Leveraging big data for gate valve performance analytics

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Big Data in Valve Analytics: Background and Objectives

The integration of big data analytics into valve performance monitoring represents a significant leap forward in industrial process optimization. This technological evolution stems from the increasing digitalization of industrial operations and the growing availability of sensor data from various components, including gate valves. The historical context of this development can be traced back to the early 2000s when the concept of Industry 4.0 began to take shape, emphasizing the importance of data-driven decision-making in manufacturing and process industries.

The primary objective of leveraging big data for gate valve performance analytics is to enhance operational efficiency, reduce downtime, and extend the lifespan of critical equipment. By collecting and analyzing vast amounts of data from sensors attached to gate valves, operators can gain unprecedented insights into valve behavior, wear patterns, and potential failure modes. This proactive approach to maintenance and performance optimization marks a significant shift from traditional reactive maintenance strategies.

The evolution of this technology has been driven by several key factors. Advancements in sensor technology have made it possible to capture a wide range of parameters, including pressure, temperature, flow rates, and vibration, at high frequencies and with greater accuracy. Simultaneously, the development of robust data transmission protocols and edge computing capabilities has enabled real-time data collection and processing, even in challenging industrial environments.

Cloud computing and advanced analytics platforms have played a crucial role in making big data analytics feasible for valve performance monitoring. These technologies provide the necessary computational power and storage capacity to handle the enormous volumes of data generated by industrial sensors. Machine learning algorithms and artificial intelligence have further enhanced the ability to extract meaningful patterns and predictive insights from this data.

The goal of implementing big data analytics in valve performance monitoring extends beyond mere fault detection. It aims to create a comprehensive understanding of valve behavior under various operating conditions, enabling predictive maintenance, optimized performance tuning, and even autonomous operation in some cases. This holistic approach to valve management has the potential to significantly reduce operational costs, improve safety, and increase overall plant efficiency.

As industries continue to embrace digital transformation, the integration of big data analytics into valve performance monitoring is expected to become increasingly sophisticated. Future developments may include the incorporation of augmented reality for maintenance support, the use of digital twins for advanced simulation and optimization, and the implementation of blockchain technology for secure data sharing across supply chains.

The primary objective of leveraging big data for gate valve performance analytics is to enhance operational efficiency, reduce downtime, and extend the lifespan of critical equipment. By collecting and analyzing vast amounts of data from sensors attached to gate valves, operators can gain unprecedented insights into valve behavior, wear patterns, and potential failure modes. This proactive approach to maintenance and performance optimization marks a significant shift from traditional reactive maintenance strategies.

The evolution of this technology has been driven by several key factors. Advancements in sensor technology have made it possible to capture a wide range of parameters, including pressure, temperature, flow rates, and vibration, at high frequencies and with greater accuracy. Simultaneously, the development of robust data transmission protocols and edge computing capabilities has enabled real-time data collection and processing, even in challenging industrial environments.

Cloud computing and advanced analytics platforms have played a crucial role in making big data analytics feasible for valve performance monitoring. These technologies provide the necessary computational power and storage capacity to handle the enormous volumes of data generated by industrial sensors. Machine learning algorithms and artificial intelligence have further enhanced the ability to extract meaningful patterns and predictive insights from this data.

The goal of implementing big data analytics in valve performance monitoring extends beyond mere fault detection. It aims to create a comprehensive understanding of valve behavior under various operating conditions, enabling predictive maintenance, optimized performance tuning, and even autonomous operation in some cases. This holistic approach to valve management has the potential to significantly reduce operational costs, improve safety, and increase overall plant efficiency.

As industries continue to embrace digital transformation, the integration of big data analytics into valve performance monitoring is expected to become increasingly sophisticated. Future developments may include the incorporation of augmented reality for maintenance support, the use of digital twins for advanced simulation and optimization, and the implementation of blockchain technology for secure data sharing across supply chains.

Market Demand for Smart Valve Solutions

The market demand for smart valve solutions has been steadily increasing in recent years, driven by the growing need for improved efficiency, reliability, and safety in various industries. As industrial processes become more complex and automated, the integration of big data analytics with gate valve performance has emerged as a critical factor in optimizing operations and reducing downtime.

In the oil and gas sector, smart valve solutions are particularly sought after due to the high-stakes nature of operations and the potential for significant cost savings. Companies are increasingly recognizing the value of real-time monitoring and predictive maintenance capabilities offered by these advanced systems. The ability to leverage big data for gate valve performance analytics allows operators to detect potential issues before they escalate, leading to substantial reductions in unplanned shutdowns and maintenance costs.

The water and wastewater treatment industry is another key market for smart valve solutions. With increasing pressure to improve water conservation and reduce energy consumption, utilities are turning to data-driven valve management systems. These solutions enable more precise control over water distribution networks, helping to minimize leaks and optimize pressure management.

In the power generation sector, the demand for smart valve solutions is driven by the need for enhanced plant efficiency and compliance with stringent environmental regulations. Big data analytics applied to gate valve performance can help power plants optimize their steam systems, reduce emissions, and improve overall energy efficiency.

The chemical and petrochemical industries are also significant contributors to the growing market demand. These sectors require precise control over complex processes, and smart valve solutions offer the ability to fine-tune operations based on real-time data analysis. This leads to improved product quality, reduced waste, and enhanced safety measures.

Manufacturing and process industries are increasingly adopting smart valve solutions as part of their Industry 4.0 initiatives. The integration of big data analytics with valve performance allows for more flexible and responsive production systems, enabling manufacturers to adapt quickly to changing market demands and optimize resource utilization.

The pharmaceutical industry, with its stringent quality control requirements, is another sector driving demand for smart valve solutions. The ability to monitor and control valve performance with high precision is crucial for maintaining the integrity of sensitive production processes and ensuring compliance with regulatory standards.

As the Internet of Things (IoT) continues to expand, the market for smart valve solutions is expected to grow further. The increasing availability of low-cost sensors and advanced data processing capabilities is making it more feasible for a wider range of industries to implement these technologies, leading to a broader adoption across various sectors.

In the oil and gas sector, smart valve solutions are particularly sought after due to the high-stakes nature of operations and the potential for significant cost savings. Companies are increasingly recognizing the value of real-time monitoring and predictive maintenance capabilities offered by these advanced systems. The ability to leverage big data for gate valve performance analytics allows operators to detect potential issues before they escalate, leading to substantial reductions in unplanned shutdowns and maintenance costs.

The water and wastewater treatment industry is another key market for smart valve solutions. With increasing pressure to improve water conservation and reduce energy consumption, utilities are turning to data-driven valve management systems. These solutions enable more precise control over water distribution networks, helping to minimize leaks and optimize pressure management.

In the power generation sector, the demand for smart valve solutions is driven by the need for enhanced plant efficiency and compliance with stringent environmental regulations. Big data analytics applied to gate valve performance can help power plants optimize their steam systems, reduce emissions, and improve overall energy efficiency.

The chemical and petrochemical industries are also significant contributors to the growing market demand. These sectors require precise control over complex processes, and smart valve solutions offer the ability to fine-tune operations based on real-time data analysis. This leads to improved product quality, reduced waste, and enhanced safety measures.

Manufacturing and process industries are increasingly adopting smart valve solutions as part of their Industry 4.0 initiatives. The integration of big data analytics with valve performance allows for more flexible and responsive production systems, enabling manufacturers to adapt quickly to changing market demands and optimize resource utilization.

The pharmaceutical industry, with its stringent quality control requirements, is another sector driving demand for smart valve solutions. The ability to monitor and control valve performance with high precision is crucial for maintaining the integrity of sensitive production processes and ensuring compliance with regulatory standards.

As the Internet of Things (IoT) continues to expand, the market for smart valve solutions is expected to grow further. The increasing availability of low-cost sensors and advanced data processing capabilities is making it more feasible for a wider range of industries to implement these technologies, leading to a broader adoption across various sectors.

Current Challenges in Gate Valve Performance Monitoring

Gate valve performance monitoring faces several significant challenges in the era of big data analytics. One of the primary issues is the sheer volume and complexity of data generated by modern industrial systems. Sensors and monitoring devices produce vast amounts of information, making it difficult to process and analyze effectively in real-time. This data deluge often leads to information overload, hindering the ability to extract meaningful insights and identify critical performance indicators.

Another challenge lies in the integration of diverse data sources. Gate valve performance is influenced by numerous factors, including pressure, temperature, flow rates, and mechanical wear. These parameters are often measured by different systems and sensors, resulting in heterogeneous data formats and structures. Harmonizing and correlating these disparate data streams to create a comprehensive view of valve performance remains a significant hurdle for many organizations.

Data quality and reliability present additional obstacles. Sensor malfunctions, communication errors, and environmental interference can introduce inaccuracies or gaps in the collected data. Ensuring the integrity and consistency of the data used for performance analytics is crucial but often challenging, especially in harsh industrial environments where gate valves typically operate.

The lack of standardized data models and analytics frameworks specific to gate valve performance is another impediment. While general-purpose big data tools exist, they may not be optimized for the unique characteristics and requirements of valve monitoring. This gap necessitates significant customization and domain expertise to develop effective analytics solutions.

Real-time processing and decision-making pose further challenges. Many industrial processes require immediate insights into valve performance to prevent failures and optimize operations. However, the computational demands of processing large volumes of data in real-time can strain existing infrastructure and analytics systems.

Moreover, the interpretation of complex data patterns and the extraction of actionable insights remain challenging. Advanced analytics techniques, such as machine learning and artificial intelligence, offer potential solutions but require specialized skills and expertise that may be scarce in traditional industrial settings.

Lastly, data security and privacy concerns add another layer of complexity. As industrial systems become more connected and data-driven, protecting sensitive performance data from cyber threats and unauthorized access becomes increasingly critical. Balancing the need for comprehensive data collection with robust security measures presents ongoing challenges for organizations leveraging big data for gate valve performance analytics.

Another challenge lies in the integration of diverse data sources. Gate valve performance is influenced by numerous factors, including pressure, temperature, flow rates, and mechanical wear. These parameters are often measured by different systems and sensors, resulting in heterogeneous data formats and structures. Harmonizing and correlating these disparate data streams to create a comprehensive view of valve performance remains a significant hurdle for many organizations.

Data quality and reliability present additional obstacles. Sensor malfunctions, communication errors, and environmental interference can introduce inaccuracies or gaps in the collected data. Ensuring the integrity and consistency of the data used for performance analytics is crucial but often challenging, especially in harsh industrial environments where gate valves typically operate.

The lack of standardized data models and analytics frameworks specific to gate valve performance is another impediment. While general-purpose big data tools exist, they may not be optimized for the unique characteristics and requirements of valve monitoring. This gap necessitates significant customization and domain expertise to develop effective analytics solutions.

Real-time processing and decision-making pose further challenges. Many industrial processes require immediate insights into valve performance to prevent failures and optimize operations. However, the computational demands of processing large volumes of data in real-time can strain existing infrastructure and analytics systems.

Moreover, the interpretation of complex data patterns and the extraction of actionable insights remain challenging. Advanced analytics techniques, such as machine learning and artificial intelligence, offer potential solutions but require specialized skills and expertise that may be scarce in traditional industrial settings.

Lastly, data security and privacy concerns add another layer of complexity. As industrial systems become more connected and data-driven, protecting sensitive performance data from cyber threats and unauthorized access becomes increasingly critical. Balancing the need for comprehensive data collection with robust security measures presents ongoing challenges for organizations leveraging big data for gate valve performance analytics.

Existing Big Data Solutions for Valve Performance Analysis

01 Improved sealing mechanisms

Gate valves with enhanced sealing mechanisms to prevent leakage and improve overall performance. These designs may include innovative sealing materials, multi-layer seals, or advanced sealing structures to ensure tight closure and minimize fluid loss.- Improved sealing performance: Gate valves with enhanced sealing mechanisms to prevent leakage and improve overall performance. This includes innovations in sealing materials, structures, and designs to ensure tight closure and minimize fluid loss.

- Optimized flow control: Advancements in gate valve designs to improve flow control capabilities. This involves modifications to the gate, seat, and body structure to enhance precision in regulating fluid flow and reduce pressure drop across the valve.

- Enhanced durability and reliability: Innovations focused on increasing the lifespan and reliability of gate valves. This includes the use of wear-resistant materials, improved manufacturing techniques, and design modifications to withstand harsh operating conditions and frequent cycling.

- Improved actuation and control systems: Advancements in gate valve actuation mechanisms and control systems. This includes innovations in electric, hydraulic, and pneumatic actuators, as well as smart control systems for remote operation and monitoring of valve performance.

- Specialized gate valve designs for specific applications: Development of gate valves tailored for specific industries or operating conditions. This includes designs optimized for high-pressure, high-temperature, corrosive environments, or specific fluid types, ensuring optimal performance in challenging applications.

02 Optimized flow control

Gate valve designs that focus on improving flow control capabilities. These may include features such as adjustable gate positions, streamlined internal geometries, or advanced control systems to provide precise regulation of fluid flow and enhance overall valve performance.Expand Specific Solutions03 Enhanced durability and wear resistance

Gate valves constructed with materials and coatings that offer increased durability and wear resistance. These improvements aim to extend the valve's lifespan, reduce maintenance requirements, and maintain consistent performance over time, even in harsh operating conditions.Expand Specific Solutions04 Smart monitoring and control systems

Integration of smart technologies and sensors into gate valves for real-time monitoring and control. These systems can provide data on valve performance, detect potential issues, and enable remote operation, leading to improved efficiency and predictive maintenance capabilities.Expand Specific Solutions05 Compact and lightweight designs

Development of gate valves with reduced size and weight without compromising performance. These designs aim to improve installation flexibility, reduce material costs, and enhance overall system efficiency, particularly in space-constrained applications.Expand Specific Solutions

Key Players in Industrial IoT and Valve Manufacturing

The market for leveraging big data in gate valve performance analytics is in its growth phase, with increasing adoption across industries. The global market size is expanding rapidly, driven by the need for improved efficiency and predictive maintenance in industrial processes. Technologically, the field is maturing, with companies like Schlumberger Technologies, Emerson Process Management, and Halliburton Energy Services leading the way in developing advanced analytics solutions. These firms are integrating big data capabilities with traditional valve monitoring systems, creating more sophisticated predictive models. Other players like KSB SE & Co. KGaA and KITZ Corp. are also making significant strides in this area, focusing on data-driven valve performance optimization for various industrial applications.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger's approach to gate valve performance analytics involves a sophisticated IoT-based system that collects data from sensors installed on valves across oil fields. Their platform, known as DELFI cognitive E&P environment, utilizes cloud computing and AI to process vast amounts of data from multiple sources. The system employs advanced machine learning algorithms to detect anomalies in valve operation, predict potential failures, and optimize valve settings for different operational conditions[2]. Schlumberger's solution also incorporates digital twin technology, creating virtual replicas of physical valve systems to simulate performance under various scenarios, enabling more accurate predictive maintenance and performance optimization[4].

Strengths: Advanced AI and cloud computing capabilities, integration with broader E&P systems. Weaknesses: High implementation costs and potential complexity for smaller operations.

Microsoft Technology Licensing LLC

Technical Solution: Microsoft's approach to gate valve performance analytics leverages its Azure IoT platform and Azure Synapse Analytics. The solution collects data from IoT-enabled gate valves and processes it using advanced analytics and machine learning models. Microsoft's system can handle massive volumes of streaming data, allowing for real-time monitoring and analysis of valve performance across large-scale industrial operations. The platform utilizes Azure Digital Twins to create comprehensive models of valve systems, enabling predictive maintenance and performance optimization[5]. Additionally, Microsoft's Power BI integration provides intuitive visualization and reporting tools for easy interpretation of complex valve performance data[6].

Strengths: Scalable cloud infrastructure, integration with widely-used business intelligence tools. Weaknesses: May require significant customization for specific industrial applications.

Core Innovations in Valve Data Analytics

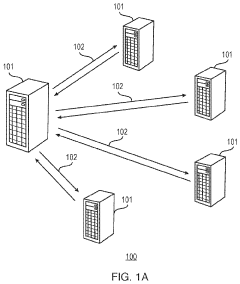

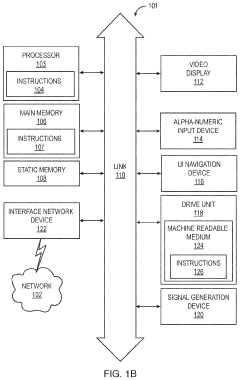

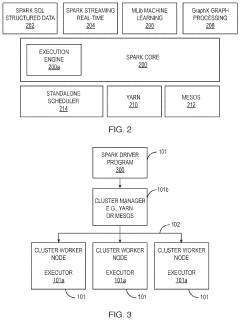

Method and system for processing big data

PatentActiveUS11392739B1

Innovation

- A demand paging system for distributed big data caching is implemented, utilizing a server node with a processor, memory, and an accelerator integrated circuit that includes a memory management unit, interface, and multiple memory types to efficiently allocate and manage virtual memory for data sets, persist data across application execution stages, and signal data page faults, thereby optimizing data processing and energy usage.

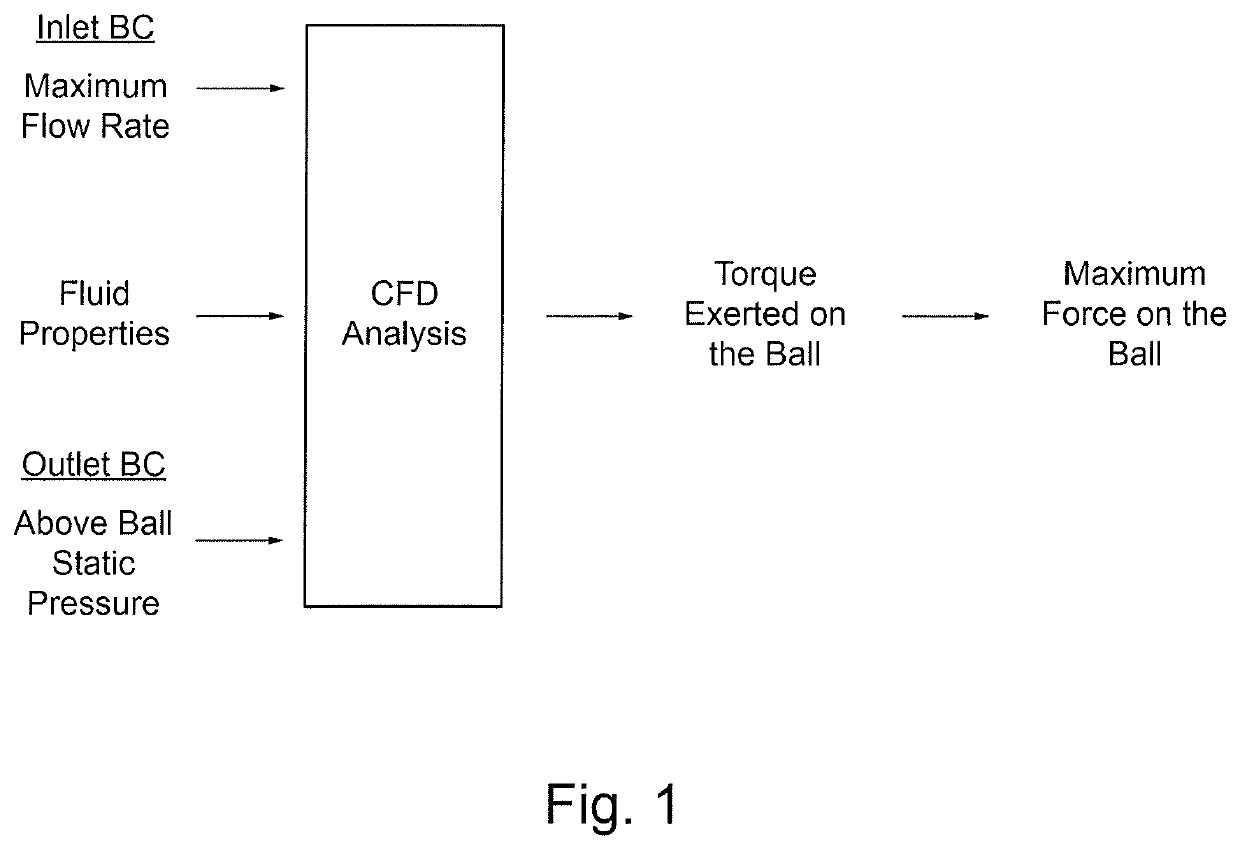

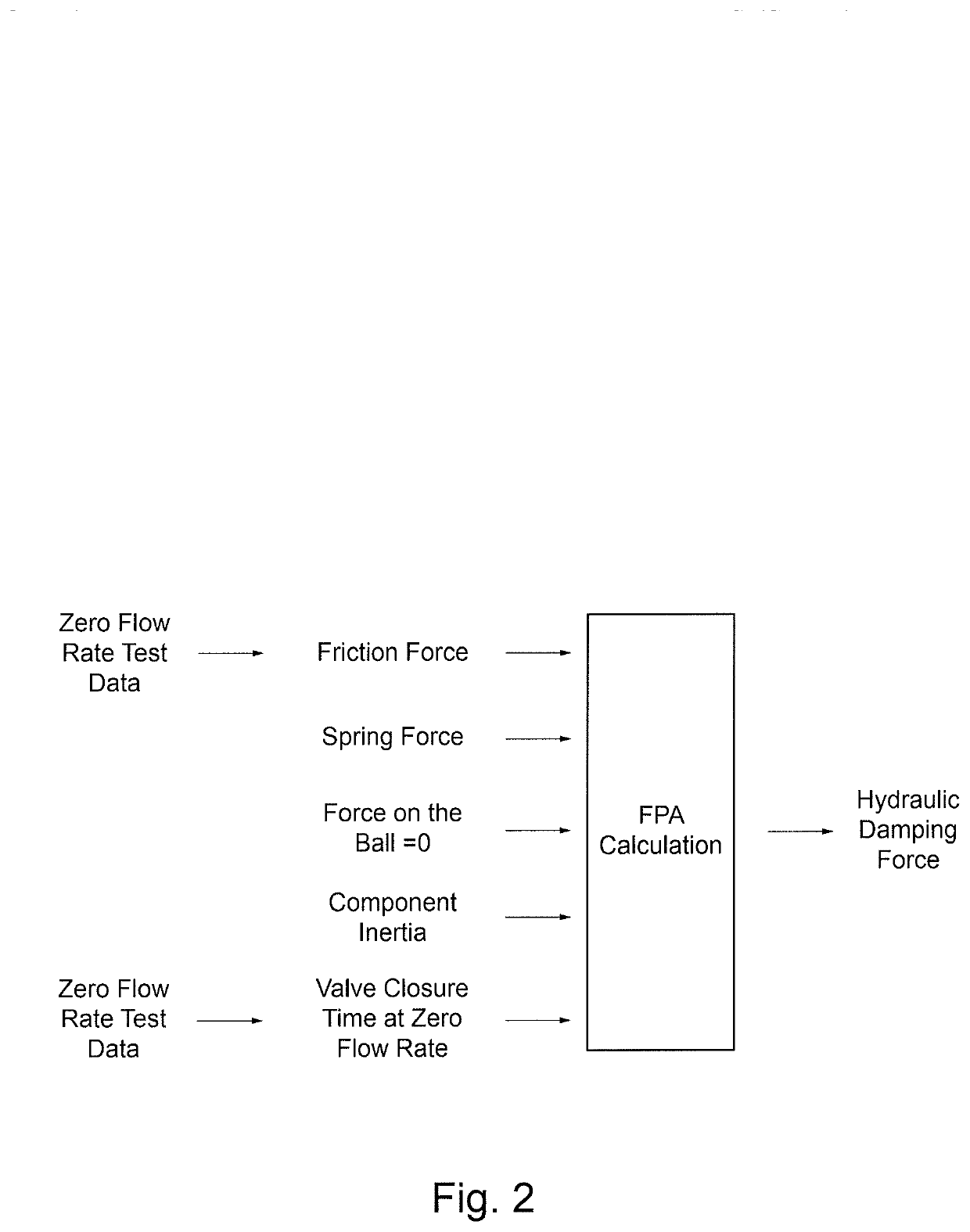

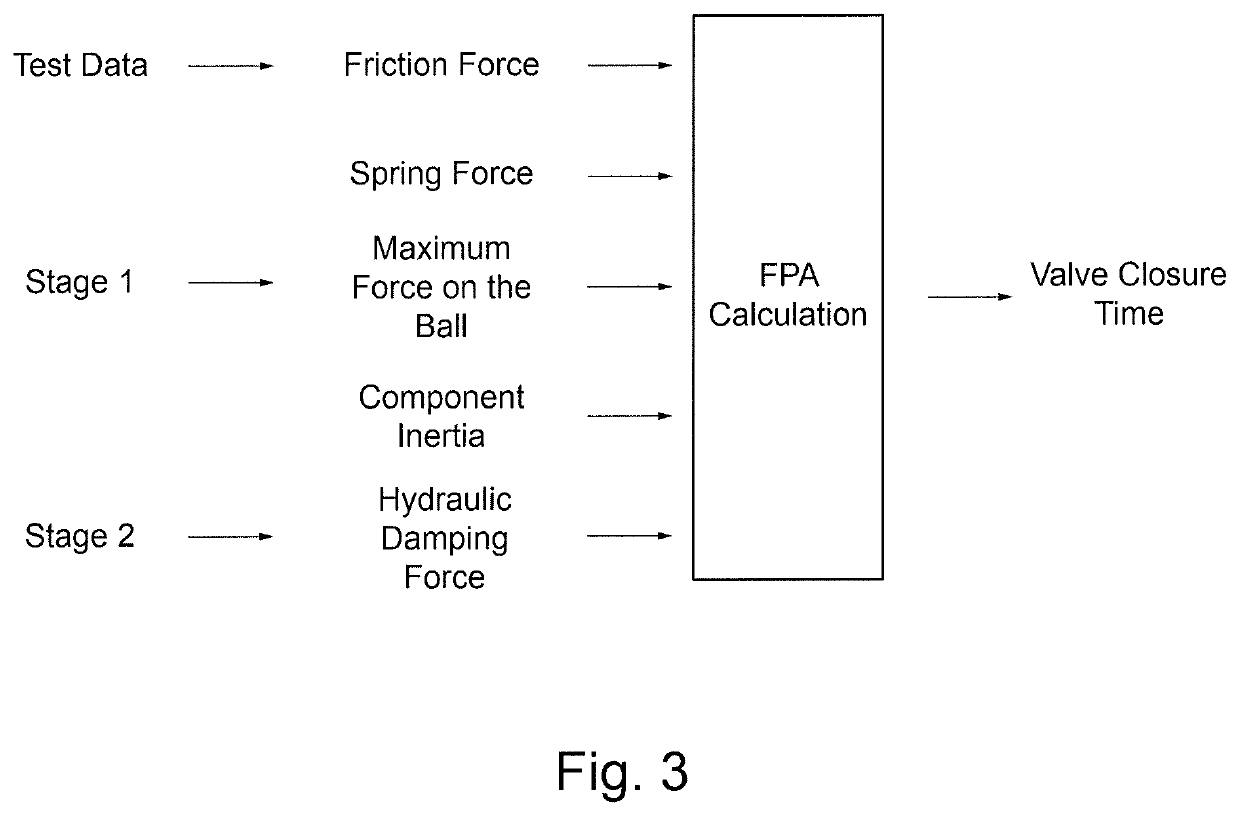

Methodology for analysis of valve dynamic closure performance

PatentInactiveUS20220058319A1

Innovation

- Decoupling the CFD model from the FPA model allows a single CFD analysis to generate torque values usable in multiple FPA calculations, enabling quicker investigation of parameter variations and faster valve design modeling to assess functionality and compliance with performance standards.

Data Security and Privacy in Industrial IoT

In the context of leveraging big data for gate valve performance analytics, data security and privacy in Industrial IoT (IIoT) are critical concerns that must be addressed. The vast amount of data collected from gate valves and other industrial equipment presents both opportunities and challenges for organizations.

IIoT systems generate, process, and transmit sensitive operational data, making them attractive targets for cyber attacks. Unauthorized access to this data could lead to disruptions in industrial processes, financial losses, and potential safety hazards. Therefore, robust security measures are essential to protect the integrity and confidentiality of gate valve performance data.

Encryption plays a vital role in securing data both at rest and in transit. Advanced encryption algorithms should be implemented to safeguard data stored in databases and cloud platforms, as well as during transmission between sensors, gateways, and analytics systems. Additionally, secure key management practices are crucial to maintain the effectiveness of encryption measures.

Access control mechanisms form another critical layer of security. Implementing strong authentication protocols, such as multi-factor authentication, helps ensure that only authorized personnel can access sensitive gate valve data and analytics tools. Role-based access control (RBAC) further enhances security by limiting user privileges based on job responsibilities.

Network segmentation and firewalls are essential for isolating IIoT systems from other corporate networks, reducing the attack surface and minimizing the potential impact of security breaches. Intrusion detection and prevention systems (IDS/IPS) should be deployed to monitor network traffic and identify potential threats in real-time.

Privacy concerns in IIoT extend beyond data security. Organizations must comply with data protection regulations and industry standards when collecting, processing, and storing gate valve performance data. This includes implementing data minimization practices, obtaining necessary consents, and providing transparency about data usage.

Anonymization and pseudonymization techniques can be employed to protect sensitive information while still allowing for meaningful analytics. These methods help balance the need for data-driven insights with privacy requirements, ensuring that individual valve identities or specific operational details are not exposed unnecessarily.

Regular security audits and vulnerability assessments are crucial for maintaining a robust security posture. These evaluations help identify potential weaknesses in the IIoT infrastructure and allow organizations to proactively address security gaps before they can be exploited by malicious actors.

IIoT systems generate, process, and transmit sensitive operational data, making them attractive targets for cyber attacks. Unauthorized access to this data could lead to disruptions in industrial processes, financial losses, and potential safety hazards. Therefore, robust security measures are essential to protect the integrity and confidentiality of gate valve performance data.

Encryption plays a vital role in securing data both at rest and in transit. Advanced encryption algorithms should be implemented to safeguard data stored in databases and cloud platforms, as well as during transmission between sensors, gateways, and analytics systems. Additionally, secure key management practices are crucial to maintain the effectiveness of encryption measures.

Access control mechanisms form another critical layer of security. Implementing strong authentication protocols, such as multi-factor authentication, helps ensure that only authorized personnel can access sensitive gate valve data and analytics tools. Role-based access control (RBAC) further enhances security by limiting user privileges based on job responsibilities.

Network segmentation and firewalls are essential for isolating IIoT systems from other corporate networks, reducing the attack surface and minimizing the potential impact of security breaches. Intrusion detection and prevention systems (IDS/IPS) should be deployed to monitor network traffic and identify potential threats in real-time.

Privacy concerns in IIoT extend beyond data security. Organizations must comply with data protection regulations and industry standards when collecting, processing, and storing gate valve performance data. This includes implementing data minimization practices, obtaining necessary consents, and providing transparency about data usage.

Anonymization and pseudonymization techniques can be employed to protect sensitive information while still allowing for meaningful analytics. These methods help balance the need for data-driven insights with privacy requirements, ensuring that individual valve identities or specific operational details are not exposed unnecessarily.

Regular security audits and vulnerability assessments are crucial for maintaining a robust security posture. These evaluations help identify potential weaknesses in the IIoT infrastructure and allow organizations to proactively address security gaps before they can be exploited by malicious actors.

Economic Impact of Big Data-Driven Valve Optimization

The economic impact of big data-driven valve optimization extends far beyond the immediate operational improvements in gate valve performance. This technological advancement has the potential to revolutionize entire industries, creating ripple effects throughout the global economy.

In the oil and gas sector, where gate valves play a crucial role, the implementation of big data analytics for valve performance optimization can lead to significant cost savings. By predicting maintenance needs and preventing unexpected failures, companies can reduce downtime and avoid costly production interruptions. Industry estimates suggest that unplanned downtime in oil and gas operations can cost up to $300,000 per hour, making the economic benefits of predictive maintenance substantial.

The improved efficiency and reliability of gate valves through big data analytics also contribute to enhanced overall plant performance. This optimization can lead to increased production output, better resource utilization, and reduced energy consumption. For large-scale industrial operations, even small improvements in efficiency can translate into millions of dollars in annual savings.

Furthermore, the adoption of big data-driven valve optimization creates new market opportunities for technology providers and data analytics firms. As industries recognize the value of these solutions, demand for specialized software, sensors, and analytics services is expected to grow, potentially creating a multi-billion dollar market segment within the industrial IoT space.

The environmental impact of optimized valve performance also has economic implications. Improved valve efficiency can lead to reduced emissions and waste, helping companies meet regulatory requirements and avoid potential fines. Additionally, companies demonstrating environmental responsibility through advanced technologies may benefit from improved public perception and potential tax incentives.

In the broader context of industrial digitalization, the success of big data applications in valve optimization serves as a proof of concept for other areas of operation. This can accelerate the adoption of data-driven decision-making across various industrial processes, leading to a cumulative economic impact that extends far beyond the initial application in valve management.

The workforce implications of this technological shift also warrant consideration. While there may be a reduction in certain traditional roles, the demand for data scientists, IoT specialists, and other high-skilled positions is likely to increase. This transformation of the job market can contribute to economic growth by fostering innovation and creating higher-value employment opportunities.

In the oil and gas sector, where gate valves play a crucial role, the implementation of big data analytics for valve performance optimization can lead to significant cost savings. By predicting maintenance needs and preventing unexpected failures, companies can reduce downtime and avoid costly production interruptions. Industry estimates suggest that unplanned downtime in oil and gas operations can cost up to $300,000 per hour, making the economic benefits of predictive maintenance substantial.

The improved efficiency and reliability of gate valves through big data analytics also contribute to enhanced overall plant performance. This optimization can lead to increased production output, better resource utilization, and reduced energy consumption. For large-scale industrial operations, even small improvements in efficiency can translate into millions of dollars in annual savings.

Furthermore, the adoption of big data-driven valve optimization creates new market opportunities for technology providers and data analytics firms. As industries recognize the value of these solutions, demand for specialized software, sensors, and analytics services is expected to grow, potentially creating a multi-billion dollar market segment within the industrial IoT space.

The environmental impact of optimized valve performance also has economic implications. Improved valve efficiency can lead to reduced emissions and waste, helping companies meet regulatory requirements and avoid potential fines. Additionally, companies demonstrating environmental responsibility through advanced technologies may benefit from improved public perception and potential tax incentives.

In the broader context of industrial digitalization, the success of big data applications in valve optimization serves as a proof of concept for other areas of operation. This can accelerate the adoption of data-driven decision-making across various industrial processes, leading to a cumulative economic impact that extends far beyond the initial application in valve management.

The workforce implications of this technological shift also warrant consideration. While there may be a reduction in certain traditional roles, the demand for data scientists, IoT specialists, and other high-skilled positions is likely to increase. This transformation of the job market can contribute to economic growth by fostering innovation and creating higher-value employment opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!