Gate valve challenges in managing rapid pressure changes in brewing

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Brewing Pressure Control Evolution and Objectives

The evolution of brewing pressure control has been a critical aspect of the beer production process, with significant advancements made over the past century. Initially, brewers relied on manual methods and rudimentary equipment to manage pressure changes during fermentation and packaging. As the industry grew and demand for consistent quality increased, the need for more precise pressure control became evident.

In the early 20th century, the introduction of stainless steel tanks and basic pressure relief valves marked the beginning of modern pressure management in brewing. These innovations allowed for better containment of carbon dioxide produced during fermentation and improved control over carbonation levels. However, the challenges of rapid pressure changes remained a significant concern, particularly during the transfer of beer between vessels and during packaging operations.

The mid-20th century saw the development of more sophisticated pressure control systems, including the introduction of automated pressure relief valves and basic pressure sensors. These advancements helped brewers maintain more stable pressure conditions throughout the brewing process, reducing the risk of over-pressurization and improving product consistency. Despite these improvements, the industry still faced challenges in managing sudden pressure fluctuations, especially in high-volume production environments.

The advent of computerized brewing systems in the late 20th century revolutionized pressure control in the brewing industry. These systems integrated pressure sensors, temperature monitors, and automated valves to provide real-time monitoring and adjustment of pressure conditions. This level of automation significantly improved the ability to manage rapid pressure changes, but also highlighted the limitations of existing valve technologies in responding to sudden fluctuations.

As the craft brewing movement gained momentum in the early 21st century, the focus shifted towards developing more flexible and responsive pressure control systems. This trend was driven by the need for smaller breweries to produce a wide variety of beer styles, each requiring specific pressure profiles during fermentation and packaging. The challenge of managing rapid pressure changes became even more pronounced in these diverse brewing environments.

Today, the brewing industry continues to pursue advancements in pressure control technology, with a particular focus on addressing the challenges posed by gate valves in managing rapid pressure changes. The objectives of current research and development efforts include improving valve response times, enhancing the durability of valve components under high-stress conditions, and developing more sophisticated control algorithms to anticipate and mitigate sudden pressure fluctuations.

In the early 20th century, the introduction of stainless steel tanks and basic pressure relief valves marked the beginning of modern pressure management in brewing. These innovations allowed for better containment of carbon dioxide produced during fermentation and improved control over carbonation levels. However, the challenges of rapid pressure changes remained a significant concern, particularly during the transfer of beer between vessels and during packaging operations.

The mid-20th century saw the development of more sophisticated pressure control systems, including the introduction of automated pressure relief valves and basic pressure sensors. These advancements helped brewers maintain more stable pressure conditions throughout the brewing process, reducing the risk of over-pressurization and improving product consistency. Despite these improvements, the industry still faced challenges in managing sudden pressure fluctuations, especially in high-volume production environments.

The advent of computerized brewing systems in the late 20th century revolutionized pressure control in the brewing industry. These systems integrated pressure sensors, temperature monitors, and automated valves to provide real-time monitoring and adjustment of pressure conditions. This level of automation significantly improved the ability to manage rapid pressure changes, but also highlighted the limitations of existing valve technologies in responding to sudden fluctuations.

As the craft brewing movement gained momentum in the early 21st century, the focus shifted towards developing more flexible and responsive pressure control systems. This trend was driven by the need for smaller breweries to produce a wide variety of beer styles, each requiring specific pressure profiles during fermentation and packaging. The challenge of managing rapid pressure changes became even more pronounced in these diverse brewing environments.

Today, the brewing industry continues to pursue advancements in pressure control technology, with a particular focus on addressing the challenges posed by gate valves in managing rapid pressure changes. The objectives of current research and development efforts include improving valve response times, enhancing the durability of valve components under high-stress conditions, and developing more sophisticated control algorithms to anticipate and mitigate sudden pressure fluctuations.

Market Demand for Advanced Brewing Pressure Management

The brewing industry has witnessed a significant surge in demand for advanced pressure management solutions, particularly in addressing the challenges associated with gate valves during rapid pressure changes. This growing market need is driven by several factors, including the increasing complexity of brewing processes, the pursuit of higher quality standards, and the need for more efficient and precise control over brewing parameters.

Craft breweries, in particular, have been at the forefront of this demand. As these smaller-scale operations strive to produce unique and high-quality beers, they require more sophisticated pressure management systems that can handle the intricacies of their specialized brewing techniques. The ability to precisely control pressure during different stages of the brewing process has become crucial for maintaining consistency and achieving desired flavor profiles.

Large-scale commercial breweries are also contributing to this market demand. With the need to optimize production efficiency and minimize waste, these breweries are seeking advanced gate valve solutions that can withstand frequent pressure fluctuations without compromising performance or requiring frequent maintenance. The potential for cost savings through improved process control and reduced downtime is a significant driver for investment in advanced pressure management technologies.

The global nature of the brewing industry has further amplified this demand. Breweries in emerging markets are rapidly adopting modern brewing technologies, creating new opportunities for advanced pressure management solutions. Additionally, established markets are seeing a trend towards upgrading existing infrastructure to meet evolving consumer preferences and regulatory requirements.

Environmental concerns and sustainability initiatives within the brewing industry are also influencing the demand for more efficient pressure management systems. Breweries are increasingly looking for solutions that can help reduce energy consumption and water usage, both of which are closely tied to pressure control in various brewing stages.

The market is also seeing a shift towards more integrated and automated brewing systems. This trend is driving demand for gate valves and pressure management solutions that can seamlessly interface with digital control systems and provide real-time data for process optimization. The ability to remotely monitor and adjust pressure parameters is becoming increasingly valuable in modern brewing operations.

As the brewing industry continues to evolve, there is a growing recognition of the critical role that precise pressure management plays in product quality and operational efficiency. This has led to increased investment in research and development by both brewing equipment manufacturers and breweries themselves, further stimulating the market for advanced gate valve solutions.

Craft breweries, in particular, have been at the forefront of this demand. As these smaller-scale operations strive to produce unique and high-quality beers, they require more sophisticated pressure management systems that can handle the intricacies of their specialized brewing techniques. The ability to precisely control pressure during different stages of the brewing process has become crucial for maintaining consistency and achieving desired flavor profiles.

Large-scale commercial breweries are also contributing to this market demand. With the need to optimize production efficiency and minimize waste, these breweries are seeking advanced gate valve solutions that can withstand frequent pressure fluctuations without compromising performance or requiring frequent maintenance. The potential for cost savings through improved process control and reduced downtime is a significant driver for investment in advanced pressure management technologies.

The global nature of the brewing industry has further amplified this demand. Breweries in emerging markets are rapidly adopting modern brewing technologies, creating new opportunities for advanced pressure management solutions. Additionally, established markets are seeing a trend towards upgrading existing infrastructure to meet evolving consumer preferences and regulatory requirements.

Environmental concerns and sustainability initiatives within the brewing industry are also influencing the demand for more efficient pressure management systems. Breweries are increasingly looking for solutions that can help reduce energy consumption and water usage, both of which are closely tied to pressure control in various brewing stages.

The market is also seeing a shift towards more integrated and automated brewing systems. This trend is driving demand for gate valves and pressure management solutions that can seamlessly interface with digital control systems and provide real-time data for process optimization. The ability to remotely monitor and adjust pressure parameters is becoming increasingly valuable in modern brewing operations.

As the brewing industry continues to evolve, there is a growing recognition of the critical role that precise pressure management plays in product quality and operational efficiency. This has led to increased investment in research and development by both brewing equipment manufacturers and breweries themselves, further stimulating the market for advanced gate valve solutions.

Gate Valve Limitations in Rapid Pressure Fluctuations

Gate valves, widely used in brewing processes, face significant challenges when managing rapid pressure changes. These valves are designed to control flow by raising or lowering a gate or wedge-shaped disc perpendicular to the flow path. However, their performance can be severely compromised under conditions of rapid pressure fluctuations, which are common in brewing operations.

One of the primary limitations of gate valves in handling rapid pressure changes is their relatively slow response time. The mechanical nature of gate valve operation, involving the movement of a large disc, inherently introduces a delay between the initiation of the valve action and its completion. This lag can be critical in scenarios where pressure changes occur rapidly, potentially leading to inadequate flow control or even system damage.

The sealing mechanism of gate valves is another area of concern when dealing with rapid pressure fluctuations. The sudden changes in pressure can cause temporary deformation of the valve components, potentially compromising the seal integrity. This can result in leakage, which is particularly problematic in brewing applications where maintaining precise pressure conditions is crucial for product quality and consistency.

Gate valves also face challenges related to wear and tear under conditions of frequent pressure changes. The repeated stress on the valve components, especially the sealing surfaces and actuator mechanisms, can lead to accelerated degradation. This not only reduces the operational lifespan of the valve but also increases the risk of failure during critical brewing processes.

The design of gate valves makes them susceptible to cavitation and flashing under rapid pressure changes. These phenomena can occur when the pressure drop across the valve is significant, leading to the formation of vapor bubbles that can cause erosion and damage to the valve internals. In brewing applications, where maintaining product integrity is paramount, such issues can have severe consequences on both equipment longevity and product quality.

Furthermore, gate valves may struggle with precise flow control under rapidly changing pressure conditions. The non-linear relationship between valve position and flow rate becomes more pronounced in such scenarios, making it challenging to achieve the fine-tuned control often required in brewing processes. This limitation can lead to inconsistencies in product quality and process efficiency.

The thermal expansion characteristics of gate valve materials can also pose challenges in environments with rapid pressure and temperature fluctuations. Differential expansion rates between various valve components can lead to misalignment or binding, potentially affecting valve performance or causing failure in extreme cases.

One of the primary limitations of gate valves in handling rapid pressure changes is their relatively slow response time. The mechanical nature of gate valve operation, involving the movement of a large disc, inherently introduces a delay between the initiation of the valve action and its completion. This lag can be critical in scenarios where pressure changes occur rapidly, potentially leading to inadequate flow control or even system damage.

The sealing mechanism of gate valves is another area of concern when dealing with rapid pressure fluctuations. The sudden changes in pressure can cause temporary deformation of the valve components, potentially compromising the seal integrity. This can result in leakage, which is particularly problematic in brewing applications where maintaining precise pressure conditions is crucial for product quality and consistency.

Gate valves also face challenges related to wear and tear under conditions of frequent pressure changes. The repeated stress on the valve components, especially the sealing surfaces and actuator mechanisms, can lead to accelerated degradation. This not only reduces the operational lifespan of the valve but also increases the risk of failure during critical brewing processes.

The design of gate valves makes them susceptible to cavitation and flashing under rapid pressure changes. These phenomena can occur when the pressure drop across the valve is significant, leading to the formation of vapor bubbles that can cause erosion and damage to the valve internals. In brewing applications, where maintaining product integrity is paramount, such issues can have severe consequences on both equipment longevity and product quality.

Furthermore, gate valves may struggle with precise flow control under rapidly changing pressure conditions. The non-linear relationship between valve position and flow rate becomes more pronounced in such scenarios, making it challenging to achieve the fine-tuned control often required in brewing processes. This limitation can lead to inconsistencies in product quality and process efficiency.

The thermal expansion characteristics of gate valve materials can also pose challenges in environments with rapid pressure and temperature fluctuations. Differential expansion rates between various valve components can lead to misalignment or binding, potentially affecting valve performance or causing failure in extreme cases.

Current Solutions for Rapid Pressure Change Management

01 Pressure-responsive valve mechanisms

Gate valves can be designed with pressure-responsive mechanisms that adjust the valve position based on pressure changes. These mechanisms may include pressure sensors, actuators, or balanced valve designs that automatically respond to pressure fluctuations, ensuring optimal flow control and system protection.- Pressure-responsive valve mechanisms: Gate valves can be designed with pressure-responsive mechanisms that adjust the valve position based on pressure changes. These mechanisms may include pressure sensors, actuators, or balanced valve designs that automatically respond to pressure fluctuations, ensuring optimal flow control and system protection.

- Pressure equalization systems: Some gate valves incorporate pressure equalization systems to manage pressure changes across the valve. These systems may include bypass channels, pressure relief valves, or balanced disc designs that help minimize the effects of pressure differentials, reducing wear and improving valve performance.

- Smart valve control systems: Advanced gate valves may feature smart control systems that monitor and respond to pressure changes in real-time. These systems can include electronic sensors, microprocessors, and actuators that adjust valve position based on pressure data, optimizing flow control and preventing pressure-related issues.

- Pressure-compensating valve designs: Gate valves can be designed with pressure-compensating features to maintain consistent performance under varying pressure conditions. These designs may include balanced discs, pressure-assisted sealing mechanisms, or flexible components that adapt to pressure changes, ensuring reliable operation across a wide range of pressures.

- Pressure monitoring and feedback systems: Some gate valves incorporate pressure monitoring and feedback systems to provide real-time data on pressure changes. These systems may include pressure sensors, data logging capabilities, and communication interfaces that allow operators to track pressure fluctuations and make informed decisions about valve operation and maintenance.

02 Pressure equalization systems

Some gate valves incorporate pressure equalization systems to minimize the effects of pressure changes on valve operation. These systems may include bypass channels, pressure balancing chambers, or specialized sealing arrangements that help maintain consistent valve performance across varying pressure conditions.Expand Specific Solutions03 Smart control and monitoring systems

Advanced gate valves may feature smart control and monitoring systems that continuously track pressure changes and adjust valve settings accordingly. These systems can include digital sensors, microprocessors, and remote monitoring capabilities to optimize valve performance and prevent pressure-related issues.Expand Specific Solutions04 Pressure relief mechanisms

Gate valves can be equipped with pressure relief mechanisms to handle sudden pressure changes or overpressure situations. These mechanisms may include relief valves, rupture discs, or specialized vent systems that activate when pressure exceeds predetermined thresholds, protecting the valve and connected systems.Expand Specific Solutions05 Material selection for pressure resistance

The choice of materials used in gate valve construction plays a crucial role in their ability to withstand pressure changes. High-strength alloys, advanced composites, or specially treated metals may be employed to enhance the valve's pressure resistance and durability under varying pressure conditions.Expand Specific Solutions

Key Players in Brewing Equipment and Valve Manufacturing

The gate valve market for managing rapid pressure changes in brewing is in a growth phase, driven by increasing demand for efficient brewing processes. The market size is expanding due to the rising craft beer industry and technological advancements in valve design. While the technology is relatively mature, there's ongoing innovation to improve performance and reliability. Key players like Robert Bosch GmbH, Ningbo Major Draft Beer Equipment Co. Ltd., and Bunn-O-Matic Corp. are leading the market with their specialized solutions. These companies are focusing on developing valves that can withstand high-pressure variations and maintain product quality, indicating a competitive landscape with a strong emphasis on technological differentiation and product reliability.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced gate valve solutions for managing rapid pressure changes in brewing processes. Their system incorporates intelligent pressure sensors and high-speed actuators to rapidly adjust valve positions in response to pressure fluctuations. The valves utilize a multi-stage design with precision-engineered flow paths to minimize turbulence and cavitation[1]. Bosch's solution also integrates machine learning algorithms to predict pressure changes based on historical data and process parameters, allowing for proactive valve adjustments[2]. This predictive capability helps maintain consistent pressure levels throughout the brewing process, resulting in improved product quality and reduced equipment wear.

Strengths: Advanced sensor technology and predictive algorithms for precise pressure control. Weaknesses: Potentially higher initial cost and complexity compared to traditional valve systems.

Ningbo Major Draft Beer Equipment Co. Ltd.

Technical Solution: Ningbo Major Draft Beer Equipment Co. Ltd. has developed a specialized gate valve system for draft beer equipment that addresses rapid pressure changes during dispensing. Their solution incorporates a dual-chamber design with a pressure-equalizing mechanism[3]. As beer is dispensed, the primary chamber maintains a consistent pressure while the secondary chamber adjusts to accommodate rapid changes. The valve system uses food-grade materials and features a quick-response actuator that can handle pressure fluctuations within milliseconds[4]. Additionally, the company has implemented a micro-foaming technology within the valve to enhance beer quality and presentation during dispensing, even under varying pressure conditions.

Strengths: Specialized design for draft beer systems with quick response times. Weaknesses: May be limited in application to broader brewing processes beyond dispensing.

Innovative Gate Valve Designs for Pressure Stability

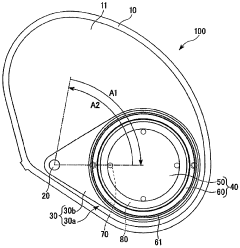

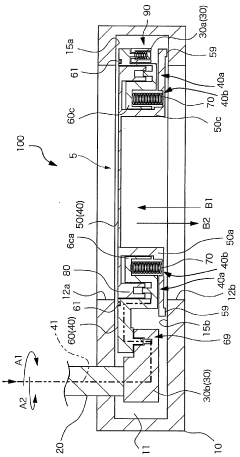

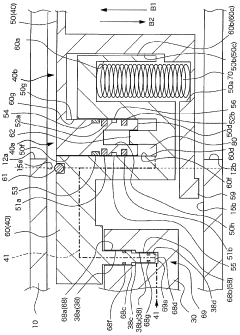

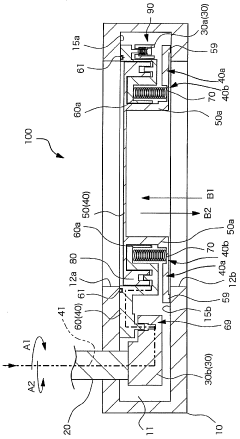

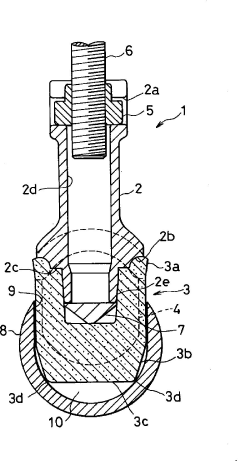

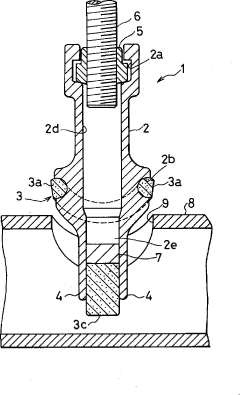

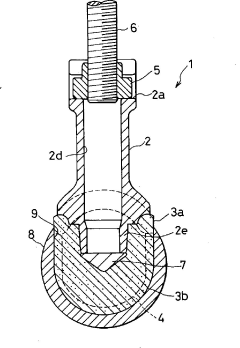

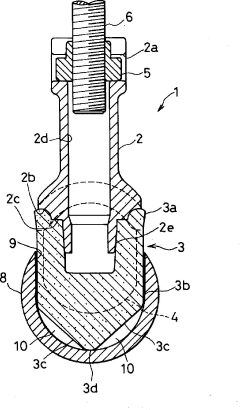

Gate valve and slide valve

PatentWO2012121410A1

Innovation

- A gate valve design featuring a neutral valve body with movable valve portions and biasing mechanisms that allow for adjustable sealing and reduced complexity, including air cylinders and seal portions for efficient operation and easy assembly, along with a rotating shaft and connecting member configuration for simplified attachment.

Gate valve

PatentInactiveJP2001082617A

Innovation

- A gate valve design featuring a deformable second seal portion that gradually changes the water flow area by forming a water-conducting portion between the seal and the inner peripheral wall, suppressing abrupt flow velocity changes and water hammer pressure through controlled deformation.

Safety Standards and Regulations in Brewing Equipment

Safety standards and regulations play a crucial role in the brewing industry, particularly concerning equipment such as gate valves used in managing rapid pressure changes. These standards are designed to ensure the safety of workers, maintain product quality, and protect the environment.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for brewery safety, including requirements for pressure vessels and valves. OSHA's standard 29 CFR 1910.119 specifically addresses process safety management of highly hazardous chemicals, which is applicable to brewing operations due to the use of pressurized systems and potentially dangerous substances.

The Food and Drug Administration (FDA) also regulates brewing equipment through its Current Good Manufacturing Practice (CGMP) regulations. These guidelines ensure that food processing equipment, including valves, meets sanitary design standards to prevent contamination and maintain product safety.

Internationally, the European Hygienic Engineering and Design Group (EHEDG) provides guidelines for hygienic equipment design in food processing, including brewing. Their standards address the construction materials, surface finish, and cleanability of equipment components like gate valves.

The Brewers Association, a trade organization representing small and independent American craft brewers, has developed its own set of safety and best practice guidelines. These include recommendations for pressure vessel safety, valve maintenance, and proper handling of equipment during brewing processes.

Specific to gate valves, the American Society of Mechanical Engineers (ASME) has developed standards such as ASME B16.34 for valves in pressure systems. This standard covers design, materials, fabrication, and testing requirements for new valves used in pressure systems, including those in brewing operations.

The National Fire Protection Association (NFPA) also provides relevant standards, particularly NFPA 30 Flammable and Combustible Liquids Code, which addresses safety concerns in facilities handling flammable liquids, including some aspects of brewing operations.

Compliance with these standards and regulations is essential for breweries to ensure safe operations, particularly when dealing with rapid pressure changes. Regular inspections, maintenance, and proper documentation of equipment such as gate valves are required to meet these safety standards and avoid potential hazards or regulatory violations.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for brewery safety, including requirements for pressure vessels and valves. OSHA's standard 29 CFR 1910.119 specifically addresses process safety management of highly hazardous chemicals, which is applicable to brewing operations due to the use of pressurized systems and potentially dangerous substances.

The Food and Drug Administration (FDA) also regulates brewing equipment through its Current Good Manufacturing Practice (CGMP) regulations. These guidelines ensure that food processing equipment, including valves, meets sanitary design standards to prevent contamination and maintain product safety.

Internationally, the European Hygienic Engineering and Design Group (EHEDG) provides guidelines for hygienic equipment design in food processing, including brewing. Their standards address the construction materials, surface finish, and cleanability of equipment components like gate valves.

The Brewers Association, a trade organization representing small and independent American craft brewers, has developed its own set of safety and best practice guidelines. These include recommendations for pressure vessel safety, valve maintenance, and proper handling of equipment during brewing processes.

Specific to gate valves, the American Society of Mechanical Engineers (ASME) has developed standards such as ASME B16.34 for valves in pressure systems. This standard covers design, materials, fabrication, and testing requirements for new valves used in pressure systems, including those in brewing operations.

The National Fire Protection Association (NFPA) also provides relevant standards, particularly NFPA 30 Flammable and Combustible Liquids Code, which addresses safety concerns in facilities handling flammable liquids, including some aspects of brewing operations.

Compliance with these standards and regulations is essential for breweries to ensure safe operations, particularly when dealing with rapid pressure changes. Regular inspections, maintenance, and proper documentation of equipment such as gate valves are required to meet these safety standards and avoid potential hazards or regulatory violations.

Economic Impact of Improved Pressure Management

Improved pressure management in brewing processes can have significant economic impacts on the industry. The ability to effectively control and manage rapid pressure changes using advanced gate valve technologies can lead to substantial cost savings and increased operational efficiency.

One of the primary economic benefits is the reduction in product loss. Traditional valve systems may struggle to handle sudden pressure fluctuations, resulting in spillage or contamination of the brew. By implementing more responsive and precise gate valve systems, breweries can minimize waste and maximize the yield from each batch. This directly translates to improved profitability and resource utilization.

Energy efficiency is another crucial factor influenced by better pressure management. Advanced gate valves can optimize the use of compressed air and steam, two essential utilities in brewing operations. By maintaining more stable pressure levels and reducing the need for frequent adjustments, breweries can significantly lower their energy consumption. This not only reduces operational costs but also aligns with sustainability goals, potentially opening up opportunities for green certifications and associated market advantages.

Equipment longevity and maintenance costs are also positively impacted by improved pressure management. Rapid pressure changes can cause wear and tear on brewing equipment, leading to frequent breakdowns and costly repairs. With more sophisticated gate valve systems, the stress on equipment is reduced, extending its operational life and decreasing maintenance frequency. This results in lower long-term capital expenditures and reduced downtime, both of which contribute to improved economic performance.

The quality and consistency of the final product are paramount in the brewing industry. Better pressure management through advanced gate valves ensures more precise control over the brewing process, leading to higher quality and more consistent products. This can enhance brand reputation, customer loyalty, and potentially command premium pricing, all of which contribute to increased revenue and market share.

Lastly, improved pressure management can lead to increased production capacity. By optimizing the brewing process and reducing downtime, breweries can potentially increase their output without significant additional investments in equipment or facilities. This scalability allows breweries to respond more effectively to market demands and capitalize on growth opportunities, further enhancing their economic position in the competitive brewing landscape.

One of the primary economic benefits is the reduction in product loss. Traditional valve systems may struggle to handle sudden pressure fluctuations, resulting in spillage or contamination of the brew. By implementing more responsive and precise gate valve systems, breweries can minimize waste and maximize the yield from each batch. This directly translates to improved profitability and resource utilization.

Energy efficiency is another crucial factor influenced by better pressure management. Advanced gate valves can optimize the use of compressed air and steam, two essential utilities in brewing operations. By maintaining more stable pressure levels and reducing the need for frequent adjustments, breweries can significantly lower their energy consumption. This not only reduces operational costs but also aligns with sustainability goals, potentially opening up opportunities for green certifications and associated market advantages.

Equipment longevity and maintenance costs are also positively impacted by improved pressure management. Rapid pressure changes can cause wear and tear on brewing equipment, leading to frequent breakdowns and costly repairs. With more sophisticated gate valve systems, the stress on equipment is reduced, extending its operational life and decreasing maintenance frequency. This results in lower long-term capital expenditures and reduced downtime, both of which contribute to improved economic performance.

The quality and consistency of the final product are paramount in the brewing industry. Better pressure management through advanced gate valves ensures more precise control over the brewing process, leading to higher quality and more consistent products. This can enhance brand reputation, customer loyalty, and potentially command premium pricing, all of which contribute to increased revenue and market share.

Lastly, improved pressure management can lead to increased production capacity. By optimizing the brewing process and reducing downtime, breweries can potentially increase their output without significant additional investments in equipment or facilities. This scalability allows breweries to respond more effectively to market demands and capitalize on growth opportunities, further enhancing their economic position in the competitive brewing landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!