Experimental validation of new gate valve concepts in space operations

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Space Gate Valve Background and Objectives

Space gate valves have played a crucial role in space operations since the early days of space exploration. These specialized valves are designed to control the flow of fluids and gases in spacecraft systems, ensuring the proper functioning of propulsion, life support, and other critical systems. The development of gate valve technology for space applications has been driven by the unique challenges posed by the harsh space environment, including extreme temperatures, vacuum conditions, and the need for high reliability.

The evolution of space gate valves has been closely tied to advancements in materials science, manufacturing techniques, and space technology. Early designs focused on basic functionality and reliability, while more recent innovations have aimed to improve performance, reduce weight, and enhance durability. As space missions have become more complex and ambitious, the demands on gate valve technology have increased, necessitating continuous innovation and refinement.

The primary objective of experimental validation for new gate valve concepts in space operations is to ensure the safety, reliability, and efficiency of these critical components. This validation process aims to verify the performance of novel designs under simulated space conditions, assess their ability to withstand the rigors of launch and long-term operation in space, and identify potential failure modes or areas for improvement.

Key goals of the experimental validation include evaluating the valve's sealing capabilities in vacuum environments, assessing its resistance to thermal cycling and radiation exposure, and measuring its response to mechanical stresses. Additionally, researchers seek to optimize the valve's mass and size while maintaining or improving its functionality, as reducing payload weight is a constant priority in space missions.

Another important aspect of the validation process is to test the valve's compatibility with various propellants and working fluids used in spacecraft systems. This includes assessing the valve's resistance to corrosion and degradation over extended periods, as well as its ability to maintain precise flow control under different operating conditions.

The experimental validation of new gate valve concepts also aims to address specific challenges faced in current space operations. These may include improving the valve's response time, reducing power consumption for actuation, and enhancing its ability to operate reliably in extreme temperature ranges. Furthermore, researchers are exploring innovative materials and coatings that can extend the valve's operational lifespan and improve its overall performance in the space environment.

By rigorously testing and validating new gate valve concepts, space agencies and private companies can ensure the continued advancement of space exploration capabilities. This process not only contributes to the safety and success of future missions but also drives technological innovation that may have applications beyond the space industry.

The evolution of space gate valves has been closely tied to advancements in materials science, manufacturing techniques, and space technology. Early designs focused on basic functionality and reliability, while more recent innovations have aimed to improve performance, reduce weight, and enhance durability. As space missions have become more complex and ambitious, the demands on gate valve technology have increased, necessitating continuous innovation and refinement.

The primary objective of experimental validation for new gate valve concepts in space operations is to ensure the safety, reliability, and efficiency of these critical components. This validation process aims to verify the performance of novel designs under simulated space conditions, assess their ability to withstand the rigors of launch and long-term operation in space, and identify potential failure modes or areas for improvement.

Key goals of the experimental validation include evaluating the valve's sealing capabilities in vacuum environments, assessing its resistance to thermal cycling and radiation exposure, and measuring its response to mechanical stresses. Additionally, researchers seek to optimize the valve's mass and size while maintaining or improving its functionality, as reducing payload weight is a constant priority in space missions.

Another important aspect of the validation process is to test the valve's compatibility with various propellants and working fluids used in spacecraft systems. This includes assessing the valve's resistance to corrosion and degradation over extended periods, as well as its ability to maintain precise flow control under different operating conditions.

The experimental validation of new gate valve concepts also aims to address specific challenges faced in current space operations. These may include improving the valve's response time, reducing power consumption for actuation, and enhancing its ability to operate reliably in extreme temperature ranges. Furthermore, researchers are exploring innovative materials and coatings that can extend the valve's operational lifespan and improve its overall performance in the space environment.

By rigorously testing and validating new gate valve concepts, space agencies and private companies can ensure the continued advancement of space exploration capabilities. This process not only contributes to the safety and success of future missions but also drives technological innovation that may have applications beyond the space industry.

Market Analysis for Space Gate Valves

The market for space gate valves is experiencing significant growth, driven by the increasing demand for reliable and efficient fluid control systems in space operations. As space exploration and satellite deployment activities continue to expand, the need for advanced gate valve technologies becomes more critical. The global space industry, valued at over $400 billion, is projected to reach $1 trillion by 2040, with a substantial portion dedicated to spacecraft and satellite systems.

Space gate valves play a crucial role in various space applications, including propulsion systems, life support systems, and thermal management. The market for these specialized valves is characterized by high technological requirements and stringent quality standards. Key factors influencing market demand include reliability, weight reduction, and performance under extreme conditions.

The commercial space sector, particularly the small satellite market, is a major driver for space gate valve demand. With the proliferation of satellite constellations for communication and Earth observation, there is a growing need for compact and efficient valve systems. The small satellite market is expected to grow at a CAGR of 20% over the next decade, creating significant opportunities for valve manufacturers.

Government space agencies and defense organizations remain important customers in the space gate valve market. NASA's Artemis program and other international lunar and Mars exploration initiatives are driving demand for advanced valve technologies capable of withstanding long-duration missions and extreme environments.

The market landscape is characterized by a mix of established aerospace companies and specialized valve manufacturers. Key players include Parker Hannifin, Moog, and Valcor Engineering, who have established reputations for high-reliability space components. Emerging players are also entering the market with innovative valve designs, focusing on miniaturization and improved performance.

Technological advancements in materials science and manufacturing processes are shaping the future of space gate valves. The adoption of additive manufacturing techniques allows for complex valve geometries and weight reduction, while new alloys and coatings enhance durability and corrosion resistance.

Challenges in the space gate valve market include the high costs associated with space-grade components and the long development cycles typical in the aerospace industry. However, the increasing commercialization of space activities and the push for standardization in smallsat components are expected to drive market growth and innovation in valve technologies.

Space gate valves play a crucial role in various space applications, including propulsion systems, life support systems, and thermal management. The market for these specialized valves is characterized by high technological requirements and stringent quality standards. Key factors influencing market demand include reliability, weight reduction, and performance under extreme conditions.

The commercial space sector, particularly the small satellite market, is a major driver for space gate valve demand. With the proliferation of satellite constellations for communication and Earth observation, there is a growing need for compact and efficient valve systems. The small satellite market is expected to grow at a CAGR of 20% over the next decade, creating significant opportunities for valve manufacturers.

Government space agencies and defense organizations remain important customers in the space gate valve market. NASA's Artemis program and other international lunar and Mars exploration initiatives are driving demand for advanced valve technologies capable of withstanding long-duration missions and extreme environments.

The market landscape is characterized by a mix of established aerospace companies and specialized valve manufacturers. Key players include Parker Hannifin, Moog, and Valcor Engineering, who have established reputations for high-reliability space components. Emerging players are also entering the market with innovative valve designs, focusing on miniaturization and improved performance.

Technological advancements in materials science and manufacturing processes are shaping the future of space gate valves. The adoption of additive manufacturing techniques allows for complex valve geometries and weight reduction, while new alloys and coatings enhance durability and corrosion resistance.

Challenges in the space gate valve market include the high costs associated with space-grade components and the long development cycles typical in the aerospace industry. However, the increasing commercialization of space activities and the push for standardization in smallsat components are expected to drive market growth and innovation in valve technologies.

Current Challenges in Space Gate Valve Technology

Space gate valve technology plays a crucial role in spacecraft systems, controlling the flow of propellants, coolants, and other fluids essential for various space operations. However, the current state of this technology faces several significant challenges that hinder its optimal performance and reliability in the harsh space environment.

One of the primary challenges is the extreme temperature fluctuations encountered in space. Gate valves must maintain their integrity and functionality across a wide temperature range, from the extreme cold of deep space to the intense heat generated during spacecraft operations. This thermal cycling can lead to material fatigue, seal degradation, and potential leakage, compromising the valve's effectiveness and safety.

The vacuum environment of space presents another major hurdle for gate valve technology. Traditional sealing mechanisms may not perform adequately in the absence of atmospheric pressure, leading to increased risk of fluid leakage. Additionally, the lack of gravity affects fluid behavior, potentially causing unpredictable flow patterns and making it difficult to ensure proper valve operation and sealing.

Radiation exposure in space poses a significant threat to the longevity and reliability of gate valves. High-energy particles can degrade materials over time, affecting the structural integrity of valve components and potentially causing electronic control systems to malfunction. This necessitates the development of radiation-hardened materials and robust control mechanisms.

Weight and size constraints in spacecraft design present another challenge for gate valve technology. Engineers must balance the need for robust, reliable valves with the imperative to minimize mass and volume. This often requires innovative design approaches and the use of advanced materials to achieve the necessary performance within strict spatial limitations.

The need for long-term reliability without maintenance is a critical challenge in space gate valve technology. Unlike terrestrial applications, valves in space cannot be easily serviced or replaced. They must operate flawlessly for extended periods, often spanning several years, without the possibility of human intervention for repairs or adjustments.

Contamination control is another significant concern. Gate valves must prevent the ingress of particulates and maintain cleanliness standards to protect sensitive spacecraft systems. This requires advanced sealing technologies and careful material selection to minimize the generation of particles during valve operation.

The development of new propulsion systems and advanced spacecraft designs introduces additional challenges. Gate valves must be compatible with a wide range of propellants, including cryogenic fluids and high-pressure gases, while maintaining their performance characteristics. This demands continuous innovation in valve design and materials to keep pace with evolving spacecraft technologies.

One of the primary challenges is the extreme temperature fluctuations encountered in space. Gate valves must maintain their integrity and functionality across a wide temperature range, from the extreme cold of deep space to the intense heat generated during spacecraft operations. This thermal cycling can lead to material fatigue, seal degradation, and potential leakage, compromising the valve's effectiveness and safety.

The vacuum environment of space presents another major hurdle for gate valve technology. Traditional sealing mechanisms may not perform adequately in the absence of atmospheric pressure, leading to increased risk of fluid leakage. Additionally, the lack of gravity affects fluid behavior, potentially causing unpredictable flow patterns and making it difficult to ensure proper valve operation and sealing.

Radiation exposure in space poses a significant threat to the longevity and reliability of gate valves. High-energy particles can degrade materials over time, affecting the structural integrity of valve components and potentially causing electronic control systems to malfunction. This necessitates the development of radiation-hardened materials and robust control mechanisms.

Weight and size constraints in spacecraft design present another challenge for gate valve technology. Engineers must balance the need for robust, reliable valves with the imperative to minimize mass and volume. This often requires innovative design approaches and the use of advanced materials to achieve the necessary performance within strict spatial limitations.

The need for long-term reliability without maintenance is a critical challenge in space gate valve technology. Unlike terrestrial applications, valves in space cannot be easily serviced or replaced. They must operate flawlessly for extended periods, often spanning several years, without the possibility of human intervention for repairs or adjustments.

Contamination control is another significant concern. Gate valves must prevent the ingress of particulates and maintain cleanliness standards to protect sensitive spacecraft systems. This requires advanced sealing technologies and careful material selection to minimize the generation of particles during valve operation.

The development of new propulsion systems and advanced spacecraft designs introduces additional challenges. Gate valves must be compatible with a wide range of propellants, including cryogenic fluids and high-pressure gases, while maintaining their performance characteristics. This demands continuous innovation in valve design and materials to keep pace with evolving spacecraft technologies.

Existing Gate Valve Solutions for Space

01 Gate valve design and structure

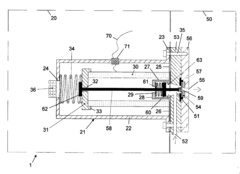

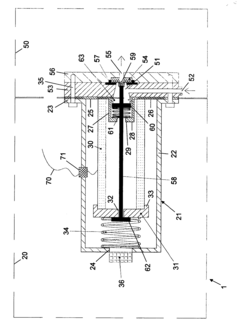

Gate valves are designed with a flat or wedge-shaped gate that moves perpendicular to the flow of fluid to control or stop flow. The structure typically includes a body, bonnet, stem, gate, and seat rings. Various improvements in design focus on enhancing sealing, reducing wear, and improving operational efficiency.- Gate valve design and structure: Gate valves are designed with a flat or wedge-shaped gate that moves perpendicular to the flow of fluid to control flow. The structure typically includes a body, bonnet, stem, and gate. Various designs focus on improving sealing, reducing friction, and enhancing durability for different applications.

- Actuation mechanisms for gate valves: Gate valves can be operated manually or through automated systems. Actuation mechanisms may include handwheels, gears, pneumatic actuators, hydraulic systems, or electric motors. These mechanisms are designed to provide precise control and efficient operation of the valve, especially in high-pressure or large-scale applications.

- Sealing technologies in gate valves: Advanced sealing technologies are crucial for preventing leakage in gate valves. This includes the use of various materials and designs for seat rings, gate faces, and stem seals. Innovations focus on improving seal performance under different pressure and temperature conditions, as well as enhancing chemical resistance.

- Gate valve materials and coatings: The selection of materials and coatings for gate valve components is critical for performance and longevity. This includes the use of corrosion-resistant alloys, specialized coatings, and advanced composites to improve wear resistance, reduce friction, and enhance chemical compatibility in various industrial applications.

- Smart and automated gate valve systems: Integration of sensors, control systems, and communication technologies in gate valves enables smart operation and monitoring. These advanced systems allow for remote control, predictive maintenance, and real-time performance analysis, improving efficiency and reliability in complex industrial processes.

02 Actuation mechanisms for gate valves

Gate valves can be operated manually or through various automated systems. Actuation mechanisms may include handwheels, gears, pneumatic actuators, hydraulic systems, or electric motors. These mechanisms are designed to provide precise control over the valve's opening and closing, often incorporating fail-safe features for emergency situations.Expand Specific Solutions03 Sealing technologies in gate valves

Advanced sealing technologies are crucial for preventing leakage in gate valves. This includes the use of specialized materials for seat rings and gates, as well as the implementation of innovative sealing geometries. Some designs incorporate multiple sealing surfaces or pressure-energized seals to ensure tight shutoff under various operating conditions.Expand Specific Solutions04 Materials and coatings for gate valve components

The selection of materials and coatings for gate valve components is critical for performance and longevity. Corrosion-resistant alloys, ceramics, and advanced polymers are used for various parts. Specialized coatings may be applied to reduce friction, enhance wear resistance, or improve chemical compatibility with the process fluid.Expand Specific Solutions05 Monitoring and control systems for gate valves

Modern gate valves often incorporate advanced monitoring and control systems. These may include position sensors, pressure monitors, and diagnostic tools that provide real-time data on valve performance. Integration with digital control systems allows for remote operation and predictive maintenance, enhancing overall system reliability and efficiency.Expand Specific Solutions

Key Players in Space Valve Industry

The experimental validation of new gate valve concepts in space operations represents an emerging field within the aerospace industry. This sector is in its early development stage, characterized by a blend of established aerospace companies and innovative startups. The market size is relatively small but growing, driven by increasing space exploration activities and satellite deployments. Technologically, the field is still maturing, with companies like ArianeGroup GmbH, NASA, and SpacePharma SA leading research efforts. While traditional valve manufacturers such as SAMSON AG and Valveworks USA contribute expertise, space-specific adaptations are being developed by aerospace specialists like Airbus Defence & Space Ltd. and MacDonald, Dettwiler & Associates, Inc., indicating a collaborative approach to advancing this niche technology.

ArianeGroup GmbH

Technical Solution: ArianeGroup has developed innovative gate valve concepts for space propulsion systems, focusing on cryogenic applications. Their approach includes the use of advanced sealing technologies to prevent leakage of cryogenic propellants [4]. The company has implemented a novel thermal management system in their valve designs, utilizing multi-layer insulation and active cooling to maintain optimal operating temperatures [6]. ArianeGroup's experimental validation process involves extensive ground testing, including cryogenic cycling and vibration tests to simulate launch conditions [7]. They have also developed a unique coating technology for valve components to enhance wear resistance and reduce friction in the space environment [8].

Strengths: Expertise in cryogenic propulsion systems and advanced materials science. Weaknesses: Primarily focused on launch vehicle applications, which may limit adaptability to other space operations.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced gate valve concepts for space operations, focusing on reliability and efficiency in extreme environments. Their approach includes the use of shape memory alloys (SMAs) for actuators, which can operate without additional power sources [1]. NASA's gate valves incorporate redundant sealing mechanisms and utilize materials resistant to atomic oxygen and radiation [3]. The agency has also explored the use of additive manufacturing techniques to create lightweight yet durable valve components, reducing overall system mass [5]. NASA's experimental validation process involves rigorous testing in simulated space environments, including thermal cycling and vacuum exposure, to ensure performance under various mission scenarios [2].

Strengths: Extensive experience in space operations, access to advanced testing facilities, and a focus on reliability in extreme conditions. Weaknesses: High development costs and potentially longer timelines for technology implementation due to stringent safety requirements.

Innovative Gate Valve Concepts for Space

Valve assembly for switching and/or regulating a media flow of an aerospace engine and aerospace engine

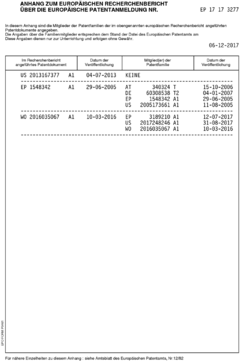

PatentActiveEP2833042A1

Innovation

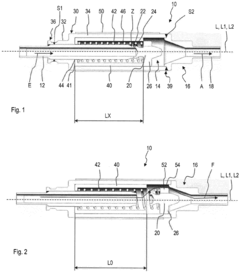

- A valve arrangement with an electric drive and a flexible separating element allows for variable control of the valve member between 'open' and 'closed' positions, ensuring the medium is hermetically separated from the drive, using electrically controllable actuators like piezo actuators for precise and adjustable control.

Valve for selectively opening a fluid conduit in a satellite drive system

PatentActiveEP3269651A1

Innovation

- A valve with a simplified structure featuring an actuator element that expands thermally to move a closure element, using shape memory materials and a prestressing device to ensure reliable sealing and one-time opening, with a compact design and reduced cross-sectional dimensions, and weld seams for enhanced tightness.

Space Environment Testing Protocols

Space Environment Testing Protocols for gate valve concepts in space operations require rigorous and comprehensive procedures to ensure the reliability and functionality of these critical components under extreme conditions. These protocols typically involve a series of tests that simulate various aspects of the space environment, including vacuum, thermal cycling, radiation exposure, and microgravity effects.

Vacuum testing is a fundamental aspect of space environment protocols. Gate valves must be tested in high-vacuum chambers to assess their performance and seal integrity in the absence of atmospheric pressure. This includes evaluating the valve's ability to maintain proper sealing and actuation under vacuum conditions, as well as identifying potential outgassing issues that could compromise the valve's performance or contaminate surrounding systems.

Thermal cycling tests are crucial for validating gate valve concepts in space operations. These tests subject the valves to extreme temperature fluctuations, simulating the rapid heating and cooling cycles experienced in orbit. The protocols typically involve cycling between temperature extremes, such as -150°C to +150°C, over multiple iterations. This process helps identify potential issues related to thermal expansion, contraction, and material fatigue.

Radiation testing is another critical component of space environment protocols for gate valves. These tests expose the valves to various types of radiation, including gamma rays, protons, and heavy ions, to assess their resilience to the harsh radiation environment of space. The protocols often include both total ionizing dose (TID) tests and single event effects (SEE) tests to evaluate long-term degradation and potential failure modes due to radiation exposure.

Vibration and shock testing protocols simulate the intense mechanical stresses experienced during launch and deployment. Gate valves must withstand these forces without compromising their functionality or structural integrity. These tests typically involve subjecting the valves to random vibration profiles and shock pulses that replicate launch conditions and other dynamic events encountered in space operations.

Microgravity testing, while challenging to fully replicate on Earth, is also considered in space environment protocols. This may involve parabolic flight tests or drop tower experiments to assess the valve's behavior in reduced gravity conditions, particularly focusing on fluid dynamics and actuation mechanisms.

Lastly, long-duration testing protocols are essential for validating gate valve concepts for extended space missions. These tests aim to simulate the prolonged exposure to space conditions and may involve continuous operation or cycling of the valve over extended periods, often lasting several months or even years, to identify potential degradation or failure modes that may only manifest over time.

Vacuum testing is a fundamental aspect of space environment protocols. Gate valves must be tested in high-vacuum chambers to assess their performance and seal integrity in the absence of atmospheric pressure. This includes evaluating the valve's ability to maintain proper sealing and actuation under vacuum conditions, as well as identifying potential outgassing issues that could compromise the valve's performance or contaminate surrounding systems.

Thermal cycling tests are crucial for validating gate valve concepts in space operations. These tests subject the valves to extreme temperature fluctuations, simulating the rapid heating and cooling cycles experienced in orbit. The protocols typically involve cycling between temperature extremes, such as -150°C to +150°C, over multiple iterations. This process helps identify potential issues related to thermal expansion, contraction, and material fatigue.

Radiation testing is another critical component of space environment protocols for gate valves. These tests expose the valves to various types of radiation, including gamma rays, protons, and heavy ions, to assess their resilience to the harsh radiation environment of space. The protocols often include both total ionizing dose (TID) tests and single event effects (SEE) tests to evaluate long-term degradation and potential failure modes due to radiation exposure.

Vibration and shock testing protocols simulate the intense mechanical stresses experienced during launch and deployment. Gate valves must withstand these forces without compromising their functionality or structural integrity. These tests typically involve subjecting the valves to random vibration profiles and shock pulses that replicate launch conditions and other dynamic events encountered in space operations.

Microgravity testing, while challenging to fully replicate on Earth, is also considered in space environment protocols. This may involve parabolic flight tests or drop tower experiments to assess the valve's behavior in reduced gravity conditions, particularly focusing on fluid dynamics and actuation mechanisms.

Lastly, long-duration testing protocols are essential for validating gate valve concepts for extended space missions. These tests aim to simulate the prolonged exposure to space conditions and may involve continuous operation or cycling of the valve over extended periods, often lasting several months or even years, to identify potential degradation or failure modes that may only manifest over time.

Reliability and Redundancy Considerations

Reliability and redundancy are critical considerations in the experimental validation of new gate valve concepts for space operations. The harsh and unforgiving environment of space demands robust and fail-safe systems to ensure mission success and astronaut safety. In the context of gate valves, which are essential components in fluid management systems, reliability is paramount.

The primary focus of reliability considerations is on the valve's ability to consistently perform its intended function under various operational conditions. This includes maintaining proper sealing, smooth actuation, and resistance to degradation over extended periods. Experimental validation must subject the new gate valve concepts to rigorous testing that simulates the extreme temperature fluctuations, vacuum conditions, and radiation exposure encountered in space.

Redundancy strategies play a crucial role in mitigating the risk of single-point failures. For gate valves in space operations, this often involves implementing parallel valve systems or incorporating backup actuation mechanisms. The experimental validation process should assess the effectiveness of these redundancy measures, ensuring that they can seamlessly take over in the event of a primary system failure.

Material selection is a key factor in both reliability and redundancy considerations. The experimental validation must evaluate the performance of advanced materials that offer enhanced durability, resistance to corrosion, and stability under space conditions. This may include testing of novel alloys, composites, or coatings that can extend the operational lifespan of the gate valves and reduce the likelihood of failure.

Fault tolerance is another critical aspect to be addressed during experimental validation. New gate valve concepts should demonstrate the ability to maintain functionality even when subjected to partial failures or degraded performance. This may involve testing scenarios where certain components are intentionally compromised to assess the valve's overall resilience.

The experimental validation process should also incorporate accelerated life testing methodologies to predict long-term reliability. By subjecting the gate valves to intensified stress conditions, researchers can extrapolate data to estimate performance over extended mission durations. This approach helps identify potential failure modes and allows for the implementation of preventive measures.

Sensor integration and health monitoring capabilities are increasingly important for enhancing reliability and facilitating predictive maintenance. Experimental validation should assess the effectiveness of embedded sensors and diagnostic systems in detecting early signs of wear, leakage, or performance degradation. This proactive approach can significantly improve the overall reliability of the gate valve system in space operations.

The primary focus of reliability considerations is on the valve's ability to consistently perform its intended function under various operational conditions. This includes maintaining proper sealing, smooth actuation, and resistance to degradation over extended periods. Experimental validation must subject the new gate valve concepts to rigorous testing that simulates the extreme temperature fluctuations, vacuum conditions, and radiation exposure encountered in space.

Redundancy strategies play a crucial role in mitigating the risk of single-point failures. For gate valves in space operations, this often involves implementing parallel valve systems or incorporating backup actuation mechanisms. The experimental validation process should assess the effectiveness of these redundancy measures, ensuring that they can seamlessly take over in the event of a primary system failure.

Material selection is a key factor in both reliability and redundancy considerations. The experimental validation must evaluate the performance of advanced materials that offer enhanced durability, resistance to corrosion, and stability under space conditions. This may include testing of novel alloys, composites, or coatings that can extend the operational lifespan of the gate valves and reduce the likelihood of failure.

Fault tolerance is another critical aspect to be addressed during experimental validation. New gate valve concepts should demonstrate the ability to maintain functionality even when subjected to partial failures or degraded performance. This may involve testing scenarios where certain components are intentionally compromised to assess the valve's overall resilience.

The experimental validation process should also incorporate accelerated life testing methodologies to predict long-term reliability. By subjecting the gate valves to intensified stress conditions, researchers can extrapolate data to estimate performance over extended mission durations. This approach helps identify potential failure modes and allows for the implementation of preventive measures.

Sensor integration and health monitoring capabilities are increasingly important for enhancing reliability and facilitating predictive maintenance. Experimental validation should assess the effectiveness of embedded sensors and diagnostic systems in detecting early signs of wear, leakage, or performance degradation. This proactive approach can significantly improve the overall reliability of the gate valve system in space operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!