Investigating cross-link polymer effects on gate valve resilience

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cross-link Polymer Background and Objectives

Cross-linked polymers have emerged as a significant area of interest in materials science, particularly in their application to gate valve resilience. The evolution of these polymers can be traced back to the mid-20th century when scientists began exploring ways to enhance the mechanical and thermal properties of conventional polymers. Over the decades, cross-linking techniques have advanced significantly, leading to the development of materials with superior strength, durability, and chemical resistance.

The primary objective of investigating cross-link polymer effects on gate valve resilience is to address the ongoing challenges in industrial valve applications. Gate valves, crucial components in fluid control systems, often face issues related to wear, corrosion, and seal degradation. By leveraging the unique properties of cross-linked polymers, researchers aim to enhance the longevity and performance of these valves under harsh operating conditions.

Recent technological trends in this field have focused on optimizing cross-linking density and developing novel cross-linking agents. These advancements have led to polymers with improved thermal stability, enhanced chemical resistance, and better mechanical properties. The integration of such materials into gate valve components promises to revolutionize their resilience and operational efficiency.

One of the key areas of investigation is the impact of cross-linked polymers on the sealing mechanisms of gate valves. Traditional elastomeric seals often suffer from compression set and chemical degradation, leading to leakage and reduced valve performance. Cross-linked polymers offer the potential to create seals with superior recovery properties and resistance to aggressive media, thereby extending the service life of gate valves in challenging environments.

Another critical aspect of this research is the exploration of cross-linked polymer coatings for valve body and gate components. These coatings can provide enhanced protection against corrosion and erosion, which are common issues in industries such as oil and gas, chemical processing, and water treatment. The development of advanced coating technologies using cross-linked polymers aims to significantly improve the durability and reliability of gate valves in these demanding applications.

The investigation also extends to the molecular structure of cross-linked polymers and its influence on macroscopic properties relevant to valve performance. By understanding the relationship between cross-link density, polymer chain mobility, and mechanical behavior, researchers can tailor materials specifically for gate valve applications. This molecular-level approach is expected to yield breakthroughs in creating polymers that maintain their properties under extreme temperatures and pressures.

As the research progresses, the ultimate goal is to develop a new generation of gate valves that incorporate cross-linked polymers in various components, from seals to protective coatings. These advanced valves are expected to offer unprecedented levels of reliability, reduced maintenance requirements, and extended operational lifespans, thereby addressing long-standing challenges in fluid control systems across multiple industries.

The primary objective of investigating cross-link polymer effects on gate valve resilience is to address the ongoing challenges in industrial valve applications. Gate valves, crucial components in fluid control systems, often face issues related to wear, corrosion, and seal degradation. By leveraging the unique properties of cross-linked polymers, researchers aim to enhance the longevity and performance of these valves under harsh operating conditions.

Recent technological trends in this field have focused on optimizing cross-linking density and developing novel cross-linking agents. These advancements have led to polymers with improved thermal stability, enhanced chemical resistance, and better mechanical properties. The integration of such materials into gate valve components promises to revolutionize their resilience and operational efficiency.

One of the key areas of investigation is the impact of cross-linked polymers on the sealing mechanisms of gate valves. Traditional elastomeric seals often suffer from compression set and chemical degradation, leading to leakage and reduced valve performance. Cross-linked polymers offer the potential to create seals with superior recovery properties and resistance to aggressive media, thereby extending the service life of gate valves in challenging environments.

Another critical aspect of this research is the exploration of cross-linked polymer coatings for valve body and gate components. These coatings can provide enhanced protection against corrosion and erosion, which are common issues in industries such as oil and gas, chemical processing, and water treatment. The development of advanced coating technologies using cross-linked polymers aims to significantly improve the durability and reliability of gate valves in these demanding applications.

The investigation also extends to the molecular structure of cross-linked polymers and its influence on macroscopic properties relevant to valve performance. By understanding the relationship between cross-link density, polymer chain mobility, and mechanical behavior, researchers can tailor materials specifically for gate valve applications. This molecular-level approach is expected to yield breakthroughs in creating polymers that maintain their properties under extreme temperatures and pressures.

As the research progresses, the ultimate goal is to develop a new generation of gate valves that incorporate cross-linked polymers in various components, from seals to protective coatings. These advanced valves are expected to offer unprecedented levels of reliability, reduced maintenance requirements, and extended operational lifespans, thereby addressing long-standing challenges in fluid control systems across multiple industries.

Market Demand Analysis for Resilient Gate Valves

The market demand for resilient gate valves has been steadily increasing in recent years, driven by the growing need for reliable and durable fluid control systems across various industries. The global gate valve market, which includes resilient gate valves, is projected to experience significant growth over the next decade. This growth is primarily attributed to the expansion of industrial infrastructure, particularly in developing economies, and the increasing investments in water and wastewater treatment facilities worldwide.

The oil and gas industry remains a major consumer of resilient gate valves, as these components play a crucial role in controlling fluid flow in pipelines, refineries, and offshore platforms. The industry's focus on operational efficiency and safety has led to a higher demand for valves that can withstand harsh environments and maintain performance over extended periods. This trend is expected to continue as exploration and production activities expand into more challenging terrains and deeper waters.

Water and wastewater management sectors are also significant contributors to the market demand for resilient gate valves. Municipalities and water utilities are increasingly investing in upgrading their aging infrastructure, which includes the replacement of outdated valves with more resilient and efficient models. The growing emphasis on water conservation and the need for smart water management systems further drive the demand for advanced valve technologies.

The power generation industry, particularly in the context of renewable energy sources, presents another area of growth for resilient gate valves. As countries worldwide shift towards cleaner energy production, there is an increasing need for reliable valve systems in hydroelectric, geothermal, and concentrated solar power plants. These applications often require valves that can handle extreme temperatures and pressures, making resilient gate valves an attractive option.

Chemical and petrochemical industries also contribute significantly to the market demand. The corrosive nature of many chemicals necessitates the use of highly resilient valves that can maintain their integrity and performance over time. As these industries continue to expand and innovate, the demand for specialized valve solutions is expected to grow correspondingly.

The market for resilient gate valves is also being shaped by evolving regulatory standards and environmental concerns. Stricter regulations regarding emissions control and leak prevention are driving industries to adopt more reliable and efficient valve technologies. This trend is particularly evident in regions with stringent environmental policies, such as Europe and North America.

Emerging economies in Asia-Pacific and Latin America are expected to be key growth drivers for the resilient gate valve market. Rapid industrialization, urbanization, and infrastructure development in these regions are creating substantial opportunities for valve manufacturers. Additionally, the increasing adoption of automation and smart technologies in industrial processes is likely to fuel the demand for advanced valve systems with enhanced monitoring and control capabilities.

The oil and gas industry remains a major consumer of resilient gate valves, as these components play a crucial role in controlling fluid flow in pipelines, refineries, and offshore platforms. The industry's focus on operational efficiency and safety has led to a higher demand for valves that can withstand harsh environments and maintain performance over extended periods. This trend is expected to continue as exploration and production activities expand into more challenging terrains and deeper waters.

Water and wastewater management sectors are also significant contributors to the market demand for resilient gate valves. Municipalities and water utilities are increasingly investing in upgrading their aging infrastructure, which includes the replacement of outdated valves with more resilient and efficient models. The growing emphasis on water conservation and the need for smart water management systems further drive the demand for advanced valve technologies.

The power generation industry, particularly in the context of renewable energy sources, presents another area of growth for resilient gate valves. As countries worldwide shift towards cleaner energy production, there is an increasing need for reliable valve systems in hydroelectric, geothermal, and concentrated solar power plants. These applications often require valves that can handle extreme temperatures and pressures, making resilient gate valves an attractive option.

Chemical and petrochemical industries also contribute significantly to the market demand. The corrosive nature of many chemicals necessitates the use of highly resilient valves that can maintain their integrity and performance over time. As these industries continue to expand and innovate, the demand for specialized valve solutions is expected to grow correspondingly.

The market for resilient gate valves is also being shaped by evolving regulatory standards and environmental concerns. Stricter regulations regarding emissions control and leak prevention are driving industries to adopt more reliable and efficient valve technologies. This trend is particularly evident in regions with stringent environmental policies, such as Europe and North America.

Emerging economies in Asia-Pacific and Latin America are expected to be key growth drivers for the resilient gate valve market. Rapid industrialization, urbanization, and infrastructure development in these regions are creating substantial opportunities for valve manufacturers. Additionally, the increasing adoption of automation and smart technologies in industrial processes is likely to fuel the demand for advanced valve systems with enhanced monitoring and control capabilities.

Current Challenges in Gate Valve Resilience

Gate valve resilience faces several significant challenges in the current technological landscape. One of the primary issues is the degradation of valve components due to harsh operating conditions, including high temperatures, pressures, and corrosive environments. These factors can lead to premature wear, material fatigue, and eventual failure of critical valve parts, compromising the overall integrity and performance of the gate valve system.

Another challenge lies in the sealing mechanisms of gate valves. Traditional sealing materials often struggle to maintain their effectiveness over extended periods, especially when exposed to aggressive fluids or extreme temperature fluctuations. This results in increased leakage rates and reduced operational efficiency, necessitating more frequent maintenance and replacement cycles.

The dynamic nature of industrial processes also poses a significant challenge to gate valve resilience. Rapid changes in flow rates, pressure differentials, and fluid compositions can subject valves to unpredictable stress patterns, potentially leading to accelerated wear and tear. This variability makes it difficult to design valve components that can consistently withstand such diverse operating conditions while maintaining optimal performance.

Furthermore, the increasing demand for lightweight and compact valve designs in various industries presents a challenge in balancing material strength with weight reduction. Engineers must find innovative ways to enhance valve resilience without significantly increasing the overall mass or dimensions of the valve assembly, which can be particularly challenging in space-constrained applications.

The integration of smart technologies and sensors into gate valve systems, while offering potential benefits in terms of monitoring and predictive maintenance, also introduces new challenges. These include ensuring the reliability of electronic components in harsh environments, managing data security, and developing robust algorithms for accurate fault detection and performance optimization.

Lastly, the industry faces a significant challenge in developing sustainable and environmentally friendly valve solutions. This includes finding alternatives to traditional materials and lubricants that may have adverse environmental impacts, while still meeting the stringent performance and durability requirements of modern industrial applications.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, mechanical engineering, and digital technologies. The investigation of cross-link polymer effects on gate valve resilience represents a promising avenue for overcoming some of these obstacles, potentially offering enhanced durability, improved sealing properties, and greater resistance to harsh operating conditions.

Another challenge lies in the sealing mechanisms of gate valves. Traditional sealing materials often struggle to maintain their effectiveness over extended periods, especially when exposed to aggressive fluids or extreme temperature fluctuations. This results in increased leakage rates and reduced operational efficiency, necessitating more frequent maintenance and replacement cycles.

The dynamic nature of industrial processes also poses a significant challenge to gate valve resilience. Rapid changes in flow rates, pressure differentials, and fluid compositions can subject valves to unpredictable stress patterns, potentially leading to accelerated wear and tear. This variability makes it difficult to design valve components that can consistently withstand such diverse operating conditions while maintaining optimal performance.

Furthermore, the increasing demand for lightweight and compact valve designs in various industries presents a challenge in balancing material strength with weight reduction. Engineers must find innovative ways to enhance valve resilience without significantly increasing the overall mass or dimensions of the valve assembly, which can be particularly challenging in space-constrained applications.

The integration of smart technologies and sensors into gate valve systems, while offering potential benefits in terms of monitoring and predictive maintenance, also introduces new challenges. These include ensuring the reliability of electronic components in harsh environments, managing data security, and developing robust algorithms for accurate fault detection and performance optimization.

Lastly, the industry faces a significant challenge in developing sustainable and environmentally friendly valve solutions. This includes finding alternatives to traditional materials and lubricants that may have adverse environmental impacts, while still meeting the stringent performance and durability requirements of modern industrial applications.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, mechanical engineering, and digital technologies. The investigation of cross-link polymer effects on gate valve resilience represents a promising avenue for overcoming some of these obstacles, potentially offering enhanced durability, improved sealing properties, and greater resistance to harsh operating conditions.

Existing Cross-link Polymer Solutions for Valves

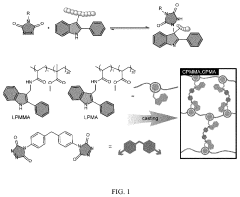

01 Cross-linked polymer compositions for improved resilience

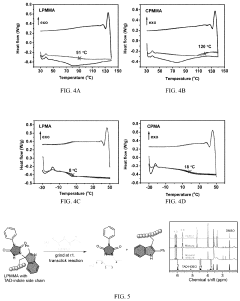

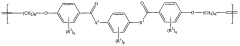

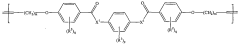

Cross-linked polymer compositions are developed to enhance material resilience. These compositions often incorporate specific monomers, cross-linking agents, and polymerization techniques to achieve desired mechanical properties. The resulting materials exhibit improved elasticity, durability, and resistance to deformation under stress.- Cross-linked polymer compositions for improved resilience: Cross-linked polymer compositions are developed to enhance material resilience. These compositions often incorporate specific monomers, cross-linking agents, and polymerization techniques to achieve desired mechanical properties. The resulting materials exhibit improved elasticity, durability, and resistance to deformation under stress.

- Resilient cross-linked polymers in tire manufacturing: Cross-linked polymers are utilized in tire manufacturing to improve resilience and overall performance. These materials contribute to enhanced tire durability, reduced rolling resistance, and improved traction. The cross-linking process is optimized to balance resilience with other critical tire properties.

- Self-healing cross-linked polymers for increased resilience: Self-healing cross-linked polymers are developed to enhance material resilience through autonomous repair mechanisms. These polymers incorporate dynamic covalent bonds or other reversible cross-linking strategies, allowing them to recover from damage and maintain their resilient properties over extended periods of use.

- Nanocomposite cross-linked polymers for enhanced resilience: Nanocomposite cross-linked polymers are engineered to achieve superior resilience by incorporating nanoscale fillers or reinforcements. These materials combine the benefits of cross-linking with the unique properties of nanoparticles, resulting in improved mechanical strength, elasticity, and overall resilience.

- Environmentally-friendly resilient cross-linked polymers: Research focuses on developing environmentally-friendly cross-linked polymers with high resilience. These materials utilize bio-based monomers, sustainable cross-linking agents, or recyclable polymer systems to achieve desired resilience properties while minimizing environmental impact.

02 Resilient cross-linked polymers in tire manufacturing

Cross-linked polymers are utilized in tire manufacturing to improve resilience and overall performance. These materials contribute to enhanced tread durability, reduced rolling resistance, and improved grip in various driving conditions. The cross-linking process is optimized to balance resilience with other essential tire properties.Expand Specific Solutions03 Self-healing cross-linked polymers for increased resilience

Self-healing cross-linked polymers are developed to enhance material resilience through autonomous repair mechanisms. These polymers incorporate dynamic covalent bonds or encapsulated healing agents that can restore mechanical properties after damage, leading to improved longevity and sustained resilience under repeated stress.Expand Specific Solutions04 Nanocomposite cross-linked polymers for enhanced resilience

Nanocomposite cross-linked polymers are engineered to achieve superior resilience by incorporating nanoscale fillers or reinforcements. These materials combine the benefits of cross-linking with the unique properties of nanoparticles, resulting in improved mechanical strength, elasticity, and resistance to environmental factors.Expand Specific Solutions05 Environmentally-friendly cross-linked polymers with high resilience

Research focuses on developing environmentally-friendly cross-linked polymers that maintain high resilience. These materials utilize bio-based monomers, sustainable cross-linking agents, or recyclable polymer systems to reduce environmental impact while preserving the desired resilient properties for various applications.Expand Specific Solutions

Key Players in Polymer and Valve Industries

The investigation of cross-link polymer effects on gate valve resilience is currently in a growth phase, with increasing market demand driven by industrial applications. The global market for advanced polymer materials in valve manufacturing is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is progressing rapidly, with companies like AGC, Inc., DAIKIN INDUSTRIES Ltd., and Wacker Chemie AG leading innovation in polymer development. These firms are investing heavily in R&D to enhance polymer properties for improved valve performance. While the technology is advancing, it's not yet fully mature, leaving room for further developments in cross-linking techniques and material optimization. Collaboration between academic institutions and industry players is accelerating progress in this field.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed advanced cross-linked polymer formulations specifically designed for gate valve applications. Their approach involves incorporating fluoropolymer-based materials with enhanced cross-linking density to improve resilience and chemical resistance. The company utilizes a proprietary blend of perfluoroelastomers (FFKM) and fluoroelastomers (FKM) to create a hybrid material that combines the best properties of both[1]. This cross-linked polymer system demonstrates superior resistance to high temperatures, aggressive chemicals, and mechanical stress, making it ideal for demanding valve environments[2]. Dow's technology also incorporates nano-scale reinforcement particles to further enhance the material's strength and durability[3].

Strengths: Excellent chemical and temperature resistance, improved mechanical properties, and long-term durability. Weaknesses: Potentially higher production costs and more complex manufacturing process compared to traditional materials.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed a novel silicone-based cross-linked polymer system for gate valve applications. Their approach utilizes room-temperature vulcanizing (RTV) silicone elastomers with tailored cross-linking agents to achieve optimal resilience and sealing properties. The company's technology incorporates a unique combination of reinforcing silica fillers and proprietary cross-linking catalysts to enhance the material's mechanical strength and chemical resistance[4]. Wacker's cross-linked silicone polymers exhibit excellent compression set resistance and maintain their elastic properties over a wide temperature range, making them suitable for various industrial valve applications[5]. The company has also developed specialized surface treatment techniques to improve the adhesion of their silicone materials to metal valve components, ensuring long-term performance and reliability[6].

Strengths: Excellent temperature resistance, good compression set properties, and versatile application range. Weaknesses: May have lower chemical resistance compared to fluoropolymer-based solutions in certain aggressive environments.

Core Innovations in Polymer-Enhanced Valve Design

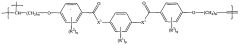

Reversible stress-responsive material, preparation method, and use thereof

PatentActiveUS20230391963A1

Innovation

- A reversible stress-responsive material is developed using N-(1H-2-phenyl-indole-3-methyl)acrylamide (NPI) and N-(1H-indole-3-methyl)acrylamide (NIAM) as indolyl structural units, combined with linear polymers and initiators, to create a prepolymer solution that undergoes specific heating and reaction steps, allowing for room-temperature reversible C—N covalent crosslinking through triazolinedione-indole click chemistry.

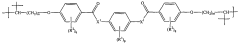

Crosslinked liquid crystalline polymer, method for the preparation thereof, and articles derived therefrom

PatentWO2006086011A2

Innovation

- Development of crosslinked liquid crystalline polymers that demonstrate both one-way and two-way shape memory effects at distinct transition temperatures, allowing for transformation between three shapes: one stable below the first temperature, one between the two transition temperatures, and another above the higher temperature, triggered by heating or environmental stimuli.

Environmental Impact of Polymer-Enhanced Valves

The environmental impact of polymer-enhanced valves is a critical consideration in the development and implementation of cross-linked polymer technologies for gate valve resilience. These advanced valves offer improved performance and longevity, but their environmental footprint must be carefully assessed throughout their lifecycle.

During the manufacturing process, the production of cross-linked polymers may involve the use of various chemicals and energy-intensive processes. This can lead to increased carbon emissions and potential chemical waste. However, advancements in green chemistry and sustainable manufacturing practices are gradually mitigating these concerns. Manufacturers are increasingly adopting eco-friendly production methods, such as using bio-based polymers or implementing closed-loop recycling systems to minimize waste.

The enhanced durability of polymer-enhanced valves contributes positively to their environmental profile. By extending the operational lifespan of gate valves, these innovations reduce the frequency of replacements, thereby decreasing the overall resource consumption and waste generation associated with valve production and disposal. This longevity factor is particularly significant in industries where valve failures can lead to costly shutdowns or environmental hazards.

In terms of operational efficiency, polymer-enhanced valves often demonstrate improved sealing capabilities and reduced friction. This can result in lower energy consumption during valve operation, particularly in high-pressure or high-temperature applications. The reduced energy demand translates to a smaller carbon footprint over the valve's operational life.

End-of-life considerations for polymer-enhanced valves present both challenges and opportunities. While traditional metal valves are more readily recyclable, the complex composition of polymer-enhanced valves may complicate recycling processes. However, emerging technologies in polymer recycling and the development of biodegradable cross-linked polymers show promise in addressing these end-of-life issues.

The use of polymer-enhanced valves in sensitive environments, such as water treatment facilities or chemical plants, raises questions about potential leaching of polymer components. Rigorous testing and compliance with environmental regulations are essential to ensure that these valves do not introduce harmful substances into the ecosystem. Ongoing research focuses on developing polymers that maintain their performance characteristics while minimizing environmental risks.

In conclusion, while polymer-enhanced valves offer significant performance benefits, their environmental impact is multifaceted. The industry continues to strive for a balance between technological advancement and environmental stewardship, with ongoing efforts to improve the sustainability of these innovative valve solutions throughout their lifecycle.

During the manufacturing process, the production of cross-linked polymers may involve the use of various chemicals and energy-intensive processes. This can lead to increased carbon emissions and potential chemical waste. However, advancements in green chemistry and sustainable manufacturing practices are gradually mitigating these concerns. Manufacturers are increasingly adopting eco-friendly production methods, such as using bio-based polymers or implementing closed-loop recycling systems to minimize waste.

The enhanced durability of polymer-enhanced valves contributes positively to their environmental profile. By extending the operational lifespan of gate valves, these innovations reduce the frequency of replacements, thereby decreasing the overall resource consumption and waste generation associated with valve production and disposal. This longevity factor is particularly significant in industries where valve failures can lead to costly shutdowns or environmental hazards.

In terms of operational efficiency, polymer-enhanced valves often demonstrate improved sealing capabilities and reduced friction. This can result in lower energy consumption during valve operation, particularly in high-pressure or high-temperature applications. The reduced energy demand translates to a smaller carbon footprint over the valve's operational life.

End-of-life considerations for polymer-enhanced valves present both challenges and opportunities. While traditional metal valves are more readily recyclable, the complex composition of polymer-enhanced valves may complicate recycling processes. However, emerging technologies in polymer recycling and the development of biodegradable cross-linked polymers show promise in addressing these end-of-life issues.

The use of polymer-enhanced valves in sensitive environments, such as water treatment facilities or chemical plants, raises questions about potential leaching of polymer components. Rigorous testing and compliance with environmental regulations are essential to ensure that these valves do not introduce harmful substances into the ecosystem. Ongoing research focuses on developing polymers that maintain their performance characteristics while minimizing environmental risks.

In conclusion, while polymer-enhanced valves offer significant performance benefits, their environmental impact is multifaceted. The industry continues to strive for a balance between technological advancement and environmental stewardship, with ongoing efforts to improve the sustainability of these innovative valve solutions throughout their lifecycle.

Regulatory Landscape for Industrial Valve Materials

The regulatory landscape for industrial valve materials is complex and multifaceted, encompassing various standards, guidelines, and regulations set by international, national, and industry-specific bodies. These regulations are designed to ensure the safety, reliability, and performance of valves used in critical industrial applications, including those involving cross-link polymers and gate valves.

At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) play crucial roles in establishing global standards for valve materials. ISO 10497, for instance, specifies the testing of valves for fire resistance, which is particularly relevant when considering the resilience of gate valves exposed to extreme conditions. ASME B16.34 provides standards for pressure-temperature ratings, materials, design, and testing of valves used in various industries.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) set regulations that impact the selection and use of valve materials. The EPA's regulations on fugitive emissions, for example, have led to the development of low-emission valve designs, which may incorporate cross-link polymers for improved sealing properties.

The European Union's Pressure Equipment Directive (PED) 2014/68/EU is another significant regulatory framework that affects valve materials. This directive sets out essential safety requirements for pressure equipment, including valves, and mandates CE marking for products that meet these standards. The directive's requirements often necessitate the use of advanced materials, such as cross-link polymers, to achieve the required performance characteristics.

Industry-specific regulations also play a vital role in shaping the landscape for valve materials. In the oil and gas sector, for instance, the American Petroleum Institute (API) sets standards such as API 6D for pipeline valves, which includes specifications for materials used in gate valves. Similarly, the nuclear industry has its own set of stringent regulations, such as those outlined by the Nuclear Regulatory Commission (NRC) in the United States, which may influence the use of cross-link polymers in valve applications.

The chemical industry, where corrosion resistance is often a critical factor, is guided by regulations from organizations like the Chemical Industries Association (CIA) and the European Chemical Industry Council (CEFIC). These bodies provide guidelines on material selection for valves exposed to aggressive chemical environments, potentially influencing the adoption of cross-link polymers for their enhanced chemical resistance properties.

As research into cross-link polymer effects on gate valve resilience progresses, it is essential to consider how these innovations align with existing regulatory frameworks and whether they may necessitate updates to current standards. Regulatory bodies are increasingly focusing on lifecycle performance and sustainability, which may create new opportunities for advanced materials like cross-link polymers in valve applications.

At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) play crucial roles in establishing global standards for valve materials. ISO 10497, for instance, specifies the testing of valves for fire resistance, which is particularly relevant when considering the resilience of gate valves exposed to extreme conditions. ASME B16.34 provides standards for pressure-temperature ratings, materials, design, and testing of valves used in various industries.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) set regulations that impact the selection and use of valve materials. The EPA's regulations on fugitive emissions, for example, have led to the development of low-emission valve designs, which may incorporate cross-link polymers for improved sealing properties.

The European Union's Pressure Equipment Directive (PED) 2014/68/EU is another significant regulatory framework that affects valve materials. This directive sets out essential safety requirements for pressure equipment, including valves, and mandates CE marking for products that meet these standards. The directive's requirements often necessitate the use of advanced materials, such as cross-link polymers, to achieve the required performance characteristics.

Industry-specific regulations also play a vital role in shaping the landscape for valve materials. In the oil and gas sector, for instance, the American Petroleum Institute (API) sets standards such as API 6D for pipeline valves, which includes specifications for materials used in gate valves. Similarly, the nuclear industry has its own set of stringent regulations, such as those outlined by the Nuclear Regulatory Commission (NRC) in the United States, which may influence the use of cross-link polymers in valve applications.

The chemical industry, where corrosion resistance is often a critical factor, is guided by regulations from organizations like the Chemical Industries Association (CIA) and the European Chemical Industry Council (CEFIC). These bodies provide guidelines on material selection for valves exposed to aggressive chemical environments, potentially influencing the adoption of cross-link polymers for their enhanced chemical resistance properties.

As research into cross-link polymer effects on gate valve resilience progresses, it is essential to consider how these innovations align with existing regulatory frameworks and whether they may necessitate updates to current standards. Regulatory bodies are increasingly focusing on lifecycle performance and sustainability, which may create new opportunities for advanced materials like cross-link polymers in valve applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!