Corrosion resistance evaluation in gate valves using duplex stainless steels

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Duplex SS Corrosion Background and Objectives

Duplex stainless steels have emerged as a crucial material in the manufacturing of gate valves, particularly in corrosive environments. The evolution of these alloys can be traced back to the 1930s when the first duplex stainless steel was developed. Since then, continuous improvements have led to the creation of various grades with enhanced corrosion resistance properties.

The primary objective of utilizing duplex stainless steels in gate valves is to combat corrosion effectively while maintaining structural integrity. These alloys combine the strengths of austenitic and ferritic stainless steels, offering a unique balance of mechanical properties and corrosion resistance. The dual-phase microstructure, typically consisting of approximately equal amounts of austenite and ferrite, contributes to their superior performance in challenging environments.

In recent years, the demand for more durable and reliable gate valves has intensified, particularly in industries such as oil and gas, chemical processing, and marine applications. This surge in demand has driven the need for advanced corrosion resistance evaluation techniques specific to duplex stainless steels in gate valve applications. The goal is to accurately predict and extend the service life of these critical components under various operating conditions.

The corrosion resistance of duplex stainless steels in gate valves is influenced by several factors, including alloy composition, microstructure, surface finish, and environmental conditions. Understanding these factors and their interplay is crucial for developing effective evaluation methodologies. Recent technological advancements have enabled more precise analysis of corrosion mechanisms at the microstructural level, leading to improved alloy designs and manufacturing processes.

One of the key trends in this field is the development of super duplex and hyper duplex grades, which offer even greater corrosion resistance in extreme environments. These advanced alloys are pushing the boundaries of what is possible in terms of material performance, opening up new possibilities for gate valve applications in previously challenging settings.

The objectives of current research and development efforts in this area are multifaceted. They include enhancing the accuracy and reliability of corrosion resistance evaluation methods, developing predictive models for long-term performance, and exploring novel surface treatment techniques to further improve corrosion resistance. Additionally, there is a growing focus on understanding the synergistic effects of different corrosion mechanisms and how they impact the overall performance of gate valves in real-world applications.

As the industry continues to evolve, the importance of standardized testing protocols and performance criteria for duplex stainless steels in gate valves cannot be overstated. Establishing robust evaluation methodologies will not only ensure the reliability of these critical components but also drive innovation in material science and manufacturing processes.

The primary objective of utilizing duplex stainless steels in gate valves is to combat corrosion effectively while maintaining structural integrity. These alloys combine the strengths of austenitic and ferritic stainless steels, offering a unique balance of mechanical properties and corrosion resistance. The dual-phase microstructure, typically consisting of approximately equal amounts of austenite and ferrite, contributes to their superior performance in challenging environments.

In recent years, the demand for more durable and reliable gate valves has intensified, particularly in industries such as oil and gas, chemical processing, and marine applications. This surge in demand has driven the need for advanced corrosion resistance evaluation techniques specific to duplex stainless steels in gate valve applications. The goal is to accurately predict and extend the service life of these critical components under various operating conditions.

The corrosion resistance of duplex stainless steels in gate valves is influenced by several factors, including alloy composition, microstructure, surface finish, and environmental conditions. Understanding these factors and their interplay is crucial for developing effective evaluation methodologies. Recent technological advancements have enabled more precise analysis of corrosion mechanisms at the microstructural level, leading to improved alloy designs and manufacturing processes.

One of the key trends in this field is the development of super duplex and hyper duplex grades, which offer even greater corrosion resistance in extreme environments. These advanced alloys are pushing the boundaries of what is possible in terms of material performance, opening up new possibilities for gate valve applications in previously challenging settings.

The objectives of current research and development efforts in this area are multifaceted. They include enhancing the accuracy and reliability of corrosion resistance evaluation methods, developing predictive models for long-term performance, and exploring novel surface treatment techniques to further improve corrosion resistance. Additionally, there is a growing focus on understanding the synergistic effects of different corrosion mechanisms and how they impact the overall performance of gate valves in real-world applications.

As the industry continues to evolve, the importance of standardized testing protocols and performance criteria for duplex stainless steels in gate valves cannot be overstated. Establishing robust evaluation methodologies will not only ensure the reliability of these critical components but also drive innovation in material science and manufacturing processes.

Market Demand for Corrosion-Resistant Gate Valves

The market demand for corrosion-resistant gate valves, particularly those utilizing duplex stainless steels, has been steadily increasing across various industries. This growth is primarily driven by the need for more durable and reliable valve solutions in harsh operating environments.

In the oil and gas sector, the demand for corrosion-resistant gate valves is particularly strong. Offshore platforms, refineries, and pipelines require valves that can withstand aggressive media and extreme conditions. The superior corrosion resistance of duplex stainless steels makes them an ideal choice for these applications, leading to increased market demand.

The chemical processing industry is another significant market for corrosion-resistant gate valves. As chemical manufacturers handle increasingly corrosive substances, the need for valves that can maintain integrity and performance over extended periods has grown. Duplex stainless steel gate valves offer excellent resistance to a wide range of chemicals, making them highly sought after in this sector.

Water treatment and desalination plants represent a rapidly expanding market for corrosion-resistant gate valves. The exposure to saltwater and various chemicals in these facilities necessitates the use of materials that can withstand corrosive environments. Duplex stainless steels have proven to be effective in these applications, driving up demand for gate valves made from these alloys.

The power generation industry, particularly in nuclear and thermal power plants, has also contributed to the growing market for corrosion-resistant gate valves. These facilities require valves that can maintain their integrity under high temperatures and pressures while resisting corrosion from various coolants and process fluids.

Market analysts have observed a trend towards the replacement of traditional materials with duplex stainless steels in gate valve applications. This shift is driven by the long-term cost savings associated with reduced maintenance and extended service life offered by corrosion-resistant valves.

The global focus on sustainability and environmental protection has further boosted the demand for corrosion-resistant gate valves. Industries are increasingly seeking solutions that minimize leaks, reduce waste, and extend equipment life cycles. Duplex stainless steel gate valves align well with these objectives, contributing to their growing market appeal.

As industries continue to push the boundaries of operational efficiency and safety, the market for corrosion-resistant gate valves is expected to expand further. Manufacturers are likely to invest in research and development to enhance the performance of duplex stainless steel valves, potentially opening up new application areas and market opportunities.

In the oil and gas sector, the demand for corrosion-resistant gate valves is particularly strong. Offshore platforms, refineries, and pipelines require valves that can withstand aggressive media and extreme conditions. The superior corrosion resistance of duplex stainless steels makes them an ideal choice for these applications, leading to increased market demand.

The chemical processing industry is another significant market for corrosion-resistant gate valves. As chemical manufacturers handle increasingly corrosive substances, the need for valves that can maintain integrity and performance over extended periods has grown. Duplex stainless steel gate valves offer excellent resistance to a wide range of chemicals, making them highly sought after in this sector.

Water treatment and desalination plants represent a rapidly expanding market for corrosion-resistant gate valves. The exposure to saltwater and various chemicals in these facilities necessitates the use of materials that can withstand corrosive environments. Duplex stainless steels have proven to be effective in these applications, driving up demand for gate valves made from these alloys.

The power generation industry, particularly in nuclear and thermal power plants, has also contributed to the growing market for corrosion-resistant gate valves. These facilities require valves that can maintain their integrity under high temperatures and pressures while resisting corrosion from various coolants and process fluids.

Market analysts have observed a trend towards the replacement of traditional materials with duplex stainless steels in gate valve applications. This shift is driven by the long-term cost savings associated with reduced maintenance and extended service life offered by corrosion-resistant valves.

The global focus on sustainability and environmental protection has further boosted the demand for corrosion-resistant gate valves. Industries are increasingly seeking solutions that minimize leaks, reduce waste, and extend equipment life cycles. Duplex stainless steel gate valves align well with these objectives, contributing to their growing market appeal.

As industries continue to push the boundaries of operational efficiency and safety, the market for corrosion-resistant gate valves is expected to expand further. Manufacturers are likely to invest in research and development to enhance the performance of duplex stainless steel valves, potentially opening up new application areas and market opportunities.

Current Challenges in Duplex SS Corrosion Resistance

Despite the numerous advantages of duplex stainless steels (DSS) in gate valve applications, several challenges persist in evaluating and ensuring their corrosion resistance. One of the primary concerns is the complex microstructure of DSS, which consists of both austenite and ferrite phases. This dual-phase structure, while beneficial for overall mechanical properties, can lead to preferential corrosion of one phase over the other under certain conditions, making accurate corrosion resistance evaluation difficult.

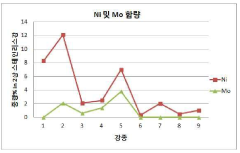

The presence of various alloying elements in DSS, such as chromium, nickel, molybdenum, and nitrogen, further complicates the corrosion behavior. These elements can segregate differently between the two phases, creating localized areas of varying corrosion resistance. This heterogeneity poses challenges in predicting long-term corrosion performance and necessitates sophisticated evaluation techniques.

Environmental factors play a crucial role in the corrosion resistance of DSS gate valves. The diverse operating conditions, including temperature fluctuations, pressure variations, and exposure to different corrosive media, make it challenging to develop standardized testing protocols that accurately simulate real-world scenarios. This variability can lead to discrepancies between laboratory test results and actual field performance.

Another significant challenge is the potential for localized corrosion, such as pitting and crevice corrosion, which are particularly insidious forms of attack in DSS. These types of corrosion can initiate in small, hard-to-detect areas and propagate rapidly, making early detection and accurate evaluation critical yet difficult. The presence of weld zones in gate valves adds another layer of complexity, as these areas can exhibit different corrosion behaviors compared to the base material.

The long-term stability of the DSS microstructure under service conditions is also a concern. Prolonged exposure to elevated temperatures or certain environments can lead to phase transformations or the precipitation of detrimental intermetallic phases, which can significantly alter the corrosion resistance properties. Evaluating these time-dependent changes and their impact on corrosion resistance presents a considerable challenge.

Furthermore, the interaction between mechanical stress and corrosion, known as stress corrosion cracking (SCC), remains a critical issue for DSS in gate valve applications. Assessing the susceptibility to SCC requires specialized testing methods that combine mechanical loading with corrosive environments, adding complexity to the evaluation process.

Lastly, the development of reliable accelerated testing methods for corrosion resistance evaluation continues to be a challenge. While accelerated tests are necessary for timely assessment, ensuring that these tests accurately predict long-term performance without introducing artifacts or unrealistic conditions is an ongoing area of research and development in the field of DSS corrosion resistance evaluation for gate valves.

The presence of various alloying elements in DSS, such as chromium, nickel, molybdenum, and nitrogen, further complicates the corrosion behavior. These elements can segregate differently between the two phases, creating localized areas of varying corrosion resistance. This heterogeneity poses challenges in predicting long-term corrosion performance and necessitates sophisticated evaluation techniques.

Environmental factors play a crucial role in the corrosion resistance of DSS gate valves. The diverse operating conditions, including temperature fluctuations, pressure variations, and exposure to different corrosive media, make it challenging to develop standardized testing protocols that accurately simulate real-world scenarios. This variability can lead to discrepancies between laboratory test results and actual field performance.

Another significant challenge is the potential for localized corrosion, such as pitting and crevice corrosion, which are particularly insidious forms of attack in DSS. These types of corrosion can initiate in small, hard-to-detect areas and propagate rapidly, making early detection and accurate evaluation critical yet difficult. The presence of weld zones in gate valves adds another layer of complexity, as these areas can exhibit different corrosion behaviors compared to the base material.

The long-term stability of the DSS microstructure under service conditions is also a concern. Prolonged exposure to elevated temperatures or certain environments can lead to phase transformations or the precipitation of detrimental intermetallic phases, which can significantly alter the corrosion resistance properties. Evaluating these time-dependent changes and their impact on corrosion resistance presents a considerable challenge.

Furthermore, the interaction between mechanical stress and corrosion, known as stress corrosion cracking (SCC), remains a critical issue for DSS in gate valve applications. Assessing the susceptibility to SCC requires specialized testing methods that combine mechanical loading with corrosive environments, adding complexity to the evaluation process.

Lastly, the development of reliable accelerated testing methods for corrosion resistance evaluation continues to be a challenge. While accelerated tests are necessary for timely assessment, ensuring that these tests accurately predict long-term performance without introducing artifacts or unrealistic conditions is an ongoing area of research and development in the field of DSS corrosion resistance evaluation for gate valves.

Existing Corrosion Evaluation Methods for Gate Valves

01 Composition optimization for improved corrosion resistance

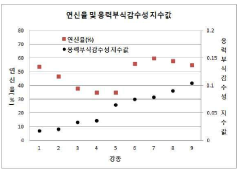

Duplex stainless steels can be optimized by adjusting their chemical composition to enhance corrosion resistance. This includes balancing the levels of chromium, nickel, molybdenum, and nitrogen to create a stable microstructure that resists various forms of corrosion, such as pitting and stress corrosion cracking.- Composition optimization for corrosion resistance: Duplex stainless steels can be optimized for corrosion resistance by carefully adjusting their chemical composition. This includes balancing the levels of chromium, nickel, molybdenum, and nitrogen to enhance the formation of protective passive layers. The precise control of these elements contributes to improved resistance against various forms of corrosion, including pitting and crevice corrosion.

- Heat treatment processes: Specific heat treatment processes can significantly improve the corrosion resistance of duplex stainless steels. These processes may include solution annealing, quenching, and controlled cooling rates. Proper heat treatment helps in achieving the desired microstructure balance between austenite and ferrite phases, which is crucial for optimal corrosion resistance properties.

- Surface modification techniques: Various surface modification techniques can be applied to enhance the corrosion resistance of duplex stainless steels. These may include surface hardening, nitriding, or the application of protective coatings. Such treatments can create a more robust surface layer that provides additional protection against corrosive environments.

- Microstructure control: Controlling the microstructure of duplex stainless steels is essential for optimizing their corrosion resistance. This involves managing the balance between austenite and ferrite phases, grain size, and distribution of secondary phases. Techniques such as controlled rolling and rapid cooling can be employed to achieve the desired microstructure for enhanced corrosion resistance.

- Alloying with specific elements: The addition of specific alloying elements can significantly improve the corrosion resistance of duplex stainless steels. Elements such as tungsten, copper, or rare earth metals can be incorporated in small amounts to enhance the stability of the passive layer and improve resistance to localized corrosion. The synergistic effects of these elements with the base composition contribute to superior corrosion resistance properties.

02 Heat treatment processes for corrosion resistance

Specific heat treatment processes can significantly improve the corrosion resistance of duplex stainless steels. These processes may include solution annealing, quenching, and controlled cooling rates to achieve optimal phase balance and distribution of alloying elements, resulting in enhanced resistance to various corrosive environments.Expand Specific Solutions03 Surface modification techniques

Various surface modification techniques can be applied to duplex stainless steels to further enhance their corrosion resistance. These may include shot peening, laser surface treatment, or the application of protective coatings, which can create a more resistant surface layer or alter the surface properties to improve overall corrosion resistance.Expand Specific Solutions04 Microstructure control for improved corrosion resistance

Controlling the microstructure of duplex stainless steels is crucial for enhancing their corrosion resistance. This involves optimizing the balance between austenite and ferrite phases, minimizing detrimental precipitates, and ensuring a uniform distribution of alloying elements throughout the microstructure.Expand Specific Solutions05 Corrosion testing and performance evaluation

Developing and implementing advanced corrosion testing methods is essential for evaluating and improving the corrosion resistance of duplex stainless steels. These may include electrochemical tests, long-term exposure tests in various environments, and accelerated corrosion tests to assess performance under different conditions and optimize alloy design.Expand Specific Solutions

Key Players in Duplex SS and Gate Valve Industries

The corrosion resistance evaluation of gate valves using duplex stainless steels is a critical area of research in the advanced materials and industrial equipment sectors. This field is in a mature stage of development, with established players like Sandvik Intellectual Property AB, NIPPON STEEL CORP., and JFE Steel Corp. leading the way. The market size for corrosion-resistant valves is substantial, driven by demands from industries such as oil and gas, chemical processing, and water treatment. Technologically, companies like POSCO Holdings, Inc. and Kubota Corp. are at the forefront, continuously improving the performance and durability of duplex stainless steels for valve applications. The competition in this space is intense, with firms like Sanyo Special Steel Co., Ltd. and Huangshan Longte Metal Products Co., Ltd. also making significant contributions to the field.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed advanced duplex stainless steels for gate valves with enhanced corrosion resistance. Their SAF 2507 super duplex grade offers exceptional pitting and crevice corrosion resistance in chloride-containing environments[1]. The material's high chromium (25%), molybdenum (4%), and nitrogen content contribute to its superior corrosion resistance. Sandvik employs a proprietary heat treatment process to optimize the microstructure, ensuring a balanced austenite-ferrite ratio for optimal performance[2]. Additionally, they have implemented advanced surface finishing techniques to further enhance the corrosion resistance of their valve components[3].

Strengths: Exceptional corrosion resistance in aggressive environments, high mechanical strength, and good weldability. Weaknesses: Higher cost compared to standard stainless steels, limited availability in some product forms.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed a range of duplex stainless steels specifically tailored for gate valve applications in corrosive environments. Their NSSC 2120 grade offers improved pitting corrosion resistance and higher strength compared to conventional austenitic stainless steels[4]. The company utilizes a controlled nitrogen addition process during steel production to enhance corrosion resistance and mechanical properties. Nippon Steel has also implemented advanced manufacturing techniques, such as electroslag remelting (ESR), to produce high-purity duplex stainless steels with improved corrosion resistance[5]. Their research has focused on optimizing the microstructure to achieve a balanced austenite-ferrite ratio, crucial for maintaining corrosion resistance in welded components[6].

Strengths: High corrosion resistance, excellent mechanical properties, and good weldability. Weaknesses: Higher production costs and potential for intermetallic phase formation during improper heat treatment.

Innovative Corrosion Testing Techniques for Duplex SS

Duplex stainless steel with excellent resistance to stress corrosion cracking

PatentInactiveKR1020150073381A

Innovation

- A two-phase stainless steel composition with controlled amounts of carbon, silicon, manganese, nitrogen, chromium, nickel, copper, and tungsten, along with a balanced austenite and ferrite phase fraction, optimized to enhance stress corrosion resistance and reduce the need for expensive additives, thereby improving formability and reducing production costs.

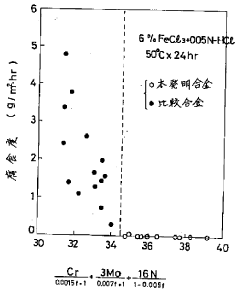

Duplex stainless steel excellent in pitting corrosion resistance

PatentInactiveJP1999080901A

Innovation

- The use of specific parameters, specifically [Cr] + 3[Mo] + 16[N] ≥ 34.5 in the austenite phase, along with controlled ranges for other elements, ensures accurate determination of pitting corrosion resistance, preventing excessive addition of Cr, Mo, and N.

Environmental Factors Affecting Corrosion in Gate Valves

The environmental factors affecting corrosion in gate valves are crucial considerations in the evaluation of corrosion resistance for duplex stainless steels. These factors can significantly impact the performance and longevity of gate valves in various industrial applications.

Temperature plays a vital role in corrosion processes. Higher temperatures generally accelerate corrosion rates, affecting the protective passive film on duplex stainless steels. In gate valves, temperature fluctuations can lead to thermal cycling, potentially causing stress and weakening the material's resistance to corrosion.

The pH level of the fluid passing through the gate valve is another critical factor. Duplex stainless steels typically exhibit excellent corrosion resistance in neutral to slightly alkaline environments. However, exposure to highly acidic or alkaline conditions can compromise their protective properties, leading to localized corrosion or pitting.

Chloride concentration is particularly significant for gate valves in marine or chemical processing environments. High chloride levels can break down the passive film on duplex stainless steels, initiating pitting corrosion. The synergistic effect of chlorides and elevated temperatures can further exacerbate corrosion issues.

Oxygen content in the fluid medium affects the formation and maintenance of the protective oxide layer on duplex stainless steels. While oxygen is generally beneficial for passivation, low-oxygen environments can lead to active corrosion, especially in the presence of aggressive ions.

Flow velocity and turbulence within the gate valve can influence corrosion behavior. High-velocity flows may cause erosion-corrosion, particularly in areas of turbulence or where the flow changes direction. Conversely, stagnant conditions can lead to the accumulation of corrosive species and localized attacks.

The presence of microorganisms in the fluid can lead to microbiologically influenced corrosion (MIC). Certain bacteria can create localized acidic environments or produce corrosive metabolites, potentially compromising the corrosion resistance of duplex stainless steels in gate valves.

Mechanical stresses, both static and cyclic, can impact corrosion resistance. Gate valves are subject to various stresses during operation, which can lead to stress corrosion cracking (SCC) under certain environmental conditions. The combination of tensile stress and corrosive media can accelerate material degradation.

Understanding these environmental factors is essential for accurately evaluating the corrosion resistance of duplex stainless steels in gate valves. It enables engineers to select appropriate materials, design protective measures, and implement effective maintenance strategies to ensure the longevity and reliability of gate valves in diverse operational environments.

Temperature plays a vital role in corrosion processes. Higher temperatures generally accelerate corrosion rates, affecting the protective passive film on duplex stainless steels. In gate valves, temperature fluctuations can lead to thermal cycling, potentially causing stress and weakening the material's resistance to corrosion.

The pH level of the fluid passing through the gate valve is another critical factor. Duplex stainless steels typically exhibit excellent corrosion resistance in neutral to slightly alkaline environments. However, exposure to highly acidic or alkaline conditions can compromise their protective properties, leading to localized corrosion or pitting.

Chloride concentration is particularly significant for gate valves in marine or chemical processing environments. High chloride levels can break down the passive film on duplex stainless steels, initiating pitting corrosion. The synergistic effect of chlorides and elevated temperatures can further exacerbate corrosion issues.

Oxygen content in the fluid medium affects the formation and maintenance of the protective oxide layer on duplex stainless steels. While oxygen is generally beneficial for passivation, low-oxygen environments can lead to active corrosion, especially in the presence of aggressive ions.

Flow velocity and turbulence within the gate valve can influence corrosion behavior. High-velocity flows may cause erosion-corrosion, particularly in areas of turbulence or where the flow changes direction. Conversely, stagnant conditions can lead to the accumulation of corrosive species and localized attacks.

The presence of microorganisms in the fluid can lead to microbiologically influenced corrosion (MIC). Certain bacteria can create localized acidic environments or produce corrosive metabolites, potentially compromising the corrosion resistance of duplex stainless steels in gate valves.

Mechanical stresses, both static and cyclic, can impact corrosion resistance. Gate valves are subject to various stresses during operation, which can lead to stress corrosion cracking (SCC) under certain environmental conditions. The combination of tensile stress and corrosive media can accelerate material degradation.

Understanding these environmental factors is essential for accurately evaluating the corrosion resistance of duplex stainless steels in gate valves. It enables engineers to select appropriate materials, design protective measures, and implement effective maintenance strategies to ensure the longevity and reliability of gate valves in diverse operational environments.

Lifecycle Cost Analysis of Corrosion-Resistant Gate Valves

The lifecycle cost analysis of corrosion-resistant gate valves is a critical aspect of evaluating the long-term economic viability of using duplex stainless steels in valve construction. This analysis encompasses various factors that contribute to the total cost of ownership over the valve's operational lifespan.

Initial acquisition costs for duplex stainless steel gate valves are typically higher than those made from conventional materials. However, the superior corrosion resistance of duplex stainless steels can lead to significant savings in maintenance and replacement costs over time. These alloys exhibit excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, which are common issues in harsh operating environments.

Maintenance costs for duplex stainless steel gate valves are generally lower due to their enhanced durability. The frequency of inspections, repairs, and part replacements is reduced, resulting in decreased downtime and associated labor costs. Additionally, the extended service life of these valves means fewer complete replacements over the lifecycle of the system.

Energy efficiency is another factor to consider in the lifecycle cost analysis. Duplex stainless steel gate valves maintain their smooth surface finish over time, reducing friction and potential flow restrictions. This can lead to lower pumping costs and improved overall system efficiency compared to valves that degrade more rapidly due to corrosion.

The environmental impact and disposal costs should also be factored into the lifecycle analysis. Duplex stainless steels are highly recyclable, potentially offsetting some of the end-of-life costs and reducing the environmental footprint of the valve system.

When conducting a lifecycle cost analysis, it is essential to consider the specific operating conditions, such as temperature, pressure, and chemical composition of the fluid being handled. These factors can significantly influence the corrosion rate and, consequently, the long-term performance and cost-effectiveness of the valve.

Risk assessment and potential failure costs must be included in the analysis. While duplex stainless steels offer excellent corrosion resistance, the consequences of a potential failure should be evaluated, including production losses, safety hazards, and environmental impacts.

In conclusion, while the initial investment in duplex stainless steel gate valves may be higher, the lifecycle cost analysis often reveals substantial long-term savings. The extended service life, reduced maintenance requirements, and improved reliability typically result in a lower total cost of ownership, making duplex stainless steel an economically attractive option for corrosion-resistant gate valves in demanding applications.

Initial acquisition costs for duplex stainless steel gate valves are typically higher than those made from conventional materials. However, the superior corrosion resistance of duplex stainless steels can lead to significant savings in maintenance and replacement costs over time. These alloys exhibit excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, which are common issues in harsh operating environments.

Maintenance costs for duplex stainless steel gate valves are generally lower due to their enhanced durability. The frequency of inspections, repairs, and part replacements is reduced, resulting in decreased downtime and associated labor costs. Additionally, the extended service life of these valves means fewer complete replacements over the lifecycle of the system.

Energy efficiency is another factor to consider in the lifecycle cost analysis. Duplex stainless steel gate valves maintain their smooth surface finish over time, reducing friction and potential flow restrictions. This can lead to lower pumping costs and improved overall system efficiency compared to valves that degrade more rapidly due to corrosion.

The environmental impact and disposal costs should also be factored into the lifecycle analysis. Duplex stainless steels are highly recyclable, potentially offsetting some of the end-of-life costs and reducing the environmental footprint of the valve system.

When conducting a lifecycle cost analysis, it is essential to consider the specific operating conditions, such as temperature, pressure, and chemical composition of the fluid being handled. These factors can significantly influence the corrosion rate and, consequently, the long-term performance and cost-effectiveness of the valve.

Risk assessment and potential failure costs must be included in the analysis. While duplex stainless steels offer excellent corrosion resistance, the consequences of a potential failure should be evaluated, including production losses, safety hazards, and environmental impacts.

In conclusion, while the initial investment in duplex stainless steel gate valves may be higher, the lifecycle cost analysis often reveals substantial long-term savings. The extended service life, reduced maintenance requirements, and improved reliability typically result in a lower total cost of ownership, making duplex stainless steel an economically attractive option for corrosion-resistant gate valves in demanding applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!