Gate valve solutions for efficient liquid nitrogen management

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Gate Valve Evolution and Objectives

Cryogenic gate valves have played a crucial role in the management of liquid nitrogen and other cryogenic fluids since the mid-20th century. The evolution of these valves has been driven by the increasing demands of industries such as aerospace, healthcare, and semiconductor manufacturing, where precise control of ultra-low temperature fluids is essential.

In the early stages of cryogenic technology, basic gate valve designs were adapted from conventional applications, often resulting in suboptimal performance due to thermal contraction and material limitations. The 1960s and 1970s saw significant advancements in metallurgy and sealing technologies, enabling the development of specialized cryogenic gate valves capable of withstanding extreme temperature fluctuations.

The introduction of advanced materials such as austenitic stainless steels and high-performance polymers in the 1980s marked a turning point in cryogenic gate valve design. These materials offered superior resistance to thermal shock and improved sealing capabilities, leading to enhanced reliability and longevity of valve components exposed to liquid nitrogen temperatures.

Throughout the 1990s and early 2000s, the focus shifted towards improving operational efficiency and reducing heat ingress. Innovations in stem sealing techniques, such as bellows seals and cryogenic packing systems, significantly minimized leakage and thermal losses. Concurrently, advancements in actuator technologies enabled more precise control and automation of cryogenic gate valves, facilitating their integration into complex liquid nitrogen management systems.

Recent developments have centered on enhancing the overall performance and versatility of cryogenic gate valves. The incorporation of smart technologies, including sensors and digital control systems, has enabled real-time monitoring and predictive maintenance, thereby improving system reliability and reducing downtime. Additionally, modular designs and standardized interfaces have been introduced to simplify installation and maintenance procedures.

Looking ahead, the objectives for cryogenic gate valve solutions in liquid nitrogen management are multifaceted. Primary goals include further minimizing heat transfer and leakage rates, extending operational lifespans, and improving overall system efficiency. There is also a growing emphasis on developing more compact and lightweight valve designs to meet the demands of space-constrained applications and emerging industries such as small-scale LNG production.

Another key objective is the integration of advanced materials and manufacturing techniques, such as 3D printing of complex valve components, to enhance performance and reduce production costs. Furthermore, the industry is striving to develop gate valve solutions that offer greater flexibility in handling varying flow rates and pressures, addressing the need for adaptable liquid nitrogen management systems across diverse applications.

In the early stages of cryogenic technology, basic gate valve designs were adapted from conventional applications, often resulting in suboptimal performance due to thermal contraction and material limitations. The 1960s and 1970s saw significant advancements in metallurgy and sealing technologies, enabling the development of specialized cryogenic gate valves capable of withstanding extreme temperature fluctuations.

The introduction of advanced materials such as austenitic stainless steels and high-performance polymers in the 1980s marked a turning point in cryogenic gate valve design. These materials offered superior resistance to thermal shock and improved sealing capabilities, leading to enhanced reliability and longevity of valve components exposed to liquid nitrogen temperatures.

Throughout the 1990s and early 2000s, the focus shifted towards improving operational efficiency and reducing heat ingress. Innovations in stem sealing techniques, such as bellows seals and cryogenic packing systems, significantly minimized leakage and thermal losses. Concurrently, advancements in actuator technologies enabled more precise control and automation of cryogenic gate valves, facilitating their integration into complex liquid nitrogen management systems.

Recent developments have centered on enhancing the overall performance and versatility of cryogenic gate valves. The incorporation of smart technologies, including sensors and digital control systems, has enabled real-time monitoring and predictive maintenance, thereby improving system reliability and reducing downtime. Additionally, modular designs and standardized interfaces have been introduced to simplify installation and maintenance procedures.

Looking ahead, the objectives for cryogenic gate valve solutions in liquid nitrogen management are multifaceted. Primary goals include further minimizing heat transfer and leakage rates, extending operational lifespans, and improving overall system efficiency. There is also a growing emphasis on developing more compact and lightweight valve designs to meet the demands of space-constrained applications and emerging industries such as small-scale LNG production.

Another key objective is the integration of advanced materials and manufacturing techniques, such as 3D printing of complex valve components, to enhance performance and reduce production costs. Furthermore, the industry is striving to develop gate valve solutions that offer greater flexibility in handling varying flow rates and pressures, addressing the need for adaptable liquid nitrogen management systems across diverse applications.

LN2 Flow Control Market Analysis

The liquid nitrogen (LN2) flow control market is experiencing significant growth driven by increasing demand across various industries, particularly in healthcare, electronics, and food processing. The global market for cryogenic valves, including those used for LN2 management, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

In the healthcare sector, the rising adoption of cryogenic technologies for medical treatments, such as cryosurgery and cryopreservation, is fueling the demand for precise LN2 flow control solutions. Hospitals, research laboratories, and biobanks are key consumers in this segment, requiring reliable gate valve systems to maintain the integrity of biological samples and ensure safe handling of liquid nitrogen.

The semiconductor industry is another major driver of the LN2 flow control market. As chip manufacturers push for smaller and more powerful processors, the need for efficient cooling solutions becomes critical. Liquid nitrogen is extensively used in the production and testing of semiconductors, creating a steady demand for advanced gate valve technologies that can withstand extreme temperatures and provide precise flow regulation.

Food processing and packaging industries are also contributing to market growth. The use of liquid nitrogen for quick freezing and preservation of food products is gaining traction, particularly in the production of frozen foods and the transportation of perishable goods. This trend is creating new opportunities for gate valve manufacturers to develop solutions tailored to the food industry's specific requirements.

Geographically, North America and Europe currently dominate the LN2 flow control market, owing to their advanced healthcare and industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare investments, and the expansion of the electronics manufacturing sector in countries like China, Japan, and South Korea.

The market is characterized by intense competition among key players, including major valve manufacturers and specialized cryogenic equipment providers. These companies are focusing on product innovation, such as the development of smart valves with integrated sensors and remote monitoring capabilities, to gain a competitive edge. Additionally, there is a growing emphasis on improving the energy efficiency and reliability of gate valve solutions to meet the stringent requirements of industries dealing with liquid nitrogen.

In the healthcare sector, the rising adoption of cryogenic technologies for medical treatments, such as cryosurgery and cryopreservation, is fueling the demand for precise LN2 flow control solutions. Hospitals, research laboratories, and biobanks are key consumers in this segment, requiring reliable gate valve systems to maintain the integrity of biological samples and ensure safe handling of liquid nitrogen.

The semiconductor industry is another major driver of the LN2 flow control market. As chip manufacturers push for smaller and more powerful processors, the need for efficient cooling solutions becomes critical. Liquid nitrogen is extensively used in the production and testing of semiconductors, creating a steady demand for advanced gate valve technologies that can withstand extreme temperatures and provide precise flow regulation.

Food processing and packaging industries are also contributing to market growth. The use of liquid nitrogen for quick freezing and preservation of food products is gaining traction, particularly in the production of frozen foods and the transportation of perishable goods. This trend is creating new opportunities for gate valve manufacturers to develop solutions tailored to the food industry's specific requirements.

Geographically, North America and Europe currently dominate the LN2 flow control market, owing to their advanced healthcare and industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare investments, and the expansion of the electronics manufacturing sector in countries like China, Japan, and South Korea.

The market is characterized by intense competition among key players, including major valve manufacturers and specialized cryogenic equipment providers. These companies are focusing on product innovation, such as the development of smart valves with integrated sensors and remote monitoring capabilities, to gain a competitive edge. Additionally, there is a growing emphasis on improving the energy efficiency and reliability of gate valve solutions to meet the stringent requirements of industries dealing with liquid nitrogen.

Gate Valve Challenges in LN2 Applications

Gate valves play a crucial role in liquid nitrogen (LN2) management systems, but their application in cryogenic environments presents unique challenges. The extreme low temperatures of LN2, typically around -196°C (-320°F), impose severe stress on valve materials and components, leading to potential failures and compromised performance.

One of the primary challenges is material selection. Traditional valve materials may become brittle or lose their mechanical properties at cryogenic temperatures, risking fractures or leaks. Specialized materials such as austenitic stainless steels, nickel alloys, or copper alloys are often required to maintain structural integrity and functionality in LN2 applications.

Thermal contraction is another significant issue. As temperatures drop, materials contract at different rates, potentially causing misalignments, gaps, or excessive stress on valve components. This can lead to leakage, increased wear, or even complete valve failure. Designers must carefully consider thermal expansion coefficients and incorporate appropriate tolerances to mitigate these effects.

Sealing presents a formidable challenge in LN2 gate valve applications. Conventional elastomeric seals become rigid and ineffective at cryogenic temperatures, necessitating the use of specialized sealing materials or metal-to-metal seals. However, achieving and maintaining a tight seal under extreme temperature fluctuations and thermal cycling remains a complex engineering task.

Lubrication is another critical concern. Standard lubricants solidify or lose their effectiveness at LN2 temperatures, potentially causing valve seizure or increased friction. Dry lubricants or specially formulated cryogenic lubricants must be employed to ensure smooth valve operation and prevent galling or cold welding of moving parts.

The formation of ice or frost on external valve components can impede operation and compromise safety. Moisture from the atmosphere can condense and freeze on exposed surfaces, potentially interfering with actuators or creating additional thermal stress. Proper insulation and design considerations are necessary to minimize these effects.

Thermal shock resistance is crucial for gate valves in LN2 systems. Rapid temperature changes, such as during system cool-down or warm-up cycles, can induce severe thermal stresses that may lead to cracking or distortion of valve components. Materials and designs must be carefully selected to withstand these thermal cycles without degradation.

Lastly, the potential for pressure build-up due to trapped LN2 vaporization poses a significant safety risk. Gate valves must incorporate appropriate pressure relief mechanisms or be designed to withstand the maximum possible pressure to prevent catastrophic failures.

One of the primary challenges is material selection. Traditional valve materials may become brittle or lose their mechanical properties at cryogenic temperatures, risking fractures or leaks. Specialized materials such as austenitic stainless steels, nickel alloys, or copper alloys are often required to maintain structural integrity and functionality in LN2 applications.

Thermal contraction is another significant issue. As temperatures drop, materials contract at different rates, potentially causing misalignments, gaps, or excessive stress on valve components. This can lead to leakage, increased wear, or even complete valve failure. Designers must carefully consider thermal expansion coefficients and incorporate appropriate tolerances to mitigate these effects.

Sealing presents a formidable challenge in LN2 gate valve applications. Conventional elastomeric seals become rigid and ineffective at cryogenic temperatures, necessitating the use of specialized sealing materials or metal-to-metal seals. However, achieving and maintaining a tight seal under extreme temperature fluctuations and thermal cycling remains a complex engineering task.

Lubrication is another critical concern. Standard lubricants solidify or lose their effectiveness at LN2 temperatures, potentially causing valve seizure or increased friction. Dry lubricants or specially formulated cryogenic lubricants must be employed to ensure smooth valve operation and prevent galling or cold welding of moving parts.

The formation of ice or frost on external valve components can impede operation and compromise safety. Moisture from the atmosphere can condense and freeze on exposed surfaces, potentially interfering with actuators or creating additional thermal stress. Proper insulation and design considerations are necessary to minimize these effects.

Thermal shock resistance is crucial for gate valves in LN2 systems. Rapid temperature changes, such as during system cool-down or warm-up cycles, can induce severe thermal stresses that may lead to cracking or distortion of valve components. Materials and designs must be carefully selected to withstand these thermal cycles without degradation.

Lastly, the potential for pressure build-up due to trapped LN2 vaporization poses a significant safety risk. Gate valves must incorporate appropriate pressure relief mechanisms or be designed to withstand the maximum possible pressure to prevent catastrophic failures.

Current LN2 Gate Valve Solutions

01 Improved valve seat design

Enhanced valve seat designs can significantly improve gate valve efficiency. This includes optimized sealing surfaces, materials selection for better wear resistance, and innovative seat configurations that reduce friction and improve sealing performance. These improvements lead to reduced leakage, longer service life, and more efficient operation of gate valves.- Improved sealing mechanisms: Gate valves with enhanced sealing mechanisms can significantly improve efficiency. These designs often incorporate advanced materials and innovative sealing structures to minimize leakage and reduce friction, resulting in better flow control and increased operational efficiency.

- Optimized gate design: Efficiency of gate valves can be improved through optimized gate designs. This includes modifications to the gate shape, surface finish, and material selection to reduce resistance and improve flow characteristics. Such designs can lead to reduced pressure drop and increased overall valve efficiency.

- Advanced actuation systems: Incorporating advanced actuation systems in gate valves can enhance their efficiency. These may include electric, hydraulic, or pneumatic actuators with improved control mechanisms, allowing for more precise and responsive valve operation. This results in better flow regulation and reduced energy consumption.

- Flow path optimization: Optimizing the internal flow path of gate valves can significantly improve their efficiency. This involves redesigning the valve body and internal components to minimize turbulence, reduce pressure drop, and enhance flow characteristics. Such improvements lead to better overall valve performance and energy efficiency.

- Smart valve technology: Integration of smart technologies in gate valves can greatly enhance their efficiency. This includes incorporating sensors, monitoring systems, and automated control mechanisms to optimize valve operation based on real-time data. Smart valves can adapt to changing conditions, predict maintenance needs, and improve overall system efficiency.

02 Advanced gate design and materials

Utilizing advanced gate designs and materials can enhance the efficiency of gate valves. This includes streamlined gate shapes to reduce flow resistance, use of lightweight yet durable materials, and surface treatments to improve wear resistance and reduce friction. These advancements result in smoother operation, better sealing, and increased overall valve efficiency.Expand Specific Solutions03 Optimized flow path geometry

Improving the internal geometry of gate valves can significantly enhance their efficiency. This involves designing optimized flow paths that minimize turbulence, reduce pressure drops, and improve overall fluid dynamics within the valve. Such improvements lead to better flow characteristics, reduced energy losses, and increased valve efficiency.Expand Specific Solutions04 Smart actuation and control systems

Incorporating smart actuation and control systems can greatly improve gate valve efficiency. This includes the use of advanced sensors, automated control algorithms, and precision actuators to optimize valve operation. These systems allow for more precise control, predictive maintenance, and real-time performance monitoring, resulting in improved overall valve efficiency and reliability.Expand Specific Solutions05 Sealing technology advancements

Advancements in sealing technology play a crucial role in improving gate valve efficiency. This includes the development of novel sealing materials, innovative sealing mechanisms, and improved seal designs that enhance leak-tightness and reduce friction. These advancements result in better sealing performance, reduced maintenance requirements, and increased overall valve efficiency.Expand Specific Solutions

Key Players in Cryogenic Valve Industry

The gate valve solutions for efficient liquid nitrogen management market is in a growth phase, driven by increasing demand for cryogenic applications across various industries. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficiency and safety. Key players like Air Liquide SA, Messer SE & Co. KGaA, and Iwatani Corp. are leading the market with advanced cryogenic valve solutions. Companies such as Robert Bosch GmbH and Ford Global Technologies LLC are also contributing to technological advancements in this sector, particularly in automotive and industrial applications.

Air Liquide SA

Technical Solution: Air Liquide SA has developed advanced gate valve solutions for efficient liquid nitrogen management. Their technology incorporates cryogenic-specific designs to ensure optimal performance in extreme low-temperature environments. The company's gate valves feature specialized sealing materials and thermal insulation to prevent leakage and maintain valve integrity. Air Liquide's solutions also include smart valve technology with integrated sensors for real-time monitoring and control, enabling precise flow regulation and improved safety[1]. The valves are designed with a focus on minimizing heat ingress, which is crucial for maintaining liquid nitrogen quality and reducing boil-off rates[2].

Strengths: Extensive experience in cryogenic applications, advanced sealing technology, and smart valve integration. Weaknesses: Potentially higher initial costs due to specialized materials and technology.

Nitrocraft

Technical Solution: Nitrocraft specializes in gate valve solutions for liquid nitrogen management, with a focus on compact and lightweight designs. Their valves utilize advanced composite materials that offer excellent thermal insulation properties while reducing overall weight[7]. Nitrocraft's gate valves feature a proprietary self-lubricating seat design that ensures smooth operation even after prolonged periods of inactivity. The company has developed a unique pressure-balancing system within their valves, which minimizes the force required for actuation and improves reliability in high-pressure applications[8]. Nitrocraft's solutions also include integrated safety features such as pressure relief mechanisms and fail-safe positioning to enhance operational safety.

Strengths: Lightweight and compact design, self-lubricating components, and integrated safety features. Weaknesses: May have limitations in extremely high-flow applications due to size constraints.

Innovative Sealing Technologies for Cryogenics

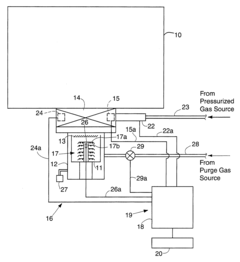

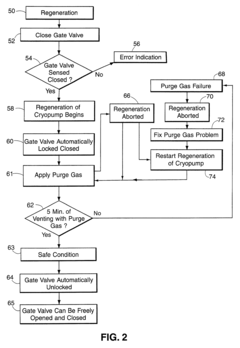

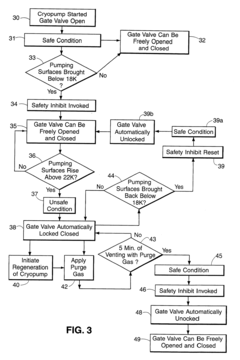

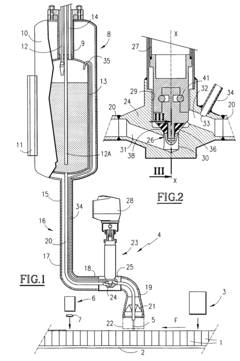

Cryopump with gate valve control

PatentInactiveUS6327863B1

Innovation

- A cryopump system with an integrated electronic controller that automatically determines safe or unsafe conditions based on operational modes and sensed parameters, locking the gate valve closed during unsafe conditions, such as the presence of combustible gases, and unlocking it only when safe conditions are met, ensuring the gate valve remains closed until hydrogen gas is purged or temperatures return to safe levels.

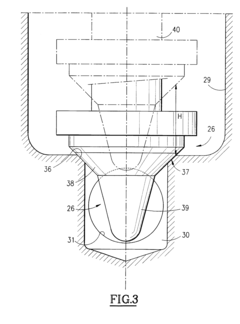

Cryogenic valve in an apparatus for packaging a product

PatentInactiveEP0893347A1

Innovation

- A degassing pipe is tapped downstream of the throttle member in the main pipe to effectively evacuate gas phase accumulations, allowing for precise adjustment of the liquid nitrogen flow rate by utilizing a cryogenic valve with a frustoconical seat and obturator design that includes a bore connecting to the degassing pipe, ensuring the cryogenic liquid remains substantially free from vaporization issues.

Safety Standards for Cryogenic Equipment

Safety standards for cryogenic equipment are crucial in the context of gate valve solutions for efficient liquid nitrogen management. These standards are designed to ensure the safe handling, storage, and use of cryogenic fluids, particularly liquid nitrogen, which poses unique hazards due to its extremely low temperature and potential for rapid expansion.

The primary safety standards governing cryogenic equipment are set by organizations such as the Compressed Gas Association (CGA), the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO). These standards cover various aspects of cryogenic systems, including material selection, design requirements, testing procedures, and operational guidelines.

Material selection is a critical component of safety standards for cryogenic equipment. Materials used in gate valves and other components must maintain their mechanical properties at extremely low temperatures. Austenitic stainless steels, such as 304 and 316, are commonly specified due to their excellent low-temperature toughness and resistance to brittle fracture.

Design requirements for cryogenic gate valves include specifications for pressure ratings, thermal cycling resistance, and leak-tightness. The ASME Boiler and Pressure Vessel Code, Section VIII, provides guidelines for the design and construction of pressure vessels used in cryogenic applications. This code addresses factors such as material allowable stresses, wall thickness calculations, and nozzle reinforcement requirements.

Testing procedures are an integral part of safety standards for cryogenic equipment. Cryogenic gate valves must undergo rigorous testing to ensure their performance and safety under extreme conditions. These tests include cryogenic cycling, where valves are subjected to repeated temperature fluctuations between ambient and cryogenic temperatures, as well as leak tests to verify seal integrity at both high pressures and low temperatures.

Operational guidelines outlined in safety standards cover aspects such as proper insulation, pressure relief devices, and ventilation requirements. The CGA P-12 standard, "Safe Handling of Cryogenic Liquids," provides comprehensive guidance on the safe operation of cryogenic systems, including recommendations for personal protective equipment and emergency procedures.

Compliance with these safety standards is essential for manufacturers and operators of gate valve solutions for liquid nitrogen management. Regular inspections, maintenance, and personnel training are required to ensure ongoing adherence to safety standards and to mitigate risks associated with cryogenic operations.

The primary safety standards governing cryogenic equipment are set by organizations such as the Compressed Gas Association (CGA), the American Society of Mechanical Engineers (ASME), and the International Organization for Standardization (ISO). These standards cover various aspects of cryogenic systems, including material selection, design requirements, testing procedures, and operational guidelines.

Material selection is a critical component of safety standards for cryogenic equipment. Materials used in gate valves and other components must maintain their mechanical properties at extremely low temperatures. Austenitic stainless steels, such as 304 and 316, are commonly specified due to their excellent low-temperature toughness and resistance to brittle fracture.

Design requirements for cryogenic gate valves include specifications for pressure ratings, thermal cycling resistance, and leak-tightness. The ASME Boiler and Pressure Vessel Code, Section VIII, provides guidelines for the design and construction of pressure vessels used in cryogenic applications. This code addresses factors such as material allowable stresses, wall thickness calculations, and nozzle reinforcement requirements.

Testing procedures are an integral part of safety standards for cryogenic equipment. Cryogenic gate valves must undergo rigorous testing to ensure their performance and safety under extreme conditions. These tests include cryogenic cycling, where valves are subjected to repeated temperature fluctuations between ambient and cryogenic temperatures, as well as leak tests to verify seal integrity at both high pressures and low temperatures.

Operational guidelines outlined in safety standards cover aspects such as proper insulation, pressure relief devices, and ventilation requirements. The CGA P-12 standard, "Safe Handling of Cryogenic Liquids," provides comprehensive guidance on the safe operation of cryogenic systems, including recommendations for personal protective equipment and emergency procedures.

Compliance with these safety standards is essential for manufacturers and operators of gate valve solutions for liquid nitrogen management. Regular inspections, maintenance, and personnel training are required to ensure ongoing adherence to safety standards and to mitigate risks associated with cryogenic operations.

Environmental Impact of LN2 Systems

The environmental impact of liquid nitrogen (LN2) systems, particularly those utilizing gate valve solutions for efficient management, is a critical consideration in various industries. These systems, while essential for many processes, can have significant environmental implications if not properly managed.

One of the primary environmental concerns associated with LN2 systems is the potential for atmospheric nitrogen enrichment. When liquid nitrogen evaporates, it releases gaseous nitrogen into the atmosphere. While nitrogen is naturally abundant in the air, localized increases in concentration can affect local ecosystems and potentially contribute to air quality issues in confined spaces.

Energy consumption is another crucial environmental factor to consider. The production, liquefaction, and storage of liquid nitrogen require substantial energy inputs. This energy demand often relies on fossil fuel-based power sources, contributing to greenhouse gas emissions and climate change. However, the use of gate valve solutions for efficient LN2 management can help mitigate some of these impacts by reducing waste and optimizing system performance.

Water usage and thermal pollution are additional environmental considerations. Some LN2 systems, particularly in industrial applications, may require water for cooling processes. The discharge of this water, often at altered temperatures, can impact aquatic ecosystems if not properly managed. Efficient gate valve solutions can play a role in minimizing water usage and controlling thermal discharge.

The potential for accidental releases of liquid nitrogen poses both safety and environmental risks. Large-scale releases can cause rapid localized cooling, potentially damaging vegetation and disrupting local wildlife. Moreover, the expansion of liquid nitrogen as it vaporizes can lead to oxygen displacement in confined spaces, creating hazardous conditions for both humans and local fauna.

On a positive note, LN2 systems, when properly managed, can contribute to environmental benefits in certain applications. For instance, in the food industry, LN2 can be used for flash freezing, which can reduce food waste and extend shelf life, indirectly contributing to resource conservation. Similarly, in scientific research and medical applications, LN2 enables the preservation of biological samples, supporting advancements that may have long-term environmental benefits.

The lifecycle environmental impact of LN2 systems, including the production and disposal of equipment such as gate valves, should also be considered. The manufacturing of specialized components often involves resource-intensive processes and the use of materials with their own environmental footprints. End-of-life considerations, including the proper disposal or recycling of system components, are crucial for minimizing long-term environmental impacts.

In conclusion, while LN2 systems with efficient gate valve solutions offer numerous benefits across various industries, their environmental impact must be carefully managed. Balancing the necessity of these systems with sustainable practices, energy efficiency, and proper safety measures is essential for minimizing negative environmental consequences while maximizing the benefits of this technology.

One of the primary environmental concerns associated with LN2 systems is the potential for atmospheric nitrogen enrichment. When liquid nitrogen evaporates, it releases gaseous nitrogen into the atmosphere. While nitrogen is naturally abundant in the air, localized increases in concentration can affect local ecosystems and potentially contribute to air quality issues in confined spaces.

Energy consumption is another crucial environmental factor to consider. The production, liquefaction, and storage of liquid nitrogen require substantial energy inputs. This energy demand often relies on fossil fuel-based power sources, contributing to greenhouse gas emissions and climate change. However, the use of gate valve solutions for efficient LN2 management can help mitigate some of these impacts by reducing waste and optimizing system performance.

Water usage and thermal pollution are additional environmental considerations. Some LN2 systems, particularly in industrial applications, may require water for cooling processes. The discharge of this water, often at altered temperatures, can impact aquatic ecosystems if not properly managed. Efficient gate valve solutions can play a role in minimizing water usage and controlling thermal discharge.

The potential for accidental releases of liquid nitrogen poses both safety and environmental risks. Large-scale releases can cause rapid localized cooling, potentially damaging vegetation and disrupting local wildlife. Moreover, the expansion of liquid nitrogen as it vaporizes can lead to oxygen displacement in confined spaces, creating hazardous conditions for both humans and local fauna.

On a positive note, LN2 systems, when properly managed, can contribute to environmental benefits in certain applications. For instance, in the food industry, LN2 can be used for flash freezing, which can reduce food waste and extend shelf life, indirectly contributing to resource conservation. Similarly, in scientific research and medical applications, LN2 enables the preservation of biological samples, supporting advancements that may have long-term environmental benefits.

The lifecycle environmental impact of LN2 systems, including the production and disposal of equipment such as gate valves, should also be considered. The manufacturing of specialized components often involves resource-intensive processes and the use of materials with their own environmental footprints. End-of-life considerations, including the proper disposal or recycling of system components, are crucial for minimizing long-term environmental impacts.

In conclusion, while LN2 systems with efficient gate valve solutions offer numerous benefits across various industries, their environmental impact must be carefully managed. Balancing the necessity of these systems with sustainable practices, energy efficiency, and proper safety measures is essential for minimizing negative environmental consequences while maximizing the benefits of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!