Gate valve calibration methodologies for optimal fluid dynamics

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Calibration Background and Objectives

Gate valve calibration has been a critical aspect of fluid dynamics control in various industries for decades. The evolution of this technology has been driven by the increasing demand for precision and efficiency in fluid management systems. From manual calibration methods to advanced automated techniques, the field has witnessed significant advancements aimed at optimizing fluid flow and enhancing overall system performance.

The primary objective of gate valve calibration is to ensure accurate control of fluid flow rates, pressure, and direction within a system. This is crucial for maintaining operational efficiency, safety, and compliance with industry standards. As industries such as oil and gas, water treatment, and chemical processing continue to evolve, the need for more sophisticated calibration methodologies has become paramount.

Historically, gate valve calibration relied heavily on manual processes and operator expertise. However, the limitations of these methods, including human error and inconsistency, have led to the development of more precise and repeatable calibration techniques. The integration of digital technologies and sensor-based systems has marked a significant milestone in this evolution, enabling real-time monitoring and adjustment of valve performance.

Recent technological trends in gate valve calibration focus on achieving optimal fluid dynamics through advanced modeling and simulation techniques. These approaches allow for the prediction of valve behavior under various operating conditions, facilitating more accurate calibration and reducing the need for extensive physical testing. Additionally, the incorporation of machine learning algorithms has opened new possibilities for predictive maintenance and adaptive calibration strategies.

The current landscape of gate valve calibration methodologies is characterized by a blend of traditional mechanical approaches and cutting-edge digital solutions. Industry leaders are increasingly adopting smart valve technologies that incorporate embedded sensors and actuators, enabling continuous monitoring and automatic adjustment of valve positions. This shift towards intelligent systems aims to minimize downtime, reduce maintenance costs, and improve overall system reliability.

As we look towards the future, the objectives of gate valve calibration continue to expand beyond mere accuracy. There is a growing emphasis on developing calibration methods that can adapt to changing environmental conditions and fluid properties in real-time. Furthermore, the integration of calibration data with broader industrial IoT ecosystems is becoming a key focus, aiming to enhance overall plant efficiency and enable more comprehensive asset management strategies.

The primary objective of gate valve calibration is to ensure accurate control of fluid flow rates, pressure, and direction within a system. This is crucial for maintaining operational efficiency, safety, and compliance with industry standards. As industries such as oil and gas, water treatment, and chemical processing continue to evolve, the need for more sophisticated calibration methodologies has become paramount.

Historically, gate valve calibration relied heavily on manual processes and operator expertise. However, the limitations of these methods, including human error and inconsistency, have led to the development of more precise and repeatable calibration techniques. The integration of digital technologies and sensor-based systems has marked a significant milestone in this evolution, enabling real-time monitoring and adjustment of valve performance.

Recent technological trends in gate valve calibration focus on achieving optimal fluid dynamics through advanced modeling and simulation techniques. These approaches allow for the prediction of valve behavior under various operating conditions, facilitating more accurate calibration and reducing the need for extensive physical testing. Additionally, the incorporation of machine learning algorithms has opened new possibilities for predictive maintenance and adaptive calibration strategies.

The current landscape of gate valve calibration methodologies is characterized by a blend of traditional mechanical approaches and cutting-edge digital solutions. Industry leaders are increasingly adopting smart valve technologies that incorporate embedded sensors and actuators, enabling continuous monitoring and automatic adjustment of valve positions. This shift towards intelligent systems aims to minimize downtime, reduce maintenance costs, and improve overall system reliability.

As we look towards the future, the objectives of gate valve calibration continue to expand beyond mere accuracy. There is a growing emphasis on developing calibration methods that can adapt to changing environmental conditions and fluid properties in real-time. Furthermore, the integration of calibration data with broader industrial IoT ecosystems is becoming a key focus, aiming to enhance overall plant efficiency and enable more comprehensive asset management strategies.

Market Demand Analysis for Precision Valve Control

The market demand for precision valve control, particularly in gate valve calibration methodologies for optimal fluid dynamics, has been experiencing significant growth across various industries. This surge is primarily driven by the increasing need for enhanced efficiency, safety, and reliability in fluid handling systems.

In the oil and gas sector, which remains a major consumer of gate valves, the demand for precise control has intensified due to the industry's focus on maximizing production while minimizing operational costs. Offshore operations, in particular, require highly accurate valve control to maintain safety standards and optimize production rates. The market in this sector is expected to grow steadily as exploration and production activities continue to expand into more challenging environments.

The water and wastewater treatment industry has also emerged as a key driver for precision valve control. With growing urbanization and stricter environmental regulations, there is an increased emphasis on efficient water management systems. Precise gate valve calibration plays a crucial role in controlling water flow, pressure, and distribution, leading to reduced water loss and improved overall system performance.

In the power generation sector, the transition towards more flexible and efficient power plants has heightened the demand for advanced valve control systems. Gate valves with precise calibration capabilities are essential for managing steam flow in thermal power plants and controlling coolant systems in nuclear facilities. The growing adoption of renewable energy sources has also created new opportunities for valve manufacturers, particularly in concentrated solar power plants and geothermal energy systems.

The chemical and petrochemical industries continue to be significant contributors to the market demand for precision valve control. These sectors require highly accurate flow control to maintain product quality, ensure process efficiency, and adhere to stringent safety standards. The increasing complexity of chemical processes and the push towards automation have further amplified the need for sophisticated valve calibration methodologies.

The pharmaceutical and biotechnology sectors have also shown a growing interest in precision valve control. The demand is driven by the need for maintaining sterile conditions, ensuring accurate dosing, and complying with strict regulatory requirements. As these industries continue to expand and innovate, the market for precision-controlled gate valves is expected to grow correspondingly.

Geographically, North America and Europe currently lead the market for precision valve control technologies, owing to their mature industrial sectors and stringent regulatory environments. However, rapid industrialization and infrastructure development in Asia-Pacific regions, particularly in countries like China and India, are creating substantial growth opportunities for valve manufacturers and calibration service providers.

In the oil and gas sector, which remains a major consumer of gate valves, the demand for precise control has intensified due to the industry's focus on maximizing production while minimizing operational costs. Offshore operations, in particular, require highly accurate valve control to maintain safety standards and optimize production rates. The market in this sector is expected to grow steadily as exploration and production activities continue to expand into more challenging environments.

The water and wastewater treatment industry has also emerged as a key driver for precision valve control. With growing urbanization and stricter environmental regulations, there is an increased emphasis on efficient water management systems. Precise gate valve calibration plays a crucial role in controlling water flow, pressure, and distribution, leading to reduced water loss and improved overall system performance.

In the power generation sector, the transition towards more flexible and efficient power plants has heightened the demand for advanced valve control systems. Gate valves with precise calibration capabilities are essential for managing steam flow in thermal power plants and controlling coolant systems in nuclear facilities. The growing adoption of renewable energy sources has also created new opportunities for valve manufacturers, particularly in concentrated solar power plants and geothermal energy systems.

The chemical and petrochemical industries continue to be significant contributors to the market demand for precision valve control. These sectors require highly accurate flow control to maintain product quality, ensure process efficiency, and adhere to stringent safety standards. The increasing complexity of chemical processes and the push towards automation have further amplified the need for sophisticated valve calibration methodologies.

The pharmaceutical and biotechnology sectors have also shown a growing interest in precision valve control. The demand is driven by the need for maintaining sterile conditions, ensuring accurate dosing, and complying with strict regulatory requirements. As these industries continue to expand and innovate, the market for precision-controlled gate valves is expected to grow correspondingly.

Geographically, North America and Europe currently lead the market for precision valve control technologies, owing to their mature industrial sectors and stringent regulatory environments. However, rapid industrialization and infrastructure development in Asia-Pacific regions, particularly in countries like China and India, are creating substantial growth opportunities for valve manufacturers and calibration service providers.

Current Challenges in Gate Valve Calibration

Gate valve calibration for optimal fluid dynamics faces several significant challenges in the current technological landscape. One of the primary issues is the complexity of fluid behavior within valve systems. Fluid dynamics can be highly unpredictable, especially under varying pressure and temperature conditions, making it difficult to establish consistent calibration methodologies.

The lack of standardized calibration procedures across different industries and valve types further complicates the process. Each application may require unique calibration approaches, leading to inconsistencies in performance and reliability. This variability makes it challenging to develop universal calibration methods that can be applied across diverse operational environments.

Another major challenge is the integration of advanced sensing and measurement technologies into existing valve systems. While modern sensors can provide highly accurate data, retrofitting older valve installations with these technologies can be costly and time-consuming. This creates a disparity between newer, more easily calibrated systems and older, less adaptable ones.

The dynamic nature of industrial processes also poses a significant challenge to gate valve calibration. Fluctuations in flow rates, pressure, and fluid composition can occur rapidly, requiring calibration methods that can adapt in real-time. Developing such responsive calibration systems remains a technical hurdle for many manufacturers and operators.

Environmental factors add another layer of complexity to valve calibration. Extreme temperatures, corrosive fluids, and high-pressure environments can affect valve performance and calibration accuracy. Designing calibration methodologies that remain effective under these harsh conditions continues to be a significant challenge in the field.

The increasing demand for precision in fluid control systems has raised the bar for calibration accuracy. Achieving and maintaining tight tolerances in valve positioning and flow control requires highly sophisticated calibration techniques. This level of precision is particularly challenging in large-scale industrial applications where even minor calibration errors can lead to significant operational inefficiencies.

Lastly, the challenge of data management and interpretation in calibration processes cannot be overlooked. As calibration systems become more complex and data-driven, there is a growing need for advanced analytics and machine learning algorithms to process and interpret the vast amounts of data generated. Developing these analytical tools and integrating them into existing calibration workflows represents a significant technological challenge for the industry.

The lack of standardized calibration procedures across different industries and valve types further complicates the process. Each application may require unique calibration approaches, leading to inconsistencies in performance and reliability. This variability makes it challenging to develop universal calibration methods that can be applied across diverse operational environments.

Another major challenge is the integration of advanced sensing and measurement technologies into existing valve systems. While modern sensors can provide highly accurate data, retrofitting older valve installations with these technologies can be costly and time-consuming. This creates a disparity between newer, more easily calibrated systems and older, less adaptable ones.

The dynamic nature of industrial processes also poses a significant challenge to gate valve calibration. Fluctuations in flow rates, pressure, and fluid composition can occur rapidly, requiring calibration methods that can adapt in real-time. Developing such responsive calibration systems remains a technical hurdle for many manufacturers and operators.

Environmental factors add another layer of complexity to valve calibration. Extreme temperatures, corrosive fluids, and high-pressure environments can affect valve performance and calibration accuracy. Designing calibration methodologies that remain effective under these harsh conditions continues to be a significant challenge in the field.

The increasing demand for precision in fluid control systems has raised the bar for calibration accuracy. Achieving and maintaining tight tolerances in valve positioning and flow control requires highly sophisticated calibration techniques. This level of precision is particularly challenging in large-scale industrial applications where even minor calibration errors can lead to significant operational inefficiencies.

Lastly, the challenge of data management and interpretation in calibration processes cannot be overlooked. As calibration systems become more complex and data-driven, there is a growing need for advanced analytics and machine learning algorithms to process and interpret the vast amounts of data generated. Developing these analytical tools and integrating them into existing calibration workflows represents a significant technological challenge for the industry.

Existing Gate Valve Calibration Methodologies

01 Flow control mechanisms in gate valves

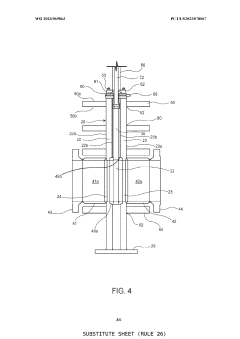

Gate valves employ various flow control mechanisms to regulate fluid dynamics. These mechanisms include adjustable gate positions, specialized sealing surfaces, and flow path designs that minimize turbulence and pressure drops. Advanced gate valve designs incorporate features to optimize fluid flow characteristics and improve overall system efficiency.- Flow control mechanisms in gate valves: Gate valves employ various flow control mechanisms to regulate fluid dynamics. These mechanisms include adjustable gate positions, specialized sealing surfaces, and flow path designs that minimize turbulence and pressure drops. Advanced gate valve designs incorporate features to optimize flow characteristics and reduce energy losses during fluid passage.

- Fluid dynamics modeling for gate valve design: Computational fluid dynamics (CFD) and advanced modeling techniques are used to analyze and optimize gate valve designs. These methods help engineers predict flow patterns, pressure distributions, and potential areas of turbulence or cavitation. By simulating various operating conditions, designers can refine valve geometries to enhance performance and efficiency.

- Gate valve seat and sealing innovations: Innovations in gate valve seat and sealing technologies focus on improving fluid dynamics and leak prevention. Advanced materials and designs are employed to create more effective seals, reduce friction, and maintain consistent performance under various pressure and temperature conditions. These improvements contribute to better flow characteristics and extended valve lifespan.

- Actuation systems for precise flow control: Gate valve actuation systems play a crucial role in fluid dynamics control. Advanced actuators, including electric, hydraulic, and pneumatic systems, enable precise gate positioning and rapid response to flow changes. These systems incorporate feedback mechanisms and smart controls to optimize valve performance and adapt to varying fluid conditions.

- Gate valve design for specific fluid applications: Specialized gate valve designs cater to specific fluid applications, considering factors such as viscosity, temperature, and chemical composition. These designs may incorporate features like streamlined flow paths, erosion-resistant materials, or multi-stage pressure reduction to address unique fluid dynamics challenges in industries such as oil and gas, chemical processing, or water treatment.

02 Pressure balancing and sealing techniques

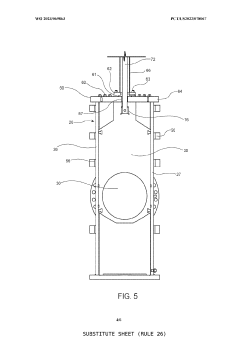

Gate valves utilize pressure balancing and sealing techniques to enhance performance in high-pressure fluid systems. These techniques involve the use of pressure-equalizing chambers, balanced seal designs, and specialized materials to minimize friction and wear while maintaining tight seals. Such features contribute to improved fluid dynamics and valve longevity.Expand Specific Solutions03 Fluid flow optimization through valve geometry

The internal geometry of gate valves plays a crucial role in optimizing fluid flow. Streamlined valve body designs, contoured gate edges, and carefully engineered flow passages help reduce turbulence, minimize pressure losses, and improve overall fluid dynamics. These geometric considerations are essential for maximizing valve efficiency and performance.Expand Specific Solutions04 Actuation systems for precise flow control

Advanced actuation systems in gate valves enable precise control over fluid dynamics. These systems may include electric, hydraulic, or pneumatic actuators with position feedback mechanisms. Such precise control allows for fine-tuning of flow rates, rapid response to system changes, and improved overall fluid management in various applications.Expand Specific Solutions05 Materials and coatings for enhanced fluid dynamics

Specialized materials and coatings are employed in gate valve construction to enhance fluid dynamics. These may include low-friction materials for internal components, corrosion-resistant alloys for valve bodies, and advanced surface treatments to reduce turbulence and improve flow characteristics. The selection of appropriate materials and coatings is crucial for optimizing valve performance in various fluid environments.Expand Specific Solutions

Key Players in Valve Calibration Industry

The gate valve calibration market for fluid dynamics optimization is in a growth phase, driven by increasing demand for precision in industrial processes. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like Caterpillar, Robert Bosch, and Continental Automotive Technologies leading innovation. These firms are developing sophisticated calibration methodologies, integrating IoT and AI for real-time adjustments. Emerging players like Fujikin and Celeros Flow Technology are also contributing to market maturation, focusing on specialized applications and sustainable solutions. The competitive landscape is characterized by a mix of established industrial giants and niche specialists, fostering a dynamic environment for technological advancement.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced gate valve calibration system that utilizes machine learning algorithms to optimize fluid dynamics. Their approach combines real-time sensor data with predictive modeling to continuously adjust valve positions. The system employs a network of pressure and flow sensors throughout the pipeline, feeding data into a central control unit. This unit uses artificial intelligence to analyze patterns and predict optimal valve settings based on current and forecasted conditions. The calibration process is dynamic, allowing for rapid adjustments to maintain optimal flow rates and pressure levels across varying operational scenarios[1][3]. Additionally, Bosch has integrated this system with their IoT platform, enabling remote monitoring and control, as well as predictive maintenance capabilities[5].

Strengths: Highly adaptive to changing conditions, reduces energy consumption, and minimizes wear on valve components. Weaknesses: Initial implementation cost may be high, and the system requires significant computational resources.

Horiba Stec Co. Ltd.

Technical Solution: Horiba Stec has pioneered a high-precision gate valve calibration methodology specifically designed for semiconductor manufacturing processes. Their approach utilizes ultra-high purity mass flow controllers (MFCs) in conjunction with advanced pressure transducers to achieve unprecedented accuracy in gas flow control. The calibration process involves a multi-point verification system that checks valve performance across a wide range of flow rates and pressures. Horiba's proprietary software algorithms compensate for temperature fluctuations and gas composition variations, ensuring consistent performance in critical applications. The company has also developed a novel in-situ calibration technique that allows for real-time adjustments without interrupting the manufacturing process, significantly reducing downtime[2][4]. This methodology has been proven to achieve flow accuracy within ±0.5% of setpoint, even for ultra-low flow rates[6].

Strengths: Extremely high accuracy, suitable for critical processes in semiconductor manufacturing. Weaknesses: Specialized for high-purity gas applications, may be overly complex for simpler fluid systems.

Innovative Approaches in Fluid Dynamics Optimization

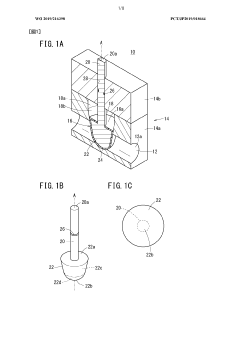

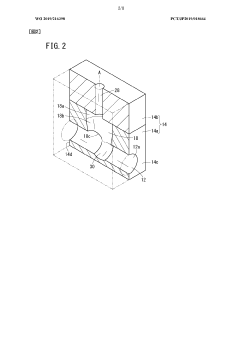

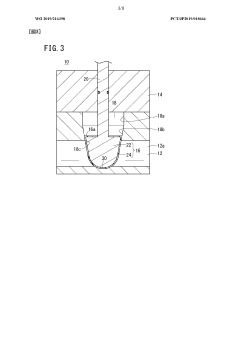

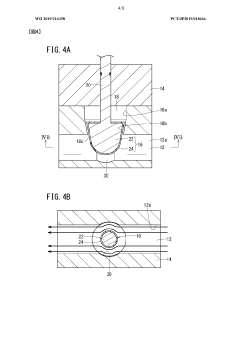

Gate valve

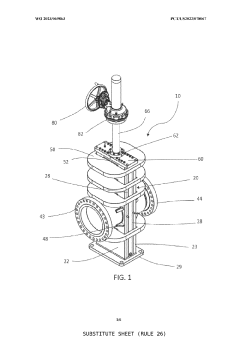

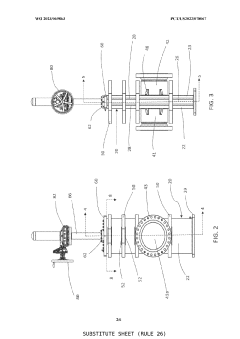

PatentWO2019216398A1

Innovation

- A gate valve design featuring a valve body with a streamlined curved surface and a seal member that minimizes fluid disturbance, allowing for a larger flow rate even when the valve body is stopped mid-stroke, achieved by reducing turbulent flow and maintaining smooth fluid flow through a rectified path.

Optimized gate valve assembly

PatentWO2023069863A1

Innovation

- The optimized gate valve assembly features a design with a valve body composed of side and end plates, reinforcement ribs, and fluid conduits with reduced welding, optimized reinforcement structures, and a bonnet for easier maintenance, reducing manufacturing time and costs while enhancing durability and safety.

Regulatory Standards for Industrial Valve Calibration

Regulatory standards for industrial valve calibration play a crucial role in ensuring the safety, reliability, and efficiency of fluid control systems across various industries. These standards are established and enforced by regulatory bodies and industry organizations to maintain consistency and quality in valve calibration processes.

The International Organization for Standardization (ISO) has developed several standards relevant to valve calibration, including ISO 5208 for industrial valves and ISO 9001 for quality management systems. These standards provide guidelines for testing procedures, documentation requirements, and performance criteria for industrial valves.

In the United States, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have jointly developed standards such as ANSI/ASME B16.34 for valves, flanges, and fittings. These standards specify design, materials, testing, and inspection requirements for industrial valves, including calibration procedures.

The European Union has established the Pressure Equipment Directive (PED) 2014/68/EU, which sets safety standards for pressure equipment, including industrial valves. This directive mandates regular calibration and testing of valves used in high-pressure applications to ensure compliance with safety requirements.

Specific to gate valve calibration, regulatory standards often focus on factors such as leakage rates, opening and closing times, and torque requirements. For example, the American Petroleum Institute (API) has developed standards like API 598 for valve inspection and testing, which includes specifications for gate valve calibration in oil and gas applications.

Regulatory bodies also emphasize the importance of traceability in calibration processes. This requires maintaining detailed records of calibration procedures, equipment used, and results obtained. The National Institute of Standards and Technology (NIST) in the United States provides guidelines for establishing and maintaining calibration traceability.

Compliance with these regulatory standards is often mandatory for industries dealing with hazardous materials, high-pressure systems, or critical processes. Regular audits and inspections are conducted to ensure adherence to these standards, with non-compliance potentially resulting in fines, operational restrictions, or legal consequences.

As technology advances, regulatory standards for valve calibration continue to evolve. Recent updates have incorporated considerations for digital calibration techniques, remote monitoring capabilities, and integration with industrial Internet of Things (IIoT) systems. These advancements aim to improve the accuracy, efficiency, and reliability of valve calibration processes while maintaining stringent safety standards.

The International Organization for Standardization (ISO) has developed several standards relevant to valve calibration, including ISO 5208 for industrial valves and ISO 9001 for quality management systems. These standards provide guidelines for testing procedures, documentation requirements, and performance criteria for industrial valves.

In the United States, the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) have jointly developed standards such as ANSI/ASME B16.34 for valves, flanges, and fittings. These standards specify design, materials, testing, and inspection requirements for industrial valves, including calibration procedures.

The European Union has established the Pressure Equipment Directive (PED) 2014/68/EU, which sets safety standards for pressure equipment, including industrial valves. This directive mandates regular calibration and testing of valves used in high-pressure applications to ensure compliance with safety requirements.

Specific to gate valve calibration, regulatory standards often focus on factors such as leakage rates, opening and closing times, and torque requirements. For example, the American Petroleum Institute (API) has developed standards like API 598 for valve inspection and testing, which includes specifications for gate valve calibration in oil and gas applications.

Regulatory bodies also emphasize the importance of traceability in calibration processes. This requires maintaining detailed records of calibration procedures, equipment used, and results obtained. The National Institute of Standards and Technology (NIST) in the United States provides guidelines for establishing and maintaining calibration traceability.

Compliance with these regulatory standards is often mandatory for industries dealing with hazardous materials, high-pressure systems, or critical processes. Regular audits and inspections are conducted to ensure adherence to these standards, with non-compliance potentially resulting in fines, operational restrictions, or legal consequences.

As technology advances, regulatory standards for valve calibration continue to evolve. Recent updates have incorporated considerations for digital calibration techniques, remote monitoring capabilities, and integration with industrial Internet of Things (IIoT) systems. These advancements aim to improve the accuracy, efficiency, and reliability of valve calibration processes while maintaining stringent safety standards.

Environmental Impact of Optimized Valve Operations

Optimized valve operations, particularly in gate valve calibration for fluid dynamics, can have significant environmental impacts. The precise control of fluid flow through improved calibration methodologies not only enhances operational efficiency but also contributes to reduced environmental footprint across various industries.

One of the primary environmental benefits of optimized valve operations is the reduction in energy consumption. Properly calibrated gate valves minimize pressure drops and flow restrictions, leading to decreased pumping requirements. This energy efficiency translates directly into lower greenhouse gas emissions associated with power generation, contributing to climate change mitigation efforts.

Furthermore, optimized valve operations can substantially reduce fluid leakage and wastage. Accurate calibration ensures tight sealing and precise flow control, preventing unintended releases of potentially harmful substances into the environment. This is particularly crucial in industries dealing with hazardous materials, where even small leaks can have severe ecological consequences.

In water management systems, optimized gate valve operations play a vital role in conservation efforts. By enabling precise control over water distribution, these systems can significantly reduce water waste, a critical factor in regions facing water scarcity. The ability to fine-tune flow rates also allows for more efficient irrigation practices in agriculture, minimizing water usage while maintaining crop yields.

The oil and gas industry, known for its environmental challenges, can benefit greatly from improved valve calibration methodologies. Optimized valve operations in this sector can lead to reduced methane emissions, a potent greenhouse gas, by ensuring better control over gas flows and minimizing fugitive emissions during extraction and transportation processes.

In chemical processing plants, precise valve control is essential for maintaining optimal reaction conditions. This not only improves product quality but also reduces the likelihood of off-spec batches that may require disposal, thereby minimizing waste generation and associated environmental impacts.

The environmental benefits extend to maintenance practices as well. Well-calibrated valves experience less wear and tear, leading to extended operational lifespans. This reduces the frequency of valve replacements, consequently decreasing the environmental impact associated with manufacturing and disposing of valve components.

Moreover, optimized valve operations contribute to improved process safety, reducing the risk of accidents that could lead to environmental contamination. By ensuring accurate and responsive flow control, these systems help prevent overpressure scenarios and other potentially hazardous situations that might result in spills or releases of harmful substances.

One of the primary environmental benefits of optimized valve operations is the reduction in energy consumption. Properly calibrated gate valves minimize pressure drops and flow restrictions, leading to decreased pumping requirements. This energy efficiency translates directly into lower greenhouse gas emissions associated with power generation, contributing to climate change mitigation efforts.

Furthermore, optimized valve operations can substantially reduce fluid leakage and wastage. Accurate calibration ensures tight sealing and precise flow control, preventing unintended releases of potentially harmful substances into the environment. This is particularly crucial in industries dealing with hazardous materials, where even small leaks can have severe ecological consequences.

In water management systems, optimized gate valve operations play a vital role in conservation efforts. By enabling precise control over water distribution, these systems can significantly reduce water waste, a critical factor in regions facing water scarcity. The ability to fine-tune flow rates also allows for more efficient irrigation practices in agriculture, minimizing water usage while maintaining crop yields.

The oil and gas industry, known for its environmental challenges, can benefit greatly from improved valve calibration methodologies. Optimized valve operations in this sector can lead to reduced methane emissions, a potent greenhouse gas, by ensuring better control over gas flows and minimizing fugitive emissions during extraction and transportation processes.

In chemical processing plants, precise valve control is essential for maintaining optimal reaction conditions. This not only improves product quality but also reduces the likelihood of off-spec batches that may require disposal, thereby minimizing waste generation and associated environmental impacts.

The environmental benefits extend to maintenance practices as well. Well-calibrated valves experience less wear and tear, leading to extended operational lifespans. This reduces the frequency of valve replacements, consequently decreasing the environmental impact associated with manufacturing and disposing of valve components.

Moreover, optimized valve operations contribute to improved process safety, reducing the risk of accidents that could lead to environmental contamination. By ensuring accurate and responsive flow control, these systems help prevent overpressure scenarios and other potentially hazardous situations that might result in spills or releases of harmful substances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!