Gate valve fatigue testing using accelerated life-cycle methodologies

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Valve Fatigue Testing Background and Objectives

Gate valve fatigue testing using accelerated life-cycle methodologies has emerged as a critical area of research and development in the valve industry. This technology aims to enhance the reliability and longevity of gate valves, which are essential components in various industrial applications, including oil and gas, water treatment, and power generation.

The evolution of gate valve technology can be traced back to the early 20th century, with significant advancements occurring in materials, design, and manufacturing processes over the decades. As industrial demands have grown more complex and stringent, the need for robust and long-lasting gate valves has become paramount. This has led to an increased focus on understanding and mitigating fatigue-related failures, which account for a substantial portion of valve malfunctions in the field.

Accelerated life-cycle methodologies have gained prominence in recent years as a means to expedite the testing and validation of gate valve durability. These techniques aim to simulate years of operational wear and stress within a compressed timeframe, allowing manufacturers and researchers to identify potential failure modes and optimize valve designs more efficiently. The development of these methodologies has been driven by the need to reduce time-to-market for new valve designs while ensuring their reliability under diverse and challenging operating conditions.

The primary objectives of gate valve fatigue testing using accelerated life-cycle methodologies are multifaceted. Firstly, it seeks to establish standardized testing protocols that can accurately predict the long-term performance of gate valves in various industrial environments. This includes simulating extreme temperature fluctuations, pressure cycles, and corrosive media exposure that valves may encounter during their operational lifespan.

Secondly, the technology aims to identify and characterize the primary mechanisms of fatigue-induced failure in gate valves. This involves analyzing the effects of cyclic loading on critical components such as valve stems, seats, and body-bonnet joints. By understanding these failure modes, engineers can develop more resilient designs and select appropriate materials to enhance valve longevity.

Another key objective is to leverage data analytics and machine learning algorithms to interpret the vast amounts of data generated during accelerated testing. This approach enables researchers to identify subtle patterns and correlations that may not be apparent through traditional analysis methods, potentially leading to breakthrough insights in valve design and material selection.

Furthermore, the technology seeks to bridge the gap between laboratory testing and real-world performance by incorporating field data and operational feedback into the accelerated testing models. This integration aims to improve the accuracy and relevance of fatigue predictions, ultimately leading to more reliable and cost-effective gate valve solutions for industry.

The evolution of gate valve technology can be traced back to the early 20th century, with significant advancements occurring in materials, design, and manufacturing processes over the decades. As industrial demands have grown more complex and stringent, the need for robust and long-lasting gate valves has become paramount. This has led to an increased focus on understanding and mitigating fatigue-related failures, which account for a substantial portion of valve malfunctions in the field.

Accelerated life-cycle methodologies have gained prominence in recent years as a means to expedite the testing and validation of gate valve durability. These techniques aim to simulate years of operational wear and stress within a compressed timeframe, allowing manufacturers and researchers to identify potential failure modes and optimize valve designs more efficiently. The development of these methodologies has been driven by the need to reduce time-to-market for new valve designs while ensuring their reliability under diverse and challenging operating conditions.

The primary objectives of gate valve fatigue testing using accelerated life-cycle methodologies are multifaceted. Firstly, it seeks to establish standardized testing protocols that can accurately predict the long-term performance of gate valves in various industrial environments. This includes simulating extreme temperature fluctuations, pressure cycles, and corrosive media exposure that valves may encounter during their operational lifespan.

Secondly, the technology aims to identify and characterize the primary mechanisms of fatigue-induced failure in gate valves. This involves analyzing the effects of cyclic loading on critical components such as valve stems, seats, and body-bonnet joints. By understanding these failure modes, engineers can develop more resilient designs and select appropriate materials to enhance valve longevity.

Another key objective is to leverage data analytics and machine learning algorithms to interpret the vast amounts of data generated during accelerated testing. This approach enables researchers to identify subtle patterns and correlations that may not be apparent through traditional analysis methods, potentially leading to breakthrough insights in valve design and material selection.

Furthermore, the technology seeks to bridge the gap between laboratory testing and real-world performance by incorporating field data and operational feedback into the accelerated testing models. This integration aims to improve the accuracy and relevance of fatigue predictions, ultimately leading to more reliable and cost-effective gate valve solutions for industry.

Market Demand for Accelerated Life-Cycle Testing

The market demand for accelerated life-cycle testing of gate valves has been steadily increasing in recent years, driven by several key factors in the industrial sector. Oil and gas, chemical processing, and power generation industries are particularly interested in this technology due to the critical role gate valves play in their operations and the high costs associated with valve failures.

One of the primary drivers for this demand is the need for improved reliability and safety in industrial processes. As industries push for higher efficiency and longer operational periods between maintenance shutdowns, the importance of accurately predicting valve lifespan and performance under various conditions has become paramount. Accelerated life-cycle testing allows companies to simulate years of wear and tear in a fraction of the time, providing valuable data for maintenance scheduling and risk assessment.

Cost reduction is another significant factor fueling the market demand. By accurately predicting when a valve might fail, companies can optimize their maintenance schedules, reducing both planned and unplanned downtime. This proactive approach to maintenance can lead to substantial savings in operational costs and prevent potential catastrophic failures that could result in production losses or safety incidents.

The growing emphasis on environmental regulations and sustainability has also contributed to the increased demand for accelerated life-cycle testing. As industries face stricter emissions controls and environmental standards, the ability to ensure long-term valve performance and minimize leakage becomes crucial. Accelerated testing helps in developing and validating valve designs that can maintain their integrity over extended periods, thus supporting compliance with environmental regulations.

Furthermore, the trend towards digitalization and Industry 4.0 has created a new dimension of demand for accelerated life-cycle testing. As more industrial processes incorporate smart valves and IoT-enabled monitoring systems, there is a growing need to validate the long-term performance of these advanced components under various operational conditions. Accelerated testing provides the data necessary to develop predictive maintenance algorithms and optimize the integration of smart valves into industrial control systems.

The market for accelerated life-cycle testing services and equipment is expected to grow significantly in the coming years. This growth is not limited to traditional industrial sectors but is also expanding into emerging fields such as renewable energy and water treatment, where valve reliability is equally critical. As companies continue to seek ways to improve operational efficiency and reduce lifecycle costs, the demand for advanced testing methodologies is likely to remain strong, driving innovation in testing technologies and analytical methods.

One of the primary drivers for this demand is the need for improved reliability and safety in industrial processes. As industries push for higher efficiency and longer operational periods between maintenance shutdowns, the importance of accurately predicting valve lifespan and performance under various conditions has become paramount. Accelerated life-cycle testing allows companies to simulate years of wear and tear in a fraction of the time, providing valuable data for maintenance scheduling and risk assessment.

Cost reduction is another significant factor fueling the market demand. By accurately predicting when a valve might fail, companies can optimize their maintenance schedules, reducing both planned and unplanned downtime. This proactive approach to maintenance can lead to substantial savings in operational costs and prevent potential catastrophic failures that could result in production losses or safety incidents.

The growing emphasis on environmental regulations and sustainability has also contributed to the increased demand for accelerated life-cycle testing. As industries face stricter emissions controls and environmental standards, the ability to ensure long-term valve performance and minimize leakage becomes crucial. Accelerated testing helps in developing and validating valve designs that can maintain their integrity over extended periods, thus supporting compliance with environmental regulations.

Furthermore, the trend towards digitalization and Industry 4.0 has created a new dimension of demand for accelerated life-cycle testing. As more industrial processes incorporate smart valves and IoT-enabled monitoring systems, there is a growing need to validate the long-term performance of these advanced components under various operational conditions. Accelerated testing provides the data necessary to develop predictive maintenance algorithms and optimize the integration of smart valves into industrial control systems.

The market for accelerated life-cycle testing services and equipment is expected to grow significantly in the coming years. This growth is not limited to traditional industrial sectors but is also expanding into emerging fields such as renewable energy and water treatment, where valve reliability is equally critical. As companies continue to seek ways to improve operational efficiency and reduce lifecycle costs, the demand for advanced testing methodologies is likely to remain strong, driving innovation in testing technologies and analytical methods.

Current Challenges in Gate Valve Fatigue Testing

Gate valve fatigue testing faces several significant challenges in the current technological landscape. One of the primary issues is the time-consuming nature of traditional testing methods. Conventional fatigue tests often require months or even years to complete, which is impractical for rapid product development cycles and timely market entry. This prolonged testing period not only delays product launches but also increases development costs substantially.

Another challenge lies in the difficulty of accurately simulating real-world operating conditions in laboratory settings. Gate valves are subjected to complex and varied stresses in actual use, including pressure fluctuations, temperature changes, and corrosive environments. Replicating these diverse conditions simultaneously in a controlled testing environment presents a significant technical hurdle. This discrepancy between lab tests and real-world scenarios can lead to inaccurate predictions of valve performance and lifespan.

The lack of standardization in accelerated life-cycle testing methodologies for gate valves is also a pressing concern. Different manufacturers and testing facilities may employ varying approaches, making it challenging to compare results across the industry. This inconsistency hampers the establishment of reliable benchmarks and complicates the process of validating new valve designs or materials.

Furthermore, the development of appropriate acceleration factors for fatigue testing poses a considerable challenge. Determining the correct balance between accelerated testing conditions and maintaining the relevance of results to real-world performance is a complex task. Overly aggressive acceleration may lead to failure modes that are not representative of actual use, while insufficient acceleration may not provide timely results.

The increasing complexity of gate valve designs, incorporating advanced materials and sophisticated control systems, adds another layer of difficulty to fatigue testing. These modern valves often have multiple components with different fatigue characteristics, requiring more comprehensive and nuanced testing approaches. Traditional methods may not adequately address the interplay between these various components under fatigue conditions.

Lastly, there is a growing need for more sophisticated data analysis and interpretation techniques in gate valve fatigue testing. The vast amount of data generated during accelerated life-cycle tests requires advanced statistical methods and predictive modeling to extract meaningful insights. Developing and implementing these analytical tools presents a significant challenge, particularly in terms of ensuring their accuracy and reliability across different valve types and operating conditions.

Another challenge lies in the difficulty of accurately simulating real-world operating conditions in laboratory settings. Gate valves are subjected to complex and varied stresses in actual use, including pressure fluctuations, temperature changes, and corrosive environments. Replicating these diverse conditions simultaneously in a controlled testing environment presents a significant technical hurdle. This discrepancy between lab tests and real-world scenarios can lead to inaccurate predictions of valve performance and lifespan.

The lack of standardization in accelerated life-cycle testing methodologies for gate valves is also a pressing concern. Different manufacturers and testing facilities may employ varying approaches, making it challenging to compare results across the industry. This inconsistency hampers the establishment of reliable benchmarks and complicates the process of validating new valve designs or materials.

Furthermore, the development of appropriate acceleration factors for fatigue testing poses a considerable challenge. Determining the correct balance between accelerated testing conditions and maintaining the relevance of results to real-world performance is a complex task. Overly aggressive acceleration may lead to failure modes that are not representative of actual use, while insufficient acceleration may not provide timely results.

The increasing complexity of gate valve designs, incorporating advanced materials and sophisticated control systems, adds another layer of difficulty to fatigue testing. These modern valves often have multiple components with different fatigue characteristics, requiring more comprehensive and nuanced testing approaches. Traditional methods may not adequately address the interplay between these various components under fatigue conditions.

Lastly, there is a growing need for more sophisticated data analysis and interpretation techniques in gate valve fatigue testing. The vast amount of data generated during accelerated life-cycle tests requires advanced statistical methods and predictive modeling to extract meaningful insights. Developing and implementing these analytical tools presents a significant challenge, particularly in terms of ensuring their accuracy and reliability across different valve types and operating conditions.

Existing Accelerated Testing Solutions for Gate Valves

01 Fatigue-resistant gate valve design

Innovative designs for gate valves that enhance resistance to fatigue, including improved material selection, structural reinforcements, and stress-reducing geometries. These designs aim to extend the operational lifespan of gate valves in high-stress environments.- Fatigue-resistant gate valve design: Innovative designs for gate valves that enhance resistance to fatigue, including improved material selection, structural reinforcements, and stress distribution techniques. These designs aim to extend the operational life of gate valves in high-stress environments.

- Stress analysis and simulation for gate valves: Advanced methods for analyzing and simulating stress distribution in gate valves, including finite element analysis and computational fluid dynamics. These techniques help identify potential fatigue points and optimize valve design for improved durability.

- Coating and surface treatment for fatigue prevention: Application of specialized coatings and surface treatments to gate valve components to enhance fatigue resistance. These treatments can include hardening, nitriding, or the use of advanced composite materials to reduce wear and extend valve life.

- Sealing mechanisms for reduced fatigue: Innovative sealing mechanisms designed to minimize fatigue in gate valves, including advanced gasket materials, self-adjusting seals, and pressure-balanced designs. These mechanisms aim to reduce stress on valve components during operation.

- Maintenance and monitoring systems for fatigue prevention: Development of advanced maintenance and monitoring systems for gate valves to detect early signs of fatigue and prevent failure. These systems may include sensors, predictive maintenance algorithms, and real-time monitoring capabilities.

02 Stress analysis and fatigue prediction

Advanced methods for analyzing stress distribution and predicting fatigue in gate valves, utilizing computational modeling and simulation techniques. These approaches help identify potential weak points and optimize valve designs for improved fatigue resistance.Expand Specific Solutions03 Coating and surface treatments

Application of specialized coatings and surface treatments to gate valve components to enhance fatigue resistance. These treatments can include hardening processes, anti-corrosion coatings, and friction-reducing surface modifications.Expand Specific Solutions04 Sealing and lubrication improvements

Enhancements in sealing mechanisms and lubrication systems for gate valves to reduce friction, wear, and fatigue. These improvements focus on minimizing metal-to-metal contact and ensuring proper lubrication throughout the valve's operational life.Expand Specific Solutions05 Fatigue monitoring and maintenance

Development of monitoring systems and maintenance strategies to detect and mitigate fatigue in gate valves. These approaches include real-time monitoring, predictive maintenance techniques, and optimized inspection schedules to prevent fatigue-related failures.Expand Specific Solutions

Key Players in Valve Testing Industry

The gate valve fatigue testing market using accelerated life-cycle methodologies is in a growth phase, driven by increasing demand for reliable and long-lasting valves in critical industries. The market size is expanding as more companies invest in advanced testing technologies to ensure product quality and safety. Technologically, the field is advancing rapidly, with companies like TA Instruments-Waters LLC and Fisher Controls International LLC leading in developing sophisticated testing equipment. Universities such as Technische Universität Wien and Beihang University are contributing to research and innovation in this area. Major industrial players like IHI Corp., Mitsubishi Heavy Industries, and Siemens AG are likely investing in these testing methodologies to enhance their valve products' reliability and performance.

Fisher Controls International LLC

Technical Solution: Fisher Controls International LLC has implemented a sophisticated gate valve fatigue testing program using accelerated life-cycle methodologies. Their approach combines physical testing with advanced computational modeling to predict valve performance over extended periods. The company's test facilities can simulate up to 20 years of operational wear within a few months by utilizing high-frequency actuation and extreme environmental conditions[2]. Fisher Controls also incorporates machine learning algorithms to analyze test data and refine predictive models, enabling more accurate forecasting of valve lifespan and maintenance requirements[5].

Strengths: Integration of physical testing with computational modeling, rapid simulation of long-term wear, and use of AI for predictive analysis. Weaknesses: Potential overreliance on computational models and challenges in accurately replicating all real-world variables.

Vetco Gray, Inc.

Technical Solution: Vetco Gray, Inc. has developed an advanced gate valve fatigue testing methodology using accelerated life-cycle techniques. Their approach involves subjecting gate valves to high-frequency cycling under simulated operational conditions, including pressure, temperature, and fluid flow variations. The company utilizes specialized test rigs capable of applying up to 10,000 cycles per day, significantly reducing the time required for long-term fatigue assessment[1]. Additionally, they employ advanced sensors and data acquisition systems to continuously monitor valve performance, material degradation, and potential failure modes throughout the accelerated testing process[3].

Strengths: Rapid assessment of long-term valve reliability, ability to simulate diverse operational conditions, and comprehensive data collection for failure analysis. Weaknesses: High initial equipment costs and potential discrepancies between accelerated and real-world aging processes.

Core Innovations in Fatigue Testing Techniques

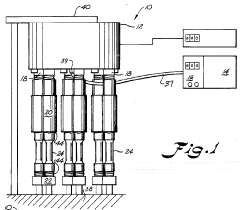

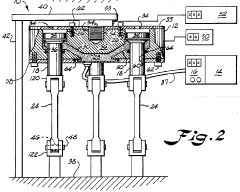

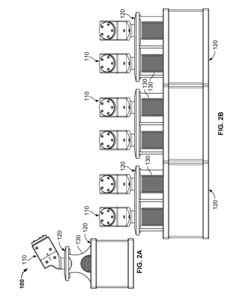

Fatigue testing a plurality of test specimens and method

PatentInactiveUS4676110A

Innovation

- A fatigue testing apparatus with a pulling head featuring multiple piston rods and cylinders that utilize pressurized fluid to apply cyclical tension loading to multiple specimens simultaneously, maintaining consistent loading even after specimen breakage by using a common pressurized fluid source and venting system to ensure equal tension across all specimens.

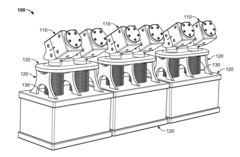

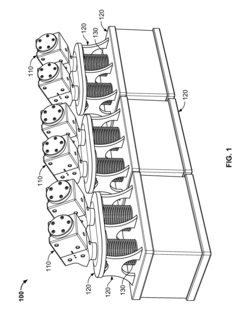

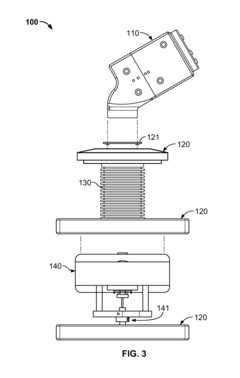

Systems for testing valves

PatentActiveUS20180193146A1

Innovation

- The development of a system comprising a chamber assembly with a proximal and distal chamber portion, a valve holder, and baffles to minimize wave reflection, allowing for high-speed testing that meets ISO requirements with minimal pressure overshoot, and includes adjustable components for fluid dynamic tuning and closed-loop control.

Standards and Regulations for Valve Fatigue Testing

Valve fatigue testing is governed by a comprehensive set of standards and regulations to ensure the safety, reliability, and performance of gate valves in various industries. These standards are developed and maintained by international organizations, industry associations, and regulatory bodies to provide consistent guidelines for manufacturers, testing facilities, and end-users.

The American Society of Mechanical Engineers (ASME) has established several standards relevant to valve fatigue testing, including ASME B16.34 for valves in general and ASME B16.10 for face-to-face and end-to-end dimensions of valves. These standards specify the minimum requirements for design, materials, fabrication, and testing of valves, including fatigue testing procedures.

The International Organization for Standardization (ISO) has also developed standards applicable to valve fatigue testing, such as ISO 5208 for industrial valves and ISO 10497 for fire-type testing. These standards provide guidelines for pressure testing, including cyclic testing to simulate fatigue conditions.

In the oil and gas industry, the American Petroleum Institute (API) has established standards like API 6D for pipeline valves and API 6A for wellhead and tree equipment, which include requirements for fatigue testing. These standards often incorporate accelerated life-cycle methodologies to assess long-term performance in a shorter timeframe.

The European Committee for Standardization (CEN) has developed EN 12266-1 and EN 12266-2, which specify test procedures and acceptance criteria for industrial valves, including fatigue testing requirements. These standards are widely adopted across Europe and often referenced globally.

For nuclear applications, the ASME Boiler and Pressure Vessel Code Section III provides specific requirements for valve fatigue testing in nuclear power plants. These standards are particularly stringent due to the critical nature of nuclear applications.

Regulatory bodies such as the U.S. Nuclear Regulatory Commission (NRC) and the European Nuclear Safety Regulators Group (ENSREG) also provide guidelines and enforce regulations related to valve fatigue testing in nuclear facilities.

In the aerospace industry, standards like SAE AS5856 for aerospace valve fatigue testing are used to ensure the reliability of valves in aircraft and spacecraft applications. These standards often require more rigorous testing protocols due to the extreme conditions encountered in aerospace environments.

It is important to note that while these standards provide a framework for valve fatigue testing, specific industries or applications may have additional requirements or modifications to these standards. Manufacturers and testing facilities must stay updated with the latest revisions and interpretations of these standards to ensure compliance and product reliability.

The American Society of Mechanical Engineers (ASME) has established several standards relevant to valve fatigue testing, including ASME B16.34 for valves in general and ASME B16.10 for face-to-face and end-to-end dimensions of valves. These standards specify the minimum requirements for design, materials, fabrication, and testing of valves, including fatigue testing procedures.

The International Organization for Standardization (ISO) has also developed standards applicable to valve fatigue testing, such as ISO 5208 for industrial valves and ISO 10497 for fire-type testing. These standards provide guidelines for pressure testing, including cyclic testing to simulate fatigue conditions.

In the oil and gas industry, the American Petroleum Institute (API) has established standards like API 6D for pipeline valves and API 6A for wellhead and tree equipment, which include requirements for fatigue testing. These standards often incorporate accelerated life-cycle methodologies to assess long-term performance in a shorter timeframe.

The European Committee for Standardization (CEN) has developed EN 12266-1 and EN 12266-2, which specify test procedures and acceptance criteria for industrial valves, including fatigue testing requirements. These standards are widely adopted across Europe and often referenced globally.

For nuclear applications, the ASME Boiler and Pressure Vessel Code Section III provides specific requirements for valve fatigue testing in nuclear power plants. These standards are particularly stringent due to the critical nature of nuclear applications.

Regulatory bodies such as the U.S. Nuclear Regulatory Commission (NRC) and the European Nuclear Safety Regulators Group (ENSREG) also provide guidelines and enforce regulations related to valve fatigue testing in nuclear facilities.

In the aerospace industry, standards like SAE AS5856 for aerospace valve fatigue testing are used to ensure the reliability of valves in aircraft and spacecraft applications. These standards often require more rigorous testing protocols due to the extreme conditions encountered in aerospace environments.

It is important to note that while these standards provide a framework for valve fatigue testing, specific industries or applications may have additional requirements or modifications to these standards. Manufacturers and testing facilities must stay updated with the latest revisions and interpretations of these standards to ensure compliance and product reliability.

Environmental Impact of Accelerated Testing Methods

Accelerated life-cycle testing methodologies for gate valves, while efficient in providing rapid results, can have significant environmental implications. These methods often involve subjecting valves to extreme conditions, which may require substantial energy consumption and potentially harmful materials. The increased testing frequency and intensity can lead to higher electricity usage, contributing to greenhouse gas emissions if not sourced from renewable energy.

Furthermore, the accelerated wear and tear on test specimens may result in increased waste generation. Gate valves subjected to accelerated testing are likely to deteriorate faster, potentially leading to more frequent disposal of materials that might otherwise have had a longer lifespan. This raises concerns about resource depletion and the environmental impact of manufacturing replacement components.

The use of specialized lubricants, coolants, or other chemicals in accelerated testing processes can also pose environmental risks. These substances may contain harmful compounds that, if not properly managed, could lead to soil or water contamination. Proper disposal and treatment of these materials are crucial to mitigate potential ecological damage.

Noise pollution is another environmental consideration in accelerated testing. The intense and prolonged operation of gate valves during these tests may generate significant noise levels, potentially affecting local ecosystems and wildlife if testing facilities are located near sensitive habitats.

However, it's important to note that accelerated testing methods can also have positive environmental impacts. By enabling more rapid product development and validation, these techniques can lead to the creation of more efficient and durable gate valves. This, in turn, can result in reduced material consumption and energy usage over the long term, as more reliable valves require less frequent replacement and maintenance.

Additionally, accelerated testing allows for the identification of potential failure modes and environmental vulnerabilities more quickly. This can lead to the development of more resilient designs that are better suited to withstand harsh environmental conditions, potentially reducing the overall environmental impact of gate valve installations in various industries.

To mitigate the negative environmental effects of accelerated testing, researchers and engineers are exploring more sustainable testing methodologies. These include the use of advanced simulation techniques to reduce physical testing requirements, the implementation of energy-efficient testing equipment, and the development of environmentally friendly lubricants and coolants specifically designed for accelerated life-cycle tests.

Furthermore, the accelerated wear and tear on test specimens may result in increased waste generation. Gate valves subjected to accelerated testing are likely to deteriorate faster, potentially leading to more frequent disposal of materials that might otherwise have had a longer lifespan. This raises concerns about resource depletion and the environmental impact of manufacturing replacement components.

The use of specialized lubricants, coolants, or other chemicals in accelerated testing processes can also pose environmental risks. These substances may contain harmful compounds that, if not properly managed, could lead to soil or water contamination. Proper disposal and treatment of these materials are crucial to mitigate potential ecological damage.

Noise pollution is another environmental consideration in accelerated testing. The intense and prolonged operation of gate valves during these tests may generate significant noise levels, potentially affecting local ecosystems and wildlife if testing facilities are located near sensitive habitats.

However, it's important to note that accelerated testing methods can also have positive environmental impacts. By enabling more rapid product development and validation, these techniques can lead to the creation of more efficient and durable gate valves. This, in turn, can result in reduced material consumption and energy usage over the long term, as more reliable valves require less frequent replacement and maintenance.

Additionally, accelerated testing allows for the identification of potential failure modes and environmental vulnerabilities more quickly. This can lead to the development of more resilient designs that are better suited to withstand harsh environmental conditions, potentially reducing the overall environmental impact of gate valve installations in various industries.

To mitigate the negative environmental effects of accelerated testing, researchers and engineers are exploring more sustainable testing methodologies. These include the use of advanced simulation techniques to reduce physical testing requirements, the implementation of energy-efficient testing equipment, and the development of environmentally friendly lubricants and coolants specifically designed for accelerated life-cycle tests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!