Gate valve inspection methodologies for underground plumbing systems

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Inspection Background and Objectives

Gate valve inspection in underground plumbing systems has become increasingly critical as urban infrastructure ages and the demand for reliable water distribution grows. The evolution of this technology can be traced back to the early 20th century when manual inspections were the norm. Over time, the field has progressed significantly, incorporating advanced technologies to enhance efficiency and accuracy.

The primary objective of gate valve inspection methodologies is to ensure the proper functioning and longevity of these crucial components in underground plumbing networks. Gate valves play a vital role in controlling water flow and isolating sections of the system for maintenance or emergency repairs. As such, their regular inspection and maintenance are essential for preventing water loss, minimizing service disruptions, and safeguarding public health.

Recent technological advancements have led to the development of sophisticated inspection techniques, including acoustic sensors, electromagnetic methods, and robotic systems. These innovations aim to overcome the challenges associated with accessing and assessing valves in subterranean environments. The integration of data analytics and artificial intelligence has further enhanced the ability to predict valve failures and optimize maintenance schedules.

The current trend in gate valve inspection focuses on non-invasive methods that can provide accurate assessments without the need for excavation. This approach not only reduces costs but also minimizes disruption to urban environments and daily life. Additionally, there is a growing emphasis on developing real-time monitoring systems that can continuously evaluate valve performance and alert operators to potential issues before they escalate.

As water management becomes increasingly critical in the face of climate change and urbanization, the importance of efficient gate valve inspection methodologies cannot be overstated. The field is expected to continue evolving, with future developments likely to include more advanced sensors, improved data integration, and enhanced predictive maintenance capabilities. These advancements will contribute to more resilient and sustainable water distribution systems, ultimately benefiting communities worldwide.

The primary objective of gate valve inspection methodologies is to ensure the proper functioning and longevity of these crucial components in underground plumbing networks. Gate valves play a vital role in controlling water flow and isolating sections of the system for maintenance or emergency repairs. As such, their regular inspection and maintenance are essential for preventing water loss, minimizing service disruptions, and safeguarding public health.

Recent technological advancements have led to the development of sophisticated inspection techniques, including acoustic sensors, electromagnetic methods, and robotic systems. These innovations aim to overcome the challenges associated with accessing and assessing valves in subterranean environments. The integration of data analytics and artificial intelligence has further enhanced the ability to predict valve failures and optimize maintenance schedules.

The current trend in gate valve inspection focuses on non-invasive methods that can provide accurate assessments without the need for excavation. This approach not only reduces costs but also minimizes disruption to urban environments and daily life. Additionally, there is a growing emphasis on developing real-time monitoring systems that can continuously evaluate valve performance and alert operators to potential issues before they escalate.

As water management becomes increasingly critical in the face of climate change and urbanization, the importance of efficient gate valve inspection methodologies cannot be overstated. The field is expected to continue evolving, with future developments likely to include more advanced sensors, improved data integration, and enhanced predictive maintenance capabilities. These advancements will contribute to more resilient and sustainable water distribution systems, ultimately benefiting communities worldwide.

Market Demand for Underground Plumbing Inspection

The market demand for underground plumbing inspection, particularly for gate valve inspection methodologies, has been steadily increasing in recent years. This growth is primarily driven by the aging infrastructure in many developed countries, where underground plumbing systems are reaching the end of their operational lifespan. As these systems deteriorate, the risk of leaks, contamination, and system failures rises, creating a pressing need for effective inspection and maintenance solutions.

In urban areas, where the majority of underground plumbing systems are concentrated, the demand for inspection services is particularly high. Municipal water authorities and utility companies are increasingly recognizing the importance of proactive maintenance to prevent costly emergencies and service disruptions. This has led to a growing market for advanced inspection technologies that can accurately assess the condition of underground gate valves without the need for extensive excavation.

The residential sector also contributes significantly to the market demand. Homeowners and property managers are becoming more aware of the potential risks associated with aging plumbing systems, driving the need for regular inspections. This trend is further supported by insurance companies, which often require periodic assessments of plumbing infrastructure to mitigate risks and reduce claims.

Environmental concerns and water conservation efforts are also fueling the demand for gate valve inspection methodologies. Leaks in underground plumbing systems can lead to significant water loss and potential contamination of surrounding soil and groundwater. As a result, regulatory bodies are implementing stricter guidelines for water management, creating additional pressure on utility companies and property owners to invest in regular inspections and maintenance.

The market for underground plumbing inspection is not limited to developed countries. Emerging economies are also experiencing rapid urbanization and infrastructure development, leading to an increased need for efficient plumbing systems and their maintenance. This global expansion of the market is creating new opportunities for inspection technology providers and service companies.

Technological advancements in inspection methodologies are further driving market growth. Non-invasive techniques such as acoustic sensors, ground-penetrating radar, and robotic cameras are gaining popularity due to their ability to provide accurate assessments without the need for extensive excavation. These innovations are making inspections more cost-effective and less disruptive, thereby increasing the frequency and scope of inspections.

The COVID-19 pandemic has also indirectly influenced the market demand for underground plumbing inspections. With more people spending time at home, there has been an increased focus on home maintenance and improvement, including plumbing systems. This heightened awareness is expected to continue driving demand for inspection services in the residential sector.

In urban areas, where the majority of underground plumbing systems are concentrated, the demand for inspection services is particularly high. Municipal water authorities and utility companies are increasingly recognizing the importance of proactive maintenance to prevent costly emergencies and service disruptions. This has led to a growing market for advanced inspection technologies that can accurately assess the condition of underground gate valves without the need for extensive excavation.

The residential sector also contributes significantly to the market demand. Homeowners and property managers are becoming more aware of the potential risks associated with aging plumbing systems, driving the need for regular inspections. This trend is further supported by insurance companies, which often require periodic assessments of plumbing infrastructure to mitigate risks and reduce claims.

Environmental concerns and water conservation efforts are also fueling the demand for gate valve inspection methodologies. Leaks in underground plumbing systems can lead to significant water loss and potential contamination of surrounding soil and groundwater. As a result, regulatory bodies are implementing stricter guidelines for water management, creating additional pressure on utility companies and property owners to invest in regular inspections and maintenance.

The market for underground plumbing inspection is not limited to developed countries. Emerging economies are also experiencing rapid urbanization and infrastructure development, leading to an increased need for efficient plumbing systems and their maintenance. This global expansion of the market is creating new opportunities for inspection technology providers and service companies.

Technological advancements in inspection methodologies are further driving market growth. Non-invasive techniques such as acoustic sensors, ground-penetrating radar, and robotic cameras are gaining popularity due to their ability to provide accurate assessments without the need for extensive excavation. These innovations are making inspections more cost-effective and less disruptive, thereby increasing the frequency and scope of inspections.

The COVID-19 pandemic has also indirectly influenced the market demand for underground plumbing inspections. With more people spending time at home, there has been an increased focus on home maintenance and improvement, including plumbing systems. This heightened awareness is expected to continue driving demand for inspection services in the residential sector.

Current Challenges in Gate Valve Inspection

Gate valve inspection in underground plumbing systems faces numerous challenges that hinder effective maintenance and reliability. One of the primary obstacles is the limited accessibility of these valves, often buried deep beneath streets or buildings. This positioning makes visual inspections and manual operations extremely difficult, if not impossible, without extensive excavation.

The harsh underground environment poses another significant challenge. Valves are constantly exposed to moisture, soil contaminants, and corrosive elements, accelerating wear and degradation. This environmental stress can lead to premature failure or reduced functionality, making accurate assessment of valve condition crucial yet increasingly complex.

Technological limitations also present a considerable hurdle. Traditional inspection methods often rely on indirect indicators of valve health, such as pressure differentials or flow rates. These methods, while useful, may not provide a comprehensive picture of the valve's internal condition, leading to potential misdiagnosis or overlooked issues.

The lack of standardized inspection protocols specifically tailored for underground gate valves further complicates the process. Different municipalities and water management entities may employ varying inspection techniques and schedules, resulting in inconsistent data collection and analysis across different systems.

Time and resource constraints add another layer of difficulty. Conducting thorough inspections of extensive underground valve networks is time-consuming and labor-intensive. Many utilities struggle to balance the need for comprehensive inspections with budget limitations and the desire to minimize service disruptions.

The aging infrastructure in many urban areas exacerbates these challenges. As underground plumbing systems reach or exceed their intended lifespans, the likelihood of valve failures increases, making accurate and timely inspections even more critical. However, the sheer number of aging valves in need of inspection often overwhelms available resources.

Lastly, the interpretation of inspection data presents its own set of challenges. Even when data can be collected, translating it into actionable insights requires specialized expertise. The complexity of underground systems and the interplay of various factors affecting valve performance make it difficult to establish clear correlations between inspection findings and necessary maintenance actions.

The harsh underground environment poses another significant challenge. Valves are constantly exposed to moisture, soil contaminants, and corrosive elements, accelerating wear and degradation. This environmental stress can lead to premature failure or reduced functionality, making accurate assessment of valve condition crucial yet increasingly complex.

Technological limitations also present a considerable hurdle. Traditional inspection methods often rely on indirect indicators of valve health, such as pressure differentials or flow rates. These methods, while useful, may not provide a comprehensive picture of the valve's internal condition, leading to potential misdiagnosis or overlooked issues.

The lack of standardized inspection protocols specifically tailored for underground gate valves further complicates the process. Different municipalities and water management entities may employ varying inspection techniques and schedules, resulting in inconsistent data collection and analysis across different systems.

Time and resource constraints add another layer of difficulty. Conducting thorough inspections of extensive underground valve networks is time-consuming and labor-intensive. Many utilities struggle to balance the need for comprehensive inspections with budget limitations and the desire to minimize service disruptions.

The aging infrastructure in many urban areas exacerbates these challenges. As underground plumbing systems reach or exceed their intended lifespans, the likelihood of valve failures increases, making accurate and timely inspections even more critical. However, the sheer number of aging valves in need of inspection often overwhelms available resources.

Lastly, the interpretation of inspection data presents its own set of challenges. Even when data can be collected, translating it into actionable insights requires specialized expertise. The complexity of underground systems and the interplay of various factors affecting valve performance make it difficult to establish clear correlations between inspection findings and necessary maintenance actions.

Existing Gate Valve Inspection Methodologies

01 Visual inspection methods

Gate valve inspection often involves visual examination techniques to assess the condition of valve components. This can include checking for wear, corrosion, or damage to the valve body, seat, and gate. Visual inspections may be conducted using specialized tools or equipment to access hard-to-reach areas of the valve.- Visual inspection methods: Gate valve inspection often involves visual examination techniques to assess the condition of various components. This may include checking for signs of wear, corrosion, or damage on the valve body, stem, and sealing surfaces. Visual inspection can be performed using specialized tools or equipment to access hard-to-reach areas of the valve.

- Non-destructive testing techniques: Non-destructive testing (NDT) methods are employed for gate valve inspection to detect internal defects or flaws without damaging the valve. These techniques may include ultrasonic testing, radiographic inspection, or magnetic particle testing to identify cracks, voids, or other irregularities in the valve material or components.

- Pressure testing and leak detection: Gate valves are often subjected to pressure tests to verify their sealing capabilities and identify potential leaks. This may involve applying pressure to the valve body and monitoring for any pressure drops or visible leakage. Various methods and equipment can be used for leak detection, including bubble tests, acoustic emission, or tracer gas techniques.

- Automated inspection systems: Advanced automated systems are being developed for gate valve inspection to improve efficiency and accuracy. These systems may incorporate robotics, computer vision, or artificial intelligence to perform various inspection tasks. Automated systems can help reduce human error and provide more consistent results in valve inspection processes.

- In-line inspection techniques: In-line inspection methods allow for the examination of gate valves without removing them from the pipeline or system. These techniques may involve the use of specialized tools or devices that can be inserted into the pipeline to assess the valve's condition, functionality, and performance while it remains in service. In-line inspection can help minimize downtime and reduce the need for valve disassembly.

02 Non-destructive testing techniques

Non-destructive testing (NDT) methods are employed for gate valve inspection without causing damage to the valve. These techniques may include ultrasonic testing, radiographic inspection, or magnetic particle testing to detect internal flaws, cracks, or material defects that are not visible to the naked eye.Expand Specific Solutions03 Automated inspection systems

Advanced automated systems are developed for gate valve inspection, incorporating sensors, cameras, and data analysis software. These systems can perform rapid and accurate inspections, detecting issues such as leaks, misalignments, or abnormal wear patterns. Automated inspections can be particularly useful for large-scale industrial applications or in hazardous environments.Expand Specific Solutions04 Pressure testing and leak detection

Pressure testing is a crucial aspect of gate valve inspection to ensure proper sealing and functionality. This may involve hydrostatic or pneumatic testing to verify the valve's ability to withstand operating pressures and detect any leaks. Specialized equipment and procedures are used to conduct these tests safely and effectively.Expand Specific Solutions05 In-line inspection techniques

In-line inspection methods allow for the examination of gate valves without removing them from the pipeline or system. These techniques may utilize specialized tools or devices that can be inserted into the pipeline to assess valve condition, measure wear, or detect potential issues while the system remains operational or with minimal disruption.Expand Specific Solutions

Key Players in Plumbing Inspection Industry

The gate valve inspection market for underground plumbing systems is in a growth phase, driven by increasing infrastructure investments and aging pipeline networks. The market size is expanding as utilities and municipalities prioritize asset management and leak prevention. Technologically, the field is advancing rapidly, with companies like Square Robot, Inc. and The Detection Group, Inc. developing innovative robotic and IoT-based inspection solutions. Established players such as Halliburton Energy Services, Inc. and Robert Bosch GmbH are leveraging their expertise to enhance traditional inspection methodologies. The competitive landscape is diverse, with a mix of specialized inspection firms, large industrial conglomerates, and emerging tech startups vying for market share.

Square Robot, Inc.

Technical Solution: Square Robot, Inc. has pioneered an innovative robotic solution for gate valve inspection in underground plumbing systems. Their autonomous robots are designed to navigate through complex pipe networks, accessing areas that are difficult or dangerous for human inspectors[1]. These robots are equipped with high-definition cameras, ultrasonic sensors, and LIDAR technology to create detailed 3D maps of the underground infrastructure[2]. For gate valve inspection, the robots utilize machine vision algorithms to identify valves and assess their condition, checking for signs of corrosion, wear, or misalignment[3]. The robots can also perform non-destructive testing on valve components using advanced sensors. Data collected during inspections is transmitted in real-time to operators, who can make informed decisions about maintenance or replacement needs[4]. Square Robot's technology allows for frequent and thorough inspections without service interruptions or excavation, significantly reducing inspection costs and improving overall system reliability[5].

Strengths: Non-invasive inspection, ability to access hard-to-reach areas, and real-time data collection. Weaknesses: Limited to pipe systems large enough for robot entry and potential high initial investment costs.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed a comprehensive gate valve inspection system for underground plumbing that leverages their expertise in sensor technology and IoT solutions. Their approach combines smart sensors with advanced data analytics to provide continuous monitoring of gate valve performance[1]. Bosch's system utilizes pressure sensors, flow meters, and temperature probes installed around critical valve points to detect anomalies in real-time[2]. The data is processed using machine learning algorithms that can identify patterns indicative of valve wear, leakage, or impending failure[3]. Additionally, Bosch has integrated their valve monitoring system with augmented reality (AR) technology, allowing maintenance teams to visualize underground infrastructure and valve status through mobile devices, streamlining inspection and repair processes[4]. The system also incorporates predictive maintenance capabilities, using historical data and AI to forecast when valves may require servicing or replacement, thus optimizing maintenance schedules and reducing downtime[5].

Strengths: Continuous monitoring, predictive maintenance capabilities, and integration with AR for enhanced visualization. Weaknesses: Reliance on complex sensor networks and potential cybersecurity concerns with IoT integration.

Innovative Techniques for Underground Valve Inspection

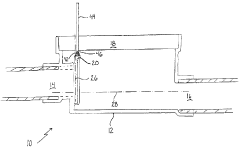

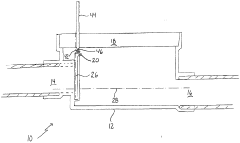

Valve inspection chamber with gate valve

PatentInactiveCA2339462A1

Innovation

- A valve inspection chamber with a housing featuring a gate valve receptacle and retrieval system, allowing the gate valve member to be inserted and retrieved through a vertical inspection opening, with engagement mechanisms to maintain the valve in place until a preset force is applied, enabling efficient access and servicing without manholes.

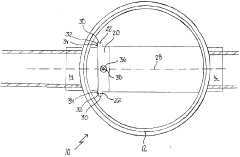

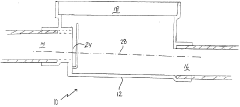

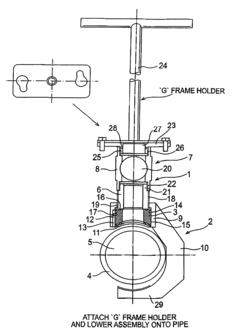

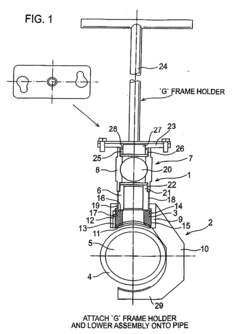

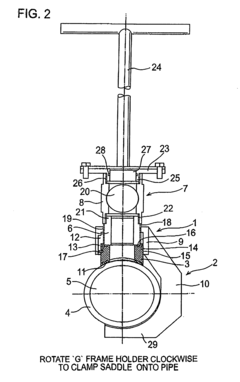

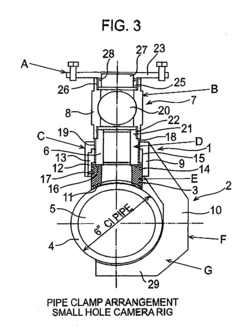

Apparatus for permitting access to the interior of a subterranean fluid-carrying pipe by way of an excavation which has uncovered the wall of the pipe

PatentInactiveUS20080260466A1

Innovation

- A valve assembly with a clamping member, such as a hook, that can be lowered into the excavation and engaged with the pipe wall to securely attach the saddle and prevent gas leakage, using a jacking stem and ball valve with a housing that aligns and obscures the hole to prevent fluid escape, allowing for 'no gas' operations.

Regulatory Framework for Plumbing Inspections

The regulatory framework for plumbing inspections in underground systems, particularly for gate valve inspections, is a complex and multifaceted structure that varies across jurisdictions. In the United States, the primary regulatory body overseeing plumbing standards is the International Association of Plumbing and Mechanical Officials (IAPMO), which develops and maintains the Uniform Plumbing Code (UPC). This code serves as the foundation for many state and local plumbing regulations, including those pertaining to gate valve inspections in underground systems.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in setting water quality standards that indirectly influence plumbing inspection requirements. The Safe Drinking Water Act (SDWA) mandates regular inspections and maintenance of water distribution systems, which includes underground plumbing components like gate valves.

State-level regulations often build upon these federal standards, with each state having its own plumbing code that may include specific requirements for gate valve inspections. For instance, California's Plumbing Code, based on the UPC, outlines detailed procedures for inspecting and maintaining underground plumbing systems, including gate valves.

Local municipalities may further refine these regulations, often implementing more stringent inspection schedules or methodologies. Many cities require periodic inspections of underground plumbing systems, with some mandating annual checks for critical infrastructure components like gate valves.

The American Water Works Association (AWWA) provides industry standards that are widely adopted in regulatory frameworks. Their Manual M44 on Distribution Valves offers comprehensive guidelines for the inspection and maintenance of gate valves in underground systems, which many jurisdictions incorporate into their regulatory requirements.

Compliance with these regulations typically involves a combination of visual inspections, pressure testing, and non-destructive evaluation techniques. Regulatory bodies often specify the frequency of inspections, the qualifications required for inspectors, and the documentation processes for recording and reporting inspection results.

Enforcement of these regulations is usually carried out by local building departments or water utilities. Penalties for non-compliance can range from fines to service interruptions, emphasizing the importance of adhering to established inspection protocols.

As technology advances, regulatory frameworks are evolving to incorporate new inspection methodologies. For example, some jurisdictions are beginning to accept remote sensing and robotic inspection techniques as valid methods for assessing the condition of underground gate valves, provided they meet certain performance criteria.

At the federal level, the Environmental Protection Agency (EPA) plays a crucial role in setting water quality standards that indirectly influence plumbing inspection requirements. The Safe Drinking Water Act (SDWA) mandates regular inspections and maintenance of water distribution systems, which includes underground plumbing components like gate valves.

State-level regulations often build upon these federal standards, with each state having its own plumbing code that may include specific requirements for gate valve inspections. For instance, California's Plumbing Code, based on the UPC, outlines detailed procedures for inspecting and maintaining underground plumbing systems, including gate valves.

Local municipalities may further refine these regulations, often implementing more stringent inspection schedules or methodologies. Many cities require periodic inspections of underground plumbing systems, with some mandating annual checks for critical infrastructure components like gate valves.

The American Water Works Association (AWWA) provides industry standards that are widely adopted in regulatory frameworks. Their Manual M44 on Distribution Valves offers comprehensive guidelines for the inspection and maintenance of gate valves in underground systems, which many jurisdictions incorporate into their regulatory requirements.

Compliance with these regulations typically involves a combination of visual inspections, pressure testing, and non-destructive evaluation techniques. Regulatory bodies often specify the frequency of inspections, the qualifications required for inspectors, and the documentation processes for recording and reporting inspection results.

Enforcement of these regulations is usually carried out by local building departments or water utilities. Penalties for non-compliance can range from fines to service interruptions, emphasizing the importance of adhering to established inspection protocols.

As technology advances, regulatory frameworks are evolving to incorporate new inspection methodologies. For example, some jurisdictions are beginning to accept remote sensing and robotic inspection techniques as valid methods for assessing the condition of underground gate valves, provided they meet certain performance criteria.

Environmental Impact of Inspection Methods

The environmental impact of gate valve inspection methodologies for underground plumbing systems is a critical consideration in urban infrastructure management. Traditional inspection methods often involve excavation, which can lead to significant soil disturbance and potential damage to surrounding ecosystems. These invasive techniques may result in the destruction of plant root systems, disruption of soil microorganisms, and alteration of local drainage patterns.

Non-invasive inspection technologies, such as acoustic sensors and ground-penetrating radar, offer a more environmentally friendly alternative. These methods minimize surface disturbance and reduce the need for extensive excavation, thereby preserving soil integrity and protecting local flora and fauna. However, the energy consumption and electromagnetic emissions associated with these technologies must be carefully evaluated for their long-term environmental effects.

The use of robotic inspection systems presents a balanced approach, combining minimal invasiveness with high inspection accuracy. These systems can navigate through existing access points, reducing the need for new excavations. However, the production and disposal of specialized robotic equipment may have its own environmental implications, including the use of rare earth metals and electronic waste generation.

Chemical tracer methods, while effective for leak detection, raise concerns about potential groundwater contamination. The environmental persistence and toxicity of tracer compounds must be thoroughly assessed to prevent long-term ecological impacts. Similarly, pressure testing techniques may stress pipe systems, potentially leading to increased leakage and water waste if not properly managed.

The choice of inspection method also affects carbon emissions associated with the inspection process. Methods requiring heavy machinery or extensive vehicle use contribute to higher carbon footprints compared to more localized, human-operated techniques. Additionally, the frequency of inspections impacts the cumulative environmental effect, with more frequent invasive inspections potentially causing greater long-term ecological disruption.

Considering the lifecycle environmental impact, the durability and longevity of inspection equipment play a crucial role. Techniques that require frequent replacement or updating of equipment may lead to increased electronic waste and resource consumption. Conversely, methods that extend the lifespan of existing plumbing infrastructure through early detection and preventive maintenance can significantly reduce the overall environmental impact of urban water systems.

In conclusion, the environmental impact of gate valve inspection methodologies varies widely, with newer technologies generally offering reduced ecological disturbance. However, a holistic assessment considering factors such as energy use, waste generation, and long-term ecosystem effects is essential for selecting truly sustainable inspection practices for underground plumbing systems.

Non-invasive inspection technologies, such as acoustic sensors and ground-penetrating radar, offer a more environmentally friendly alternative. These methods minimize surface disturbance and reduce the need for extensive excavation, thereby preserving soil integrity and protecting local flora and fauna. However, the energy consumption and electromagnetic emissions associated with these technologies must be carefully evaluated for their long-term environmental effects.

The use of robotic inspection systems presents a balanced approach, combining minimal invasiveness with high inspection accuracy. These systems can navigate through existing access points, reducing the need for new excavations. However, the production and disposal of specialized robotic equipment may have its own environmental implications, including the use of rare earth metals and electronic waste generation.

Chemical tracer methods, while effective for leak detection, raise concerns about potential groundwater contamination. The environmental persistence and toxicity of tracer compounds must be thoroughly assessed to prevent long-term ecological impacts. Similarly, pressure testing techniques may stress pipe systems, potentially leading to increased leakage and water waste if not properly managed.

The choice of inspection method also affects carbon emissions associated with the inspection process. Methods requiring heavy machinery or extensive vehicle use contribute to higher carbon footprints compared to more localized, human-operated techniques. Additionally, the frequency of inspections impacts the cumulative environmental effect, with more frequent invasive inspections potentially causing greater long-term ecological disruption.

Considering the lifecycle environmental impact, the durability and longevity of inspection equipment play a crucial role. Techniques that require frequent replacement or updating of equipment may lead to increased electronic waste and resource consumption. Conversely, methods that extend the lifespan of existing plumbing infrastructure through early detection and preventive maintenance can significantly reduce the overall environmental impact of urban water systems.

In conclusion, the environmental impact of gate valve inspection methodologies varies widely, with newer technologies generally offering reduced ecological disturbance. However, a holistic assessment considering factors such as energy use, waste generation, and long-term ecosystem effects is essential for selecting truly sustainable inspection practices for underground plumbing systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!