Gate valve construction matrix influence on mechanical performance

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Performance Objectives

Gate valves have undergone significant evolution since their inception, driven by the need for improved performance, reliability, and efficiency in various industrial applications. The development of gate valves has been closely tied to advancements in materials science, manufacturing processes, and engineering design principles. Early gate valves were primarily constructed using cast iron or bronze, with simple wedge-shaped gates and basic sealing mechanisms.

As industrial demands grew more complex, gate valve design evolved to incorporate more sophisticated materials and construction techniques. The introduction of steel and high-performance alloys allowed for increased pressure ratings and improved corrosion resistance. Parallel-sided gates replaced wedge-shaped designs in many applications, offering better sealing capabilities and reduced wear.

The advent of computer-aided design and finite element analysis in the late 20th century revolutionized gate valve engineering. These tools enabled engineers to optimize valve geometry, predict stress distributions, and simulate fluid dynamics, leading to more efficient and reliable designs. Concurrently, advancements in manufacturing technologies, such as precision machining and automated welding, improved the consistency and quality of gate valve production.

In recent years, the focus has shifted towards enhancing the mechanical performance of gate valves through innovative construction matrices. This approach involves carefully considering the interplay between various components, materials, and design features to achieve optimal functionality. Key performance objectives now include minimizing friction, reducing wear, improving sealing effectiveness, and extending operational lifespan.

The construction matrix of modern gate valves encompasses several critical elements. The body and bonnet materials are selected for their strength, corrosion resistance, and compatibility with the process fluid. Gate and seat designs are optimized for tight shutoff and smooth operation, often incorporating hard-facing materials or special coatings to enhance durability. Stem designs focus on reducing friction and improving responsiveness, while sealing systems are engineered to maintain integrity under diverse operating conditions.

Looking forward, the evolution of gate valves continues to be driven by emerging technologies and increasingly stringent performance requirements. Objectives for future development include further weight reduction without compromising strength, enhanced resistance to extreme temperatures and pressures, and improved compatibility with smart monitoring and control systems. Additionally, there is a growing emphasis on sustainability, with efforts to develop eco-friendly materials and manufacturing processes that reduce environmental impact while maintaining or improving mechanical performance.

As industrial demands grew more complex, gate valve design evolved to incorporate more sophisticated materials and construction techniques. The introduction of steel and high-performance alloys allowed for increased pressure ratings and improved corrosion resistance. Parallel-sided gates replaced wedge-shaped designs in many applications, offering better sealing capabilities and reduced wear.

The advent of computer-aided design and finite element analysis in the late 20th century revolutionized gate valve engineering. These tools enabled engineers to optimize valve geometry, predict stress distributions, and simulate fluid dynamics, leading to more efficient and reliable designs. Concurrently, advancements in manufacturing technologies, such as precision machining and automated welding, improved the consistency and quality of gate valve production.

In recent years, the focus has shifted towards enhancing the mechanical performance of gate valves through innovative construction matrices. This approach involves carefully considering the interplay between various components, materials, and design features to achieve optimal functionality. Key performance objectives now include minimizing friction, reducing wear, improving sealing effectiveness, and extending operational lifespan.

The construction matrix of modern gate valves encompasses several critical elements. The body and bonnet materials are selected for their strength, corrosion resistance, and compatibility with the process fluid. Gate and seat designs are optimized for tight shutoff and smooth operation, often incorporating hard-facing materials or special coatings to enhance durability. Stem designs focus on reducing friction and improving responsiveness, while sealing systems are engineered to maintain integrity under diverse operating conditions.

Looking forward, the evolution of gate valves continues to be driven by emerging technologies and increasingly stringent performance requirements. Objectives for future development include further weight reduction without compromising strength, enhanced resistance to extreme temperatures and pressures, and improved compatibility with smart monitoring and control systems. Additionally, there is a growing emphasis on sustainability, with efforts to develop eco-friendly materials and manufacturing processes that reduce environmental impact while maintaining or improving mechanical performance.

Market Demand Analysis for High-Performance Gate Valves

The global market for high-performance gate valves has been experiencing significant growth, driven by increasing demand across various industries such as oil and gas, power generation, water treatment, and chemical processing. This surge in demand is primarily attributed to the critical role these valves play in ensuring operational efficiency, safety, and reliability in fluid control systems.

In the oil and gas sector, which remains a key market driver, the need for high-performance gate valves is particularly pronounced. As exploration and production activities expand into more challenging environments, including deep-water and high-pressure/high-temperature (HPHT) applications, the demand for valves capable of withstanding extreme conditions has intensified. This trend is expected to continue, with the offshore oil and gas segment projected to witness substantial growth in valve requirements over the next five years.

The power generation industry, especially in emerging economies, is another significant contributor to the market demand. As countries invest in upgrading their energy infrastructure and transitioning to cleaner energy sources, the need for advanced gate valves in power plants, including nuclear facilities, has risen. These valves are crucial for maintaining safety standards and operational efficiency in critical systems.

Water and wastewater treatment sectors are also driving demand for high-performance gate valves. Increasing urbanization and stringent environmental regulations have led to the expansion and modernization of water treatment facilities worldwide. This has created a robust market for valves that can handle corrosive fluids and operate reliably in challenging environments.

The chemical processing industry, with its emphasis on process efficiency and safety, continues to be a steady source of demand for high-performance gate valves. As chemical manufacturers seek to optimize their operations and comply with stringent safety standards, the adoption of advanced valve technologies has become imperative.

Market analysis indicates a growing preference for smart and automated valve solutions. End-users across industries are increasingly looking for gate valves equipped with advanced diagnostics and control capabilities, which can integrate seamlessly with digital plant management systems. This trend towards digitalization and Industry 4.0 is expected to shape the future demand landscape for high-performance gate valves.

Geographically, while mature markets in North America and Europe continue to generate steady demand, the Asia-Pacific region is emerging as a hotspot for market growth. Rapid industrialization, infrastructure development, and increasing investments in energy and water sectors in countries like China and India are fueling the demand for high-performance gate valves in this region.

In the oil and gas sector, which remains a key market driver, the need for high-performance gate valves is particularly pronounced. As exploration and production activities expand into more challenging environments, including deep-water and high-pressure/high-temperature (HPHT) applications, the demand for valves capable of withstanding extreme conditions has intensified. This trend is expected to continue, with the offshore oil and gas segment projected to witness substantial growth in valve requirements over the next five years.

The power generation industry, especially in emerging economies, is another significant contributor to the market demand. As countries invest in upgrading their energy infrastructure and transitioning to cleaner energy sources, the need for advanced gate valves in power plants, including nuclear facilities, has risen. These valves are crucial for maintaining safety standards and operational efficiency in critical systems.

Water and wastewater treatment sectors are also driving demand for high-performance gate valves. Increasing urbanization and stringent environmental regulations have led to the expansion and modernization of water treatment facilities worldwide. This has created a robust market for valves that can handle corrosive fluids and operate reliably in challenging environments.

The chemical processing industry, with its emphasis on process efficiency and safety, continues to be a steady source of demand for high-performance gate valves. As chemical manufacturers seek to optimize their operations and comply with stringent safety standards, the adoption of advanced valve technologies has become imperative.

Market analysis indicates a growing preference for smart and automated valve solutions. End-users across industries are increasingly looking for gate valves equipped with advanced diagnostics and control capabilities, which can integrate seamlessly with digital plant management systems. This trend towards digitalization and Industry 4.0 is expected to shape the future demand landscape for high-performance gate valves.

Geographically, while mature markets in North America and Europe continue to generate steady demand, the Asia-Pacific region is emerging as a hotspot for market growth. Rapid industrialization, infrastructure development, and increasing investments in energy and water sectors in countries like China and India are fueling the demand for high-performance gate valves in this region.

Current Challenges in Gate Valve Construction

Gate valve construction faces several significant challenges in the current technological landscape, particularly concerning the influence of construction matrix on mechanical performance. One of the primary issues is the selection of appropriate materials that can withstand high pressures and temperatures while maintaining structural integrity. The construction matrix, which includes the body, bonnet, and gate, must be designed to resist deformation and wear under extreme operating conditions.

Another challenge lies in achieving optimal sealing performance. The interface between the gate and seat rings is critical for preventing leakage, but it is subject to constant stress and potential degradation over time. Engineers must balance the need for tight sealing with the requirement for smooth operation, which can be particularly challenging in large-diameter valves or those used in corrosive environments.

The impact of thermal expansion on valve components presents a significant hurdle in gate valve construction. Differential thermal expansion between various parts of the valve can lead to misalignment, increased friction, and potential failure. This issue is exacerbated in applications with frequent temperature fluctuations, requiring innovative design solutions to maintain consistent performance across a wide range of operating conditions.

Corrosion resistance remains a persistent challenge, especially in industries such as oil and gas, where gate valves are exposed to aggressive media. The construction matrix must incorporate materials and coatings that can withstand chemical attack while maintaining mechanical properties. This often involves a trade-off between corrosion resistance and other desirable characteristics such as strength or machinability.

Weight reduction is another area of focus, particularly for large-scale valves used in offshore applications. The challenge lies in reducing the overall mass of the valve without compromising its mechanical performance or pressure-bearing capacity. This requires advanced material science and structural engineering to optimize the construction matrix for both strength and weight.

Manufacturing precision poses a significant challenge in gate valve construction. Tight tolerances are essential for ensuring proper fit and function, especially in critical sealing areas. Achieving and maintaining these tolerances consistently across large production runs can be difficult, particularly for complex valve geometries or when working with hard-to-machine materials.

Lastly, the integration of smart technologies into gate valve construction presents new challenges. As the industry moves towards more automated and remotely operated systems, valve designers must incorporate sensors, actuators, and communication interfaces without compromising the valve's core mechanical functions. This requires a multidisciplinary approach, blending traditional mechanical engineering with electronics and software design.

Another challenge lies in achieving optimal sealing performance. The interface between the gate and seat rings is critical for preventing leakage, but it is subject to constant stress and potential degradation over time. Engineers must balance the need for tight sealing with the requirement for smooth operation, which can be particularly challenging in large-diameter valves or those used in corrosive environments.

The impact of thermal expansion on valve components presents a significant hurdle in gate valve construction. Differential thermal expansion between various parts of the valve can lead to misalignment, increased friction, and potential failure. This issue is exacerbated in applications with frequent temperature fluctuations, requiring innovative design solutions to maintain consistent performance across a wide range of operating conditions.

Corrosion resistance remains a persistent challenge, especially in industries such as oil and gas, where gate valves are exposed to aggressive media. The construction matrix must incorporate materials and coatings that can withstand chemical attack while maintaining mechanical properties. This often involves a trade-off between corrosion resistance and other desirable characteristics such as strength or machinability.

Weight reduction is another area of focus, particularly for large-scale valves used in offshore applications. The challenge lies in reducing the overall mass of the valve without compromising its mechanical performance or pressure-bearing capacity. This requires advanced material science and structural engineering to optimize the construction matrix for both strength and weight.

Manufacturing precision poses a significant challenge in gate valve construction. Tight tolerances are essential for ensuring proper fit and function, especially in critical sealing areas. Achieving and maintaining these tolerances consistently across large production runs can be difficult, particularly for complex valve geometries or when working with hard-to-machine materials.

Lastly, the integration of smart technologies into gate valve construction presents new challenges. As the industry moves towards more automated and remotely operated systems, valve designers must incorporate sensors, actuators, and communication interfaces without compromising the valve's core mechanical functions. This requires a multidisciplinary approach, blending traditional mechanical engineering with electronics and software design.

Existing Solutions for Enhancing Mechanical Performance

01 Improved sealing performance

Gate valves with enhanced sealing performance utilize advanced materials and designs for the valve seat and gate. These improvements reduce leakage, increase durability, and ensure better overall mechanical performance under various operating conditions.- Improved sealing performance: Gate valves with enhanced sealing mechanisms to prevent leakage and improve overall mechanical performance. This includes innovations in sealing materials, designs, and structures to ensure tight closure and reliable operation under various pressure conditions.

- Structural optimization for durability: Advancements in gate valve structural design to enhance durability and longevity. This involves reinforcing critical components, optimizing material selection, and improving overall valve construction to withstand high pressures, temperatures, and frequent operation cycles.

- Enhanced actuation mechanisms: Innovations in gate valve actuation systems to improve operational efficiency and reliability. This includes developments in manual, pneumatic, hydraulic, and electric actuators, as well as improvements in stem designs and connections to ensure smooth and precise valve movement.

- Advanced material selection: Utilization of advanced materials in gate valve construction to enhance mechanical properties and resistance to corrosion, erosion, and extreme operating conditions. This includes the use of high-performance alloys, composites, and surface treatments to improve overall valve performance and lifespan.

- Intelligent monitoring and control: Integration of smart technologies and sensors for real-time monitoring and control of gate valve performance. This includes the implementation of diagnostic systems, predictive maintenance capabilities, and remote operation features to enhance valve reliability and efficiency in various industrial applications.

02 Structural optimization

Optimized gate valve structures focus on improving strength, stability, and operational efficiency. This includes redesigned valve bodies, reinforced components, and streamlined internal geometries to enhance mechanical performance and reduce wear.Expand Specific Solutions03 Advanced actuation mechanisms

Innovative actuation mechanisms for gate valves incorporate improved gearing systems, hydraulic or pneumatic assists, and electronic controls. These advancements result in smoother operation, increased precision, and enhanced overall mechanical performance.Expand Specific Solutions04 Material selection and surface treatments

The use of high-performance materials and advanced surface treatments significantly improves the mechanical properties of gate valves. This includes corrosion-resistant alloys, ceramic coatings, and hardened surfaces to enhance durability and extend operational life.Expand Specific Solutions05 Testing and quality control methods

Advanced testing and quality control methods are employed to ensure optimal mechanical performance of gate valves. These include computerized simulations, non-destructive testing techniques, and rigorous performance validation procedures to guarantee reliability and compliance with industry standards.Expand Specific Solutions

Key Players in Gate Valve Manufacturing

The gate valve construction matrix influence on mechanical performance is a critical area of study in the valve industry, currently in a mature development stage. The market for gate valves is substantial, driven by demand in oil and gas, water treatment, and industrial applications. Technological advancements focus on improving valve performance, durability, and efficiency. Key players like KSB SE & Co. KGaA, Worldwide Oilfield Machine, Inc., and NOV, Inc. are at the forefront of innovation, investing in research and development to enhance gate valve designs. These companies leverage advanced materials and manufacturing techniques to optimize the construction matrix, resulting in improved mechanical performance and reliability in diverse operational conditions.

KSB SE & Co. KGaA

Technical Solution: KSB has developed advanced gate valve construction matrices using innovative materials and design techniques. Their approach focuses on optimizing the valve body and gate structure to enhance mechanical performance. KSB employs finite element analysis (FEA) to simulate stress distribution and identify potential weak points in the valve construction[1]. They have introduced a proprietary composite material for valve seats that offers improved wear resistance and sealing properties[2]. KSB's gate valves feature a reinforced stem design that reduces bending and improves overall valve reliability. The company has also implemented a unique coating process for internal valve components to minimize friction and extend service life[3].

Strengths: Advanced material science, comprehensive FEA simulations, and innovative coating technologies. Weaknesses: Potentially higher production costs and longer manufacturing lead times due to complex designs and materials.

Worldwide Oilfield Machine, Inc.

Technical Solution: Worldwide Oilfield Machine (WOM) has developed a specialized gate valve construction matrix tailored for harsh oilfield environments. Their approach incorporates high-strength alloys and advanced surface treatments to enhance mechanical performance under extreme pressures and temperatures. WOM's gate valves feature a patented stem seal design that significantly reduces the risk of leakage[4]. The company utilizes computational fluid dynamics (CFD) to optimize flow characteristics and minimize pressure drop across the valve[5]. WOM has also introduced a modular gate valve design that allows for easier maintenance and component replacement, reducing downtime in critical operations.

Strengths: Robust designs for extreme conditions, advanced sealing technology, and modular construction for improved maintainability. Weaknesses: Higher initial costs and potential overengineering for less demanding applications.

Core Innovations in Gate Valve Construction Materials

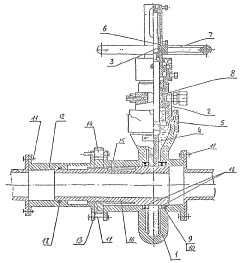

Gate valve

PatentInactiveEP1058797A1

Innovation

- The gate valve design features oval flow and blocking surfaces with transverse longitudinal axes, reducing overall height and flow losses, allowing for a shorter housing neck and increased pressure load capacity, and uses an offset oval flow cross-section to accommodate larger nominal sizes with 8-hole flanges, along with a clamping housing or flanges for easier assembly and reduced drag coefficient.

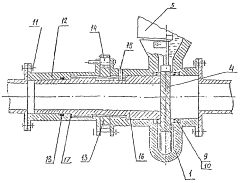

Valve provided with a safety device

PatentWO2008080197A2

Innovation

- The valve design incorporates an elongated housing flange with an adapter and a rod that moves via a screw and gear mechanism, allowing the working elements to be isolated from the medium's pressure, enabling maintenance without shutting off the flow by using sealing elements and a special protrusion to guide the rod's movement.

Regulatory Standards for Industrial Valve Performance

Regulatory standards play a crucial role in ensuring the safety, reliability, and performance of industrial valves, including gate valves. These standards are developed and maintained by various international and national organizations to establish minimum requirements for design, manufacturing, testing, and maintenance of valves used in different industries.

The American Society of Mechanical Engineers (ASME) has developed several standards that directly impact gate valve performance. ASME B16.34 specifies the pressure-temperature ratings, materials, dimensions, tolerances, testing, and marking for valves used in piping systems. This standard is particularly relevant to gate valve construction and its influence on mechanical performance, as it sets the baseline for material selection and design parameters.

Another significant standard is API 6D, developed by the American Petroleum Institute, which focuses on pipeline valves, including gate valves. This standard addresses the design, manufacturing, assembly, testing, and documentation of valves used in pipeline transportation systems for petroleum and natural gas industries. It provides specific requirements for valve body materials, pressure ratings, and testing procedures that directly impact the mechanical performance of gate valves.

The International Organization for Standardization (ISO) has also contributed to valve performance standards. ISO 5208 establishes pressure testing requirements for industrial valves, including gate valves. This standard defines the procedures for hydrostatic shell testing, hydrostatic seat testing, and pneumatic seat testing, which are essential for verifying the mechanical integrity and sealing capabilities of gate valves.

In Europe, the Pressure Equipment Directive (PED) 2014/68/EU sets out the standards for the design and fabrication of pressure equipment, including industrial valves. This directive influences the construction matrix of gate valves by specifying essential safety requirements and conformity assessment procedures.

The influence of these regulatory standards on gate valve mechanical performance is significant. They dictate material selection criteria, ensuring that valve components can withstand specified pressures and temperatures. The standards also define testing protocols that validate the valve's ability to maintain its mechanical integrity under various operating conditions. Furthermore, they establish dimensional requirements that affect the valve's overall structure and its interaction with connected piping systems.

Compliance with these standards not only ensures the safety and reliability of gate valves but also facilitates international trade by harmonizing requirements across different regions. As technology advances and industry needs evolve, these standards are periodically reviewed and updated to incorporate new knowledge and best practices, continually improving the mechanical performance of gate valves and other industrial valves.

The American Society of Mechanical Engineers (ASME) has developed several standards that directly impact gate valve performance. ASME B16.34 specifies the pressure-temperature ratings, materials, dimensions, tolerances, testing, and marking for valves used in piping systems. This standard is particularly relevant to gate valve construction and its influence on mechanical performance, as it sets the baseline for material selection and design parameters.

Another significant standard is API 6D, developed by the American Petroleum Institute, which focuses on pipeline valves, including gate valves. This standard addresses the design, manufacturing, assembly, testing, and documentation of valves used in pipeline transportation systems for petroleum and natural gas industries. It provides specific requirements for valve body materials, pressure ratings, and testing procedures that directly impact the mechanical performance of gate valves.

The International Organization for Standardization (ISO) has also contributed to valve performance standards. ISO 5208 establishes pressure testing requirements for industrial valves, including gate valves. This standard defines the procedures for hydrostatic shell testing, hydrostatic seat testing, and pneumatic seat testing, which are essential for verifying the mechanical integrity and sealing capabilities of gate valves.

In Europe, the Pressure Equipment Directive (PED) 2014/68/EU sets out the standards for the design and fabrication of pressure equipment, including industrial valves. This directive influences the construction matrix of gate valves by specifying essential safety requirements and conformity assessment procedures.

The influence of these regulatory standards on gate valve mechanical performance is significant. They dictate material selection criteria, ensuring that valve components can withstand specified pressures and temperatures. The standards also define testing protocols that validate the valve's ability to maintain its mechanical integrity under various operating conditions. Furthermore, they establish dimensional requirements that affect the valve's overall structure and its interaction with connected piping systems.

Compliance with these standards not only ensures the safety and reliability of gate valves but also facilitates international trade by harmonizing requirements across different regions. As technology advances and industry needs evolve, these standards are periodically reviewed and updated to incorporate new knowledge and best practices, continually improving the mechanical performance of gate valves and other industrial valves.

Environmental Impact of Gate Valve Materials

The environmental impact of gate valve materials is a critical consideration in the design and construction of these essential components. The choice of materials used in gate valves can significantly affect their ecological footprint throughout their lifecycle, from production to disposal. Traditional gate valve materials, such as cast iron and carbon steel, have been widely used due to their durability and cost-effectiveness. However, these materials often have substantial environmental implications, including high energy consumption during production and potential pollution risks during disposal.

In recent years, there has been a growing trend towards more environmentally friendly materials for gate valve construction. Advanced alloys and composite materials are being developed and implemented to reduce the overall environmental impact. These materials often offer improved corrosion resistance, reduced weight, and enhanced longevity, which contribute to a lower environmental burden over the valve's lifespan. For instance, the use of stainless steel alloys can significantly reduce the need for frequent replacements and maintenance, thereby minimizing waste generation and resource consumption.

The production processes for gate valve materials also play a crucial role in their environmental impact. Manufacturers are increasingly adopting cleaner production techniques, such as recycling metal scraps and implementing energy-efficient manufacturing processes. These practices help to reduce greenhouse gas emissions and minimize the depletion of natural resources associated with material extraction and processing.

Furthermore, the environmental impact of gate valve materials extends to their performance in various applications. Materials that offer better sealing properties and reduced leakage potential can contribute to improved energy efficiency in fluid systems and minimize the risk of environmental contamination. This is particularly important in industries dealing with hazardous substances or in environmentally sensitive areas.

The end-of-life management of gate valve materials is another critical aspect of their environmental impact. As the circular economy concept gains traction, there is an increasing focus on designing gate valves with materials that can be easily recycled or repurposed. This approach not only reduces waste but also conserves resources by keeping materials in use for longer periods. Additionally, some manufacturers are exploring biodegradable options for certain valve components, further reducing the long-term environmental impact of these products.

In recent years, there has been a growing trend towards more environmentally friendly materials for gate valve construction. Advanced alloys and composite materials are being developed and implemented to reduce the overall environmental impact. These materials often offer improved corrosion resistance, reduced weight, and enhanced longevity, which contribute to a lower environmental burden over the valve's lifespan. For instance, the use of stainless steel alloys can significantly reduce the need for frequent replacements and maintenance, thereby minimizing waste generation and resource consumption.

The production processes for gate valve materials also play a crucial role in their environmental impact. Manufacturers are increasingly adopting cleaner production techniques, such as recycling metal scraps and implementing energy-efficient manufacturing processes. These practices help to reduce greenhouse gas emissions and minimize the depletion of natural resources associated with material extraction and processing.

Furthermore, the environmental impact of gate valve materials extends to their performance in various applications. Materials that offer better sealing properties and reduced leakage potential can contribute to improved energy efficiency in fluid systems and minimize the risk of environmental contamination. This is particularly important in industries dealing with hazardous substances or in environmentally sensitive areas.

The end-of-life management of gate valve materials is another critical aspect of their environmental impact. As the circular economy concept gains traction, there is an increasing focus on designing gate valves with materials that can be easily recycled or repurposed. This approach not only reduces waste but also conserves resources by keeping materials in use for longer periods. Additionally, some manufacturers are exploring biodegradable options for certain valve components, further reducing the long-term environmental impact of these products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!