Gate valve challenges in controlling supercritical CO2 flows

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercritical CO2 Flow Control Objectives

The primary objective of supercritical CO2 flow control in gate valve applications is to achieve precise and reliable regulation of fluid dynamics under extreme pressure and temperature conditions. This goal encompasses several key aspects that address the unique challenges posed by supercritical CO2.

Firstly, the control system must maintain stable flow rates across a wide range of operating conditions. Supercritical CO2 exhibits significant density variations with small changes in pressure and temperature, making it crucial to design valves that can adapt to these fluctuations while maintaining consistent flow characteristics.

Secondly, the objective includes minimizing pressure drops across the valve to optimize overall system efficiency. This is particularly important in power generation applications, where even small losses can significantly impact the overall cycle performance. The valve design must balance the need for precise control with the requirement to minimize energy losses.

Another critical objective is to ensure long-term reliability and durability of the valve components. Supercritical CO2 can be highly corrosive and erosive, especially when contaminants are present. The materials and design of the valve must withstand these harsh conditions over extended periods without degradation in performance or safety.

Leak prevention is a paramount objective, given the high pressures involved and the potential environmental impact of CO2 releases. The valve sealing mechanisms must maintain their integrity under varying thermal and mechanical stresses, preventing both internal and external leakage.

Furthermore, the control system should aim to provide rapid response times to changes in flow conditions or system demands. This responsiveness is essential for maintaining process stability and safety, particularly in applications such as power generation where load fluctuations are common.

The objectives also extend to the integration of advanced monitoring and diagnostic capabilities. Real-time data on valve performance, wear patterns, and potential failure modes can significantly enhance maintenance strategies and operational reliability.

Lastly, the development of standardized testing and certification procedures for supercritical CO2 valves is a crucial objective. This standardization will facilitate the comparison of different valve designs and ensure consistent performance across various applications and operating environments.

Firstly, the control system must maintain stable flow rates across a wide range of operating conditions. Supercritical CO2 exhibits significant density variations with small changes in pressure and temperature, making it crucial to design valves that can adapt to these fluctuations while maintaining consistent flow characteristics.

Secondly, the objective includes minimizing pressure drops across the valve to optimize overall system efficiency. This is particularly important in power generation applications, where even small losses can significantly impact the overall cycle performance. The valve design must balance the need for precise control with the requirement to minimize energy losses.

Another critical objective is to ensure long-term reliability and durability of the valve components. Supercritical CO2 can be highly corrosive and erosive, especially when contaminants are present. The materials and design of the valve must withstand these harsh conditions over extended periods without degradation in performance or safety.

Leak prevention is a paramount objective, given the high pressures involved and the potential environmental impact of CO2 releases. The valve sealing mechanisms must maintain their integrity under varying thermal and mechanical stresses, preventing both internal and external leakage.

Furthermore, the control system should aim to provide rapid response times to changes in flow conditions or system demands. This responsiveness is essential for maintaining process stability and safety, particularly in applications such as power generation where load fluctuations are common.

The objectives also extend to the integration of advanced monitoring and diagnostic capabilities. Real-time data on valve performance, wear patterns, and potential failure modes can significantly enhance maintenance strategies and operational reliability.

Lastly, the development of standardized testing and certification procedures for supercritical CO2 valves is a crucial objective. This standardization will facilitate the comparison of different valve designs and ensure consistent performance across various applications and operating environments.

Market Analysis for CO2 Flow Control Valves

The market for CO2 flow control valves, particularly those designed for supercritical CO2 applications, is experiencing significant growth driven by the increasing focus on carbon capture, utilization, and storage (CCUS) technologies. As global efforts to reduce greenhouse gas emissions intensify, the demand for efficient and reliable valves capable of handling supercritical CO2 flows is expected to surge.

The oil and gas industry remains a primary market for these specialized valves, with enhanced oil recovery (EOR) operations utilizing CO2 injection as a key application. Additionally, the power generation sector, especially in regions with stringent emission regulations, is adopting CCUS technologies, further boosting the demand for high-performance CO2 flow control valves.

Geographically, North America currently leads the market, with the United States at the forefront due to its extensive CO2 pipeline infrastructure and numerous EOR projects. Europe follows closely, driven by ambitious carbon reduction targets and investments in CCUS technologies. The Asia-Pacific region, particularly China, is expected to witness rapid growth in demand as it ramps up efforts to combat climate change.

The market is characterized by a mix of established industrial valve manufacturers and specialized companies focusing on high-pressure, corrosion-resistant valve solutions. Key players are investing heavily in research and development to address the unique challenges posed by supercritical CO2, such as rapid decompression, phase changes, and material degradation.

Technological advancements in valve design, including the use of advanced materials like super duplex stainless steels and specialized coatings, are driving market growth. These innovations aim to improve valve performance, longevity, and reliability under the extreme conditions associated with supercritical CO2 flows.

The market is also influenced by regulatory frameworks and government initiatives promoting CCUS technologies. Policies incentivizing carbon capture projects and setting emission reduction targets are indirectly boosting the demand for specialized CO2 flow control valves.

Despite the positive outlook, challenges remain. The high cost of specialized valves capable of withstanding supercritical CO2 conditions can be a barrier to adoption, particularly for smaller-scale projects. Additionally, the technical complexity of these valves requires specialized knowledge for installation and maintenance, potentially limiting market penetration in regions with less developed industrial infrastructure.

Looking ahead, the market for CO2 flow control valves is poised for continued growth as CCUS technologies become more widespread and critical to achieving global climate goals. Innovations in valve design and materials science are expected to drive down costs and improve performance, further expanding market opportunities across various industries involved in CO2 handling and storage.

The oil and gas industry remains a primary market for these specialized valves, with enhanced oil recovery (EOR) operations utilizing CO2 injection as a key application. Additionally, the power generation sector, especially in regions with stringent emission regulations, is adopting CCUS technologies, further boosting the demand for high-performance CO2 flow control valves.

Geographically, North America currently leads the market, with the United States at the forefront due to its extensive CO2 pipeline infrastructure and numerous EOR projects. Europe follows closely, driven by ambitious carbon reduction targets and investments in CCUS technologies. The Asia-Pacific region, particularly China, is expected to witness rapid growth in demand as it ramps up efforts to combat climate change.

The market is characterized by a mix of established industrial valve manufacturers and specialized companies focusing on high-pressure, corrosion-resistant valve solutions. Key players are investing heavily in research and development to address the unique challenges posed by supercritical CO2, such as rapid decompression, phase changes, and material degradation.

Technological advancements in valve design, including the use of advanced materials like super duplex stainless steels and specialized coatings, are driving market growth. These innovations aim to improve valve performance, longevity, and reliability under the extreme conditions associated with supercritical CO2 flows.

The market is also influenced by regulatory frameworks and government initiatives promoting CCUS technologies. Policies incentivizing carbon capture projects and setting emission reduction targets are indirectly boosting the demand for specialized CO2 flow control valves.

Despite the positive outlook, challenges remain. The high cost of specialized valves capable of withstanding supercritical CO2 conditions can be a barrier to adoption, particularly for smaller-scale projects. Additionally, the technical complexity of these valves requires specialized knowledge for installation and maintenance, potentially limiting market penetration in regions with less developed industrial infrastructure.

Looking ahead, the market for CO2 flow control valves is poised for continued growth as CCUS technologies become more widespread and critical to achieving global climate goals. Innovations in valve design and materials science are expected to drive down costs and improve performance, further expanding market opportunities across various industries involved in CO2 handling and storage.

Gate Valve Limitations in Supercritical CO2 Systems

Gate valves have long been a staple in controlling fluid flows across various industries. However, when it comes to managing supercritical CO2 flows, these valves face significant limitations that challenge their effectiveness and reliability. The unique properties of supercritical CO2, including its high density, low viscosity, and potential for rapid expansion, create a demanding environment that pushes conventional gate valve designs to their limits.

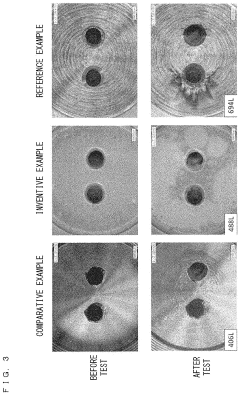

One of the primary challenges is the erosion of valve components due to the high-velocity flow of supercritical CO2. The fluid's low viscosity and high density contribute to increased erosive potential, particularly at the valve seat and gate surfaces. This erosion can lead to premature wear, reduced sealing capabilities, and ultimately, valve failure. The problem is exacerbated in applications where frequent cycling or throttling is required, as the repeated impact of the fluid on valve surfaces accelerates material degradation.

Sealing issues present another significant limitation. The extreme pressure differentials often encountered in supercritical CO2 systems can cause deformation of valve components, compromising the tight seals necessary for effective flow control. Traditional sealing materials may also degrade or become brittle when exposed to supercritical CO2, further reducing valve performance and increasing the risk of leakage.

The potential for rapid depressurization and phase change of supercritical CO2 poses additional challenges. As the fluid expands, it can cool rapidly, leading to the formation of dry ice within the valve body. This phenomenon, known as Joule-Thomson cooling, can cause blockages, impair valve operation, and potentially damage internal components. Gate valves, with their linear closure mechanism, are particularly susceptible to these issues compared to other valve types.

Corrosion resistance is another critical factor limiting the effectiveness of conventional gate valves in supercritical CO2 applications. The combination of high pressure, potential contaminants, and the inherent properties of supercritical CO2 can accelerate corrosion processes, particularly in the presence of moisture. This corrosion not only affects the structural integrity of the valve but can also lead to the formation of particulates that further compromise valve performance.

The dimensional stability of gate valves under supercritical CO2 conditions is also a concern. Extreme pressure fluctuations and temperature variations can cause thermal expansion and contraction of valve components, potentially leading to misalignment, increased friction, or incomplete closure. This instability can result in reduced control precision and increased maintenance requirements.

Lastly, the limitations of gate valves in supercritical CO2 systems extend to their dynamic response characteristics. The relatively slow opening and closing times of gate valves may be inadequate for applications requiring rapid flow control or emergency shutoff in high-pressure CO2 environments. This limitation can pose safety risks and operational inefficiencies in critical processes involving supercritical CO2 flows.

One of the primary challenges is the erosion of valve components due to the high-velocity flow of supercritical CO2. The fluid's low viscosity and high density contribute to increased erosive potential, particularly at the valve seat and gate surfaces. This erosion can lead to premature wear, reduced sealing capabilities, and ultimately, valve failure. The problem is exacerbated in applications where frequent cycling or throttling is required, as the repeated impact of the fluid on valve surfaces accelerates material degradation.

Sealing issues present another significant limitation. The extreme pressure differentials often encountered in supercritical CO2 systems can cause deformation of valve components, compromising the tight seals necessary for effective flow control. Traditional sealing materials may also degrade or become brittle when exposed to supercritical CO2, further reducing valve performance and increasing the risk of leakage.

The potential for rapid depressurization and phase change of supercritical CO2 poses additional challenges. As the fluid expands, it can cool rapidly, leading to the formation of dry ice within the valve body. This phenomenon, known as Joule-Thomson cooling, can cause blockages, impair valve operation, and potentially damage internal components. Gate valves, with their linear closure mechanism, are particularly susceptible to these issues compared to other valve types.

Corrosion resistance is another critical factor limiting the effectiveness of conventional gate valves in supercritical CO2 applications. The combination of high pressure, potential contaminants, and the inherent properties of supercritical CO2 can accelerate corrosion processes, particularly in the presence of moisture. This corrosion not only affects the structural integrity of the valve but can also lead to the formation of particulates that further compromise valve performance.

The dimensional stability of gate valves under supercritical CO2 conditions is also a concern. Extreme pressure fluctuations and temperature variations can cause thermal expansion and contraction of valve components, potentially leading to misalignment, increased friction, or incomplete closure. This instability can result in reduced control precision and increased maintenance requirements.

Lastly, the limitations of gate valves in supercritical CO2 systems extend to their dynamic response characteristics. The relatively slow opening and closing times of gate valves may be inadequate for applications requiring rapid flow control or emergency shutoff in high-pressure CO2 environments. This limitation can pose safety risks and operational inefficiencies in critical processes involving supercritical CO2 flows.

Current Gate Valve Solutions for Supercritical CO2

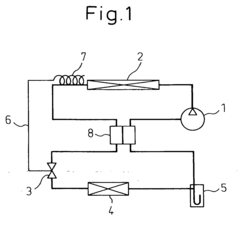

01 Automated control systems for gate valves

Advanced control systems are implemented to automate the operation of gate valves. These systems often incorporate sensors, actuators, and programmable logic controllers (PLCs) to monitor and adjust valve positions based on various parameters such as flow rate, pressure, and temperature. This automation enhances efficiency, reduces human error, and allows for remote operation of gate valves in complex industrial processes.- Automated control systems for gate valves: Advanced control systems are implemented to automate the operation of gate valves. These systems often incorporate sensors, actuators, and programmable logic controllers (PLCs) to monitor and adjust valve positions based on various parameters such as flow rate, pressure, and temperature. This automation enhances efficiency, reduces human error, and allows for remote operation of gate valves in complex industrial processes.

- Hydraulic and pneumatic actuation mechanisms: Gate valves can be controlled using hydraulic or pneumatic actuation systems. These mechanisms utilize fluid or air pressure to open, close, or adjust the valve position. Hydraulic systems offer high force capabilities, while pneumatic systems provide quick response times. Both types of actuation can be integrated with control systems for precise and reliable valve operation in various applications.

- Electronic positioning and feedback systems: Modern gate valve control incorporates electronic positioning systems and feedback mechanisms. These systems use sensors and encoders to accurately determine and report valve position. The feedback is then used by control systems to make real-time adjustments, ensuring precise control over flow rates and pressure. This technology is particularly useful in applications requiring high accuracy and repeatability.

- Fail-safe and emergency shutdown features: Gate valve control systems often include fail-safe mechanisms and emergency shutdown features. These are designed to automatically close or open the valve in case of power failure, system malfunction, or other critical situations. Such features may involve spring-return actuators, backup power supplies, or dedicated emergency circuits to ensure safe operation and prevent potential hazards in industrial processes.

- Smart diagnostics and predictive maintenance: Advanced gate valve control systems incorporate smart diagnostics and predictive maintenance capabilities. These features use data analytics and machine learning algorithms to monitor valve performance, detect potential issues, and predict maintenance needs. By analyzing parameters such as operating cycles, torque, and response times, these systems can optimize valve performance, reduce downtime, and extend equipment lifespan.

02 Hydraulic and pneumatic actuation mechanisms

Gate valves can be controlled using hydraulic or pneumatic actuation systems. These mechanisms utilize fluid or air pressure to open, close, or adjust the valve position. They offer advantages such as high force output, precise control, and the ability to operate in hazardous environments. The design of these systems often includes safety features to prevent unintended valve closure or opening.Expand Specific Solutions03 Electronic positioning and feedback systems

Modern gate valve control systems incorporate electronic positioning and feedback mechanisms. These systems use sensors and encoders to accurately determine the valve's position and provide real-time feedback to the control unit. This allows for precise adjustment of the valve opening, improved process control, and early detection of valve malfunctions or wear.Expand Specific Solutions04 Fail-safe and emergency shutdown mechanisms

Gate valve control systems often include fail-safe and emergency shutdown features. These mechanisms are designed to automatically close or open the valve in case of power failure, system malfunction, or other critical situations. They may utilize stored energy sources such as springs or accumulators to ensure reliable operation during emergencies, enhancing overall system safety and preventing potential accidents.Expand Specific Solutions05 Smart diagnostics and predictive maintenance

Advanced gate valve control systems incorporate smart diagnostics and predictive maintenance capabilities. These features use data analytics, machine learning algorithms, and IoT connectivity to monitor valve performance, detect anomalies, and predict potential failures. This proactive approach helps optimize maintenance schedules, reduce downtime, and extend the operational life of gate valves in industrial applications.Expand Specific Solutions

Key Players in Supercritical CO2 Valve Industry

The gate valve industry for controlling supercritical CO2 flows is in a growth phase, driven by increasing demand for carbon capture and storage technologies. The market size is expanding as more countries invest in reducing carbon emissions. Technologically, the field is advancing rapidly but still faces challenges in materials and design to withstand extreme conditions. Key players like China National Petroleum Corp., Chongqing Chuanyi Control Valve Co., and Smartguy Intelligent Equipment are investing heavily in R&D to develop more efficient and durable valves. Established industrial giants such as Honeywell and Mitsubishi Heavy Industries are also entering this specialized market, leveraging their expertise in related technologies.

China National Petroleum Corp.

Technical Solution: CNPC has developed gate valve solutions for supercritical CO2 applications, particularly focusing on enhanced oil recovery (EOR) and CCS projects. Their valve design incorporates corrosion-resistant materials and specialized coatings to withstand the harsh conditions of supercritical CO2 environments[10]. CNPC's gate valves feature a unique stem sealing system that maintains integrity under high pressure fluctuations common in CO2 injection operations[11]. The company has also implemented advanced manufacturing techniques, such as 3D printing, to create complex internal geometries that optimize flow characteristics for supercritical CO2[12].

Strengths: Extensive experience in oil and gas operations, strong domestic market presence. Weaknesses: May face challenges in international markets due to geopolitical factors.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a range of gate valves designed to handle supercritical CO2 flows, particularly for CCS and enhanced oil recovery (EOR) applications. Their solution incorporates advanced sealing technologies, including metal-to-metal seals and specialized elastomers resistant to CO2 degradation[4]. Honeywell's gate valves feature a unique trim design that helps manage the pressure drop across the valve, reducing the risk of cavitation and erosion in supercritical CO2 service[5]. The company has also implemented advanced control systems that allow for precise flow regulation, critical in managing the often unpredictable behavior of supercritical CO2[6].

Strengths: Strong expertise in control systems and automation, wide range of industrial applications. Weaknesses: May face challenges in extreme temperature applications.

Core Innovations in CO2 Flow Control Valves

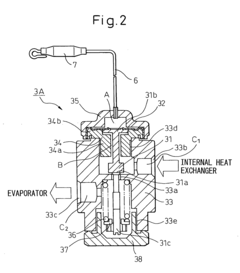

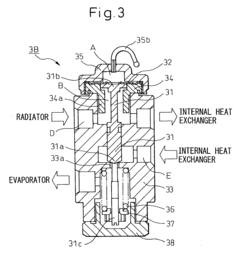

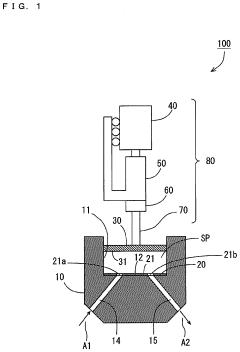

High pressure control valve

PatentInactiveEP1785681A1

Innovation

- A high pressure control valve is designed to control refrigerant pressure based on the temperature of the refrigerant leaving the radiator, with a temperature sensing section charged with CO2 at a density of 200 to 600 kg/m³, using an elastic member or noncondensable gas to reduce the charging density and control pressure, allowing for reduced mechanical strength and manufacturing costs.

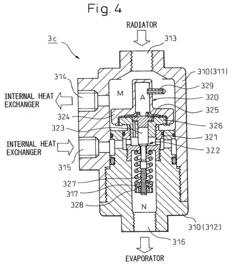

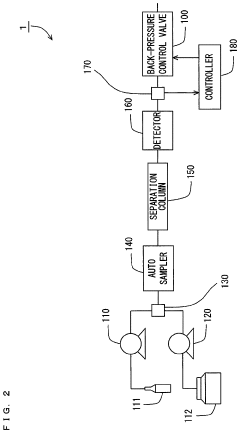

Back-pressure control valve

PatentInactiveUS20220228667A1

Innovation

- The pressure control surface of the back-pressure control valve is formed using a soft resin material, such as PEEK, with a thickness between 10 μm and 50 μm, and a diaphragm made of a resin material, allowing for precise pressure control and reducing cavitation-induced erosion.

Environmental Impact of CO2 Flow Control Systems

The environmental impact of CO2 flow control systems, particularly in the context of gate valve challenges for supercritical CO2 flows, is a critical consideration in the development and implementation of carbon capture and storage (CCS) technologies. These systems play a crucial role in managing the transportation and storage of CO2, which is essential for mitigating greenhouse gas emissions and combating climate change.

One of the primary environmental concerns associated with CO2 flow control systems is the potential for leakage. Supercritical CO2 is highly pressurized and can easily escape through small gaps or imperfections in valves and pipelines. Such leaks not only reduce the effectiveness of CCS efforts but also pose risks to local ecosystems and human health. The release of concentrated CO2 can lead to localized increases in atmospheric CO2 levels, potentially causing respiratory issues for nearby flora and fauna.

The materials used in gate valves and other components of CO2 flow control systems also have environmental implications. Many traditional valve materials are susceptible to degradation when exposed to supercritical CO2, which can be highly corrosive. This degradation may lead to the release of harmful substances into the environment or require frequent replacement of components, increasing the overall environmental footprint of the system through increased resource consumption and waste generation.

Energy consumption is another significant factor to consider. Controlling supercritical CO2 flows often requires substantial energy input, particularly when dealing with high-pressure systems. The environmental impact of this energy use depends on the source of the power, with renewable energy sources offering a more sustainable option compared to fossil fuel-based electricity generation.

The manufacturing processes for specialized gate valves and other CO2 flow control components can also have environmental implications. The production of high-performance materials and precision-engineered parts may involve energy-intensive processes and the use of rare or environmentally sensitive materials. Minimizing the environmental impact of these manufacturing processes is an important consideration in the overall sustainability of CO2 flow control systems.

In the event of system failures or accidents, the environmental consequences can be severe. Rapid decompression of supercritical CO2 can cause localized freezing and asphyxiation risks, potentially harming nearby wildlife and vegetation. Additionally, the sudden release of large volumes of CO2 could have broader climate impacts, albeit on a smaller scale compared to continuous industrial emissions.

On the positive side, effective CO2 flow control systems are essential for the success of CCS projects, which have the potential to significantly reduce global CO2 emissions. By enabling the safe and efficient transport and storage of captured CO2, these systems contribute to the overall goal of mitigating climate change and its associated environmental impacts.

One of the primary environmental concerns associated with CO2 flow control systems is the potential for leakage. Supercritical CO2 is highly pressurized and can easily escape through small gaps or imperfections in valves and pipelines. Such leaks not only reduce the effectiveness of CCS efforts but also pose risks to local ecosystems and human health. The release of concentrated CO2 can lead to localized increases in atmospheric CO2 levels, potentially causing respiratory issues for nearby flora and fauna.

The materials used in gate valves and other components of CO2 flow control systems also have environmental implications. Many traditional valve materials are susceptible to degradation when exposed to supercritical CO2, which can be highly corrosive. This degradation may lead to the release of harmful substances into the environment or require frequent replacement of components, increasing the overall environmental footprint of the system through increased resource consumption and waste generation.

Energy consumption is another significant factor to consider. Controlling supercritical CO2 flows often requires substantial energy input, particularly when dealing with high-pressure systems. The environmental impact of this energy use depends on the source of the power, with renewable energy sources offering a more sustainable option compared to fossil fuel-based electricity generation.

The manufacturing processes for specialized gate valves and other CO2 flow control components can also have environmental implications. The production of high-performance materials and precision-engineered parts may involve energy-intensive processes and the use of rare or environmentally sensitive materials. Minimizing the environmental impact of these manufacturing processes is an important consideration in the overall sustainability of CO2 flow control systems.

In the event of system failures or accidents, the environmental consequences can be severe. Rapid decompression of supercritical CO2 can cause localized freezing and asphyxiation risks, potentially harming nearby wildlife and vegetation. Additionally, the sudden release of large volumes of CO2 could have broader climate impacts, albeit on a smaller scale compared to continuous industrial emissions.

On the positive side, effective CO2 flow control systems are essential for the success of CCS projects, which have the potential to significantly reduce global CO2 emissions. By enabling the safe and efficient transport and storage of captured CO2, these systems contribute to the overall goal of mitigating climate change and its associated environmental impacts.

Safety Standards for Supercritical CO2 Equipment

Safety standards for supercritical CO2 equipment are crucial in ensuring the safe operation and handling of systems involving this unique fluid state. These standards address the specific challenges posed by supercritical CO2, which exhibits properties of both a liquid and a gas, making it particularly demanding in terms of equipment design and operational procedures.

The primary focus of these safety standards is on pressure containment and material compatibility. Supercritical CO2 operates at high pressures, typically above 73.8 bar, requiring equipment to withstand significant stress. Standards specify minimum pressure ratings, material selection criteria, and design factors to ensure structural integrity under these extreme conditions. Additionally, they address the potential for rapid decompression and the associated risks of equipment failure or personnel injury.

Corrosion resistance is another critical aspect covered by these standards. Supercritical CO2 can be highly corrosive, especially in the presence of water or other impurities. Safety guidelines mandate the use of corrosion-resistant materials and coatings, as well as regular inspection and maintenance protocols to detect and prevent corrosion-related failures.

Temperature management is also a key consideration in these safety standards. The critical point of CO2 occurs at 31.1°C, and equipment must be designed to operate safely across a wide temperature range. Standards outline requirements for thermal insulation, temperature monitoring systems, and safety measures to prevent rapid temperature fluctuations that could compromise equipment integrity.

Leak detection and containment form another crucial component of these safety standards. Given the high pressures involved and the potential for CO2 to displace oxygen in confined spaces, robust leak detection systems and emergency shutdown procedures are mandated. Standards specify the types of sensors, their placement, and response times required for early detection of leaks.

Furthermore, these safety standards address the unique properties of supercritical CO2 in terms of its expansion behavior and phase changes. They provide guidelines for designing and operating pressure relief systems, including the sizing of relief valves and the management of CO2 venting to ensure safe dispersion.

Operational procedures and personnel safety are also covered extensively. Standards outline requirements for operator training, personal protective equipment, and emergency response protocols specific to supercritical CO2 environments. This includes guidelines for safe startup, shutdown, and maintenance procedures, as well as risk assessment methodologies for identifying and mitigating potential hazards.

The primary focus of these safety standards is on pressure containment and material compatibility. Supercritical CO2 operates at high pressures, typically above 73.8 bar, requiring equipment to withstand significant stress. Standards specify minimum pressure ratings, material selection criteria, and design factors to ensure structural integrity under these extreme conditions. Additionally, they address the potential for rapid decompression and the associated risks of equipment failure or personnel injury.

Corrosion resistance is another critical aspect covered by these standards. Supercritical CO2 can be highly corrosive, especially in the presence of water or other impurities. Safety guidelines mandate the use of corrosion-resistant materials and coatings, as well as regular inspection and maintenance protocols to detect and prevent corrosion-related failures.

Temperature management is also a key consideration in these safety standards. The critical point of CO2 occurs at 31.1°C, and equipment must be designed to operate safely across a wide temperature range. Standards outline requirements for thermal insulation, temperature monitoring systems, and safety measures to prevent rapid temperature fluctuations that could compromise equipment integrity.

Leak detection and containment form another crucial component of these safety standards. Given the high pressures involved and the potential for CO2 to displace oxygen in confined spaces, robust leak detection systems and emergency shutdown procedures are mandated. Standards specify the types of sensors, their placement, and response times required for early detection of leaks.

Furthermore, these safety standards address the unique properties of supercritical CO2 in terms of its expansion behavior and phase changes. They provide guidelines for designing and operating pressure relief systems, including the sizing of relief valves and the management of CO2 venting to ensure safe dispersion.

Operational procedures and personnel safety are also covered extensively. Standards outline requirements for operator training, personal protective equipment, and emergency response protocols specific to supercritical CO2 environments. This includes guidelines for safe startup, shutdown, and maintenance procedures, as well as risk assessment methodologies for identifying and mitigating potential hazards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!