Development of autonomous gate valve control systems

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autonomous Valve Control Background and Objectives

Autonomous gate valve control systems have emerged as a critical technology in various industries, particularly in oil and gas, water management, and process control. The evolution of these systems can be traced back to the early days of industrial automation, where manual valve operation was the norm. As industries sought to improve efficiency, reduce human error, and enhance safety, the development of automated valve control systems gained momentum.

The progression of autonomous gate valve control systems has been closely tied to advancements in sensor technology, artificial intelligence, and industrial Internet of Things (IIoT). Early automated systems relied on simple feedback mechanisms and predefined rules. However, modern autonomous systems incorporate sophisticated algorithms, machine learning capabilities, and real-time data analysis to make intelligent decisions without human intervention.

The primary objective of developing autonomous gate valve control systems is to achieve optimal flow control, minimize downtime, and maximize operational efficiency. These systems aim to respond rapidly to changing conditions, predict potential issues before they occur, and self-adjust to maintain optimal performance. By reducing the need for manual intervention, they also contribute to improved safety in hazardous environments and remote locations.

Another key goal is to enhance the overall reliability and longevity of valve systems. Autonomous control can help prevent issues such as water hammer, cavitation, and excessive wear by precisely controlling valve opening and closing sequences. This not only extends the life of the equipment but also reduces maintenance costs and improves system integrity.

The development of these systems also aligns with the broader trend of digital transformation in industries. As companies move towards smart factories and digital twins, autonomous valve control systems play a crucial role in creating fully integrated and responsive industrial ecosystems. They provide valuable data for predictive maintenance, process optimization, and overall system performance analysis.

Looking ahead, the future objectives for autonomous gate valve control systems include further integration with artificial intelligence and machine learning to enable predictive capabilities and self-optimization. There is also a push towards developing more robust and adaptable systems that can operate effectively in diverse and challenging environments, from deep-sea oil rigs to complex chemical processing plants.

As industries continue to evolve, the development of autonomous gate valve control systems will likely focus on enhancing interoperability with other smart systems, improving cybersecurity measures to protect against potential threats, and reducing the environmental impact through more efficient resource management and reduced energy consumption.

The progression of autonomous gate valve control systems has been closely tied to advancements in sensor technology, artificial intelligence, and industrial Internet of Things (IIoT). Early automated systems relied on simple feedback mechanisms and predefined rules. However, modern autonomous systems incorporate sophisticated algorithms, machine learning capabilities, and real-time data analysis to make intelligent decisions without human intervention.

The primary objective of developing autonomous gate valve control systems is to achieve optimal flow control, minimize downtime, and maximize operational efficiency. These systems aim to respond rapidly to changing conditions, predict potential issues before they occur, and self-adjust to maintain optimal performance. By reducing the need for manual intervention, they also contribute to improved safety in hazardous environments and remote locations.

Another key goal is to enhance the overall reliability and longevity of valve systems. Autonomous control can help prevent issues such as water hammer, cavitation, and excessive wear by precisely controlling valve opening and closing sequences. This not only extends the life of the equipment but also reduces maintenance costs and improves system integrity.

The development of these systems also aligns with the broader trend of digital transformation in industries. As companies move towards smart factories and digital twins, autonomous valve control systems play a crucial role in creating fully integrated and responsive industrial ecosystems. They provide valuable data for predictive maintenance, process optimization, and overall system performance analysis.

Looking ahead, the future objectives for autonomous gate valve control systems include further integration with artificial intelligence and machine learning to enable predictive capabilities and self-optimization. There is also a push towards developing more robust and adaptable systems that can operate effectively in diverse and challenging environments, from deep-sea oil rigs to complex chemical processing plants.

As industries continue to evolve, the development of autonomous gate valve control systems will likely focus on enhancing interoperability with other smart systems, improving cybersecurity measures to protect against potential threats, and reducing the environmental impact through more efficient resource management and reduced energy consumption.

Market Analysis for Smart Valve Systems

The market for smart valve systems, particularly autonomous gate valve control systems, has been experiencing significant growth in recent years. This surge is driven by the increasing demand for automation and efficiency in various industries, including oil and gas, water and wastewater management, and industrial manufacturing. The global smart valve market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other industrial automation sectors.

One of the primary drivers for this market growth is the need for improved operational efficiency and reduced downtime in industrial processes. Autonomous gate valve control systems offer real-time monitoring and control capabilities, allowing for predictive maintenance and rapid response to changing conditions. This results in significant cost savings for end-users, as well as enhanced safety and reliability in critical operations.

The oil and gas industry remains a major contributor to the smart valve market, with a growing emphasis on digitalization and automation in upstream, midstream, and downstream operations. The adoption of autonomous gate valve control systems in this sector is driven by the need for precise flow control, improved safety measures, and the ability to operate in remote or hazardous environments.

Water and wastewater management is another key sector driving the demand for smart valve systems. As municipalities and utilities face increasing pressure to conserve water resources and improve infrastructure efficiency, autonomous gate valve control systems offer solutions for leak detection, pressure management, and overall system optimization.

In the industrial manufacturing sector, the integration of smart valve systems aligns with the broader trend of Industry 4.0 and the Industrial Internet of Things (IIoT). These systems enable manufacturers to achieve greater process control, energy efficiency, and product quality through real-time data analysis and automated decision-making.

The market for autonomous gate valve control systems is also benefiting from advancements in related technologies, such as artificial intelligence, machine learning, and edge computing. These innovations are enhancing the capabilities of smart valve systems, enabling more sophisticated predictive analytics and autonomous operation.

Geographically, North America and Europe currently lead the smart valve market, owing to their established industrial bases and early adoption of automation technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing investments in smart city projects.

One of the primary drivers for this market growth is the need for improved operational efficiency and reduced downtime in industrial processes. Autonomous gate valve control systems offer real-time monitoring and control capabilities, allowing for predictive maintenance and rapid response to changing conditions. This results in significant cost savings for end-users, as well as enhanced safety and reliability in critical operations.

The oil and gas industry remains a major contributor to the smart valve market, with a growing emphasis on digitalization and automation in upstream, midstream, and downstream operations. The adoption of autonomous gate valve control systems in this sector is driven by the need for precise flow control, improved safety measures, and the ability to operate in remote or hazardous environments.

Water and wastewater management is another key sector driving the demand for smart valve systems. As municipalities and utilities face increasing pressure to conserve water resources and improve infrastructure efficiency, autonomous gate valve control systems offer solutions for leak detection, pressure management, and overall system optimization.

In the industrial manufacturing sector, the integration of smart valve systems aligns with the broader trend of Industry 4.0 and the Industrial Internet of Things (IIoT). These systems enable manufacturers to achieve greater process control, energy efficiency, and product quality through real-time data analysis and automated decision-making.

The market for autonomous gate valve control systems is also benefiting from advancements in related technologies, such as artificial intelligence, machine learning, and edge computing. These innovations are enhancing the capabilities of smart valve systems, enabling more sophisticated predictive analytics and autonomous operation.

Geographically, North America and Europe currently lead the smart valve market, owing to their established industrial bases and early adoption of automation technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing investments in smart city projects.

Current Challenges in Autonomous Valve Technology

The development of autonomous gate valve control systems faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the complexity of integrating various sensors and actuators into a cohesive and reliable system. These components must work seamlessly together to accurately monitor valve conditions, detect potential issues, and execute precise control actions.

Another major challenge lies in the development of robust algorithms capable of handling diverse operational scenarios and environmental conditions. These algorithms must be able to process large amounts of real-time data from multiple sources, make intelligent decisions, and adapt to changing circumstances without human intervention. The unpredictability of industrial environments and the potential for unexpected events further complicate this task.

Ensuring the reliability and safety of autonomous valve systems is paramount, particularly in critical industries such as oil and gas, where failures can have severe consequences. Developing fail-safe mechanisms, redundancy systems, and comprehensive error detection and recovery protocols presents a significant technical hurdle. Additionally, cybersecurity concerns are becoming increasingly important as these systems become more connected and vulnerable to potential cyber attacks.

The power management and energy efficiency of autonomous valve control systems pose another challenge. Many industrial environments have limited power resources, and the systems must operate continuously for extended periods. Balancing the need for constant monitoring and rapid response times with energy conservation is a complex engineering problem that requires innovative solutions.

Interoperability and standardization issues also present obstacles to the widespread adoption of autonomous valve technology. Different manufacturers often use proprietary protocols and interfaces, making it difficult to integrate systems from multiple vendors or retrofit existing infrastructure. The lack of industry-wide standards for autonomous valve control systems hampers compatibility and scalability.

The harsh operating conditions in many industrial settings, such as extreme temperatures, high pressures, and corrosive environments, place significant demands on the hardware components of autonomous valve systems. Developing sensors, actuators, and control units that can withstand these conditions while maintaining accuracy and reliability over long periods is a persistent challenge for engineers and materials scientists.

Lastly, the cost-effectiveness of implementing autonomous valve control systems remains a concern for many industries. While the long-term benefits of improved efficiency and reduced downtime are clear, the initial investment and ongoing maintenance costs can be substantial. Striking the right balance between advanced functionality and economic viability is crucial for widespread adoption and continued development of this technology.

Another major challenge lies in the development of robust algorithms capable of handling diverse operational scenarios and environmental conditions. These algorithms must be able to process large amounts of real-time data from multiple sources, make intelligent decisions, and adapt to changing circumstances without human intervention. The unpredictability of industrial environments and the potential for unexpected events further complicate this task.

Ensuring the reliability and safety of autonomous valve systems is paramount, particularly in critical industries such as oil and gas, where failures can have severe consequences. Developing fail-safe mechanisms, redundancy systems, and comprehensive error detection and recovery protocols presents a significant technical hurdle. Additionally, cybersecurity concerns are becoming increasingly important as these systems become more connected and vulnerable to potential cyber attacks.

The power management and energy efficiency of autonomous valve control systems pose another challenge. Many industrial environments have limited power resources, and the systems must operate continuously for extended periods. Balancing the need for constant monitoring and rapid response times with energy conservation is a complex engineering problem that requires innovative solutions.

Interoperability and standardization issues also present obstacles to the widespread adoption of autonomous valve technology. Different manufacturers often use proprietary protocols and interfaces, making it difficult to integrate systems from multiple vendors or retrofit existing infrastructure. The lack of industry-wide standards for autonomous valve control systems hampers compatibility and scalability.

The harsh operating conditions in many industrial settings, such as extreme temperatures, high pressures, and corrosive environments, place significant demands on the hardware components of autonomous valve systems. Developing sensors, actuators, and control units that can withstand these conditions while maintaining accuracy and reliability over long periods is a persistent challenge for engineers and materials scientists.

Lastly, the cost-effectiveness of implementing autonomous valve control systems remains a concern for many industries. While the long-term benefits of improved efficiency and reduced downtime are clear, the initial investment and ongoing maintenance costs can be substantial. Striking the right balance between advanced functionality and economic viability is crucial for widespread adoption and continued development of this technology.

Existing Autonomous Valve Control Solutions

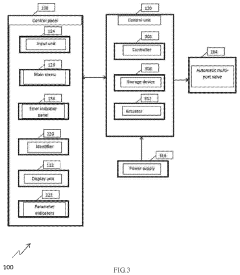

01 Automated control systems for gate valves

Autonomous control systems for gate valves utilize sensors, actuators, and programmable logic controllers to monitor and adjust valve positions based on various parameters such as flow rate, pressure, and temperature. These systems can operate without human intervention, improving efficiency and safety in fluid control applications.- Automated control systems for gate valves: Autonomous control systems for gate valves utilize sensors, actuators, and programmable logic controllers to monitor and adjust valve positions based on various parameters such as flow rate, pressure, and temperature. These systems can operate without human intervention, improving efficiency and safety in fluid control applications.

- Remote monitoring and control of gate valves: Remote monitoring and control systems allow operators to manage gate valves from a centralized location or via mobile devices. These systems often incorporate wireless communication technologies, enabling real-time data transmission and remote adjustment of valve settings, enhancing operational flexibility and reducing on-site personnel requirements.

- Intelligent gate valve systems with predictive maintenance: Advanced gate valve control systems incorporate machine learning algorithms and data analytics to predict potential failures and schedule maintenance activities. These systems analyze historical data, operational patterns, and real-time sensor inputs to optimize valve performance and minimize downtime.

- Integration of gate valve control with broader industrial automation systems: Autonomous gate valve control systems are increasingly integrated with larger industrial automation frameworks, such as SCADA systems or Industrial Internet of Things (IIoT) platforms. This integration allows for coordinated control of multiple valves and other equipment, optimizing overall process efficiency and facilitating comprehensive data analysis.

- Fail-safe mechanisms in autonomous gate valve systems: Autonomous gate valve control systems incorporate fail-safe mechanisms to ensure safe operation in case of system failures or power outages. These mechanisms may include automatic valve closure, backup power sources, or redundant control systems to maintain process safety and prevent potential hazards.

02 Remote monitoring and control of gate valves

Remote monitoring and control systems allow operators to manage gate valves from a centralized location. These systems often incorporate wireless communication technologies, enabling real-time data transmission and remote operation of valves in challenging or hazardous environments.Expand Specific Solutions03 Intelligent gate valve systems with predictive maintenance

Advanced gate valve control systems incorporate machine learning algorithms and data analytics to predict potential failures and schedule maintenance activities. These systems analyze historical data and real-time performance metrics to optimize valve operation and minimize downtime.Expand Specific Solutions04 Integration of gate valve control with process automation

Gate valve control systems are integrated into broader process automation frameworks, allowing for seamless coordination with other equipment and systems. This integration enables optimized process control, energy efficiency, and improved overall plant performance.Expand Specific Solutions05 Fail-safe mechanisms in autonomous gate valve systems

Autonomous gate valve control systems incorporate fail-safe mechanisms to ensure safe operation in case of power failure, communication loss, or system malfunction. These mechanisms may include emergency shutdown procedures, backup power sources, and redundant control systems to maintain valve integrity and prevent potential hazards.Expand Specific Solutions

Key Players in Autonomous Valve Industry

The development of autonomous gate valve control systems is in an emerging stage, with the market showing significant growth potential. The technology is advancing rapidly, driven by increasing demand for automation in various industries. Market size is expanding as more sectors recognize the benefits of autonomous valve control. In terms of technological maturity, companies like Fisher Controls International LLC and Emerson Process Management Regulator Technologies, Inc. are leading the way with advanced solutions. Other players such as Zhejiang Zhongde Automatic Control Valve Co. Ltd. and Sichuan Zhongding Intelligent Technology Co., Ltd. are also making strides in this field, indicating a competitive landscape with room for innovation and market share growth.

Fisher Controls International LLC

Technical Solution: Fisher Controls, a subsidiary of Emerson, has developed the FIELDVUE™ digital valve controller for autonomous gate valve control. This system utilizes advanced diagnostics and control algorithms to provide precise valve positioning and predictive maintenance capabilities. The FIELDVUE controller incorporates Fisher's ValveLink™ software, which enables real-time monitoring of valve performance and facilitates remote diagnostics[5]. The system features adaptive tuning algorithms that automatically adjust control parameters based on changing process conditions, ensuring optimal valve performance. Fisher's solution also includes integration with various industrial communication protocols, such as HART and FOUNDATION Fieldbus, for seamless integration with existing control systems[6].

Strengths: High precision control, extensive diagnostic capabilities, and compatibility with various industrial communication standards. Weaknesses: May require specialized training for maintenance personnel and potential limitations in retrofitting older valve systems.

Emerson Process Management Regulator Technologies, Inc.

Technical Solution: Emerson has developed advanced autonomous gate valve control systems utilizing their DeltaV™ distributed control system (DCS) platform. This system integrates smart sensors, predictive diagnostics, and machine learning algorithms to enable real-time monitoring and autonomous decision-making for gate valve operations. The DeltaV platform incorporates digital twin technology to create virtual models of physical gate valves, allowing for predictive maintenance and optimization of valve performance[1]. Emerson's solution also includes wireless communication protocols for remote monitoring and control, enhancing flexibility and reducing installation costs. The system employs adaptive control algorithms that continuously learn from operational data to improve valve positioning accuracy and response times[2].

Strengths: Comprehensive integration with existing industrial control systems, advanced predictive maintenance capabilities, and scalability across various industries. Weaknesses: Potential high initial implementation costs and reliance on proprietary technology ecosystem.

Core Innovations in Smart Valve Technology

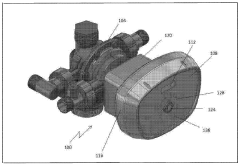

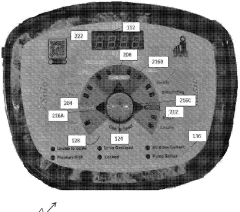

Automatic multi-port valve controlling device

PatentWO2024023850A1

Innovation

- An automatic multi-port valve controlling device with a control panel featuring a rotary clickable input unit, a main menu with sub-menus, error indicators, and a QR code identifier for easy operation and configuration, allowing users to select and set parameters intuitively.

Safety and Reliability Considerations

Safety and reliability are paramount considerations in the development of autonomous gate valve control systems. These systems, which operate critical components in various industrial processes, must be designed with robust safety measures and high reliability standards to prevent accidents, minimize downtime, and ensure optimal performance.

One of the primary safety considerations is the implementation of fail-safe mechanisms. In the event of a system failure or power loss, the gate valve should automatically move to a predetermined safe position, typically fully closed or fully open, depending on the specific application. This ensures that the process remains in a controlled state even during unexpected events.

Redundancy is another crucial aspect of safety and reliability. Autonomous gate valve control systems should incorporate redundant sensors, actuators, and control units to maintain operation in case of component failure. This redundancy can be achieved through parallel systems or by implementing diverse technologies to mitigate common mode failures.

Cybersecurity is an increasingly important consideration in autonomous systems. As these valve control systems are often connected to broader industrial control networks, they must be protected against unauthorized access and potential cyber-attacks. This includes implementing secure communication protocols, regular software updates, and strict access controls.

Environmental factors also play a significant role in the safety and reliability of these systems. The control components must be designed to withstand harsh industrial environments, including extreme temperatures, vibrations, and potentially corrosive atmospheres. This requires careful selection of materials and robust enclosures to ensure long-term reliability.

Regular maintenance and diagnostics are essential for maintaining the safety and reliability of autonomous gate valve control systems. Implementing predictive maintenance techniques, such as condition monitoring and data analytics, can help identify potential issues before they lead to failures. This proactive approach can significantly reduce unplanned downtime and extend the system's operational life.

Human-machine interface (HMI) design is another critical aspect of safety. While the system operates autonomously, there must be clear and intuitive interfaces for operators to monitor system status and intervene if necessary. This includes implementing clear alarm systems and emergency stop functions that are easily accessible and understandable.

Finally, comprehensive testing and validation procedures are crucial for ensuring the safety and reliability of autonomous gate valve control systems. This includes extensive simulation testing, hardware-in-the-loop testing, and field trials under various operating conditions. Compliance with relevant industry standards and regulations, such as IEC 61508 for functional safety, is also essential for demonstrating the system's reliability and safety performance.

One of the primary safety considerations is the implementation of fail-safe mechanisms. In the event of a system failure or power loss, the gate valve should automatically move to a predetermined safe position, typically fully closed or fully open, depending on the specific application. This ensures that the process remains in a controlled state even during unexpected events.

Redundancy is another crucial aspect of safety and reliability. Autonomous gate valve control systems should incorporate redundant sensors, actuators, and control units to maintain operation in case of component failure. This redundancy can be achieved through parallel systems or by implementing diverse technologies to mitigate common mode failures.

Cybersecurity is an increasingly important consideration in autonomous systems. As these valve control systems are often connected to broader industrial control networks, they must be protected against unauthorized access and potential cyber-attacks. This includes implementing secure communication protocols, regular software updates, and strict access controls.

Environmental factors also play a significant role in the safety and reliability of these systems. The control components must be designed to withstand harsh industrial environments, including extreme temperatures, vibrations, and potentially corrosive atmospheres. This requires careful selection of materials and robust enclosures to ensure long-term reliability.

Regular maintenance and diagnostics are essential for maintaining the safety and reliability of autonomous gate valve control systems. Implementing predictive maintenance techniques, such as condition monitoring and data analytics, can help identify potential issues before they lead to failures. This proactive approach can significantly reduce unplanned downtime and extend the system's operational life.

Human-machine interface (HMI) design is another critical aspect of safety. While the system operates autonomously, there must be clear and intuitive interfaces for operators to monitor system status and intervene if necessary. This includes implementing clear alarm systems and emergency stop functions that are easily accessible and understandable.

Finally, comprehensive testing and validation procedures are crucial for ensuring the safety and reliability of autonomous gate valve control systems. This includes extensive simulation testing, hardware-in-the-loop testing, and field trials under various operating conditions. Compliance with relevant industry standards and regulations, such as IEC 61508 for functional safety, is also essential for demonstrating the system's reliability and safety performance.

Integration with Industrial IoT Platforms

The integration of autonomous gate valve control systems with Industrial IoT (IIoT) platforms represents a significant advancement in industrial automation and process control. This integration enables seamless communication between valve systems and broader industrial networks, facilitating real-time monitoring, data analysis, and remote control capabilities. IIoT platforms serve as the backbone for connecting diverse industrial devices and systems, allowing for enhanced operational efficiency and decision-making processes.

One of the primary benefits of integrating autonomous gate valve control systems with IIoT platforms is the ability to collect and analyze vast amounts of data. Sensors embedded in the valve systems can continuously monitor parameters such as flow rates, pressure, temperature, and valve position. This data is then transmitted to the IIoT platform, where advanced analytics tools can process it to provide valuable insights into system performance, predict maintenance needs, and optimize overall process efficiency.

The integration also enables remote monitoring and control capabilities, allowing operators to manage valve systems from centralized control rooms or even off-site locations. This feature is particularly valuable for industries with geographically dispersed operations or hazardous environments where minimizing on-site personnel is crucial. Through secure network connections, operators can adjust valve settings, initiate emergency shutdowns, or perform routine maintenance tasks without physical presence at the valve location.

Furthermore, the integration of autonomous gate valve control systems with IIoT platforms facilitates predictive maintenance strategies. By analyzing historical data and real-time performance metrics, machine learning algorithms can identify patterns and anomalies that may indicate impending equipment failure or suboptimal performance. This proactive approach to maintenance can significantly reduce downtime, extend equipment lifespan, and optimize maintenance schedules and resource allocation.

Interoperability is a key consideration in the integration process. IIoT platforms must support various communication protocols and data formats to ensure seamless integration with different valve control systems and other industrial equipment. Standardization efforts, such as OPC UA (Open Platform Communications Unified Architecture), are playing a crucial role in enabling interoperability across diverse industrial systems and devices.

Security is another critical aspect of integrating autonomous gate valve control systems with IIoT platforms. As these systems become more connected, they also become potential targets for cyber attacks. Robust security measures, including encryption, authentication protocols, and regular security audits, must be implemented to protect sensitive data and prevent unauthorized access to critical control systems.

The integration of autonomous gate valve control systems with IIoT platforms is driving the evolution of smart factories and process plants. By leveraging the power of data analytics, machine learning, and cloud computing, industries can achieve unprecedented levels of automation, efficiency, and flexibility in their operations. As this integration continues to mature, we can expect to see further innovations in areas such as edge computing, artificial intelligence-driven decision-making, and advanced visualization techniques for improved human-machine interaction.

One of the primary benefits of integrating autonomous gate valve control systems with IIoT platforms is the ability to collect and analyze vast amounts of data. Sensors embedded in the valve systems can continuously monitor parameters such as flow rates, pressure, temperature, and valve position. This data is then transmitted to the IIoT platform, where advanced analytics tools can process it to provide valuable insights into system performance, predict maintenance needs, and optimize overall process efficiency.

The integration also enables remote monitoring and control capabilities, allowing operators to manage valve systems from centralized control rooms or even off-site locations. This feature is particularly valuable for industries with geographically dispersed operations or hazardous environments where minimizing on-site personnel is crucial. Through secure network connections, operators can adjust valve settings, initiate emergency shutdowns, or perform routine maintenance tasks without physical presence at the valve location.

Furthermore, the integration of autonomous gate valve control systems with IIoT platforms facilitates predictive maintenance strategies. By analyzing historical data and real-time performance metrics, machine learning algorithms can identify patterns and anomalies that may indicate impending equipment failure or suboptimal performance. This proactive approach to maintenance can significantly reduce downtime, extend equipment lifespan, and optimize maintenance schedules and resource allocation.

Interoperability is a key consideration in the integration process. IIoT platforms must support various communication protocols and data formats to ensure seamless integration with different valve control systems and other industrial equipment. Standardization efforts, such as OPC UA (Open Platform Communications Unified Architecture), are playing a crucial role in enabling interoperability across diverse industrial systems and devices.

Security is another critical aspect of integrating autonomous gate valve control systems with IIoT platforms. As these systems become more connected, they also become potential targets for cyber attacks. Robust security measures, including encryption, authentication protocols, and regular security audits, must be implemented to protect sensitive data and prevent unauthorized access to critical control systems.

The integration of autonomous gate valve control systems with IIoT platforms is driving the evolution of smart factories and process plants. By leveraging the power of data analytics, machine learning, and cloud computing, industries can achieve unprecedented levels of automation, efficiency, and flexibility in their operations. As this integration continues to mature, we can expect to see further innovations in areas such as edge computing, artificial intelligence-driven decision-making, and advanced visualization techniques for improved human-machine interaction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!