Challenges

Smart gate valves in adaptive industrial controls face several significant technical challenges that hinder their optimal performance and widespread adoption. One of the primary issues is the complexity of real-time control algorithms required to manage valve operations in dynamic industrial environments. These algorithms must process vast amounts of sensor data, predict system behavior, and make split-second decisions to adjust valve positions, all while maintaining system stability and efficiency.

Another major challenge lies in the development of robust and reliable sensors capable of accurately measuring various process parameters under harsh industrial conditions. These sensors must withstand extreme temperatures, pressures, and corrosive environments while providing precise, high-frequency measurements to support adaptive control strategies. The integration of these sensors with valve actuators and control systems presents additional technical hurdles, particularly in terms of data transmission and processing speeds.

The need for advanced materials in smart valve construction also poses significant challenges. Valve components must exhibit exceptional wear resistance, thermal stability, and chemical compatibility to ensure long-term reliability in diverse industrial applications. Developing materials that meet these requirements while remaining cost-effective for large-scale production is an ongoing area of research and development.

Energy efficiency and power management represent another set of technical challenges for smart gate valves. Minimizing power consumption while maintaining rapid response times and precise control is crucial, especially in remote or hazardous environments where power sources may be limited. This necessitates the development of low-power electronics and efficient actuator designs that can operate reliably under varying conditions.

Cybersecurity concerns also present significant challenges in the implementation of smart valve systems. As these valves become increasingly connected and integrated into industrial control networks, they become potential targets for cyber attacks. Developing robust security protocols and encryption methods to protect valve operations and data integrity is essential for ensuring the safety and reliability of industrial processes.

Interoperability and standardization pose additional challenges in the smart valve industry. The lack of universal communication protocols and control interfaces can lead to compatibility issues when integrating smart valves from different manufacturers into existing industrial control systems. Establishing industry-wide standards for data exchange and control interfaces is crucial for promoting wider adoption and seamless integration of smart valve technologies.

Another major challenge lies in the development of robust and reliable sensors capable of accurately measuring various process parameters under harsh industrial conditions. These sensors must withstand extreme temperatures, pressures, and corrosive environments while providing precise, high-frequency measurements to support adaptive control strategies. The integration of these sensors with valve actuators and control systems presents additional technical hurdles, particularly in terms of data transmission and processing speeds.

The need for advanced materials in smart valve construction also poses significant challenges. Valve components must exhibit exceptional wear resistance, thermal stability, and chemical compatibility to ensure long-term reliability in diverse industrial applications. Developing materials that meet these requirements while remaining cost-effective for large-scale production is an ongoing area of research and development.

Energy efficiency and power management represent another set of technical challenges for smart gate valves. Minimizing power consumption while maintaining rapid response times and precise control is crucial, especially in remote or hazardous environments where power sources may be limited. This necessitates the development of low-power electronics and efficient actuator designs that can operate reliably under varying conditions.

Cybersecurity concerns also present significant challenges in the implementation of smart valve systems. As these valves become increasingly connected and integrated into industrial control networks, they become potential targets for cyber attacks. Developing robust security protocols and encryption methods to protect valve operations and data integrity is essential for ensuring the safety and reliability of industrial processes.

Interoperability and standardization pose additional challenges in the smart valve industry. The lack of universal communication protocols and control interfaces can lead to compatibility issues when integrating smart valves from different manufacturers into existing industrial control systems. Establishing industry-wide standards for data exchange and control interfaces is crucial for promoting wider adoption and seamless integration of smart valve technologies.

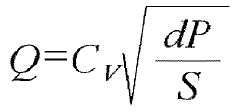

Current Validation Methods

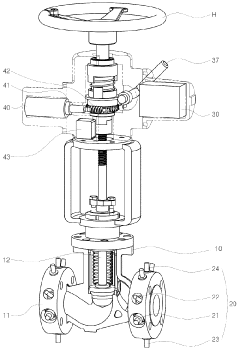

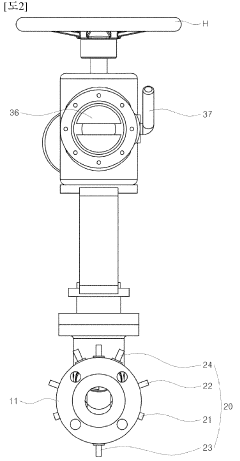

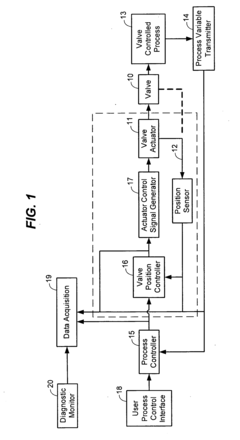

01 Smart control systems for gate valves

Advanced control systems are integrated into gate valves to enhance their performance and functionality. These systems may include sensors, actuators, and microprocessors that enable real-time monitoring, remote operation, and automated adjustments based on various parameters such as flow rate, pressure, and temperature.- Smart control systems for gate valves: Advanced control systems are integrated into gate valves to enhance their performance and functionality. These systems may include sensors, actuators, and microprocessors that enable real-time monitoring, remote operation, and automated adjustments based on various parameters such as flow rate, pressure, and temperature.

- Improved sealing mechanisms: Smart gate valves incorporate innovative sealing technologies to prevent leakage and improve overall performance. These may include self-adjusting seals, multi-layer sealing systems, or advanced materials that can withstand high pressures and temperatures while maintaining tight closure.

- Energy-efficient actuators: High-performance actuators are developed for smart gate valves to optimize energy consumption and improve operational efficiency. These actuators may utilize advanced motor technologies, energy recovery systems, or adaptive power management to reduce energy usage while maintaining precise control over valve operations.

- Predictive maintenance capabilities: Smart gate valves are equipped with sensors and diagnostic tools that enable predictive maintenance. These systems can monitor valve performance, detect potential issues before they become critical, and provide real-time data for maintenance planning, thereby reducing downtime and improving overall reliability.

- Integration with industrial IoT systems: Smart gate valves are designed to seamlessly integrate with industrial Internet of Things (IoT) platforms. This integration allows for enhanced data collection, analysis, and communication with other industrial systems, enabling better process control, optimization, and decision-making in complex industrial environments.

02 Improved sealing mechanisms

Smart gate valves incorporate innovative sealing technologies to prevent leakage and improve overall performance. These may include self-adjusting seals, multi-layer sealing systems, or advanced materials that can withstand high pressures and temperatures while maintaining tight closure.Expand Specific Solutions03 Energy-efficient actuators

High-performance actuators are developed for smart gate valves to optimize energy consumption and improve operational efficiency. These actuators may utilize advanced motor technologies, energy recovery systems, or adaptive power management to reduce energy usage while maintaining precise control over valve operations.Expand Specific Solutions04 Predictive maintenance capabilities

Smart gate valves are equipped with sensors and diagnostic tools that enable predictive maintenance. These systems can monitor valve performance, detect potential issues before they become critical, and provide real-time data for maintenance scheduling, thereby reducing downtime and improving overall reliability.Expand Specific Solutions05 Integration with industrial IoT systems

Smart gate valves are designed to seamlessly integrate with industrial Internet of Things (IoT) platforms. This integration allows for enhanced data collection, analysis, and remote monitoring capabilities, enabling operators to optimize valve performance, improve process efficiency, and implement advanced control strategies across entire industrial systems.Expand Specific Solutions

Key Industry Players

The performance validation of smart gate valves in adaptive industrial controls is an emerging field in the industrial automation sector. The market is in its early growth stage, with increasing demand driven by the need for more efficient and intelligent control systems. The global market size for smart valves is projected to grow significantly in the coming years, fueled by Industry 4.0 initiatives and the push for greater process optimization. Technologically, the field is rapidly evolving, with companies like Yokogawa Electric, Fisher Controls International, and SAMSON AG leading innovation in smart valve technology. These firms are developing advanced solutions integrating IoT, AI, and predictive maintenance capabilities. However, the technology is still maturing, with ongoing research focused on improving reliability, accuracy, and integration with broader industrial control systems.

Fisher Controls International LLC

Technical Solution: Fisher Controls has developed an advanced smart gate valve system for adaptive industrial controls. Their solution incorporates digital positioners with high-resolution sensors and microprocessors for precise control and real-time diagnostics. The system uses adaptive algorithms to continuously optimize valve performance based on process conditions. Fisher's FIELDVUE digital valve controllers enable condition monitoring and predictive maintenance, reducing downtime[1]. The valves feature high-cycle life designs and materials optimized for specific applications, ensuring long-term reliability in demanding industrial environments[2]. Fisher's control valve diagnostic tools provide detailed performance data for validation and optimization.

Strengths: Industry-leading digital control technology, extensive application expertise, and global support network. Weaknesses: Higher initial cost compared to traditional valves, may require specialized training for maintenance personnel.

Yokogawa Electric Corp.

Technical Solution: Yokogawa has developed a comprehensive smart valve solution for adaptive industrial controls. Their approach integrates advanced positioners with their DCS and asset management systems for seamless operation and monitoring. Yokogawa's ValveNavi software enables detailed valve signature analysis and diagnostics, facilitating performance validation and predictive maintenance[3]. Their smart valves incorporate high-precision sensors and adaptive control algorithms to optimize performance in real-time. Yokogawa's solution also includes wireless communication options for remote monitoring and control, enhancing flexibility in industrial settings[4]. The company's valve solutions are designed to meet stringent safety and reliability standards, with SIL 3 capability for critical applications.

Strengths: Strong integration with process control systems, advanced diagnostics capabilities, and focus on safety-critical applications. Weaknesses: May have limited compatibility with third-party systems, potentially higher implementation costs for full system integration.

Innovative Valve Designs

Smart valve system capable of active control, malfunction diagnosis, and operation status monitoring by artificial intelligence learning

PatentWO2023153675A1

Innovation

- A smart valve system equipped with sensors for pressure, temperature, and vibration monitoring, utilizing artificial intelligence algorithms to predict flow rates and valve failures, and controlling the valve actuator based on real-time data without the need for auxiliary equipment, enabling active flow control and fault diagnosis.

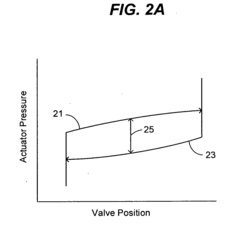

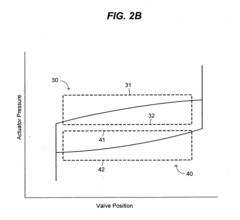

Computerized evaluation of valve signature graphs

PatentInactiveUS20080004836A1

Innovation

- A method and system that collect and analyze process control device signature data against user-configurable boundaries and settings, allowing for automated detection of issues such as friction, torque, shaft integrity, and stick-slip conditions by comparing current graphs to baseline or factory settings, with alerts generated for deviations.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing smart gate valves in adaptive industrial control systems. The performance validation of these valves must adhere to various industry standards and regulations to ensure safety, reliability, and environmental protection. In the context of smart gate valves, compliance requirements typically encompass several key areas.

Firstly, safety standards are paramount. Organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) have established guidelines for the safe operation of industrial control systems. Smart gate valves must comply with standards like IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems. This includes requirements for risk assessment, safety integrity levels (SIL), and lifecycle management.

Environmental regulations also play a significant role in the deployment of smart gate valves. Agencies like the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe set standards for emissions control and environmental impact. Smart gate valves used in industries such as oil and gas or chemical processing must meet stringent requirements for leak detection and prevention, as well as fugitive emissions reduction.

Quality management systems are another crucial aspect of regulatory compliance. ISO 9001 certification is often required for manufacturers and implementers of smart gate valves, ensuring consistent quality and continuous improvement in production and installation processes. Additionally, industry-specific standards like API 6D for pipeline valves in the oil and gas sector must be adhered to.

Cybersecurity regulations have become increasingly important with the integration of smart technologies in industrial controls. Standards such as IEC 62443 for industrial automation and control systems security provide guidelines for protecting smart gate valves and associated control systems from cyber threats. Compliance with these standards is essential to prevent unauthorized access and ensure the integrity of valve operations.

Data privacy and protection regulations, such as the General Data Protection Regulation (GDPR) in the European Union, may also apply to smart gate valve systems that collect and process operational data. Ensuring compliance with these regulations is crucial when implementing data analytics and remote monitoring capabilities.

Lastly, performance validation of smart gate valves must consider industry-specific regulations. For instance, in the water treatment industry, valves may need to comply with NSF/ANSI 61 for drinking water system components. In the pharmaceutical industry, FDA regulations for Good Manufacturing Practices (GMP) would apply to valve systems used in drug production processes.

Adhering to these regulatory requirements not only ensures legal compliance but also contributes to the overall reliability, safety, and efficiency of smart gate valve implementations in adaptive industrial control systems. Regular audits and certifications are necessary to maintain compliance and adapt to evolving regulatory landscapes.

Firstly, safety standards are paramount. Organizations such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) have established guidelines for the safe operation of industrial control systems. Smart gate valves must comply with standards like IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems. This includes requirements for risk assessment, safety integrity levels (SIL), and lifecycle management.

Environmental regulations also play a significant role in the deployment of smart gate valves. Agencies like the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) in Europe set standards for emissions control and environmental impact. Smart gate valves used in industries such as oil and gas or chemical processing must meet stringent requirements for leak detection and prevention, as well as fugitive emissions reduction.

Quality management systems are another crucial aspect of regulatory compliance. ISO 9001 certification is often required for manufacturers and implementers of smart gate valves, ensuring consistent quality and continuous improvement in production and installation processes. Additionally, industry-specific standards like API 6D for pipeline valves in the oil and gas sector must be adhered to.

Cybersecurity regulations have become increasingly important with the integration of smart technologies in industrial controls. Standards such as IEC 62443 for industrial automation and control systems security provide guidelines for protecting smart gate valves and associated control systems from cyber threats. Compliance with these standards is essential to prevent unauthorized access and ensure the integrity of valve operations.

Data privacy and protection regulations, such as the General Data Protection Regulation (GDPR) in the European Union, may also apply to smart gate valve systems that collect and process operational data. Ensuring compliance with these regulations is crucial when implementing data analytics and remote monitoring capabilities.

Lastly, performance validation of smart gate valves must consider industry-specific regulations. For instance, in the water treatment industry, valves may need to comply with NSF/ANSI 61 for drinking water system components. In the pharmaceutical industry, FDA regulations for Good Manufacturing Practices (GMP) would apply to valve systems used in drug production processes.

Adhering to these regulatory requirements not only ensures legal compliance but also contributes to the overall reliability, safety, and efficiency of smart gate valve implementations in adaptive industrial control systems. Regular audits and certifications are necessary to maintain compliance and adapt to evolving regulatory landscapes.

Cybersecurity Measures

Cybersecurity measures are crucial for ensuring the safe and reliable operation of smart gate valves in adaptive industrial control systems. As these valves become increasingly connected and integrated into digital networks, they become potential targets for cyber attacks. To mitigate these risks, a multi-layered approach to cybersecurity is essential.

Firstly, robust authentication and access control mechanisms must be implemented. This includes strong password policies, multi-factor authentication, and role-based access control to ensure that only authorized personnel can interact with the valve systems. Regular audits of user access rights and privileges should be conducted to maintain the principle of least privilege.

Encryption plays a vital role in protecting data both in transit and at rest. All communication between smart gate valves, control systems, and monitoring interfaces should be encrypted using industry-standard protocols such as TLS/SSL. Sensitive data stored on valve controllers or in associated databases must also be encrypted to prevent unauthorized access in case of physical breaches.

Network segmentation and firewalls are essential for isolating smart valve systems from other parts of the industrial network. By creating separate network zones for valve control systems, the potential impact of a cyber attack can be limited. Firewalls should be configured to strictly control traffic between these zones, allowing only necessary communication protocols and ports.

Regular software updates and patch management are critical for addressing known vulnerabilities. A systematic process for testing and deploying updates to valve firmware, control software, and associated systems should be established. This process must balance the need for security with the operational requirements of the industrial environment.

Continuous monitoring and intrusion detection systems are necessary to identify and respond to potential security breaches in real-time. Anomaly detection algorithms can be employed to identify unusual patterns in valve operation or network traffic that may indicate a cyber attack. Integration with a Security Information and Event Management (SIEM) system can provide comprehensive visibility into the security posture of the valve systems.

Incident response planning is crucial for minimizing the impact of potential cyber attacks. This includes developing and regularly testing procedures for isolating affected systems, restoring from backups, and coordinating with relevant stakeholders. Staff training on cybersecurity awareness and incident response procedures is essential for effective implementation of these measures.

Firstly, robust authentication and access control mechanisms must be implemented. This includes strong password policies, multi-factor authentication, and role-based access control to ensure that only authorized personnel can interact with the valve systems. Regular audits of user access rights and privileges should be conducted to maintain the principle of least privilege.

Encryption plays a vital role in protecting data both in transit and at rest. All communication between smart gate valves, control systems, and monitoring interfaces should be encrypted using industry-standard protocols such as TLS/SSL. Sensitive data stored on valve controllers or in associated databases must also be encrypted to prevent unauthorized access in case of physical breaches.

Network segmentation and firewalls are essential for isolating smart valve systems from other parts of the industrial network. By creating separate network zones for valve control systems, the potential impact of a cyber attack can be limited. Firewalls should be configured to strictly control traffic between these zones, allowing only necessary communication protocols and ports.

Regular software updates and patch management are critical for addressing known vulnerabilities. A systematic process for testing and deploying updates to valve firmware, control software, and associated systems should be established. This process must balance the need for security with the operational requirements of the industrial environment.

Continuous monitoring and intrusion detection systems are necessary to identify and respond to potential security breaches in real-time. Anomaly detection algorithms can be employed to identify unusual patterns in valve operation or network traffic that may indicate a cyber attack. Integration with a Security Information and Event Management (SIEM) system can provide comprehensive visibility into the security posture of the valve systems.

Incident response planning is crucial for minimizing the impact of potential cyber attacks. This includes developing and regularly testing procedures for isolating affected systems, restoring from backups, and coordinating with relevant stakeholders. Staff training on cybersecurity awareness and incident response procedures is essential for effective implementation of these measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!