Gate valve innovation trends for robustness in unpredictable climates

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Climate-Resilient Gate Valve Evolution and Objectives

Gate valves have been a crucial component in fluid control systems for decades, evolving to meet the changing demands of various industries. In recent years, the focus has shifted towards developing climate-resilient gate valves capable of withstanding unpredictable weather conditions. This evolution is driven by the increasing frequency and severity of extreme weather events, which pose significant challenges to infrastructure and industrial operations.

The historical development of gate valves can be traced back to the early 20th century, with continuous improvements in materials, design, and functionality. Initially, gate valves were primarily designed for standard operating conditions, with limited consideration for extreme environmental factors. However, as climate change impacts became more apparent, the industry recognized the need for more robust and adaptable valve solutions.

The current technological trajectory aims to enhance the resilience of gate valves against a wide range of climate-related stressors. This includes resistance to extreme temperatures, corrosion from increased humidity and salinity, and the ability to maintain operational integrity during floods, storms, and other severe weather events. The objective is to develop gate valves that not only perform their primary function of flow control but also act as a safeguard against environmental uncertainties.

Key technological goals in this evolution include the development of advanced materials that can withstand thermal expansion and contraction, improved sealing mechanisms to prevent leakage under varying pressure conditions, and intelligent monitoring systems for predictive maintenance. There is also a growing emphasis on creating modular designs that allow for easy upgrades and replacements, ensuring long-term adaptability to changing climate conditions.

The industry is exploring innovative coating technologies to enhance corrosion resistance and reduce wear in harsh environments. Additionally, there is a push towards integrating smart technologies, such as IoT sensors and actuators, to enable real-time monitoring and remote operation of gate valves in challenging weather conditions. These advancements aim to improve the overall reliability and longevity of gate valves, reducing downtime and maintenance costs in critical infrastructure and industrial applications.

As the effects of climate change continue to intensify, the evolution of climate-resilient gate valves is expected to accelerate. The industry's objectives include developing valves that can operate efficiently in a broader range of temperatures, withstand higher pressures, and resist damage from debris carried by extreme weather events. This ongoing innovation is essential for ensuring the continued safety, efficiency, and reliability of fluid control systems in an era of increasing climate uncertainty.

The historical development of gate valves can be traced back to the early 20th century, with continuous improvements in materials, design, and functionality. Initially, gate valves were primarily designed for standard operating conditions, with limited consideration for extreme environmental factors. However, as climate change impacts became more apparent, the industry recognized the need for more robust and adaptable valve solutions.

The current technological trajectory aims to enhance the resilience of gate valves against a wide range of climate-related stressors. This includes resistance to extreme temperatures, corrosion from increased humidity and salinity, and the ability to maintain operational integrity during floods, storms, and other severe weather events. The objective is to develop gate valves that not only perform their primary function of flow control but also act as a safeguard against environmental uncertainties.

Key technological goals in this evolution include the development of advanced materials that can withstand thermal expansion and contraction, improved sealing mechanisms to prevent leakage under varying pressure conditions, and intelligent monitoring systems for predictive maintenance. There is also a growing emphasis on creating modular designs that allow for easy upgrades and replacements, ensuring long-term adaptability to changing climate conditions.

The industry is exploring innovative coating technologies to enhance corrosion resistance and reduce wear in harsh environments. Additionally, there is a push towards integrating smart technologies, such as IoT sensors and actuators, to enable real-time monitoring and remote operation of gate valves in challenging weather conditions. These advancements aim to improve the overall reliability and longevity of gate valves, reducing downtime and maintenance costs in critical infrastructure and industrial applications.

As the effects of climate change continue to intensify, the evolution of climate-resilient gate valves is expected to accelerate. The industry's objectives include developing valves that can operate efficiently in a broader range of temperatures, withstand higher pressures, and resist damage from debris carried by extreme weather events. This ongoing innovation is essential for ensuring the continued safety, efficiency, and reliability of fluid control systems in an era of increasing climate uncertainty.

Market Analysis for Robust Gate Valves

The global market for robust gate valves is experiencing significant growth, driven by increasing demand for reliable fluid control systems in challenging environmental conditions. As climate patterns become more unpredictable, industries such as oil and gas, water treatment, and chemical processing are seeking valve solutions that can withstand extreme temperatures, corrosive substances, and fluctuating pressures. This trend is particularly evident in regions prone to severe weather events or those with harsh operating environments.

Market research indicates that the robust gate valve segment is expected to grow at a compound annual growth rate (CAGR) of 6.5% over the next five years. This growth is attributed to the rising investments in infrastructure development, especially in emerging economies, and the expansion of industrial sectors that require high-performance valve systems. The oil and gas industry remains the largest consumer of robust gate valves, accounting for approximately 40% of the market share, followed by water and wastewater treatment at 25%.

Geographically, North America and Europe currently dominate the market for robust gate valves, owing to their advanced industrial sectors and stringent regulatory standards. However, the Asia-Pacific region is emerging as the fastest-growing market, with countries like China and India leading the charge in industrial expansion and infrastructure development. The Middle East is also showing significant potential, particularly in the oil and gas sector, where harsh desert conditions necessitate highly durable valve solutions.

A key market driver is the increasing focus on operational efficiency and reduced maintenance costs. End-users are willing to invest in premium, robust gate valves that offer longer service life and reduced downtime, even if the initial costs are higher. This shift in purchasing behavior is creating opportunities for manufacturers to develop innovative, high-value products that can command premium prices in the market.

The competitive landscape of the robust gate valve market is characterized by a mix of established global players and regional specialists. Major companies are investing heavily in research and development to create valves with advanced materials and designs that can withstand increasingly challenging operating conditions. There is also a growing trend towards the integration of smart technologies in gate valves, including sensors and monitoring systems, to enable predictive maintenance and enhance overall system reliability.

Customer demand is shifting towards customized solutions that can meet specific industry requirements. This trend is driving manufacturers to offer more flexible and adaptable valve designs, capable of handling a wider range of fluids and operating conditions. Additionally, there is an increasing emphasis on sustainability, with customers seeking valve solutions that contribute to reduced energy consumption and environmental impact.

Market research indicates that the robust gate valve segment is expected to grow at a compound annual growth rate (CAGR) of 6.5% over the next five years. This growth is attributed to the rising investments in infrastructure development, especially in emerging economies, and the expansion of industrial sectors that require high-performance valve systems. The oil and gas industry remains the largest consumer of robust gate valves, accounting for approximately 40% of the market share, followed by water and wastewater treatment at 25%.

Geographically, North America and Europe currently dominate the market for robust gate valves, owing to their advanced industrial sectors and stringent regulatory standards. However, the Asia-Pacific region is emerging as the fastest-growing market, with countries like China and India leading the charge in industrial expansion and infrastructure development. The Middle East is also showing significant potential, particularly in the oil and gas sector, where harsh desert conditions necessitate highly durable valve solutions.

A key market driver is the increasing focus on operational efficiency and reduced maintenance costs. End-users are willing to invest in premium, robust gate valves that offer longer service life and reduced downtime, even if the initial costs are higher. This shift in purchasing behavior is creating opportunities for manufacturers to develop innovative, high-value products that can command premium prices in the market.

The competitive landscape of the robust gate valve market is characterized by a mix of established global players and regional specialists. Major companies are investing heavily in research and development to create valves with advanced materials and designs that can withstand increasingly challenging operating conditions. There is also a growing trend towards the integration of smart technologies in gate valves, including sensors and monitoring systems, to enable predictive maintenance and enhance overall system reliability.

Customer demand is shifting towards customized solutions that can meet specific industry requirements. This trend is driving manufacturers to offer more flexible and adaptable valve designs, capable of handling a wider range of fluids and operating conditions. Additionally, there is an increasing emphasis on sustainability, with customers seeking valve solutions that contribute to reduced energy consumption and environmental impact.

Current Challenges in Extreme Climate Gate Valve Design

Gate valves operating in extreme climates face significant challenges that demand innovative solutions. The unpredictable nature of weather patterns, exacerbated by climate change, has exposed vulnerabilities in traditional gate valve designs. These valves, crucial for controlling fluid flow in various industries, must now withstand a broader range of environmental conditions.

One of the primary challenges is material degradation. Extreme temperatures, both hot and cold, can cause thermal expansion and contraction, leading to seal failures and leakages. Additionally, prolonged exposure to UV radiation in high-altitude or equatorial regions can accelerate the breakdown of polymer components, compromising valve integrity over time.

Corrosion resistance has become a critical concern, particularly in coastal areas where salt spray and high humidity levels are prevalent. The combination of moisture and temperature fluctuations accelerates corrosion processes, affecting both the valve body and internal components. This not only reduces the operational lifespan of the valve but also increases the risk of catastrophic failure.

Sediment and debris accumulation pose another significant challenge, especially in regions prone to flooding or sandstorms. These particles can interfere with the valve's sealing surfaces, leading to incomplete closure and potential leakage. The abrasive nature of some sediments can also cause premature wear on valve components, necessitating more frequent maintenance or replacement.

Freeze-thaw cycles in cold climates present unique challenges for gate valve design. Water expansion during freezing can cause significant damage to valve internals, while ice formation can prevent proper operation. Conversely, in extremely hot environments, lubricants and seals may degrade rapidly, leading to increased friction and potential seizure of moving parts.

The unpredictability of extreme weather events adds another layer of complexity to gate valve design. Sudden temperature changes, pressure fluctuations, and impact from debris during storms or floods can stress valve components beyond their design limits. This unpredictability necessitates a more robust and adaptable approach to valve engineering.

Addressing these challenges requires a multifaceted approach. Advanced materials science is being leveraged to develop new alloys and composites that offer superior resistance to corrosion, temperature extremes, and wear. Nanotechnology is being explored to create self-healing materials and super-hydrophobic coatings that can repel water and reduce ice formation.

Innovative sealing technologies are being developed to maintain tight shut-off under a wide range of temperatures and pressures. This includes the use of advanced elastomers and composite materials that can withstand extreme conditions while maintaining their sealing properties. Smart sensing and monitoring systems are also being integrated into valve designs to provide real-time data on valve performance and environmental conditions, enabling predictive maintenance and early warning of potential failures.

One of the primary challenges is material degradation. Extreme temperatures, both hot and cold, can cause thermal expansion and contraction, leading to seal failures and leakages. Additionally, prolonged exposure to UV radiation in high-altitude or equatorial regions can accelerate the breakdown of polymer components, compromising valve integrity over time.

Corrosion resistance has become a critical concern, particularly in coastal areas where salt spray and high humidity levels are prevalent. The combination of moisture and temperature fluctuations accelerates corrosion processes, affecting both the valve body and internal components. This not only reduces the operational lifespan of the valve but also increases the risk of catastrophic failure.

Sediment and debris accumulation pose another significant challenge, especially in regions prone to flooding or sandstorms. These particles can interfere with the valve's sealing surfaces, leading to incomplete closure and potential leakage. The abrasive nature of some sediments can also cause premature wear on valve components, necessitating more frequent maintenance or replacement.

Freeze-thaw cycles in cold climates present unique challenges for gate valve design. Water expansion during freezing can cause significant damage to valve internals, while ice formation can prevent proper operation. Conversely, in extremely hot environments, lubricants and seals may degrade rapidly, leading to increased friction and potential seizure of moving parts.

The unpredictability of extreme weather events adds another layer of complexity to gate valve design. Sudden temperature changes, pressure fluctuations, and impact from debris during storms or floods can stress valve components beyond their design limits. This unpredictability necessitates a more robust and adaptable approach to valve engineering.

Addressing these challenges requires a multifaceted approach. Advanced materials science is being leveraged to develop new alloys and composites that offer superior resistance to corrosion, temperature extremes, and wear. Nanotechnology is being explored to create self-healing materials and super-hydrophobic coatings that can repel water and reduce ice formation.

Innovative sealing technologies are being developed to maintain tight shut-off under a wide range of temperatures and pressures. This includes the use of advanced elastomers and composite materials that can withstand extreme conditions while maintaining their sealing properties. Smart sensing and monitoring systems are also being integrated into valve designs to provide real-time data on valve performance and environmental conditions, enabling predictive maintenance and early warning of potential failures.

Existing Solutions for Enhancing Gate Valve Durability

01 Improved sealing mechanisms

Gate valves with enhanced sealing mechanisms contribute to increased robustness. These designs may include advanced sealing materials, multi-layer seals, or innovative sealing geometries that improve the valve's ability to maintain a tight seal under various operating conditions. Such improvements can lead to better leak prevention and longer operational life.- Improved sealing mechanisms: Gate valves with enhanced sealing mechanisms contribute to increased robustness. These designs may include advanced sealing materials, multiple sealing surfaces, or innovative sealing geometries that improve the valve's ability to maintain a tight seal under various operating conditions, thereby increasing its reliability and longevity.

- Reinforced valve body construction: Robust gate valves often feature reinforced valve body designs. These may incorporate thicker walls, stronger materials, or structural reinforcements to withstand higher pressures and temperatures. Such designs enhance the overall durability and resistance to deformation, ensuring consistent performance in demanding environments.

- Advanced actuation systems: Gate valves with sophisticated actuation systems contribute to improved robustness. These may include hydraulic, pneumatic, or electric actuators with enhanced control mechanisms, fail-safe features, and redundancy systems. Such advancements ensure reliable operation and precise control, even in challenging conditions.

- Corrosion-resistant materials and coatings: The use of corrosion-resistant materials and protective coatings significantly enhances gate valve robustness. These may include high-grade stainless steels, specialized alloys, or advanced surface treatments that protect the valve components from chemical attack, erosion, and wear, thereby extending the valve's operational life in corrosive environments.

- Smart monitoring and diagnostic systems: Integration of smart monitoring and diagnostic systems in gate valves contributes to their robustness. These may include sensors, data analytics, and predictive maintenance algorithms that continuously monitor valve performance, detect potential issues, and enable proactive maintenance. Such systems enhance reliability by preventing unexpected failures and optimizing valve operation.

02 Reinforced valve body construction

Robust gate valves often feature reinforced valve body designs. This may involve the use of high-strength materials, optimized structural geometries, or composite constructions that enhance the valve's ability to withstand high pressures and temperature fluctuations. These improvements contribute to increased durability and reliability in demanding applications.Expand Specific Solutions03 Advanced actuation systems

Gate valve robustness can be enhanced through the implementation of advanced actuation systems. These may include improved hydraulic or pneumatic actuators, electric motor drives with precise control, or innovative mechanical linkages that provide smoother and more reliable valve operation. Such systems can improve the valve's responsiveness and reduce wear on critical components.Expand Specific Solutions04 Corrosion-resistant materials and coatings

The use of corrosion-resistant materials and protective coatings significantly contributes to gate valve robustness. This may involve the selection of specialized alloys, ceramic components, or the application of advanced surface treatments that protect the valve from harsh environmental conditions and corrosive media. These measures can extend the valve's service life and maintain its performance over time.Expand Specific Solutions05 Intelligent monitoring and diagnostics

Integration of intelligent monitoring and diagnostic systems can enhance gate valve robustness. These may include sensors for real-time performance monitoring, predictive maintenance algorithms, or remote monitoring capabilities. Such features allow for early detection of potential issues, optimized maintenance schedules, and improved overall reliability of the valve system.Expand Specific Solutions

Key Players in Climate-Resilient Valve Manufacturing

The gate valve innovation landscape for robustness in unpredictable climates is in a mature yet evolving stage, with a growing market driven by increasing demand for reliable valve solutions in extreme weather conditions. The global market size for industrial valves is expected to reach $85 billion by 2025, with gate valves being a significant segment. Technologically, companies like NOV, Inc., KSB SE & Co. KGaA, and Cameron International Corp. are leading innovation efforts, focusing on advanced materials, smart valve technologies, and predictive maintenance solutions to enhance valve performance and longevity in challenging environments.

KSB SE & Co. KGaA

Technical Solution: KSB has developed innovative gate valve solutions tailored for robustness in unpredictable climates. Their ECOLINE series incorporates advanced polymer composites that offer exceptional resistance to thermal cycling and chemical corrosion[13]. KSB's gate valves feature a unique stellite overlay on sealing surfaces, significantly enhancing wear resistance in abrasive environments[14]. The company has also implemented a smart predictive maintenance system that uses machine learning algorithms to anticipate potential valve failures based on environmental data and operational patterns[15]. Additionally, KSB's valves incorporate a modular design that allows for easy in-situ replacement of components, reducing downtime in challenging weather conditions[16].

Strengths: Advanced materials for durability, smart predictive maintenance, modular design for easy servicing. Weaknesses: Potentially higher initial investment, may require specialized training for maintenance teams.

Cameron International Corp.

Technical Solution: Cameron International has pioneered gate valve innovations specifically designed for unpredictable climates. Their TruSeal™ technology employs a dynamic sealing system that adapts to temperature fluctuations, maintaining tight shutoff across a wide range of conditions[5]. The company's gate valves incorporate a patented stem seal design that prevents leakage even under extreme pressure and temperature cycling[6]. Cameron has also developed a nanotechnology-based coating that provides superior protection against corrosion and erosion in harsh environments[7]. Their valves feature a fail-safe actuator system that ensures proper valve positioning during unexpected weather events or power failures[8].

Strengths: Adaptive sealing technology, advanced corrosion protection, fail-safe operation. Weaknesses: May have higher upfront costs, potential complexity in maintenance procedures.

Innovative Materials and Coatings for Valve Protection

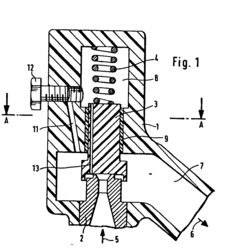

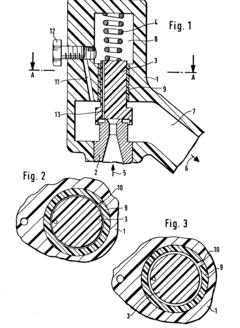

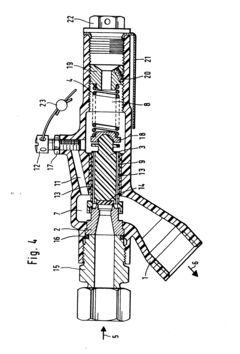

Spring-loaded safety valve

PatentInactiveEP0216982A1

Innovation

- A safety valve design where the closing pressure difference increases automatically with falling temperature, utilizing a cone guide and control pressure chamber connections that expand with temperature changes, allowing for stable operation from ambient to cryogenic temperatures, and ensuring increased sealing forces through proportional pressure differences.

Environmental Impact Assessment of Valve Technologies

The environmental impact of valve technologies has become increasingly significant in the context of climate change and sustainability concerns. Gate valves, as critical components in fluid control systems, play a substantial role in various industries, including oil and gas, water management, and chemical processing. As such, their environmental footprint warrants careful consideration.

In assessing the environmental impact of gate valve technologies, it is essential to examine their entire lifecycle, from production to disposal. The manufacturing process of gate valves typically involves the use of metals and alloys, which can have significant environmental implications in terms of resource extraction and energy consumption. Advanced materials and manufacturing techniques are being developed to reduce the environmental burden of valve production, including the use of recycled materials and more energy-efficient manufacturing processes.

During their operational lifespan, gate valves can contribute to environmental protection by preventing leaks and spills of potentially hazardous substances. However, their performance in unpredictable climates is a growing concern. Extreme weather events, temperature fluctuations, and corrosive environments can compromise valve integrity, leading to increased maintenance requirements and potential environmental risks. Innovations in sealing technologies and corrosion-resistant materials are being pursued to enhance valve robustness and longevity, thereby reducing the frequency of replacements and associated environmental impacts.

The energy efficiency of valve systems is another crucial aspect of their environmental impact. Optimized valve designs that minimize pressure drops and improve flow characteristics can contribute to overall system efficiency, reducing energy consumption and associated greenhouse gas emissions. Furthermore, the integration of smart technologies in gate valves, such as sensors and actuators, enables more precise control and predictive maintenance, potentially lowering resource waste and environmental risks.

End-of-life considerations for gate valves are also gaining attention in environmental assessments. The recyclability of valve components and the proper disposal of non-recyclable materials are important factors in minimizing the long-term environmental impact. Manufacturers are increasingly adopting design-for-disassembly principles to facilitate easier recycling and reduce landfill waste.

In conclusion, the environmental impact assessment of valve technologies, particularly gate valves, reveals a complex interplay of factors throughout their lifecycle. While these components are essential for safe and efficient fluid control, ongoing innovation is crucial to mitigate their environmental footprint and enhance their resilience in the face of unpredictable climatic conditions.

In assessing the environmental impact of gate valve technologies, it is essential to examine their entire lifecycle, from production to disposal. The manufacturing process of gate valves typically involves the use of metals and alloys, which can have significant environmental implications in terms of resource extraction and energy consumption. Advanced materials and manufacturing techniques are being developed to reduce the environmental burden of valve production, including the use of recycled materials and more energy-efficient manufacturing processes.

During their operational lifespan, gate valves can contribute to environmental protection by preventing leaks and spills of potentially hazardous substances. However, their performance in unpredictable climates is a growing concern. Extreme weather events, temperature fluctuations, and corrosive environments can compromise valve integrity, leading to increased maintenance requirements and potential environmental risks. Innovations in sealing technologies and corrosion-resistant materials are being pursued to enhance valve robustness and longevity, thereby reducing the frequency of replacements and associated environmental impacts.

The energy efficiency of valve systems is another crucial aspect of their environmental impact. Optimized valve designs that minimize pressure drops and improve flow characteristics can contribute to overall system efficiency, reducing energy consumption and associated greenhouse gas emissions. Furthermore, the integration of smart technologies in gate valves, such as sensors and actuators, enables more precise control and predictive maintenance, potentially lowering resource waste and environmental risks.

End-of-life considerations for gate valves are also gaining attention in environmental assessments. The recyclability of valve components and the proper disposal of non-recyclable materials are important factors in minimizing the long-term environmental impact. Manufacturers are increasingly adopting design-for-disassembly principles to facilitate easier recycling and reduce landfill waste.

In conclusion, the environmental impact assessment of valve technologies, particularly gate valves, reveals a complex interplay of factors throughout their lifecycle. While these components are essential for safe and efficient fluid control, ongoing innovation is crucial to mitigate their environmental footprint and enhance their resilience in the face of unpredictable climatic conditions.

Standardization and Testing for Climate-Resilient Valves

The standardization and testing of climate-resilient valves have become increasingly crucial in the face of unpredictable weather patterns and extreme environmental conditions. To ensure the robustness and reliability of gate valves in diverse climates, industry stakeholders have been working towards developing comprehensive standards and rigorous testing protocols.

One of the primary focuses of standardization efforts is the establishment of performance criteria that account for a wide range of environmental factors. These criteria encompass temperature extremes, humidity levels, corrosive atmospheres, and exposure to various chemicals. By defining these parameters, manufacturers can design and produce gate valves that meet specific climate resilience requirements.

Testing methodologies for climate-resilient valves have evolved to simulate real-world conditions more accurately. Advanced climate chambers capable of replicating diverse environmental scenarios are now employed to subject valves to accelerated aging and stress tests. These tests evaluate the valve's ability to maintain proper functionality and seal integrity under prolonged exposure to harsh conditions.

Cyclic testing has emerged as a critical component in assessing valve durability. This involves subjecting the valve to repeated opening and closing operations under varying temperature and pressure conditions. Such tests help identify potential weak points in the valve design and materials, allowing for improvements in longevity and reliability.

Material selection and compatibility testing have gained prominence in the standardization process. Manufacturers are required to demonstrate that the materials used in valve construction can withstand the corrosive effects of diverse environments. This includes testing for resistance to UV radiation, chemical exposure, and microbial growth, which are common challenges in unpredictable climates.

Leak detection and sealing performance tests have been refined to ensure valves maintain their integrity across a broad spectrum of environmental conditions. These tests evaluate the effectiveness of sealing mechanisms under different pressure differentials and temperature fluctuations, mimicking the stresses valves may encounter in real-world applications.

Standardization efforts also extend to the documentation and traceability of valve components and manufacturing processes. This ensures that climate-resilient valves can be consistently produced and that their performance can be verified against established benchmarks.

The development of international standards for climate-resilient valves has fostered collaboration among industry experts, regulatory bodies, and research institutions. This collaborative approach has led to the creation of more comprehensive and globally applicable standards, facilitating the adoption of climate-resilient technologies across different regions and industries.

One of the primary focuses of standardization efforts is the establishment of performance criteria that account for a wide range of environmental factors. These criteria encompass temperature extremes, humidity levels, corrosive atmospheres, and exposure to various chemicals. By defining these parameters, manufacturers can design and produce gate valves that meet specific climate resilience requirements.

Testing methodologies for climate-resilient valves have evolved to simulate real-world conditions more accurately. Advanced climate chambers capable of replicating diverse environmental scenarios are now employed to subject valves to accelerated aging and stress tests. These tests evaluate the valve's ability to maintain proper functionality and seal integrity under prolonged exposure to harsh conditions.

Cyclic testing has emerged as a critical component in assessing valve durability. This involves subjecting the valve to repeated opening and closing operations under varying temperature and pressure conditions. Such tests help identify potential weak points in the valve design and materials, allowing for improvements in longevity and reliability.

Material selection and compatibility testing have gained prominence in the standardization process. Manufacturers are required to demonstrate that the materials used in valve construction can withstand the corrosive effects of diverse environments. This includes testing for resistance to UV radiation, chemical exposure, and microbial growth, which are common challenges in unpredictable climates.

Leak detection and sealing performance tests have been refined to ensure valves maintain their integrity across a broad spectrum of environmental conditions. These tests evaluate the effectiveness of sealing mechanisms under different pressure differentials and temperature fluctuations, mimicking the stresses valves may encounter in real-world applications.

Standardization efforts also extend to the documentation and traceability of valve components and manufacturing processes. This ensures that climate-resilient valves can be consistently produced and that their performance can be verified against established benchmarks.

The development of international standards for climate-resilient valves has fostered collaboration among industry experts, regulatory bodies, and research institutions. This collaborative approach has led to the creation of more comprehensive and globally applicable standards, facilitating the adoption of climate-resilient technologies across different regions and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!