Gate valve enhancements for seamless micro-scale fluid control

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Objectives

Gate valves have been a cornerstone in fluid control systems for decades, evolving from simple on-off mechanisms to sophisticated devices capable of precise flow regulation. The journey of gate valve technology reflects the increasing demands for more accurate, efficient, and versatile fluid control across various industries. From its inception in large-scale industrial applications, gate valve technology has progressively miniaturized to meet the needs of micro-scale fluid control systems.

The evolution of gate valves has been driven by the need for seamless control in increasingly complex and miniaturized fluid systems. Early gate valves were primarily designed for macro-scale applications, focusing on robust construction and reliable operation. As industries such as microfluidics, biotechnology, and semiconductor manufacturing emerged, the demand for precise micro-scale fluid control grew exponentially. This shift necessitated a reimagining of gate valve design and functionality.

Recent advancements in materials science and manufacturing techniques have enabled the development of gate valves capable of operating at the micro-scale. These innovations include the use of advanced polymers and ceramics that offer superior chemical resistance and reduced friction, as well as the integration of micro-electromechanical systems (MEMS) for enhanced control precision. The miniaturization of gate valves has opened up new possibilities in fields such as lab-on-a-chip devices, microreactors, and high-throughput screening systems.

The primary objective in the evolution of gate valves for micro-scale fluid control is to achieve seamless operation while maintaining the reliability and durability associated with traditional gate valve designs. This involves overcoming challenges such as reducing dead volume, minimizing leakage, and ensuring consistent performance under varying pressure and temperature conditions. Additionally, there is a focus on developing gate valves that can integrate seamlessly with automated systems and provide real-time feedback for precise flow control.

Looking forward, the goals for gate valve enhancements in micro-scale fluid control are multifaceted. There is a push towards developing "smart" gate valves that incorporate sensors and actuators for autonomous operation and self-diagnosis. Another objective is to improve the scalability of micro-scale gate valves, allowing for their integration into complex fluidic networks without compromising system performance. Furthermore, researchers are exploring novel actuation mechanisms, such as piezoelectric and shape memory alloys, to enhance the response time and precision of micro-scale gate valves.

The evolution of gate valves for seamless micro-scale fluid control represents a convergence of mechanical engineering, materials science, and microfluidics. As this technology continues to advance, it promises to enable new breakthroughs in fields ranging from personalized medicine to environmental monitoring, underscoring the critical role of innovative fluid control solutions in shaping the future of numerous scientific and industrial domains.

The evolution of gate valves has been driven by the need for seamless control in increasingly complex and miniaturized fluid systems. Early gate valves were primarily designed for macro-scale applications, focusing on robust construction and reliable operation. As industries such as microfluidics, biotechnology, and semiconductor manufacturing emerged, the demand for precise micro-scale fluid control grew exponentially. This shift necessitated a reimagining of gate valve design and functionality.

Recent advancements in materials science and manufacturing techniques have enabled the development of gate valves capable of operating at the micro-scale. These innovations include the use of advanced polymers and ceramics that offer superior chemical resistance and reduced friction, as well as the integration of micro-electromechanical systems (MEMS) for enhanced control precision. The miniaturization of gate valves has opened up new possibilities in fields such as lab-on-a-chip devices, microreactors, and high-throughput screening systems.

The primary objective in the evolution of gate valves for micro-scale fluid control is to achieve seamless operation while maintaining the reliability and durability associated with traditional gate valve designs. This involves overcoming challenges such as reducing dead volume, minimizing leakage, and ensuring consistent performance under varying pressure and temperature conditions. Additionally, there is a focus on developing gate valves that can integrate seamlessly with automated systems and provide real-time feedback for precise flow control.

Looking forward, the goals for gate valve enhancements in micro-scale fluid control are multifaceted. There is a push towards developing "smart" gate valves that incorporate sensors and actuators for autonomous operation and self-diagnosis. Another objective is to improve the scalability of micro-scale gate valves, allowing for their integration into complex fluidic networks without compromising system performance. Furthermore, researchers are exploring novel actuation mechanisms, such as piezoelectric and shape memory alloys, to enhance the response time and precision of micro-scale gate valves.

The evolution of gate valves for seamless micro-scale fluid control represents a convergence of mechanical engineering, materials science, and microfluidics. As this technology continues to advance, it promises to enable new breakthroughs in fields ranging from personalized medicine to environmental monitoring, underscoring the critical role of innovative fluid control solutions in shaping the future of numerous scientific and industrial domains.

Micro-Fluidic Market Analysis

The micro-fluidic market has experienced significant growth in recent years, driven by advancements in technology and increasing applications across various industries. The global micro-fluidics market size was valued at approximately $20 billion in 2020 and is projected to reach $50 billion by 2027, growing at a CAGR of over 15% during the forecast period.

The demand for micro-fluidic devices and systems is primarily fueled by their applications in healthcare and life sciences. These sectors account for the largest market share, with applications in drug discovery, point-of-care diagnostics, and personalized medicine. The pharmaceutical industry, in particular, has shown increased adoption of micro-fluidic technologies for drug development and testing, contributing to market growth.

In the context of gate valve enhancements for seamless micro-scale fluid control, there is a growing need for precise and reliable fluid manipulation in micro-fluidic systems. This demand is driven by the requirements of various applications, including lab-on-a-chip devices, organ-on-a-chip platforms, and microreactors for chemical synthesis.

The market for micro-fluidic components, including valves and pumps, is expected to grow at a faster rate compared to the overall micro-fluidic market. This growth is attributed to the increasing complexity of micro-fluidic systems and the need for more sophisticated fluid control mechanisms. Gate valve enhancements play a crucial role in addressing these requirements, offering improved precision, reliability, and integration capabilities.

Geographically, North America dominates the micro-fluidic market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its strong research and development infrastructure and the presence of key industry players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in healthcare and life sciences research.

The market landscape for micro-fluidic technologies is characterized by a mix of established players and innovative startups. Key market players are focusing on developing advanced micro-fluidic solutions, including improved valve technologies, to gain a competitive edge. Collaborations between academic institutions and industry partners are also driving innovation in this field.

As the demand for more sophisticated micro-fluidic systems continues to grow, the market for enhanced gate valve technologies is expected to expand. This trend is likely to be further accelerated by emerging applications in fields such as synthetic biology, environmental monitoring, and food safety testing, which require precise and reliable fluid control at the micro-scale.

The demand for micro-fluidic devices and systems is primarily fueled by their applications in healthcare and life sciences. These sectors account for the largest market share, with applications in drug discovery, point-of-care diagnostics, and personalized medicine. The pharmaceutical industry, in particular, has shown increased adoption of micro-fluidic technologies for drug development and testing, contributing to market growth.

In the context of gate valve enhancements for seamless micro-scale fluid control, there is a growing need for precise and reliable fluid manipulation in micro-fluidic systems. This demand is driven by the requirements of various applications, including lab-on-a-chip devices, organ-on-a-chip platforms, and microreactors for chemical synthesis.

The market for micro-fluidic components, including valves and pumps, is expected to grow at a faster rate compared to the overall micro-fluidic market. This growth is attributed to the increasing complexity of micro-fluidic systems and the need for more sophisticated fluid control mechanisms. Gate valve enhancements play a crucial role in addressing these requirements, offering improved precision, reliability, and integration capabilities.

Geographically, North America dominates the micro-fluidic market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to its strong research and development infrastructure and the presence of key industry players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in healthcare and life sciences research.

The market landscape for micro-fluidic technologies is characterized by a mix of established players and innovative startups. Key market players are focusing on developing advanced micro-fluidic solutions, including improved valve technologies, to gain a competitive edge. Collaborations between academic institutions and industry partners are also driving innovation in this field.

As the demand for more sophisticated micro-fluidic systems continues to grow, the market for enhanced gate valve technologies is expected to expand. This trend is likely to be further accelerated by emerging applications in fields such as synthetic biology, environmental monitoring, and food safety testing, which require precise and reliable fluid control at the micro-scale.

Current Challenges in Micro-Scale Fluid Control

Micro-scale fluid control presents several significant challenges that hinder the seamless operation of gate valves in miniaturized systems. One of the primary issues is the difficulty in achieving precise and consistent flow control at such small scales. The behavior of fluids at the micro level differs significantly from macro-scale systems, with surface tension and viscous forces becoming dominant over inertial forces. This shift in fluid dynamics complicates the design and operation of gate valves, as traditional scaling principles may not apply.

Another challenge lies in the manufacturing of gate valves for micro-scale applications. Fabricating components with the required precision and tolerances becomes increasingly difficult as dimensions decrease. The need for smooth surfaces and tight seals is paramount, yet achieving these at the micro-scale often pushes the limits of current manufacturing capabilities. Additionally, material selection becomes critical, as the properties of materials can behave differently at such small scales, affecting both the valve's performance and longevity.

Contamination and clogging pose significant threats to micro-scale fluid control systems. Even minute particles can obstruct flow paths or interfere with valve operation, leading to system failure or inconsistent performance. This necessitates stringent cleanliness standards and potentially the integration of filtration systems, which themselves add complexity to the overall design.

The integration of actuation mechanisms for gate valves at the micro-scale presents another hurdle. Traditional mechanical actuation methods may be too large or imprecise for these applications. Alternative approaches, such as piezoelectric or electromagnetic actuators, must be explored, but these come with their own set of challenges related to power consumption, response time, and integration within confined spaces.

Thermal management is a critical concern in micro-scale fluid control systems. The high surface area to volume ratio in these systems can lead to rapid heat transfer, potentially affecting fluid properties and valve performance. Designing gate valves that can maintain consistent operation across varying temperature conditions adds another layer of complexity to the engineering challenge.

Lastly, the issue of scalability and manufacturability for commercial applications cannot be overlooked. While prototype micro-scale gate valves may be feasible in laboratory settings, translating these designs into mass-producible, cost-effective components for widespread use remains a significant challenge. This requires not only overcoming technical hurdles but also addressing economic and production-related constraints to make micro-scale fluid control solutions viable for real-world applications.

Another challenge lies in the manufacturing of gate valves for micro-scale applications. Fabricating components with the required precision and tolerances becomes increasingly difficult as dimensions decrease. The need for smooth surfaces and tight seals is paramount, yet achieving these at the micro-scale often pushes the limits of current manufacturing capabilities. Additionally, material selection becomes critical, as the properties of materials can behave differently at such small scales, affecting both the valve's performance and longevity.

Contamination and clogging pose significant threats to micro-scale fluid control systems. Even minute particles can obstruct flow paths or interfere with valve operation, leading to system failure or inconsistent performance. This necessitates stringent cleanliness standards and potentially the integration of filtration systems, which themselves add complexity to the overall design.

The integration of actuation mechanisms for gate valves at the micro-scale presents another hurdle. Traditional mechanical actuation methods may be too large or imprecise for these applications. Alternative approaches, such as piezoelectric or electromagnetic actuators, must be explored, but these come with their own set of challenges related to power consumption, response time, and integration within confined spaces.

Thermal management is a critical concern in micro-scale fluid control systems. The high surface area to volume ratio in these systems can lead to rapid heat transfer, potentially affecting fluid properties and valve performance. Designing gate valves that can maintain consistent operation across varying temperature conditions adds another layer of complexity to the engineering challenge.

Lastly, the issue of scalability and manufacturability for commercial applications cannot be overlooked. While prototype micro-scale gate valves may be feasible in laboratory settings, translating these designs into mass-producible, cost-effective components for widespread use remains a significant challenge. This requires not only overcoming technical hurdles but also addressing economic and production-related constraints to make micro-scale fluid control solutions viable for real-world applications.

Existing Gate Valve Solutions for Micro-Scale Control

01 Gate valve design for fluid control

Gate valves are designed with a flat or wedge-shaped gate that moves perpendicular to the flow of fluid. When fully open, the gate is completely removed from the flow path, allowing for minimal pressure drop. The design can include features for improved sealing, durability, and ease of operation in various fluid control applications.- Gate valve design for fluid control: Gate valves are designed with specific features to control fluid flow. These designs may include improvements in sealing mechanisms, actuation systems, and overall valve structure to enhance performance and reliability in various fluid control applications.

- Fluid flow regulation mechanisms: Various mechanisms are employed in gate valves to regulate fluid flow. These may include adjustable gates, specialized seals, and precision control systems that allow for accurate and responsive fluid management in different industrial settings.

- Pressure management in gate valves: Gate valves incorporate features for effective pressure management in fluid control systems. This includes pressure balancing mechanisms, reinforced valve bodies, and specialized sealing arrangements to handle high-pressure applications and prevent leakage.

- Actuation systems for gate valves: Advanced actuation systems are developed for gate valves to improve fluid control precision. These may include electric, hydraulic, or pneumatic actuators, as well as manual override mechanisms, ensuring reliable valve operation in various conditions.

- Materials and coatings for gate valve components: Innovative materials and coatings are used in gate valve components to enhance durability, corrosion resistance, and overall performance. This includes the use of advanced alloys, ceramic coatings, and composite materials for valve seats, gates, and body parts.

02 Actuator mechanisms for gate valves

Various actuator mechanisms are employed to operate gate valves, including manual handwheels, pneumatic systems, hydraulic systems, and electric motors. These actuators control the opening and closing of the valve, allowing for precise fluid control. Advanced designs may incorporate fail-safe features or remote operation capabilities.Expand Specific Solutions03 Sealing systems in gate valves

Effective sealing is crucial for gate valve performance. Sealing systems may include resilient seats, metal-to-metal seals, or combinations thereof. Advanced sealing technologies aim to prevent leakage under high pressure and temperature conditions, ensuring reliable fluid control across various industrial applications.Expand Specific Solutions04 Materials and coatings for gate valves

The choice of materials and coatings for gate valves is critical for their performance and longevity. Corrosion-resistant alloys, specialized coatings, and advanced composites are used to enhance durability and chemical compatibility. These materials are selected based on the specific fluid control requirements and operating conditions.Expand Specific Solutions05 Smart gate valve systems for fluid control

Integration of smart technologies in gate valves enhances fluid control capabilities. These systems may include sensors for real-time monitoring, automated control systems, and connectivity features for remote operation and diagnostics. Smart gate valves improve efficiency, safety, and precision in fluid control applications.Expand Specific Solutions

Key Players in Micro-Fluidic Valve Industry

The gate valve enhancement market for micro-scale fluid control is in a growth phase, driven by increasing demand for precision fluid management in industries such as semiconductors, medical devices, and microfluidics. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Fujikin, Inc., Canon, Inc., and Agilent Technologies, Inc. leading innovation in miniaturization, precision control, and integration with smart systems. These firms are developing advanced materials, micro-fabrication techniques, and sensor technologies to improve valve performance at the micro-scale. The competitive landscape is characterized by a mix of established industrial players and specialized niche companies, with increasing collaboration between academia and industry to drive technological breakthroughs.

Fujikin, Inc.

Technical Solution: Fujikin has pioneered micro-electromechanical systems (MEMS) based gate valves for seamless micro-scale fluid control. Their innovative design integrates silicon-based microstructures with advanced piezoelectric actuators, enabling precise control of fluid flow rates as low as nanoliters per minute[4]. The company has also developed proprietary surface treatments that minimize adhesion and reduce the risk of clogging in micro-channels. Fujikin's valves incorporate real-time flow sensing and feedback control, allowing for adaptive response to changing fluid conditions[5].

Strengths: Highly integrated solution suitable for lab-on-a-chip applications. Weaknesses: May have limitations in high-pressure or high-temperature environments.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a comprehensive micro-scale fluid control system centered around advanced gate valve technology. Their solution incorporates microfluidic chips with integrated valve arrays, allowing for complex fluid routing and mixing operations[8]. Agilent's valves utilize a proprietary elastomeric membrane that provides excellent sealing properties while minimizing dead volume. The company has also developed sophisticated control software that enables automated and precise fluid handling protocols, making their system particularly suitable for high-throughput analytical applications[9].

Strengths: Comprehensive system with excellent integration of hardware and software. Weaknesses: May be less flexible for custom or specialized applications.

Innovative Gate Valve Designs for Micro-Fluidics

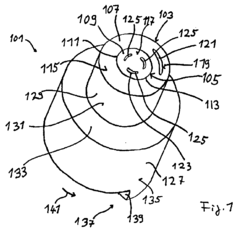

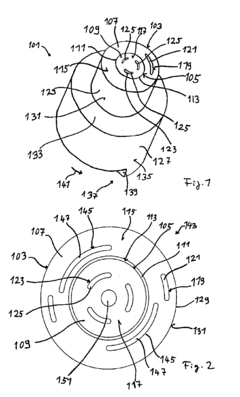

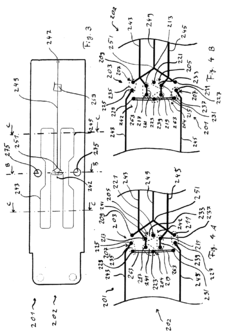

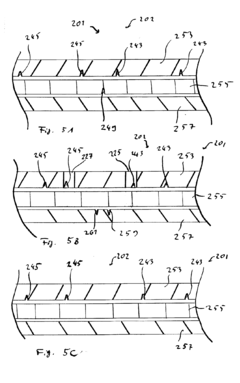

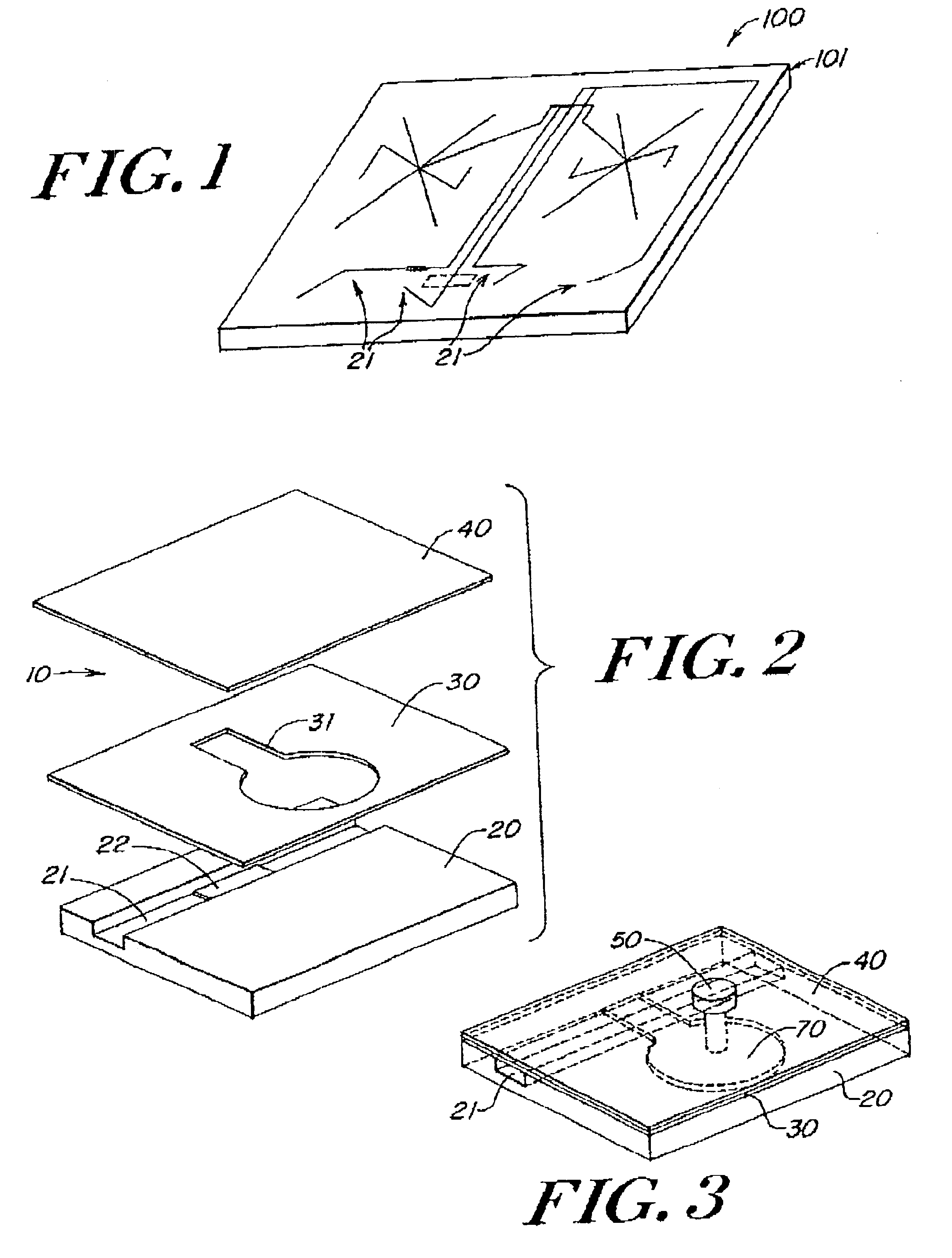

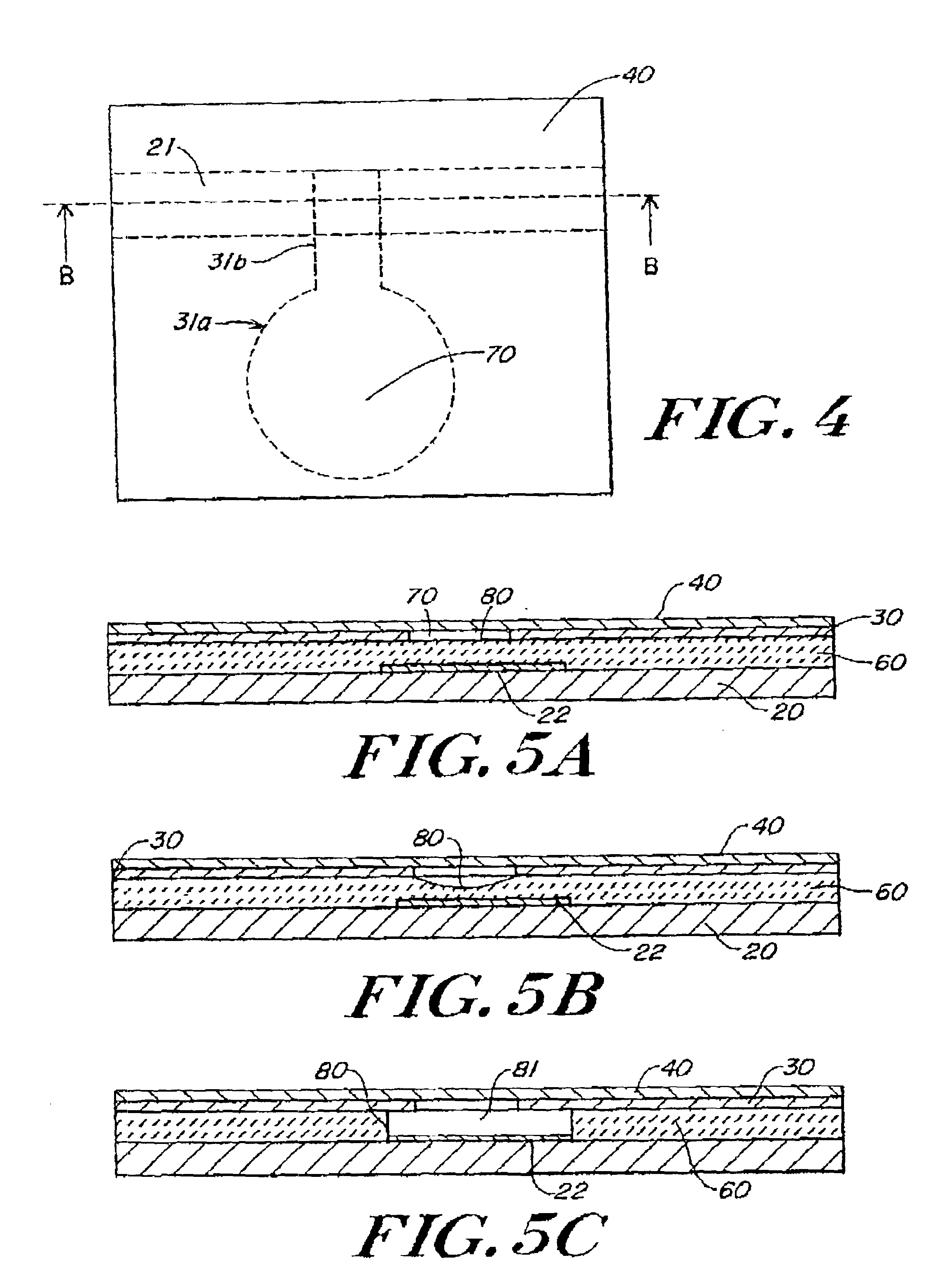

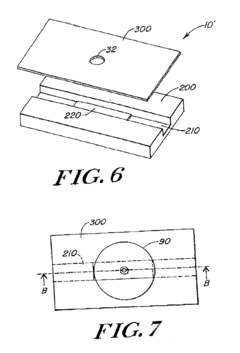

Component part of a microfluidic valve

PatentInactiveEP1520837A1

Innovation

- A microfluidic valve component with two revolving valve elements, where one is located within a through hole of the other, allowing for coaxial rotation and minimal dead volume, enabling efficient flow control and sealing of ports with a clearance fit and fluid-conducting features, facilitating complex microfluidic processes.

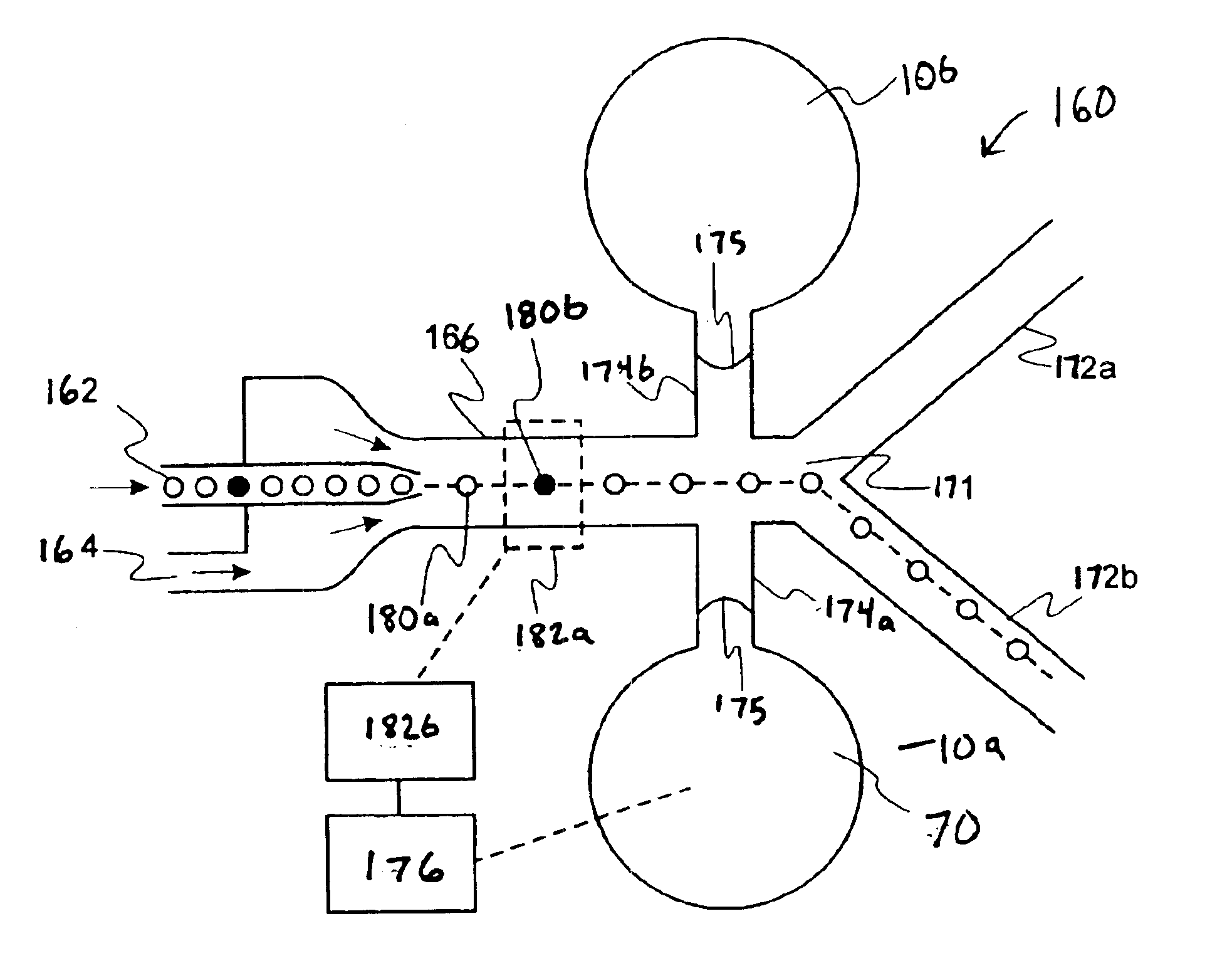

Microfluidic system including a bubble valve for regulating fluid flow through a microchannel

PatentInactiveUS6877528B2

Innovation

- A bubble valve system using an externally operated mechanical or pneumatic actuator to deflect a fluid meniscus into the microchannel, regulating liquid flow by modifying the cross-sectional area with a gas bubble, eliminating the need for heating and complex on-chip circuitry.

Materials Science Advancements for Gate Valves

Recent advancements in materials science have significantly impacted the development of gate valves for micro-scale fluid control applications. The pursuit of seamless and precise fluid manipulation at the microscale level has driven researchers to explore novel materials and manufacturing techniques. One of the key areas of focus has been the development of advanced polymers and composites that offer superior mechanical properties, chemical resistance, and biocompatibility.

Nanocomposite materials have emerged as promising candidates for gate valve components. These materials combine the benefits of traditional polymers with the enhanced properties of nanoscale fillers, such as carbon nanotubes or graphene. The incorporation of these nanofillers has led to improved strength, stiffness, and wear resistance, which are crucial for the longevity and reliability of micro-scale gate valves.

Surface modification techniques have also played a vital role in enhancing the performance of gate valves. Plasma treatment and chemical vapor deposition methods have been employed to alter the surface properties of valve components, resulting in improved wettability, reduced friction, and enhanced corrosion resistance. These modifications have enabled more precise control over fluid flow and reduced the risk of contamination in sensitive applications.

The advent of 3D printing technologies has revolutionized the manufacturing of micro-scale gate valves. Additive manufacturing techniques, such as stereolithography and two-photon polymerization, have allowed for the fabrication of complex valve geometries with unprecedented precision. This has opened up new possibilities for designing intricate flow channels and optimizing valve performance at the microscale level.

Smart materials have also found their way into gate valve design. Shape memory alloys and piezoelectric materials have been integrated into valve actuators, enabling rapid and precise control of valve opening and closing. These materials respond to external stimuli, such as temperature or electric fields, allowing for more sophisticated and responsive fluid control systems.

Biomimetic approaches have inspired the development of novel valve designs and materials. Researchers have drawn inspiration from natural systems, such as the structure of plant cell walls or the water-repellent properties of lotus leaves, to create valve surfaces with enhanced fluid handling capabilities. These bio-inspired materials and structures have shown promise in improving the efficiency and reliability of micro-scale fluid control systems.

The ongoing research in materials science continues to push the boundaries of what is possible in gate valve design for micro-scale applications. As new materials and manufacturing techniques emerge, we can expect further improvements in valve performance, durability, and functionality, ultimately leading to more advanced and reliable fluid control systems across various industries.

Nanocomposite materials have emerged as promising candidates for gate valve components. These materials combine the benefits of traditional polymers with the enhanced properties of nanoscale fillers, such as carbon nanotubes or graphene. The incorporation of these nanofillers has led to improved strength, stiffness, and wear resistance, which are crucial for the longevity and reliability of micro-scale gate valves.

Surface modification techniques have also played a vital role in enhancing the performance of gate valves. Plasma treatment and chemical vapor deposition methods have been employed to alter the surface properties of valve components, resulting in improved wettability, reduced friction, and enhanced corrosion resistance. These modifications have enabled more precise control over fluid flow and reduced the risk of contamination in sensitive applications.

The advent of 3D printing technologies has revolutionized the manufacturing of micro-scale gate valves. Additive manufacturing techniques, such as stereolithography and two-photon polymerization, have allowed for the fabrication of complex valve geometries with unprecedented precision. This has opened up new possibilities for designing intricate flow channels and optimizing valve performance at the microscale level.

Smart materials have also found their way into gate valve design. Shape memory alloys and piezoelectric materials have been integrated into valve actuators, enabling rapid and precise control of valve opening and closing. These materials respond to external stimuli, such as temperature or electric fields, allowing for more sophisticated and responsive fluid control systems.

Biomimetic approaches have inspired the development of novel valve designs and materials. Researchers have drawn inspiration from natural systems, such as the structure of plant cell walls or the water-repellent properties of lotus leaves, to create valve surfaces with enhanced fluid handling capabilities. These bio-inspired materials and structures have shown promise in improving the efficiency and reliability of micro-scale fluid control systems.

The ongoing research in materials science continues to push the boundaries of what is possible in gate valve design for micro-scale applications. As new materials and manufacturing techniques emerge, we can expect further improvements in valve performance, durability, and functionality, ultimately leading to more advanced and reliable fluid control systems across various industries.

Environmental Impact of Micro-Fluidic Systems

The environmental impact of micro-fluidic systems, particularly those incorporating gate valve enhancements for seamless micro-scale fluid control, is a critical consideration in the development and implementation of these technologies. These systems, while offering precise control and efficiency in fluid manipulation, also present unique environmental challenges and opportunities.

One of the primary environmental benefits of micro-fluidic systems is their potential for reducing resource consumption. By operating at a micro-scale, these systems typically require significantly less reagents, samples, and overall materials compared to traditional macro-scale fluid handling systems. This reduction in material usage translates to decreased waste generation and lower environmental footprint associated with the production and disposal of chemicals and biological materials.

However, the manufacturing processes for micro-fluidic devices, including those with advanced gate valve mechanisms, often involve the use of specialized materials and fabrication techniques. Some of these materials, such as certain polymers or rare earth elements used in sensor components, may have environmental implications in terms of resource extraction and end-of-life disposal. The miniaturization of components also presents challenges in terms of recyclability and proper disposal of these intricate devices.

Energy efficiency is another important aspect to consider. Micro-fluidic systems generally consume less energy during operation due to their small scale and precise control mechanisms. Enhanced gate valves contribute to this efficiency by allowing for more accurate fluid control, potentially reducing the need for repeated experiments or processes. This energy saving can lead to a decrease in the overall carbon footprint associated with laboratory and industrial processes that utilize these systems.

The application of micro-fluidic systems in environmental monitoring and remediation presents a positive environmental impact. These systems can be used for real-time detection of pollutants in water and air, enabling more rapid and efficient environmental protection measures. The precise control offered by advanced gate valves allows for more accurate sampling and analysis, potentially leading to improved environmental management strategies.

In the context of sustainable development, micro-fluidic systems with enhanced gate valves contribute to the miniaturization and portability of analytical and diagnostic tools. This can lead to reduced transportation needs for sample analysis, decentralization of testing facilities, and improved access to diagnostic capabilities in remote areas, all of which have positive environmental implications.

However, the proliferation of micro-fluidic devices also raises concerns about electronic waste. As these systems become more widespread, ensuring proper disposal and recycling of these devices becomes crucial to prevent environmental contamination from electronic components and specialized materials used in their construction.

One of the primary environmental benefits of micro-fluidic systems is their potential for reducing resource consumption. By operating at a micro-scale, these systems typically require significantly less reagents, samples, and overall materials compared to traditional macro-scale fluid handling systems. This reduction in material usage translates to decreased waste generation and lower environmental footprint associated with the production and disposal of chemicals and biological materials.

However, the manufacturing processes for micro-fluidic devices, including those with advanced gate valve mechanisms, often involve the use of specialized materials and fabrication techniques. Some of these materials, such as certain polymers or rare earth elements used in sensor components, may have environmental implications in terms of resource extraction and end-of-life disposal. The miniaturization of components also presents challenges in terms of recyclability and proper disposal of these intricate devices.

Energy efficiency is another important aspect to consider. Micro-fluidic systems generally consume less energy during operation due to their small scale and precise control mechanisms. Enhanced gate valves contribute to this efficiency by allowing for more accurate fluid control, potentially reducing the need for repeated experiments or processes. This energy saving can lead to a decrease in the overall carbon footprint associated with laboratory and industrial processes that utilize these systems.

The application of micro-fluidic systems in environmental monitoring and remediation presents a positive environmental impact. These systems can be used for real-time detection of pollutants in water and air, enabling more rapid and efficient environmental protection measures. The precise control offered by advanced gate valves allows for more accurate sampling and analysis, potentially leading to improved environmental management strategies.

In the context of sustainable development, micro-fluidic systems with enhanced gate valves contribute to the miniaturization and portability of analytical and diagnostic tools. This can lead to reduced transportation needs for sample analysis, decentralization of testing facilities, and improved access to diagnostic capabilities in remote areas, all of which have positive environmental implications.

However, the proliferation of micro-fluidic devices also raises concerns about electronic waste. As these systems become more widespread, ensuring proper disposal and recycling of these devices becomes crucial to prevent environmental contamination from electronic components and specialized materials used in their construction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!