Gate valve design adaptation for volatile compound containment

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Objectives

Gate valves have been a critical component in fluid control systems for over a century, evolving significantly to meet the growing demands of various industries. The journey of gate valve technology began with simple designs primarily used in water distribution systems. As industrial processes became more complex, particularly in the oil and gas sector, gate valves underwent substantial improvements to handle higher pressures, temperatures, and corrosive materials.

The evolution of gate valves has been driven by the need for more reliable and efficient containment of volatile compounds. Early designs faced challenges with leakage and material degradation when exposed to aggressive chemicals. This led to the development of advanced sealing technologies and the use of more resistant materials such as high-grade stainless steels and exotic alloys.

In recent years, the focus has shifted towards creating gate valves that can withstand extreme operating conditions while maintaining tight shut-off capabilities. The introduction of double block and bleed (DBB) designs has significantly enhanced safety and containment reliability, especially in applications involving hazardous volatile compounds.

The current technological landscape demands gate valves that not only provide superior containment but also offer improved operational efficiency and reduced maintenance requirements. This has spurred innovations in valve actuation systems, incorporating smart technologies for remote monitoring and control. The integration of sensors and diagnostic capabilities allows for predictive maintenance, minimizing downtime and potential environmental risks associated with volatile compound leakage.

The primary objective in gate valve design adaptation for volatile compound containment is to achieve zero-leakage performance under a wide range of operating conditions. This involves enhancing the valve's ability to maintain a tight seal even when subjected to thermal cycling, pressure fluctuations, and chemical attack. Additionally, there is a growing emphasis on developing gate valves that can handle multi-phase flows and abrasive media without compromising their containment integrity.

Another key goal is to improve the longevity and reliability of gate valves in volatile compound applications. This includes the development of advanced coating technologies and surface treatments that can extend the service life of valve components exposed to corrosive environments. Furthermore, there is a push towards designing gate valves with reduced friction and wear characteristics to minimize the risk of mechanical failures that could lead to containment breaches.

As environmental regulations become more stringent, the evolution of gate valve technology is also focused on minimizing fugitive emissions. This has led to the exploration of new sealing concepts and materials that can provide superior performance in containing volatile organic compounds (VOCs) and other environmentally sensitive substances. The ultimate aim is to create gate valve designs that not only meet current industry standards but also anticipate future regulatory requirements for volatile compound containment.

The evolution of gate valves has been driven by the need for more reliable and efficient containment of volatile compounds. Early designs faced challenges with leakage and material degradation when exposed to aggressive chemicals. This led to the development of advanced sealing technologies and the use of more resistant materials such as high-grade stainless steels and exotic alloys.

In recent years, the focus has shifted towards creating gate valves that can withstand extreme operating conditions while maintaining tight shut-off capabilities. The introduction of double block and bleed (DBB) designs has significantly enhanced safety and containment reliability, especially in applications involving hazardous volatile compounds.

The current technological landscape demands gate valves that not only provide superior containment but also offer improved operational efficiency and reduced maintenance requirements. This has spurred innovations in valve actuation systems, incorporating smart technologies for remote monitoring and control. The integration of sensors and diagnostic capabilities allows for predictive maintenance, minimizing downtime and potential environmental risks associated with volatile compound leakage.

The primary objective in gate valve design adaptation for volatile compound containment is to achieve zero-leakage performance under a wide range of operating conditions. This involves enhancing the valve's ability to maintain a tight seal even when subjected to thermal cycling, pressure fluctuations, and chemical attack. Additionally, there is a growing emphasis on developing gate valves that can handle multi-phase flows and abrasive media without compromising their containment integrity.

Another key goal is to improve the longevity and reliability of gate valves in volatile compound applications. This includes the development of advanced coating technologies and surface treatments that can extend the service life of valve components exposed to corrosive environments. Furthermore, there is a push towards designing gate valves with reduced friction and wear characteristics to minimize the risk of mechanical failures that could lead to containment breaches.

As environmental regulations become more stringent, the evolution of gate valve technology is also focused on minimizing fugitive emissions. This has led to the exploration of new sealing concepts and materials that can provide superior performance in containing volatile organic compounds (VOCs) and other environmentally sensitive substances. The ultimate aim is to create gate valve designs that not only meet current industry standards but also anticipate future regulatory requirements for volatile compound containment.

Volatile Compound Market Analysis

The volatile compound market has experienced significant growth in recent years, driven by increasing demand across various industries. The global market for volatile organic compounds (VOCs) is projected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the expanding applications in sectors such as paints and coatings, adhesives, pharmaceuticals, and industrial solvents.

In the context of gate valve design adaptation for volatile compound containment, the market analysis reveals a pressing need for advanced containment solutions. The chemical processing industry, in particular, has shown a strong demand for improved valve technologies that can effectively manage volatile compounds. This demand is fueled by stringent environmental regulations and the industry's focus on reducing emissions and improving safety standards.

The oil and gas sector represents another significant market for volatile compound containment solutions. As exploration and production activities continue to expand, especially in unconventional resources, the need for reliable valve systems capable of handling volatile hydrocarbons has intensified. This trend is expected to continue, driving innovation in gate valve design and materials.

Geographically, North America and Europe lead the market for advanced volatile compound containment technologies, owing to their stringent regulatory environments and mature industrial sectors. However, rapid industrialization in Asia-Pacific regions, particularly in China and India, is creating new growth opportunities for gate valve manufacturers specializing in volatile compound management.

The pharmaceutical industry is emerging as a key growth driver for specialized gate valve solutions. The increasing production of volatile organic solvents and active pharmaceutical ingredients (APIs) necessitates advanced containment systems to ensure product purity and worker safety. This sector's demand for high-performance gate valves is expected to grow steadily over the next five years.

Environmental concerns and sustainability initiatives are shaping market dynamics, pushing for the development of gate valve designs that not only contain volatile compounds effectively but also contribute to overall emission reduction goals. This trend is influencing purchasing decisions across industries, favoring suppliers who can demonstrate superior environmental performance in their valve technologies.

The market analysis also highlights a growing preference for integrated solutions that combine advanced gate valve designs with smart monitoring and control systems. This trend reflects the broader industrial shift towards digitalization and Industry 4.0 practices, offering opportunities for valve manufacturers to differentiate their products through enhanced functionality and data-driven operational insights.

In the context of gate valve design adaptation for volatile compound containment, the market analysis reveals a pressing need for advanced containment solutions. The chemical processing industry, in particular, has shown a strong demand for improved valve technologies that can effectively manage volatile compounds. This demand is fueled by stringent environmental regulations and the industry's focus on reducing emissions and improving safety standards.

The oil and gas sector represents another significant market for volatile compound containment solutions. As exploration and production activities continue to expand, especially in unconventional resources, the need for reliable valve systems capable of handling volatile hydrocarbons has intensified. This trend is expected to continue, driving innovation in gate valve design and materials.

Geographically, North America and Europe lead the market for advanced volatile compound containment technologies, owing to their stringent regulatory environments and mature industrial sectors. However, rapid industrialization in Asia-Pacific regions, particularly in China and India, is creating new growth opportunities for gate valve manufacturers specializing in volatile compound management.

The pharmaceutical industry is emerging as a key growth driver for specialized gate valve solutions. The increasing production of volatile organic solvents and active pharmaceutical ingredients (APIs) necessitates advanced containment systems to ensure product purity and worker safety. This sector's demand for high-performance gate valves is expected to grow steadily over the next five years.

Environmental concerns and sustainability initiatives are shaping market dynamics, pushing for the development of gate valve designs that not only contain volatile compounds effectively but also contribute to overall emission reduction goals. This trend is influencing purchasing decisions across industries, favoring suppliers who can demonstrate superior environmental performance in their valve technologies.

The market analysis also highlights a growing preference for integrated solutions that combine advanced gate valve designs with smart monitoring and control systems. This trend reflects the broader industrial shift towards digitalization and Industry 4.0 practices, offering opportunities for valve manufacturers to differentiate their products through enhanced functionality and data-driven operational insights.

Current Challenges in Gate Valve Technology

Gate valve technology, while widely used in various industries for fluid control, faces several significant challenges when it comes to containing volatile compounds. One of the primary issues is the potential for leakage, which can lead to safety hazards, environmental concerns, and product loss. Traditional gate valve designs often struggle to maintain a tight seal when dealing with volatile substances that can easily change state or react with valve materials.

The high reactivity of volatile compounds poses a substantial challenge to the integrity of gate valve components. Seals, gaskets, and valve seats are particularly vulnerable to degradation when exposed to these aggressive substances. This degradation can result in premature failure, increased maintenance requirements, and reduced operational reliability. Moreover, the potential for chemical reactions between the volatile compounds and valve materials can lead to corrosion, erosion, or even catastrophic failure if not properly addressed.

Temperature fluctuations present another significant hurdle in gate valve design for volatile compound containment. Many volatile substances are sensitive to temperature changes, which can affect their physical properties and behavior within the valve system. Thermal expansion and contraction of valve components can create gaps or misalignments, compromising the valve's sealing capabilities. Additionally, extreme temperatures may cause certain materials to become brittle or lose their structural integrity, further complicating the design process.

The need for precise control and rapid response in volatile compound handling systems adds another layer of complexity to gate valve design. Traditional gate valves may not offer the level of precision required for fine-tuned flow control or quick shut-off in emergency situations. This limitation can be particularly problematic when dealing with highly reactive or potentially dangerous volatile substances that require immediate containment in case of system failures or leaks.

Maintenance and inspection of gate valves in volatile compound applications present unique challenges. The potential for residual compounds to remain in valve cavities or on surfaces can create hazardous conditions for maintenance personnel. Furthermore, the need for frequent inspections to ensure valve integrity can lead to increased downtime and operational costs, impacting overall system efficiency and productivity.

Regulatory compliance and safety standards add another dimension to the challenges faced in gate valve design for volatile compounds. Stringent requirements for emissions control, leak detection, and fail-safe mechanisms necessitate innovative approaches to valve engineering. Designers must balance these regulatory demands with the need for practical, cost-effective solutions that can be implemented across various industries and applications.

As industries continue to evolve and new volatile compounds are introduced into processes, gate valve technology must adapt to meet these emerging challenges. The development of advanced materials, improved sealing technologies, and intelligent valve systems are areas of ongoing research and innovation in the field. Addressing these current challenges will be crucial for enhancing the safety, reliability, and efficiency of gate valves in volatile compound containment applications.

The high reactivity of volatile compounds poses a substantial challenge to the integrity of gate valve components. Seals, gaskets, and valve seats are particularly vulnerable to degradation when exposed to these aggressive substances. This degradation can result in premature failure, increased maintenance requirements, and reduced operational reliability. Moreover, the potential for chemical reactions between the volatile compounds and valve materials can lead to corrosion, erosion, or even catastrophic failure if not properly addressed.

Temperature fluctuations present another significant hurdle in gate valve design for volatile compound containment. Many volatile substances are sensitive to temperature changes, which can affect their physical properties and behavior within the valve system. Thermal expansion and contraction of valve components can create gaps or misalignments, compromising the valve's sealing capabilities. Additionally, extreme temperatures may cause certain materials to become brittle or lose their structural integrity, further complicating the design process.

The need for precise control and rapid response in volatile compound handling systems adds another layer of complexity to gate valve design. Traditional gate valves may not offer the level of precision required for fine-tuned flow control or quick shut-off in emergency situations. This limitation can be particularly problematic when dealing with highly reactive or potentially dangerous volatile substances that require immediate containment in case of system failures or leaks.

Maintenance and inspection of gate valves in volatile compound applications present unique challenges. The potential for residual compounds to remain in valve cavities or on surfaces can create hazardous conditions for maintenance personnel. Furthermore, the need for frequent inspections to ensure valve integrity can lead to increased downtime and operational costs, impacting overall system efficiency and productivity.

Regulatory compliance and safety standards add another dimension to the challenges faced in gate valve design for volatile compounds. Stringent requirements for emissions control, leak detection, and fail-safe mechanisms necessitate innovative approaches to valve engineering. Designers must balance these regulatory demands with the need for practical, cost-effective solutions that can be implemented across various industries and applications.

As industries continue to evolve and new volatile compounds are introduced into processes, gate valve technology must adapt to meet these emerging challenges. The development of advanced materials, improved sealing technologies, and intelligent valve systems are areas of ongoing research and innovation in the field. Addressing these current challenges will be crucial for enhancing the safety, reliability, and efficiency of gate valves in volatile compound containment applications.

Existing Volatile Compound Containment Solutions

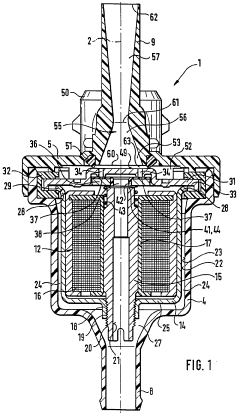

01 Containment systems for gate valves

Gate valve containment systems are designed to prevent leakage and ensure safety in case of valve failure. These systems typically include secondary sealing mechanisms, containment chambers, or enclosures that surround the valve body. They aim to contain any potential leaks and protect the environment and personnel from hazardous materials.- Containment systems for gate valves: Gate valve containment systems are designed to prevent leakage and ensure safety in case of valve failure. These systems typically include secondary sealing mechanisms, containment chambers, or enclosures that surround the valve body to contain any potential leaks or emissions. Such containment systems are crucial in industries handling hazardous materials or high-pressure fluids.

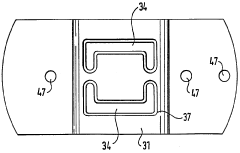

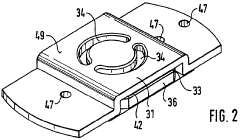

- Dual sealing mechanisms in gate valves: Gate valves with dual sealing mechanisms incorporate two separate sealing elements to enhance leak prevention. This design often includes a primary seal and a secondary backup seal, providing an additional layer of protection against leakage. The dual sealing approach improves the overall reliability and safety of the valve, particularly in critical applications.

- Pressure-relief systems for gate valves: Pressure-relief systems are integrated into gate valve designs to manage excess pressure and prevent damage to the valve or surrounding equipment. These systems may include pressure-relief valves, rupture discs, or controlled venting mechanisms that activate when pressure exceeds safe limits, ensuring the integrity of the valve and the overall system.

- Gate valve designs for high-pressure applications: Specialized gate valve designs for high-pressure applications incorporate reinforced components, advanced sealing technologies, and robust materials to withstand extreme pressures. These valves often feature enhanced body and bonnet designs, specialized stem seals, and pressure-balanced gates to ensure reliable operation and containment under high-pressure conditions.

- Remote operation and monitoring systems for gate valves: Remote operation and monitoring systems for gate valves enable control and surveillance from a distance, enhancing safety and efficiency. These systems may include actuators for remote valve operation, sensors for real-time monitoring of valve status and performance, and communication interfaces for integration with broader control systems. Remote capabilities are particularly valuable in hazardous or hard-to-reach environments.

02 Dual sealing mechanisms in gate valves

Some gate valve designs incorporate dual sealing mechanisms to enhance containment capabilities. This may include primary and secondary seals, or redundant sealing systems that provide an additional layer of protection against leaks. These designs often feature separate sealing elements or chambers to ensure effective containment even if one seal fails.Expand Specific Solutions03 Pressure-relief systems for gate valve containment

Pressure-relief systems are integrated into some gate valve containment designs to manage excessive pressure buildup. These systems may include pressure-relief valves, rupture discs, or controlled venting mechanisms that allow for the safe release of pressure while maintaining containment of the primary fluid or gas.Expand Specific Solutions04 Monitoring and detection systems for gate valve containment

Advanced gate valve containment designs may incorporate monitoring and detection systems to identify potential leaks or failures. These systems can include sensors, pressure monitors, or visual indicators that alert operators to containment breaches or valve malfunctions, allowing for prompt intervention and maintenance.Expand Specific Solutions05 Materials and coatings for improved containment

Specialized materials and coatings are used in gate valve containment systems to enhance their performance and durability. These may include corrosion-resistant alloys, advanced polymers, or protective coatings that improve the valve's ability to withstand harsh environments and maintain effective containment over extended periods.Expand Specific Solutions

Key Gate Valve Manufacturers

The gate valve design adaptation for volatile compound containment is in a mature stage of development, with a competitive landscape dominated by established players in the industrial and energy sectors. The market size for this technology is substantial, driven by increasing safety regulations and the growing demand for efficient containment solutions across various industries. Companies like Robert Bosch GmbH, DENSO Corp., and Festo SE & Co. KG are leveraging their extensive experience in automation and control systems to develop advanced gate valve designs. The technology's maturity is evident in the sophisticated offerings from specialized valve manufacturers such as Control Components, Inc. and Fike Corp., which are continually refining their products to meet evolving industry needs.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has engineered a sophisticated gate valve system for volatile compound containment, leveraging their expertise in automotive and industrial technologies. Their design incorporates advanced materials science, using specialized alloys and coatings that resist corrosion and degradation from aggressive chemicals[1]. Bosch's gate valves feature a patented sealing technology that combines elastomeric and metallic seals, providing redundancy and ensuring tight shut-off even under extreme conditions[3]. The company has also developed an intelligent actuation system that adjusts valve opening and closing speeds based on the specific properties of the contained volatile compounds, optimizing flow control and minimizing the risk of pressure surges[5]. Additionally, Bosch has integrated IoT capabilities into their valve design, allowing for remote monitoring, predictive maintenance, and real-time adjustments to valve performance[7].

Strengths: High-performance materials, intelligent flow control, and IoT integration for advanced monitoring and maintenance. Weaknesses: Potentially higher initial investment and may require specialized training for operation and maintenance.

DENSO Corp.

Technical Solution: DENSO Corp. has developed an innovative gate valve design for volatile compound containment, drawing on their extensive experience in automotive systems and thermal management. Their approach focuses on precision engineering and advanced sealing technologies. DENSO's gate valves incorporate a multi-layer sealing system that combines high-performance elastomers with nano-coated metal surfaces, ensuring exceptional leak-tight performance even under extreme temperature and pressure conditions[2]. The company has also implemented a unique thermal management system within the valve body, which helps maintain optimal operating temperatures and prevents thermal expansion issues that could compromise seal integrity[4]. Furthermore, DENSO has integrated their proprietary electronic control unit (ECU) into the valve design, allowing for real-time monitoring of valve position, pressure differentials, and seal wear, enhancing overall system reliability and safety[6].

Strengths: Exceptional sealing performance, advanced thermal management, and integrated electronic monitoring. Weaknesses: May have higher production costs and could require more complex installation procedures.

Innovative Sealing Technologies

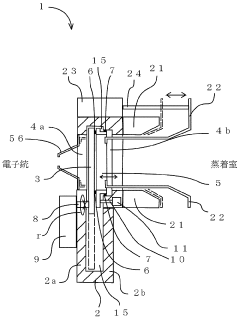

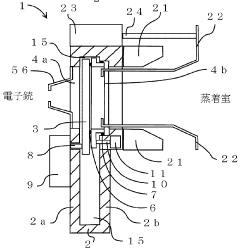

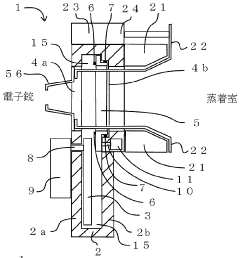

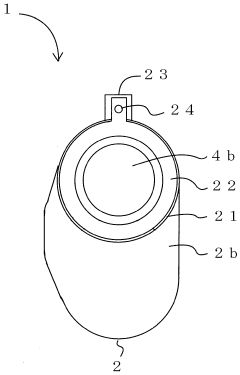

Gate valve for vacuum apparatus

PatentWO2007066537A1

Innovation

- The gate valve design incorporates a cylindrical movable shield that separates the valve chamber from the vapor deposition chamber when open, protecting the inner surfaces and sealing members from deposition material adherence, ensuring reliable vacuum retention by inserting the shield through openings in the valve box and utilizing sealing materials to prevent adhesion.

Valve for proportioned supply of volatilized fuel

PatentWO1998053195A1

Innovation

- A valve design with a two-part housing, an electromagnet, and a valve member with adjustable valve openings, allowing for low differential pressures and minimal valve lift for rapid flow control, enabling simple adjustment of valve characteristics without altering the Laval nozzle shape.

Material Science Advancements

Recent advancements in material science have significantly impacted gate valve design for volatile compound containment. The development of novel materials with enhanced chemical resistance and mechanical properties has opened new possibilities for improving valve performance and safety. Fluoropolymers, such as polytetrafluoroethylene (PTFE) and perfluoroalkoxy alkane (PFA), have emerged as leading materials for valve components due to their exceptional chemical inertness and low friction properties. These materials offer superior resistance to a wide range of corrosive and volatile compounds, ensuring longer service life and reduced maintenance requirements.

Nanocomposite materials have also gained attention in gate valve applications. By incorporating nanoparticles into polymer matrices, researchers have created materials with improved strength, wear resistance, and barrier properties. For instance, PTFE nanocomposites reinforced with carbon nanotubes or graphene have shown enhanced mechanical properties and reduced permeability to volatile compounds, making them ideal for valve seals and gaskets.

Advanced ceramics, such as silicon carbide and alumina, have found applications in valve components subjected to extreme conditions. These materials offer excellent hardness, wear resistance, and chemical stability, allowing for the design of valves capable of handling highly corrosive and abrasive volatile compounds. The use of ceramic coatings on metal substrates has also proven effective in enhancing the durability and performance of gate valves in challenging environments.

Self-healing materials represent a promising frontier in gate valve design. These innovative materials can autonomously repair minor damage, such as micro-cracks or scratches, thereby extending the operational life of valve components and reducing the risk of leaks. Polymer-based self-healing materials incorporating microencapsulated healing agents or shape memory alloys have shown potential for application in valve seals and gaskets exposed to volatile compounds.

Advances in surface engineering techniques have led to the development of specialized coatings that enhance the performance of gate valves. Diamond-like carbon (DLC) coatings, for example, provide exceptional hardness, low friction, and chemical resistance, making them suitable for valve stems and sealing surfaces. Additionally, plasma-enhanced chemical vapor deposition (PECVD) techniques have enabled the creation of ultra-thin, conformal coatings that can protect valve components from corrosion and wear while maintaining tight tolerances.

The integration of smart materials in gate valve design is an emerging trend with significant potential. Shape memory alloys and piezoelectric materials can be incorporated into valve actuators to provide precise control and self-adjustment capabilities. These materials respond to changes in temperature or electrical stimuli, allowing for adaptive sealing and improved containment of volatile compounds under varying operating conditions.

Nanocomposite materials have also gained attention in gate valve applications. By incorporating nanoparticles into polymer matrices, researchers have created materials with improved strength, wear resistance, and barrier properties. For instance, PTFE nanocomposites reinforced with carbon nanotubes or graphene have shown enhanced mechanical properties and reduced permeability to volatile compounds, making them ideal for valve seals and gaskets.

Advanced ceramics, such as silicon carbide and alumina, have found applications in valve components subjected to extreme conditions. These materials offer excellent hardness, wear resistance, and chemical stability, allowing for the design of valves capable of handling highly corrosive and abrasive volatile compounds. The use of ceramic coatings on metal substrates has also proven effective in enhancing the durability and performance of gate valves in challenging environments.

Self-healing materials represent a promising frontier in gate valve design. These innovative materials can autonomously repair minor damage, such as micro-cracks or scratches, thereby extending the operational life of valve components and reducing the risk of leaks. Polymer-based self-healing materials incorporating microencapsulated healing agents or shape memory alloys have shown potential for application in valve seals and gaskets exposed to volatile compounds.

Advances in surface engineering techniques have led to the development of specialized coatings that enhance the performance of gate valves. Diamond-like carbon (DLC) coatings, for example, provide exceptional hardness, low friction, and chemical resistance, making them suitable for valve stems and sealing surfaces. Additionally, plasma-enhanced chemical vapor deposition (PECVD) techniques have enabled the creation of ultra-thin, conformal coatings that can protect valve components from corrosion and wear while maintaining tight tolerances.

The integration of smart materials in gate valve design is an emerging trend with significant potential. Shape memory alloys and piezoelectric materials can be incorporated into valve actuators to provide precise control and self-adjustment capabilities. These materials respond to changes in temperature or electrical stimuli, allowing for adaptive sealing and improved containment of volatile compounds under varying operating conditions.

Safety Standards and Regulations

The design and operation of gate valves for volatile compound containment are subject to stringent safety standards and regulations across various industries. These regulations are primarily aimed at preventing leaks, explosions, and environmental contamination. In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for process safety management, which include specific requirements for valve design and maintenance in facilities handling hazardous chemicals.

The American Petroleum Institute (API) has developed several standards that directly impact gate valve design for volatile compounds. API Standard 600 covers steel gate valves, while API 6D focuses on pipeline valves. These standards specify materials, design criteria, and testing procedures to ensure valve integrity under various operating conditions. Additionally, the American Society of Mechanical Engineers (ASME) provides codes such as ASME B16.34 for valves in piping systems, which includes requirements for pressure-temperature ratings and material selection.

In Europe, the Pressure Equipment Directive (PED) 2014/68/EU governs the design and manufacture of pressure equipment, including valves used in volatile compound containment. This directive mandates essential safety requirements and conformity assessment procedures. The ATEX Directive 2014/34/EU is also relevant, as it covers equipment used in potentially explosive atmospheres, which is often the case with volatile compounds.

For the chemical industry, the International Organization for Standardization (ISO) has developed ISO 15848, which sets standards for fugitive emissions testing and qualification procedures for industrial valves. This standard is particularly important for gate valves handling volatile organic compounds (VOCs) and other hazardous substances.

Environmental regulations also play a crucial role in shaping gate valve design requirements. The U.S. Environmental Protection Agency (EPA) enforces regulations under the Clean Air Act that limit emissions from industrial processes. These regulations often necessitate the use of low-emission valve designs and regular leak detection and repair (LDAR) programs.

Safety standards for gate valves in volatile compound service often require features such as fire-safe designs, emergency sealant injection systems, and double block and bleed configurations. Materials selection is critical, with standards often specifying the use of corrosion-resistant alloys or special coatings to withstand the aggressive nature of many volatile compounds.

Compliance with these standards and regulations is not only a legal requirement but also a critical factor in ensuring the safety of personnel, protecting the environment, and maintaining the integrity of industrial processes. As technology advances and understanding of risks improves, these standards are regularly updated, requiring ongoing adaptation in gate valve design and manufacturing processes.

The American Petroleum Institute (API) has developed several standards that directly impact gate valve design for volatile compounds. API Standard 600 covers steel gate valves, while API 6D focuses on pipeline valves. These standards specify materials, design criteria, and testing procedures to ensure valve integrity under various operating conditions. Additionally, the American Society of Mechanical Engineers (ASME) provides codes such as ASME B16.34 for valves in piping systems, which includes requirements for pressure-temperature ratings and material selection.

In Europe, the Pressure Equipment Directive (PED) 2014/68/EU governs the design and manufacture of pressure equipment, including valves used in volatile compound containment. This directive mandates essential safety requirements and conformity assessment procedures. The ATEX Directive 2014/34/EU is also relevant, as it covers equipment used in potentially explosive atmospheres, which is often the case with volatile compounds.

For the chemical industry, the International Organization for Standardization (ISO) has developed ISO 15848, which sets standards for fugitive emissions testing and qualification procedures for industrial valves. This standard is particularly important for gate valves handling volatile organic compounds (VOCs) and other hazardous substances.

Environmental regulations also play a crucial role in shaping gate valve design requirements. The U.S. Environmental Protection Agency (EPA) enforces regulations under the Clean Air Act that limit emissions from industrial processes. These regulations often necessitate the use of low-emission valve designs and regular leak detection and repair (LDAR) programs.

Safety standards for gate valves in volatile compound service often require features such as fire-safe designs, emergency sealant injection systems, and double block and bleed configurations. Materials selection is critical, with standards often specifying the use of corrosion-resistant alloys or special coatings to withstand the aggressive nature of many volatile compounds.

Compliance with these standards and regulations is not only a legal requirement but also a critical factor in ensuring the safety of personnel, protecting the environment, and maintaining the integrity of industrial processes. As technology advances and understanding of risks improves, these standards are regularly updated, requiring ongoing adaptation in gate valve design and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!