Gate valve compatibility with biodegradable fluids

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Biodegradable Fluid Goals

Gate valves have undergone significant evolution since their inception in the late 19th century. Initially designed for simple on-off control in water and steam systems, these valves have progressively adapted to meet the demands of various industries, including oil and gas, chemical processing, and power generation. The technological advancements in materials science and manufacturing processes have played a crucial role in enhancing the performance, reliability, and versatility of gate valves.

In recent years, the focus has shifted towards developing gate valves compatible with biodegradable fluids, driven by increasing environmental concerns and stringent regulations. This transition aligns with the global push for sustainable industrial practices and the reduction of environmental impact. The primary goal is to create gate valves that can effectively handle biodegradable fluids without compromising on performance, durability, or safety.

The compatibility of gate valves with biodegradable fluids presents unique challenges and opportunities. These fluids, often derived from renewable sources, have different chemical properties compared to traditional petroleum-based fluids. As a result, the materials used in gate valve construction must be carefully selected to resist degradation, maintain seal integrity, and ensure long-term operational efficiency when exposed to these eco-friendly alternatives.

One of the key objectives in this technological evolution is to develop gate valves that can seamlessly integrate into existing systems without requiring significant modifications to infrastructure. This backward compatibility is crucial for industries looking to transition to more sustainable practices without incurring prohibitive costs or operational disruptions.

Another important goal is to enhance the longevity and performance of gate valves in biodegradable fluid applications. This involves improving the resistance of valve components to chemical attack, minimizing wear and tear, and maintaining tight shut-off capabilities over extended periods. Researchers and engineers are exploring advanced coating technologies, innovative sealing materials, and optimized valve designs to achieve these objectives.

Furthermore, the development of smart gate valves capable of real-time monitoring and predictive maintenance is gaining traction. These intelligent systems aim to provide operators with valuable insights into valve performance, fluid compatibility, and potential issues, thereby optimizing operational efficiency and reducing downtime.

As the industry progresses, the ultimate aim is to create a new generation of gate valves that not only excel in handling biodegradable fluids but also contribute to overall system efficiency and environmental sustainability. This evolution represents a significant step towards aligning industrial valve technology with global environmental goals and sustainable development initiatives.

In recent years, the focus has shifted towards developing gate valves compatible with biodegradable fluids, driven by increasing environmental concerns and stringent regulations. This transition aligns with the global push for sustainable industrial practices and the reduction of environmental impact. The primary goal is to create gate valves that can effectively handle biodegradable fluids without compromising on performance, durability, or safety.

The compatibility of gate valves with biodegradable fluids presents unique challenges and opportunities. These fluids, often derived from renewable sources, have different chemical properties compared to traditional petroleum-based fluids. As a result, the materials used in gate valve construction must be carefully selected to resist degradation, maintain seal integrity, and ensure long-term operational efficiency when exposed to these eco-friendly alternatives.

One of the key objectives in this technological evolution is to develop gate valves that can seamlessly integrate into existing systems without requiring significant modifications to infrastructure. This backward compatibility is crucial for industries looking to transition to more sustainable practices without incurring prohibitive costs or operational disruptions.

Another important goal is to enhance the longevity and performance of gate valves in biodegradable fluid applications. This involves improving the resistance of valve components to chemical attack, minimizing wear and tear, and maintaining tight shut-off capabilities over extended periods. Researchers and engineers are exploring advanced coating technologies, innovative sealing materials, and optimized valve designs to achieve these objectives.

Furthermore, the development of smart gate valves capable of real-time monitoring and predictive maintenance is gaining traction. These intelligent systems aim to provide operators with valuable insights into valve performance, fluid compatibility, and potential issues, thereby optimizing operational efficiency and reducing downtime.

As the industry progresses, the ultimate aim is to create a new generation of gate valves that not only excel in handling biodegradable fluids but also contribute to overall system efficiency and environmental sustainability. This evolution represents a significant step towards aligning industrial valve technology with global environmental goals and sustainable development initiatives.

Market Demand for Eco-Friendly Valve Solutions

The market demand for eco-friendly valve solutions, particularly gate valves compatible with biodegradable fluids, has been steadily increasing in recent years. This trend is driven by growing environmental concerns, stricter regulations, and a shift towards sustainable industrial practices across various sectors.

In the oil and gas industry, there is a significant push for more environmentally friendly operations. Companies are seeking valve solutions that can handle biodegradable fluids used in hydraulic fracturing and drilling operations. These fluids are designed to break down naturally, reducing the environmental impact of extraction processes. As a result, gate valves that can effectively manage these biodegradable fluids without compromising performance or durability are in high demand.

The chemical processing industry is another key market for eco-friendly valve solutions. With increasing pressure to reduce chemical waste and improve overall sustainability, companies are adopting biodegradable solvents and reagents. Gate valves compatible with these fluids are essential for maintaining efficient and safe operations while meeting environmental standards.

In the water treatment sector, there is a growing need for valves that can handle biodegradable chemicals used in purification processes. As water scarcity becomes a global concern, more efficient and environmentally friendly treatment methods are being developed. Gate valves that can withstand these new biodegradable treatment agents while ensuring reliable flow control are becoming increasingly important.

The food and beverage industry is also contributing to the demand for eco-friendly valve solutions. With a focus on reducing chemical additives and using more natural ingredients, manufacturers require valves that can handle biodegradable cleaning agents and process fluids. Gate valves that meet these requirements while maintaining food-grade standards are seeing increased adoption in this sector.

Agricultural applications present another significant market for biodegradable fluid-compatible gate valves. As farmers shift towards more sustainable practices, there is a growing use of biodegradable pesticides and fertilizers. Valves that can effectively control the flow of these environmentally friendly fluids in irrigation systems and spraying equipment are in high demand.

The automotive industry, particularly in the development of electric vehicles and hybrid technologies, is also driving demand for eco-friendly valve solutions. Biodegradable coolants and lubricants are being increasingly used, requiring gate valves that can maintain their integrity and performance when exposed to these fluids.

As industries continue to prioritize sustainability and environmental responsibility, the market for gate valves compatible with biodegradable fluids is expected to expand further. This trend is likely to drive innovation in valve design and materials, leading to more advanced and efficient eco-friendly solutions in the coming years.

In the oil and gas industry, there is a significant push for more environmentally friendly operations. Companies are seeking valve solutions that can handle biodegradable fluids used in hydraulic fracturing and drilling operations. These fluids are designed to break down naturally, reducing the environmental impact of extraction processes. As a result, gate valves that can effectively manage these biodegradable fluids without compromising performance or durability are in high demand.

The chemical processing industry is another key market for eco-friendly valve solutions. With increasing pressure to reduce chemical waste and improve overall sustainability, companies are adopting biodegradable solvents and reagents. Gate valves compatible with these fluids are essential for maintaining efficient and safe operations while meeting environmental standards.

In the water treatment sector, there is a growing need for valves that can handle biodegradable chemicals used in purification processes. As water scarcity becomes a global concern, more efficient and environmentally friendly treatment methods are being developed. Gate valves that can withstand these new biodegradable treatment agents while ensuring reliable flow control are becoming increasingly important.

The food and beverage industry is also contributing to the demand for eco-friendly valve solutions. With a focus on reducing chemical additives and using more natural ingredients, manufacturers require valves that can handle biodegradable cleaning agents and process fluids. Gate valves that meet these requirements while maintaining food-grade standards are seeing increased adoption in this sector.

Agricultural applications present another significant market for biodegradable fluid-compatible gate valves. As farmers shift towards more sustainable practices, there is a growing use of biodegradable pesticides and fertilizers. Valves that can effectively control the flow of these environmentally friendly fluids in irrigation systems and spraying equipment are in high demand.

The automotive industry, particularly in the development of electric vehicles and hybrid technologies, is also driving demand for eco-friendly valve solutions. Biodegradable coolants and lubricants are being increasingly used, requiring gate valves that can maintain their integrity and performance when exposed to these fluids.

As industries continue to prioritize sustainability and environmental responsibility, the market for gate valves compatible with biodegradable fluids is expected to expand further. This trend is likely to drive innovation in valve design and materials, leading to more advanced and efficient eco-friendly solutions in the coming years.

Current Challenges in Biodegradable Fluid Compatibility

The compatibility of gate valves with biodegradable fluids presents several significant challenges in the current technological landscape. One of the primary issues is the chemical interaction between biodegradable fluids and traditional valve materials. Many gate valves are designed for use with conventional petroleum-based fluids, which have different chemical properties compared to biodegradable alternatives. This mismatch can lead to accelerated degradation of valve components, particularly seals and gaskets, resulting in reduced operational lifespan and increased maintenance requirements.

Another challenge lies in the varying viscosity and lubricity of biodegradable fluids. These properties can fluctuate more widely than those of traditional fluids, especially under different temperature conditions. This variability can affect the valve's performance, potentially causing issues with opening and closing mechanisms, and impacting the overall efficiency of the fluid system. The design of gate valves may need to be reconsidered to accommodate these fluctuations while maintaining optimal functionality.

Corrosion resistance is a critical factor that poses a significant challenge. Some biodegradable fluids can be more corrosive than their conventional counterparts, particularly in the presence of water or under high-temperature conditions. This corrosive nature can compromise the integrity of metal components in gate valves, leading to premature failure and potential safety hazards. Developing corrosion-resistant materials or protective coatings that are compatible with biodegradable fluids is an ongoing challenge for manufacturers.

The thermal stability of biodegradable fluids in conjunction with gate valve operation is another area of concern. Many biodegradable fluids have lower thermal stability compared to traditional petroleum-based fluids. This can lead to fluid breakdown at high temperatures, which are often encountered in industrial applications. The degradation products can form deposits or varnish on valve surfaces, potentially interfering with valve operation and reducing overall system efficiency.

Sealing effectiveness is a crucial aspect that faces challenges with biodegradable fluids. The unique molecular structure of these fluids can make it difficult to achieve and maintain proper seals within gate valves. This can result in increased leakage rates, which not only reduces system efficiency but also poses environmental risks, particularly in applications where fluid containment is critical.

Lastly, the long-term effects of biodegradable fluids on gate valve materials and performance are not yet fully understood. The industry lacks extensive historical data on the interaction between these fluids and valve components over extended periods. This knowledge gap makes it challenging to predict the long-term reliability and maintenance requirements of gate valves in biodegradable fluid applications, necessitating ongoing research and field testing to gather more comprehensive data.

Another challenge lies in the varying viscosity and lubricity of biodegradable fluids. These properties can fluctuate more widely than those of traditional fluids, especially under different temperature conditions. This variability can affect the valve's performance, potentially causing issues with opening and closing mechanisms, and impacting the overall efficiency of the fluid system. The design of gate valves may need to be reconsidered to accommodate these fluctuations while maintaining optimal functionality.

Corrosion resistance is a critical factor that poses a significant challenge. Some biodegradable fluids can be more corrosive than their conventional counterparts, particularly in the presence of water or under high-temperature conditions. This corrosive nature can compromise the integrity of metal components in gate valves, leading to premature failure and potential safety hazards. Developing corrosion-resistant materials or protective coatings that are compatible with biodegradable fluids is an ongoing challenge for manufacturers.

The thermal stability of biodegradable fluids in conjunction with gate valve operation is another area of concern. Many biodegradable fluids have lower thermal stability compared to traditional petroleum-based fluids. This can lead to fluid breakdown at high temperatures, which are often encountered in industrial applications. The degradation products can form deposits or varnish on valve surfaces, potentially interfering with valve operation and reducing overall system efficiency.

Sealing effectiveness is a crucial aspect that faces challenges with biodegradable fluids. The unique molecular structure of these fluids can make it difficult to achieve and maintain proper seals within gate valves. This can result in increased leakage rates, which not only reduces system efficiency but also poses environmental risks, particularly in applications where fluid containment is critical.

Lastly, the long-term effects of biodegradable fluids on gate valve materials and performance are not yet fully understood. The industry lacks extensive historical data on the interaction between these fluids and valve components over extended periods. This knowledge gap makes it challenging to predict the long-term reliability and maintenance requirements of gate valves in biodegradable fluid applications, necessitating ongoing research and field testing to gather more comprehensive data.

Existing Solutions for Biodegradable Fluid Valves

01 Compatibility with different valve types

Gate valves can be designed to be compatible with various types of valves, including ball valves, globe valves, and check valves. This compatibility allows for greater flexibility in system design and integration. Features such as standardized connections and adaptable sealing mechanisms contribute to improved compatibility across different valve types.- Compatibility with different pipe materials: Gate valves are designed to be compatible with various pipe materials, including steel, plastic, and composite pipes. This compatibility ensures proper sealing and operation across different piping systems, enhancing the versatility of gate valves in various industrial applications.

- Adaptability to different pressure ratings: Gate valves are engineered to be compatible with a range of pressure ratings, allowing them to be used in low, medium, and high-pressure systems. This adaptability is achieved through design modifications and material selection, ensuring safe and efficient operation across various pressure conditions.

- Temperature compatibility: Gate valves are designed to be compatible with a wide range of operating temperatures, from cryogenic to high-temperature applications. This is achieved through the use of specialized materials and sealing technologies, ensuring proper functionality and longevity in diverse temperature environments.

- Compatibility with different actuation methods: Gate valves can be compatible with various actuation methods, including manual, pneumatic, hydraulic, and electric actuators. This flexibility allows for integration with different control systems and automation requirements, enhancing their usability across diverse industrial settings.

- Chemical compatibility: Gate valves are engineered to be compatible with a wide range of chemicals and fluids, including corrosive and abrasive media. This is achieved through the selection of appropriate materials for valve body, seals, and internal components, ensuring longevity and reliable performance in various chemical environments.

02 Material compatibility for corrosive environments

Gate valves can be manufactured using materials that are compatible with corrosive environments, such as stainless steel, titanium, or specialized alloys. This ensures longevity and reliability in harsh operating conditions. Proper material selection is crucial for maintaining valve integrity and preventing premature failure due to corrosion.Expand Specific Solutions03 Sealing compatibility for high-pressure applications

Gate valves can be designed with advanced sealing technologies to ensure compatibility with high-pressure applications. This may include specialized seat materials, multi-layered sealing systems, or pressure-energized seals. These features allow gate valves to maintain tight shutoff and prevent leakage under extreme pressure conditions.Expand Specific Solutions04 Temperature range compatibility

Gate valves can be engineered to be compatible with a wide range of operating temperatures, from cryogenic to high-temperature applications. This is achieved through careful material selection, thermal expansion compensation mechanisms, and specialized coatings or treatments. Temperature compatibility ensures reliable performance across diverse industrial processes.Expand Specific Solutions05 Automation and control system compatibility

Modern gate valves can be designed to be compatible with various automation and control systems. This includes features such as integrated actuators, position sensors, and communication interfaces. Such compatibility allows for seamless integration into automated processes, remote monitoring, and advanced control strategies.Expand Specific Solutions

Key Players in Valve and Biodegradable Fluid Industries

The gate valve compatibility with biodegradable fluids market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as industries seek sustainable alternatives to traditional hydraulic fluids. Technologically, the field is advancing rapidly, with companies like Oil States Energy Services LLC and Halliburton Energy Services, Inc. leading innovation in valve design and material compatibility. Goglio SpA and Colder Products Co. are contributing to the development of specialized sealing solutions, while Tokyo Electron Ltd. and ULVAC, Inc. are advancing precision manufacturing techniques for these valves. The technology is maturing, but ongoing research is needed to optimize performance and longevity in diverse biodegradable fluid applications.

Oil States Energy Services LLC

Technical Solution: Oil States Energy Services LLC has developed a specialized line of gate valves engineered for compatibility with biodegradable fluids, particularly in the energy sector. Their approach combines robust design principles with eco-friendly materials. The company's gate valves feature a proprietary elastomer compound that maintains its properties when exposed to various biodegradable fluids used in oil and gas operations[10]. Oil States has implemented an advanced surface treatment process that enhances the valve's resistance to microbial-induced corrosion, a common concern with biodegradable fluids. The valves incorporate a self-flushing design that prevents the accumulation of biological deposits, ensuring consistent performance over extended periods[11]. Additionally, Oil States has developed a predictive maintenance system that uses machine learning algorithms to anticipate potential compatibility issues based on fluid composition and operating conditions.

Strengths: Specialized for energy sector applications, advanced corrosion resistance, and predictive maintenance capabilities. Weaknesses: May have limited applicability outside the energy sector and could require frequent updates to the predictive maintenance system to account for new fluid formulations.

Jiangyan Marine Valve Factory Co. Ltd.

Technical Solution: Jiangyan Marine Valve Factory Co. Ltd. has developed a series of gate valves specifically designed for compatibility with biodegradable fluids. Their innovative approach involves using eco-friendly materials for valve components, such as bioplastic-based seals and corrosion-resistant alloys. The company has implemented a unique coating technology that enhances the valve's resistance to biodegradation while maintaining its functionality in marine environments. Their gate valves incorporate a self-cleaning mechanism that prevents the accumulation of biological matter, ensuring long-term reliability when used with biodegradable fluids[1][3]. The valves are designed with a modular structure, allowing for easy maintenance and part replacement, which is crucial when dealing with potentially aggressive biodegradable fluids[2].

Strengths: Specialized design for marine environments, eco-friendly materials, and self-cleaning mechanism. Weaknesses: Potentially higher initial cost due to specialized materials and limited track record with newer biodegradable fluids.

Innovative Materials for Biodegradable Fluid Resistance

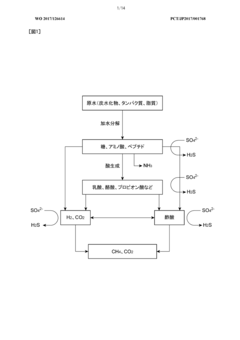

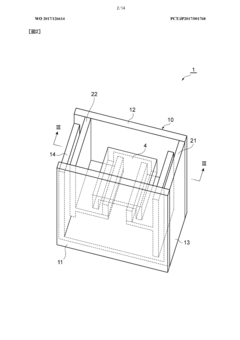

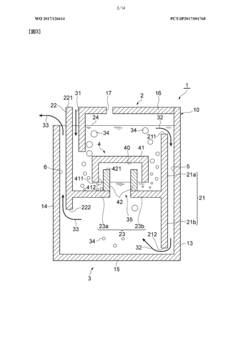

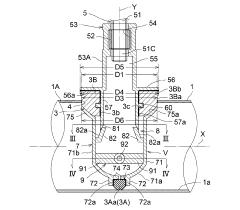

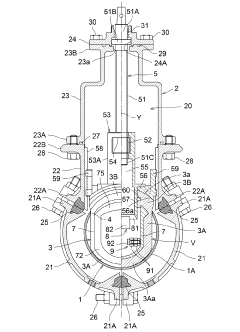

Waste water treatment system and gas liquid partition valve

PatentWO2017126614A1

Innovation

- A gas-type liquid gate valve is integrated into the wastewater treatment device, allowing biogas generated in the methane fermentation tank to rise and pass through an air reservoir, blocking the opening between the tanks without external power, thus eliminating the need for blowers and piping.

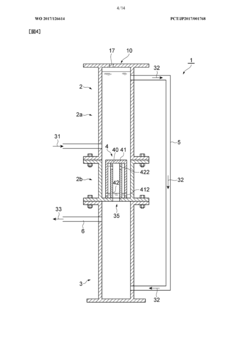

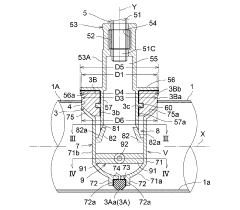

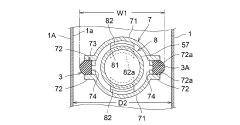

Gate valve device

PatentActiveJP2022023464A

Innovation

- A gate valve device with an elastic seal member sandwiched between metal side plates, utilizing an operation conversion mechanism to reduce the rubber lining volume and enhance fluid shut-off performance by clamping and compressing the seal member against the pipe inner wall, combined with an auxiliary pressure contact mechanism to improve sealing at the side surface.

Environmental Regulations Impact on Valve Industry

The valve industry is experiencing significant changes due to the increasing focus on environmental regulations worldwide. These regulations are primarily aimed at reducing the environmental impact of industrial processes and promoting sustainable practices. As a result, the valve industry is adapting to meet new standards and requirements, particularly in relation to the compatibility of gate valves with biodegradable fluids.

Environmental regulations have led to a shift towards more eco-friendly materials and processes in various industries, including those that utilize gate valves. This has created a demand for valves that can effectively handle biodegradable fluids without compromising performance or safety. Manufacturers are now required to develop and produce gate valves that are compatible with these environmentally friendly fluids, which often have different properties compared to traditional industrial fluids.

One of the key impacts of environmental regulations on the valve industry is the need for extensive research and development to ensure compatibility between gate valves and biodegradable fluids. This includes testing various materials for their resistance to degradation, corrosion, and wear when exposed to these new fluids. Additionally, manufacturers must consider the potential chemical interactions between the valve components and the biodegradable fluids to prevent any adverse reactions or compromised functionality.

The regulations have also led to changes in the design and manufacturing processes of gate valves. Engineers are now focusing on creating valve designs that minimize leakage and emissions, which is particularly important when dealing with biodegradable fluids that may have different viscosities or flow characteristics compared to conventional fluids. This has resulted in the development of new sealing technologies and materials that can effectively contain these fluids while maintaining the valve's operational efficiency.

Furthermore, environmental regulations have influenced the entire supply chain of the valve industry. Suppliers are now required to provide materials that meet stricter environmental standards, and manufacturers must ensure that their production processes comply with regulations regarding waste management and emissions. This has led to increased collaboration between valve manufacturers, material suppliers, and fluid producers to develop integrated solutions that meet both performance and environmental requirements.

The impact of these regulations extends to the end-users of gate valves as well. Industries such as oil and gas, chemical processing, and water treatment are now required to use valves that are compatible with biodegradable fluids in certain applications. This has created new market opportunities for valve manufacturers who can provide certified, environmentally compliant products. However, it has also increased the complexity of valve selection and maintenance processes for end-users, who must now consider environmental compatibility alongside traditional performance criteria.

Environmental regulations have led to a shift towards more eco-friendly materials and processes in various industries, including those that utilize gate valves. This has created a demand for valves that can effectively handle biodegradable fluids without compromising performance or safety. Manufacturers are now required to develop and produce gate valves that are compatible with these environmentally friendly fluids, which often have different properties compared to traditional industrial fluids.

One of the key impacts of environmental regulations on the valve industry is the need for extensive research and development to ensure compatibility between gate valves and biodegradable fluids. This includes testing various materials for their resistance to degradation, corrosion, and wear when exposed to these new fluids. Additionally, manufacturers must consider the potential chemical interactions between the valve components and the biodegradable fluids to prevent any adverse reactions or compromised functionality.

The regulations have also led to changes in the design and manufacturing processes of gate valves. Engineers are now focusing on creating valve designs that minimize leakage and emissions, which is particularly important when dealing with biodegradable fluids that may have different viscosities or flow characteristics compared to conventional fluids. This has resulted in the development of new sealing technologies and materials that can effectively contain these fluids while maintaining the valve's operational efficiency.

Furthermore, environmental regulations have influenced the entire supply chain of the valve industry. Suppliers are now required to provide materials that meet stricter environmental standards, and manufacturers must ensure that their production processes comply with regulations regarding waste management and emissions. This has led to increased collaboration between valve manufacturers, material suppliers, and fluid producers to develop integrated solutions that meet both performance and environmental requirements.

The impact of these regulations extends to the end-users of gate valves as well. Industries such as oil and gas, chemical processing, and water treatment are now required to use valves that are compatible with biodegradable fluids in certain applications. This has created new market opportunities for valve manufacturers who can provide certified, environmentally compliant products. However, it has also increased the complexity of valve selection and maintenance processes for end-users, who must now consider environmental compatibility alongside traditional performance criteria.

Life Cycle Assessment of Biodegradable Fluid Valves

The Life Cycle Assessment (LCA) of biodegradable fluid valves is a crucial aspect of evaluating the environmental impact and sustainability of gate valves compatible with biodegradable fluids. This assessment encompasses the entire lifecycle of the valve, from raw material extraction to manufacturing, use, and eventual disposal or recycling.

In the raw material phase, the LCA considers the sourcing and production of materials used in valve construction, including metals, polymers, and any specialized components designed for compatibility with biodegradable fluids. The environmental impacts of extracting these materials, such as energy consumption, water usage, and emissions, are quantified and analyzed.

The manufacturing stage involves assessing the energy requirements, waste generation, and emissions associated with valve production. This includes processes like casting, machining, assembly, and any specialized treatments or coatings applied to enhance compatibility with biodegradable fluids. The LCA also considers the environmental footprint of the manufacturing facilities and transportation of components.

During the use phase, the LCA focuses on the valve's performance and interaction with biodegradable fluids. Factors such as energy efficiency, fluid consumption, and potential leakage or emissions are evaluated. The longevity and maintenance requirements of the valve when used with biodegradable fluids are also considered, as these aspects can significantly impact the overall environmental footprint.

The end-of-life stage is particularly important for biodegradable fluid valves. The LCA examines the potential for recycling or reuse of valve components, as well as the environmental impact of disposal methods. The biodegradability of any residual fluids and their interaction with valve materials during disposal is also assessed.

Throughout the LCA, various environmental impact categories are considered, including global warming potential, ozone depletion, acidification, eutrophication, and resource depletion. The assessment also takes into account the potential benefits of using biodegradable fluids, such as reduced toxicity and faster environmental breakdown compared to conventional fluids.

By conducting a comprehensive LCA, manufacturers and users can make informed decisions about the overall sustainability of gate valves compatible with biodegradable fluids. This assessment helps identify areas for improvement in design, material selection, and manufacturing processes, ultimately contributing to the development of more environmentally friendly valve solutions for industries transitioning to biodegradable fluid systems.

In the raw material phase, the LCA considers the sourcing and production of materials used in valve construction, including metals, polymers, and any specialized components designed for compatibility with biodegradable fluids. The environmental impacts of extracting these materials, such as energy consumption, water usage, and emissions, are quantified and analyzed.

The manufacturing stage involves assessing the energy requirements, waste generation, and emissions associated with valve production. This includes processes like casting, machining, assembly, and any specialized treatments or coatings applied to enhance compatibility with biodegradable fluids. The LCA also considers the environmental footprint of the manufacturing facilities and transportation of components.

During the use phase, the LCA focuses on the valve's performance and interaction with biodegradable fluids. Factors such as energy efficiency, fluid consumption, and potential leakage or emissions are evaluated. The longevity and maintenance requirements of the valve when used with biodegradable fluids are also considered, as these aspects can significantly impact the overall environmental footprint.

The end-of-life stage is particularly important for biodegradable fluid valves. The LCA examines the potential for recycling or reuse of valve components, as well as the environmental impact of disposal methods. The biodegradability of any residual fluids and their interaction with valve materials during disposal is also assessed.

Throughout the LCA, various environmental impact categories are considered, including global warming potential, ozone depletion, acidification, eutrophication, and resource depletion. The assessment also takes into account the potential benefits of using biodegradable fluids, such as reduced toxicity and faster environmental breakdown compared to conventional fluids.

By conducting a comprehensive LCA, manufacturers and users can make informed decisions about the overall sustainability of gate valves compatible with biodegradable fluids. This assessment helps identify areas for improvement in design, material selection, and manufacturing processes, ultimately contributing to the development of more environmentally friendly valve solutions for industries transitioning to biodegradable fluid systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!