Gate valve configurations minimizing energy loss in distributed pump networks

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution

Gate valves have undergone significant evolution since their inception, driven by the need for improved efficiency and reduced energy loss in distributed pump networks. The early designs of gate valves were simple, featuring a wedge-shaped disc that moved perpendicular to the flow path. These valves were effective for on/off control but lacked precision in flow regulation and often resulted in substantial energy losses.

As industrial processes became more complex and energy efficiency gained importance, gate valve designs began to incorporate innovations aimed at minimizing turbulence and pressure drop. The introduction of parallel-sided gates in the mid-20th century marked a significant improvement, allowing for smoother flow characteristics and reduced energy loss when the valve was partially open.

The late 20th century saw the development of advanced sealing technologies, such as resilient-seated gate valves, which provided better shut-off capabilities and reduced leakage. This innovation not only improved the overall efficiency of pump networks but also extended the operational life of the valves, reducing maintenance requirements and associated energy costs.

In recent decades, the focus has shifted towards optimizing the internal geometry of gate valves to further minimize energy loss. Computational fluid dynamics (CFD) simulations have played a crucial role in this evolution, allowing engineers to model and analyze flow patterns within the valve body. This has led to the development of streamlined gate designs and optimized flow paths that significantly reduce turbulence and pressure drop.

The integration of smart technologies has been another milestone in gate valve evolution. The incorporation of sensors and actuators has enabled real-time monitoring and precise control of valve positions, allowing for dynamic adjustments to optimize flow rates and minimize energy consumption in distributed pump networks.

Material science advancements have also contributed to gate valve improvements. The use of low-friction materials for valve seats and gates has reduced the force required for valve operation, thereby decreasing the energy needed for actuation. Additionally, corrosion-resistant alloys have extended valve lifespan and maintained efficiency over longer periods.

Recent innovations have focused on the development of variable-geometry gate valves, which can adapt their internal configuration based on flow conditions. These adaptive designs promise to provide optimal energy efficiency across a wide range of operating scenarios, representing a significant leap forward in minimizing energy loss in distributed pump networks.

As the demand for energy-efficient solutions continues to grow, gate valve evolution is likely to accelerate. Future developments may include the integration of artificial intelligence for predictive maintenance and autonomous optimization, further enhancing the role of gate valves in minimizing energy loss and improving overall system efficiency in distributed pump networks.

As industrial processes became more complex and energy efficiency gained importance, gate valve designs began to incorporate innovations aimed at minimizing turbulence and pressure drop. The introduction of parallel-sided gates in the mid-20th century marked a significant improvement, allowing for smoother flow characteristics and reduced energy loss when the valve was partially open.

The late 20th century saw the development of advanced sealing technologies, such as resilient-seated gate valves, which provided better shut-off capabilities and reduced leakage. This innovation not only improved the overall efficiency of pump networks but also extended the operational life of the valves, reducing maintenance requirements and associated energy costs.

In recent decades, the focus has shifted towards optimizing the internal geometry of gate valves to further minimize energy loss. Computational fluid dynamics (CFD) simulations have played a crucial role in this evolution, allowing engineers to model and analyze flow patterns within the valve body. This has led to the development of streamlined gate designs and optimized flow paths that significantly reduce turbulence and pressure drop.

The integration of smart technologies has been another milestone in gate valve evolution. The incorporation of sensors and actuators has enabled real-time monitoring and precise control of valve positions, allowing for dynamic adjustments to optimize flow rates and minimize energy consumption in distributed pump networks.

Material science advancements have also contributed to gate valve improvements. The use of low-friction materials for valve seats and gates has reduced the force required for valve operation, thereby decreasing the energy needed for actuation. Additionally, corrosion-resistant alloys have extended valve lifespan and maintained efficiency over longer periods.

Recent innovations have focused on the development of variable-geometry gate valves, which can adapt their internal configuration based on flow conditions. These adaptive designs promise to provide optimal energy efficiency across a wide range of operating scenarios, representing a significant leap forward in minimizing energy loss in distributed pump networks.

As the demand for energy-efficient solutions continues to grow, gate valve evolution is likely to accelerate. Future developments may include the integration of artificial intelligence for predictive maintenance and autonomous optimization, further enhancing the role of gate valves in minimizing energy loss and improving overall system efficiency in distributed pump networks.

Pump Network Demands

The demand for efficient pump networks in distributed systems has grown significantly in recent years, driven by the need for energy conservation and cost reduction across various industries. These networks are crucial in applications ranging from municipal water distribution to industrial processes, where the optimization of fluid transport is paramount. The market for pump network solutions is expanding, with a particular focus on technologies that can minimize energy losses and improve overall system efficiency.

In the water distribution sector, there is a growing demand for smart pump networks that can adapt to changing consumption patterns and reduce water loss. Municipalities and water utilities are increasingly investing in advanced pump control systems and valve configurations to optimize their distribution networks. This trend is partly driven by urbanization and the need to modernize aging infrastructure in many cities worldwide.

The industrial sector presents another significant market for optimized pump networks. Manufacturing plants, chemical processing facilities, and oil refineries all rely heavily on efficient fluid transport systems. These industries are seeking solutions that can reduce energy consumption, minimize downtime, and improve process control. The demand for gate valve configurations that can minimize energy loss is particularly high in these applications, where even small improvements in efficiency can lead to substantial cost savings over time.

In the agricultural sector, there is an increasing need for efficient irrigation systems that can deliver water precisely where and when it is needed. Farmers and agribusinesses are looking for pump network solutions that can reduce water waste and energy consumption while improving crop yields. This demand is driven by factors such as water scarcity, rising energy costs, and the push for more sustainable farming practices.

The healthcare industry also presents a growing market for optimized pump networks, particularly in large hospital complexes and pharmaceutical manufacturing facilities. These environments require precise control of fluid distribution for various applications, from HVAC systems to sterile processing. The demand for energy-efficient and reliable pump networks in healthcare settings is expected to increase as the industry continues to expand and modernize its infrastructure.

As environmental regulations become more stringent worldwide, there is a rising demand for pump network solutions that can help organizations meet sustainability goals and comply with energy efficiency standards. This trend is driving innovation in valve design and control systems, with a focus on minimizing energy loss and reducing carbon footprints.

The market for pump network optimization is also being shaped by the growing adoption of Internet of Things (IoT) technologies and data analytics. There is an increasing demand for smart, connected pump systems that can provide real-time monitoring, predictive maintenance, and automated optimization. This trend is expected to accelerate as more industries embrace digital transformation and seek to leverage data-driven insights to improve their operations.

In the water distribution sector, there is a growing demand for smart pump networks that can adapt to changing consumption patterns and reduce water loss. Municipalities and water utilities are increasingly investing in advanced pump control systems and valve configurations to optimize their distribution networks. This trend is partly driven by urbanization and the need to modernize aging infrastructure in many cities worldwide.

The industrial sector presents another significant market for optimized pump networks. Manufacturing plants, chemical processing facilities, and oil refineries all rely heavily on efficient fluid transport systems. These industries are seeking solutions that can reduce energy consumption, minimize downtime, and improve process control. The demand for gate valve configurations that can minimize energy loss is particularly high in these applications, where even small improvements in efficiency can lead to substantial cost savings over time.

In the agricultural sector, there is an increasing need for efficient irrigation systems that can deliver water precisely where and when it is needed. Farmers and agribusinesses are looking for pump network solutions that can reduce water waste and energy consumption while improving crop yields. This demand is driven by factors such as water scarcity, rising energy costs, and the push for more sustainable farming practices.

The healthcare industry also presents a growing market for optimized pump networks, particularly in large hospital complexes and pharmaceutical manufacturing facilities. These environments require precise control of fluid distribution for various applications, from HVAC systems to sterile processing. The demand for energy-efficient and reliable pump networks in healthcare settings is expected to increase as the industry continues to expand and modernize its infrastructure.

As environmental regulations become more stringent worldwide, there is a rising demand for pump network solutions that can help organizations meet sustainability goals and comply with energy efficiency standards. This trend is driving innovation in valve design and control systems, with a focus on minimizing energy loss and reducing carbon footprints.

The market for pump network optimization is also being shaped by the growing adoption of Internet of Things (IoT) technologies and data analytics. There is an increasing demand for smart, connected pump systems that can provide real-time monitoring, predictive maintenance, and automated optimization. This trend is expected to accelerate as more industries embrace digital transformation and seek to leverage data-driven insights to improve their operations.

Valve Challenges

Gate valves in distributed pump networks face several significant challenges that can impact their performance and efficiency. One of the primary issues is the energy loss associated with valve operation. As fluid flows through a valve, it encounters resistance, leading to pressure drops and energy dissipation. This energy loss can be substantial, especially in large-scale networks, resulting in increased operational costs and reduced system efficiency.

Another challenge is the wear and tear on valve components due to frequent operation and exposure to high-pressure fluids. Over time, this can lead to leakage, reduced sealing effectiveness, and increased maintenance requirements. The need for regular maintenance and replacement of valve parts can result in system downtime and additional expenses.

Valve sizing and selection present another set of challenges. Improper sizing can lead to inadequate flow control, excessive pressure drops, or cavitation. Selecting the right valve for specific applications requires careful consideration of factors such as flow rates, pressure ratings, and fluid properties. Mismatched valves can lead to poor performance and increased energy consumption.

Control and automation of gate valves in distributed networks pose additional challenges. Implementing precise control strategies to optimize flow distribution and minimize energy loss across the network can be complex. This is particularly true in dynamic systems where demand fluctuates, requiring real-time adjustments to valve positions.

Corrosion and erosion of valve materials are ongoing concerns, especially in networks handling aggressive or abrasive fluids. These issues can compromise valve integrity, leading to premature failure and potential safety hazards. Selecting appropriate materials and protective coatings is crucial but can significantly impact costs.

The installation and maintenance of gate valves in distributed networks also present logistical challenges. Access to valves for inspection and repair may be limited, particularly in underground or remote locations. This can complicate maintenance procedures and increase associated costs.

Lastly, the integration of smart technologies and IoT capabilities into gate valves, while offering potential benefits in terms of monitoring and control, introduces new challenges related to cybersecurity, data management, and system compatibility. Ensuring the reliability and security of these advanced valve systems is crucial for maintaining the integrity of the entire network.

Addressing these challenges requires a multifaceted approach, combining innovative valve designs, advanced materials, intelligent control systems, and comprehensive maintenance strategies. By focusing on these areas, it is possible to develop gate valve configurations that minimize energy loss and enhance the overall efficiency of distributed pump networks.

Another challenge is the wear and tear on valve components due to frequent operation and exposure to high-pressure fluids. Over time, this can lead to leakage, reduced sealing effectiveness, and increased maintenance requirements. The need for regular maintenance and replacement of valve parts can result in system downtime and additional expenses.

Valve sizing and selection present another set of challenges. Improper sizing can lead to inadequate flow control, excessive pressure drops, or cavitation. Selecting the right valve for specific applications requires careful consideration of factors such as flow rates, pressure ratings, and fluid properties. Mismatched valves can lead to poor performance and increased energy consumption.

Control and automation of gate valves in distributed networks pose additional challenges. Implementing precise control strategies to optimize flow distribution and minimize energy loss across the network can be complex. This is particularly true in dynamic systems where demand fluctuates, requiring real-time adjustments to valve positions.

Corrosion and erosion of valve materials are ongoing concerns, especially in networks handling aggressive or abrasive fluids. These issues can compromise valve integrity, leading to premature failure and potential safety hazards. Selecting appropriate materials and protective coatings is crucial but can significantly impact costs.

The installation and maintenance of gate valves in distributed networks also present logistical challenges. Access to valves for inspection and repair may be limited, particularly in underground or remote locations. This can complicate maintenance procedures and increase associated costs.

Lastly, the integration of smart technologies and IoT capabilities into gate valves, while offering potential benefits in terms of monitoring and control, introduces new challenges related to cybersecurity, data management, and system compatibility. Ensuring the reliability and security of these advanced valve systems is crucial for maintaining the integrity of the entire network.

Addressing these challenges requires a multifaceted approach, combining innovative valve designs, advanced materials, intelligent control systems, and comprehensive maintenance strategies. By focusing on these areas, it is possible to develop gate valve configurations that minimize energy loss and enhance the overall efficiency of distributed pump networks.

Current Solutions

01 Valve design optimization for energy loss reduction

Gate valve designs can be optimized to reduce energy loss by improving flow characteristics and minimizing turbulence. This includes modifications to the valve body, gate, and seat to create smoother flow paths and reduce pressure drops across the valve.- Valve design optimization for energy loss reduction: Gate valve designs are optimized to reduce energy loss by improving flow characteristics and minimizing turbulence. This includes modifications to the valve body, gate, and seat to create smoother flow paths and reduce pressure drops across the valve.

- Advanced sealing mechanisms to prevent leakage: Innovative sealing technologies are implemented in gate valves to minimize energy loss due to leakage. These may include improved seat designs, advanced sealing materials, and pressure-responsive sealing mechanisms that adapt to varying operating conditions.

- Smart control systems for optimized valve operation: Integration of smart control systems and sensors in gate valves allows for real-time monitoring and adjustment of valve position, flow rates, and pressure differentials. This helps optimize valve operation and reduce energy losses associated with suboptimal valve settings.

- Material selection for improved performance: Careful selection of materials for valve components, such as low-friction coatings and wear-resistant alloys, helps reduce friction and erosion. This contributes to lower energy losses and extended valve life in various operating conditions.

- Flow path geometry optimization: Advanced computational fluid dynamics (CFD) analysis is used to optimize the internal geometry of gate valves. This includes streamlining flow paths, reducing sharp edges, and designing contoured surfaces to minimize turbulence and pressure drops, thereby reducing overall energy loss.

02 Smart control systems for gate valves

Implementation of smart control systems in gate valves can help minimize energy loss by optimizing valve operation based on real-time flow conditions. These systems can adjust valve positions and control flow rates to maintain efficiency and reduce unnecessary pressure drops.Expand Specific Solutions03 Sealing technology improvements

Advanced sealing technologies in gate valves can significantly reduce energy loss by preventing leakage and maintaining tight shut-off. Improved sealing materials and designs help maintain system pressure and minimize fluid loss, contributing to overall energy efficiency.Expand Specific Solutions04 Valve actuation and positioning systems

Efficient valve actuation and positioning systems can reduce energy loss in gate valves by ensuring precise control and minimizing unnecessary movement. These systems can include electric, hydraulic, or pneumatic actuators with advanced positioning capabilities to optimize flow control and reduce energy consumption.Expand Specific Solutions05 Flow path and geometry optimization

Optimizing the internal flow path and geometry of gate valves can significantly reduce energy loss. This includes streamlining the valve body, improving gate design, and enhancing seat configurations to minimize turbulence, reduce pressure drops, and improve overall flow efficiency.Expand Specific Solutions

Industry Leaders

The gate valve configuration market for distributed pump networks is in a growth phase, driven by increasing demand for energy-efficient solutions in industrial and municipal applications. The market size is expanding, with a focus on minimizing energy loss in fluid distribution systems. Technologically, the field is advancing rapidly, with companies like State Grid Corp. of China, ABB Group, and Siemens AG leading innovation. These firms are developing sophisticated valve designs and control systems to optimize flow and reduce energy consumption. Emerging players such as Bunt Planet and United Silicon Carbide are also contributing to technological advancements, particularly in smart valve solutions and power electronics for improved valve control.

ABB Group

Technical Solution: ABB Group has innovated in gate valve configurations for distributed pump networks with their Energy Saving Valve (ESV) technology. The ESV system combines advanced flow control algorithms with high-precision actuation to maintain optimal pressure differentials across the network[2]. ABB's solution incorporates a unique valve trim design that allows for more precise flow control at partial valve openings, reducing energy waste from excessive throttling. The system also features adaptive control capabilities that automatically adjust to changes in network conditions, ensuring consistent energy efficiency across varying demand scenarios[4]. Furthermore, ABB has integrated their valve technology with their distributed control systems, enabling seamless coordination with pump speed control for holistic network optimization.

Strengths: High precision control and seamless integration with existing ABB systems. Weaknesses: May be less flexible for integration with non-ABB equipment.

Siemens AG

Technical Solution: Siemens AG has developed advanced gate valve configurations for distributed pump networks that significantly reduce energy loss. Their solution incorporates smart valve technology with integrated sensors and actuators, allowing for real-time flow control and pressure optimization[1]. The system uses machine learning algorithms to predict network demand patterns and adjust valve positions accordingly, minimizing friction losses and pump energy consumption[3]. Siemens' gate valves feature a streamlined internal geometry that reduces turbulence and pressure drop across the valve. Additionally, they have implemented a distributed control architecture that enables coordinated operation of multiple valves across the network, further enhancing overall system efficiency[5].

Strengths: Comprehensive solution integrating smart technology and optimized valve design. Weaknesses: May require significant initial investment and infrastructure upgrades.

Innovative Designs

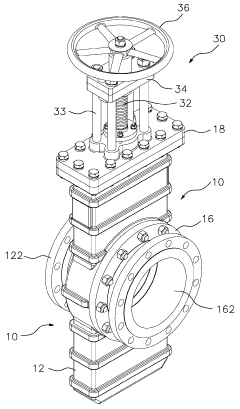

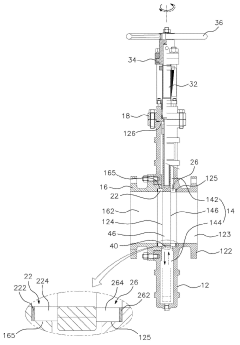

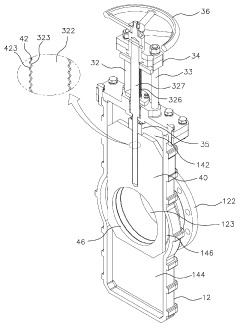

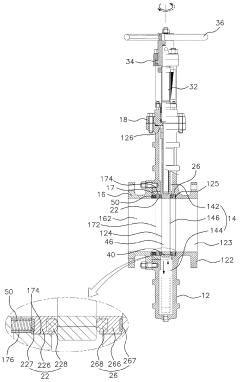

Gate valve able to minimized pressure loss in flow fluid

PatentInactiveKR1020200028682A

Innovation

- A gate valve design with vertically symmetrical structure, seat rings, and elastic means to prevent fluid inflow into sliding spaces, using detachable flanges and seat rings to maintain airtightness and minimize pressure loss.

Hydraulic system comprising pump-loss-minimising clutch actuation

PatentActiveEP3303867A1

Innovation

- A hydraulic system with a line assembly featuring a non-return valve and a two-way spool-type valve with seals, where the system builds up only the necessary pressure briefly and maintains it using valve connections, allowing the pump to operate at lower pressures and reducing energy consumption.

Fluid Dynamics Impact

The fluid dynamics impact of gate valve configurations in distributed pump networks is a critical factor in minimizing energy loss. The design and placement of gate valves significantly influence the flow characteristics, pressure distribution, and overall efficiency of the system.

In distributed pump networks, the primary concern is maintaining optimal flow rates while reducing energy consumption. Gate valves, when strategically positioned and configured, can help achieve this balance. The key lies in understanding how these valves affect the fluid dynamics within the network.

One of the main considerations is the valve's opening and closing mechanism. Traditional gate valves operate on a linear motion, which can create sudden changes in flow patterns. This abrupt alteration in fluid dynamics can lead to turbulence, pressure drops, and increased energy loss. Advanced gate valve designs incorporate features that promote smoother transitions, such as contoured gate edges or multi-stage opening processes.

The orientation of gate valves relative to the flow direction also plays a crucial role. Valves positioned perpendicular to the flow can cause significant disruption, while those aligned parallel or at optimized angles can minimize turbulence and reduce energy loss. Computational fluid dynamics (CFD) simulations have proven invaluable in determining the most efficient valve orientations for specific network configurations.

Another important aspect is the valve's internal geometry. The shape and size of the flow path through the valve can greatly impact the fluid's behavior. Streamlined internal passages and gradually changing cross-sections help maintain laminar flow, reducing friction and energy loss. Some innovative designs incorporate variable geometry that adapts to different flow conditions, further optimizing performance across a range of operating scenarios.

The material selection for gate valves also influences fluid dynamics. Smooth, low-friction surfaces reduce drag and minimize energy loss due to fluid-wall interactions. Advanced coatings and surface treatments can enhance these properties, leading to improved overall system efficiency.

In complex distributed pump networks, the cumulative effect of multiple gate valves becomes a significant factor. The interaction between valves and their collective impact on system-wide fluid dynamics must be carefully considered. Optimization algorithms and machine learning techniques are increasingly being employed to determine the ideal configuration of multiple valves within a network, balancing local and global efficiency considerations.

By addressing these fluid dynamics aspects in gate valve design and configuration, significant reductions in energy loss can be achieved in distributed pump networks. This not only leads to improved operational efficiency but also contributes to reduced environmental impact and lower operational costs for industries relying on these systems.

In distributed pump networks, the primary concern is maintaining optimal flow rates while reducing energy consumption. Gate valves, when strategically positioned and configured, can help achieve this balance. The key lies in understanding how these valves affect the fluid dynamics within the network.

One of the main considerations is the valve's opening and closing mechanism. Traditional gate valves operate on a linear motion, which can create sudden changes in flow patterns. This abrupt alteration in fluid dynamics can lead to turbulence, pressure drops, and increased energy loss. Advanced gate valve designs incorporate features that promote smoother transitions, such as contoured gate edges or multi-stage opening processes.

The orientation of gate valves relative to the flow direction also plays a crucial role. Valves positioned perpendicular to the flow can cause significant disruption, while those aligned parallel or at optimized angles can minimize turbulence and reduce energy loss. Computational fluid dynamics (CFD) simulations have proven invaluable in determining the most efficient valve orientations for specific network configurations.

Another important aspect is the valve's internal geometry. The shape and size of the flow path through the valve can greatly impact the fluid's behavior. Streamlined internal passages and gradually changing cross-sections help maintain laminar flow, reducing friction and energy loss. Some innovative designs incorporate variable geometry that adapts to different flow conditions, further optimizing performance across a range of operating scenarios.

The material selection for gate valves also influences fluid dynamics. Smooth, low-friction surfaces reduce drag and minimize energy loss due to fluid-wall interactions. Advanced coatings and surface treatments can enhance these properties, leading to improved overall system efficiency.

In complex distributed pump networks, the cumulative effect of multiple gate valves becomes a significant factor. The interaction between valves and their collective impact on system-wide fluid dynamics must be carefully considered. Optimization algorithms and machine learning techniques are increasingly being employed to determine the ideal configuration of multiple valves within a network, balancing local and global efficiency considerations.

By addressing these fluid dynamics aspects in gate valve design and configuration, significant reductions in energy loss can be achieved in distributed pump networks. This not only leads to improved operational efficiency but also contributes to reduced environmental impact and lower operational costs for industries relying on these systems.

Maintenance Strategies

Effective maintenance strategies are crucial for optimizing the performance and longevity of gate valve configurations in distributed pump networks. Regular inspection and preventive maintenance form the cornerstone of these strategies, ensuring that valves operate efficiently and minimize energy loss. Scheduled inspections should focus on identifying signs of wear, corrosion, or misalignment that could lead to increased friction and energy dissipation.

Predictive maintenance techniques, leveraging advanced sensors and data analytics, can provide real-time insights into valve performance. By monitoring parameters such as pressure differentials, flow rates, and actuator response times, operators can detect potential issues before they escalate into major problems. This proactive approach not only reduces energy loss but also prevents unexpected downtime and costly repairs.

Lubrication management is another critical aspect of maintenance for gate valves. Proper lubrication of moving parts reduces friction, minimizes wear, and ensures smooth operation. Implementing a systematic lubrication schedule, using appropriate lubricants for specific valve types and operating conditions, can significantly contribute to energy efficiency.

Valve seat and seal maintenance deserve special attention, as these components directly impact the valve's ability to control flow and prevent leakage. Regular cleaning, inspection, and replacement of seals and seats when necessary can prevent energy losses associated with internal leakage or incomplete closure.

Training and skill development for maintenance personnel are essential for implementing effective maintenance strategies. Technicians should be well-versed in the latest valve technologies, maintenance techniques, and energy efficiency principles. This knowledge enables them to perform maintenance tasks more effectively and identify opportunities for improving valve performance.

Documentation and record-keeping play a vital role in maintenance strategies. Maintaining detailed logs of valve performance, maintenance activities, and energy consumption patterns allows for trend analysis and informed decision-making. This data can be used to optimize maintenance schedules, identify recurring issues, and justify investments in more energy-efficient valve configurations.

Lastly, periodic system-wide audits should be conducted to assess the overall health and efficiency of the gate valve network. These audits can reveal systemic issues, identify valves that consistently underperform, and guide decisions on valve replacements or upgrades to more energy-efficient models. By adopting a holistic approach to maintenance, operators can ensure that gate valve configurations continue to minimize energy loss and contribute to the overall efficiency of distributed pump networks.

Predictive maintenance techniques, leveraging advanced sensors and data analytics, can provide real-time insights into valve performance. By monitoring parameters such as pressure differentials, flow rates, and actuator response times, operators can detect potential issues before they escalate into major problems. This proactive approach not only reduces energy loss but also prevents unexpected downtime and costly repairs.

Lubrication management is another critical aspect of maintenance for gate valves. Proper lubrication of moving parts reduces friction, minimizes wear, and ensures smooth operation. Implementing a systematic lubrication schedule, using appropriate lubricants for specific valve types and operating conditions, can significantly contribute to energy efficiency.

Valve seat and seal maintenance deserve special attention, as these components directly impact the valve's ability to control flow and prevent leakage. Regular cleaning, inspection, and replacement of seals and seats when necessary can prevent energy losses associated with internal leakage or incomplete closure.

Training and skill development for maintenance personnel are essential for implementing effective maintenance strategies. Technicians should be well-versed in the latest valve technologies, maintenance techniques, and energy efficiency principles. This knowledge enables them to perform maintenance tasks more effectively and identify opportunities for improving valve performance.

Documentation and record-keeping play a vital role in maintenance strategies. Maintaining detailed logs of valve performance, maintenance activities, and energy consumption patterns allows for trend analysis and informed decision-making. This data can be used to optimize maintenance schedules, identify recurring issues, and justify investments in more energy-efficient valve configurations.

Lastly, periodic system-wide audits should be conducted to assess the overall health and efficiency of the gate valve network. These audits can reveal systemic issues, identify valves that consistently underperform, and guide decisions on valve replacements or upgrades to more energy-efficient models. By adopting a holistic approach to maintenance, operators can ensure that gate valve configurations continue to minimize energy loss and contribute to the overall efficiency of distributed pump networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!